Quick Guide YM Zenit+

6

1 Important Information

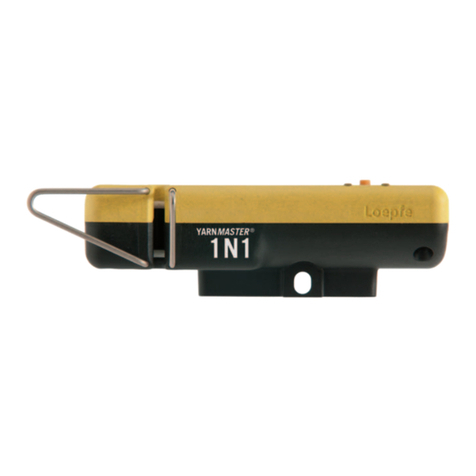

This Quick Guide contains the most important information required for set-up and operation of

yarn clearer system YarnMaster Zenit+.

See the Online Help which can be called up via the touchscreen with the Help button for

more information on the individual functions of the yarn clearer.

The complete Instruction Manual for Loepfe yarn clearer system Zenit+can be found on the

enclosed USB stick.

The yarn clearer system YarnMaster Zenit+must only be operated by authorized persons.

Authorized persons are persons qualified and trained for operation and maintenance of the yarn

clearer system.

Prior to any work, the personnel must have thoroughly read and understood Chapter 1 and 2

“General” and “Safety” of the Instruction Manual and thoroughly follow the instructions.

Assembly and initial start-up are performed by an authorized service technician of the winding

machine manufacturer or a service technician of Loepfe Brothers Ltd. For information concern-

ing installation and connections, see Chapters 21 and 22.

2 Explanation of Symbols

In this Instruction Manual, safety information is marked with symbols and signal words.

The safety information must be strictly observed to prevent accidents, personal injuries and

damage to property.

3 Start-up

If anything is not clear, contact the supervisor or supplier for your own safety.

Useful hints and recommendations.

Indicates an imminently hazardous situation which will result in death or

serious injury.

DANGER

Indicates a potentially hazardous situation which may result in damage to

property.

ATTENTION

Indicates a potentially hazardous situation which may result in damage to