- 3 -

02.20

Table of Contents

909.2710.1-06

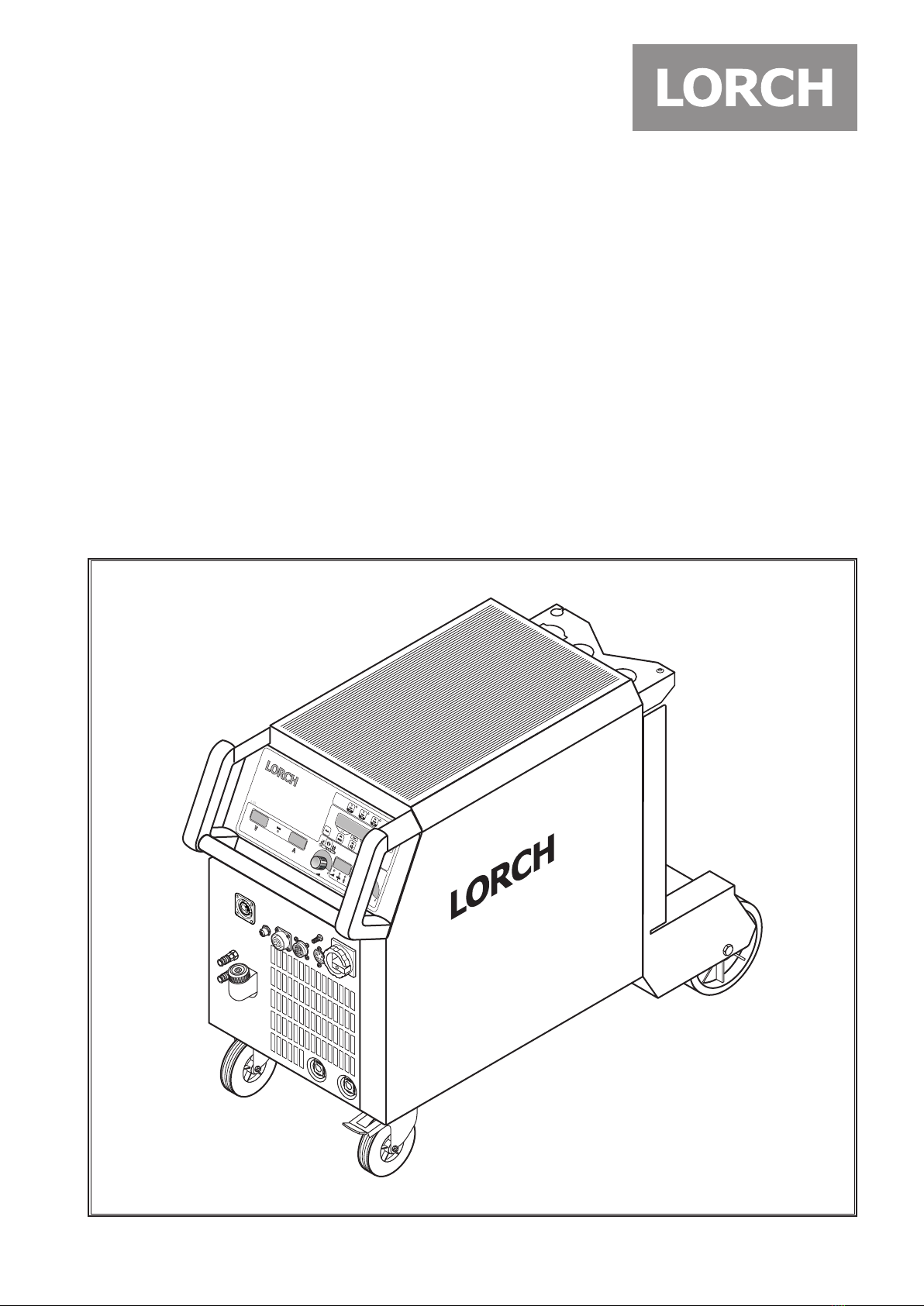

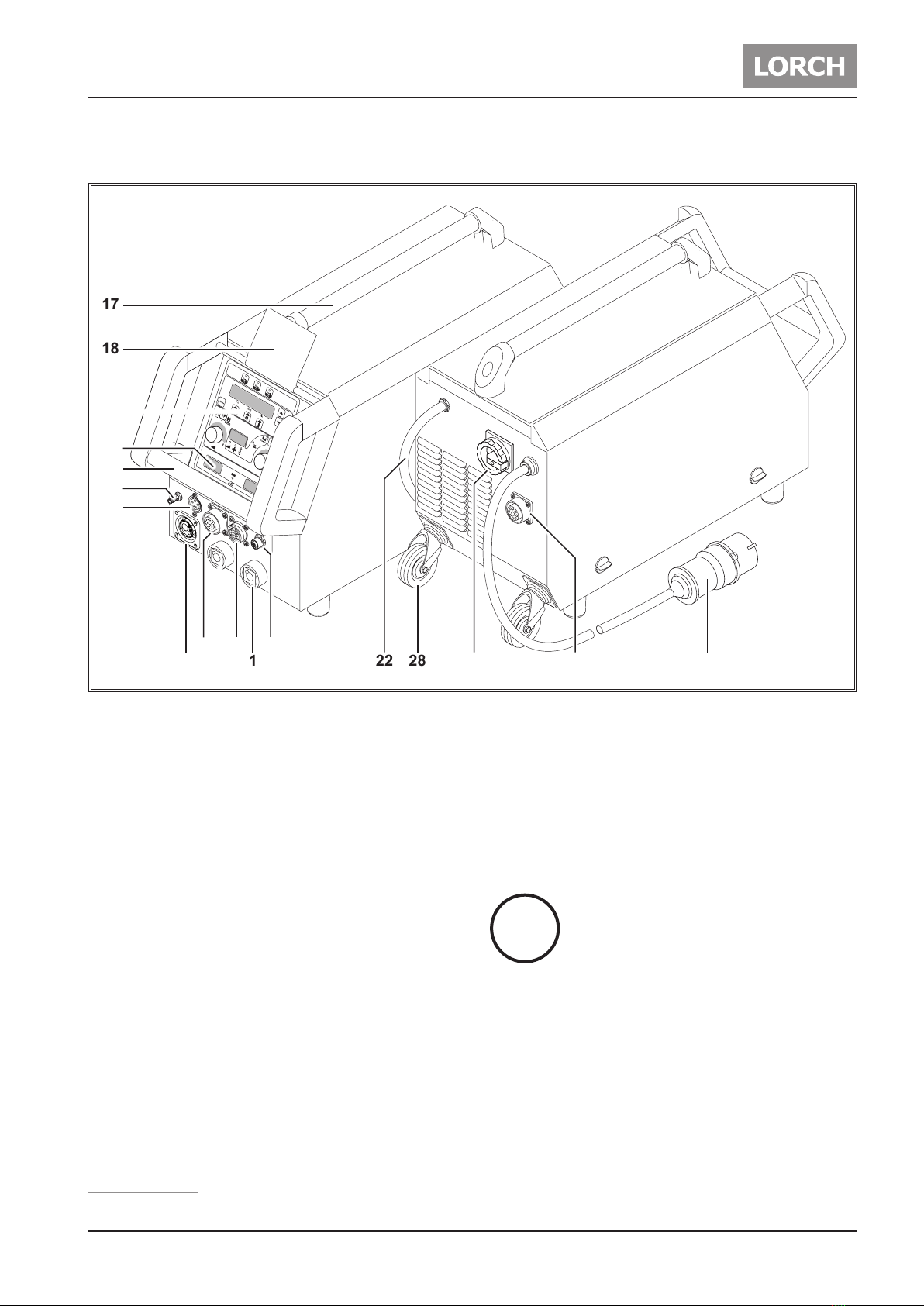

1 Machine elements ................... 4

2 Safety precautions.................. 6

2.1 Requirement ....................................... 6

2.2 Testing Lorch machines according to IEC

60974-4 .............................................. 6

3 Inverter Principle ................... 7

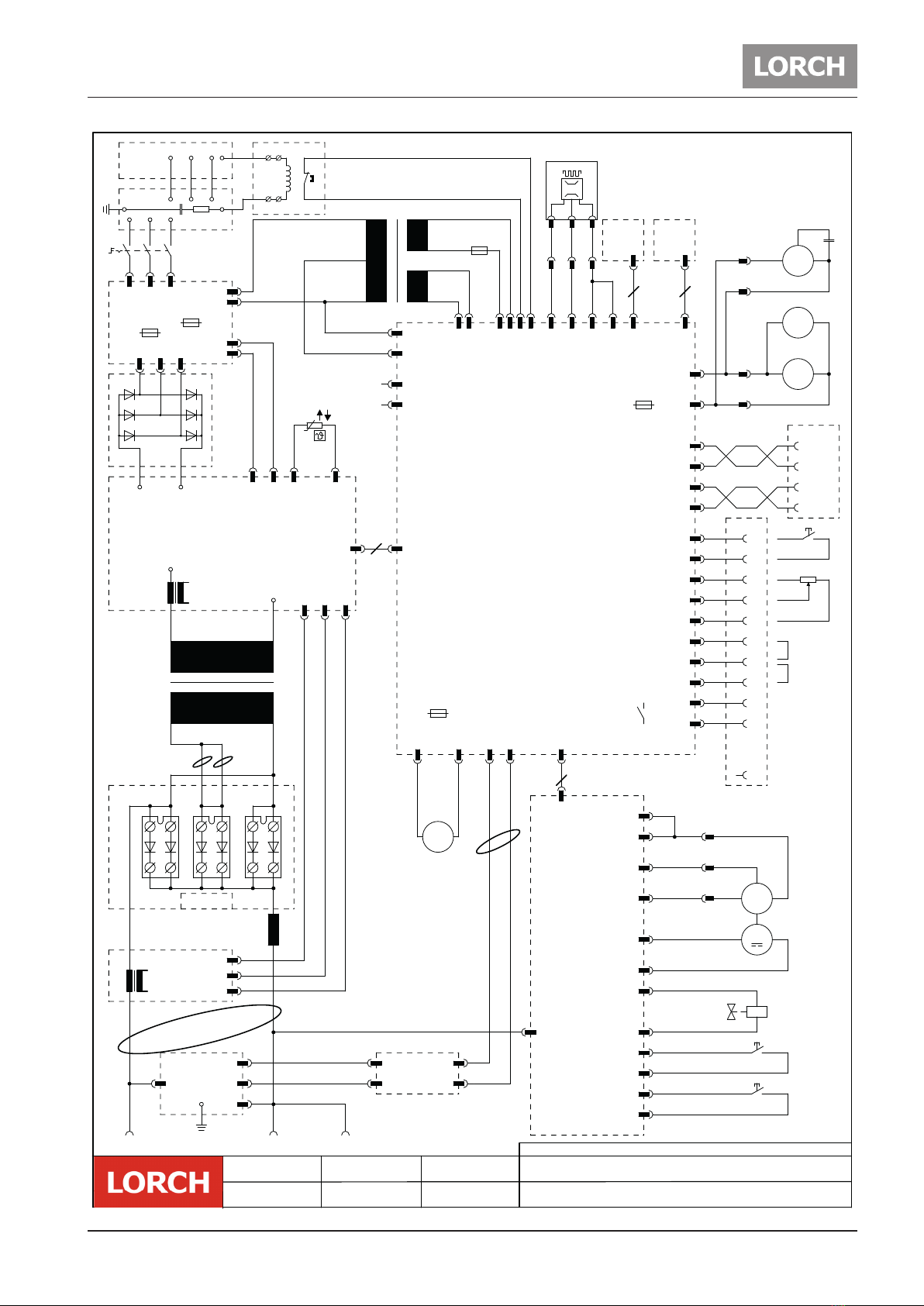

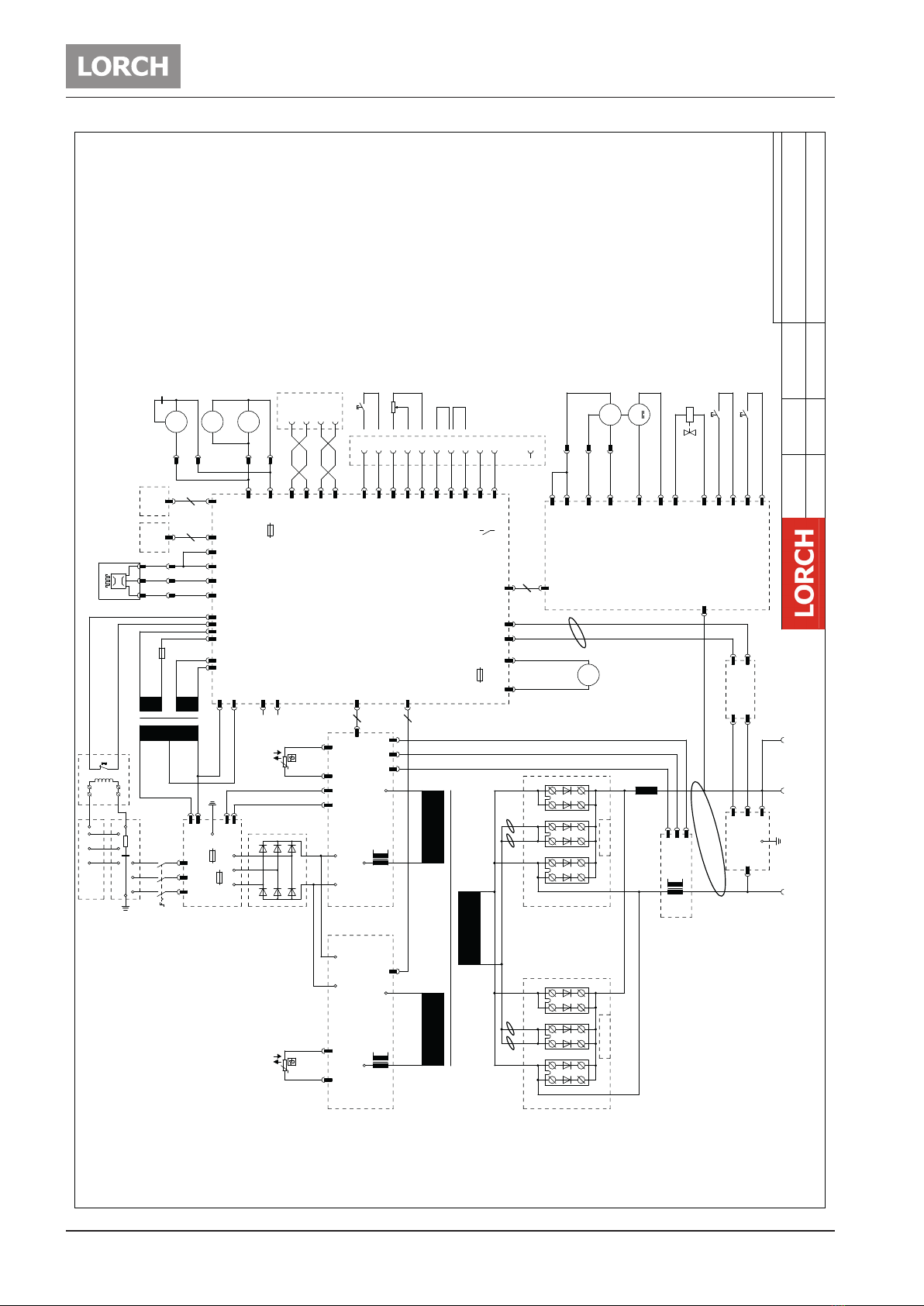

4 Machine Wiring Diagrams ....... 8

5 Common Logic Functions .......12

6 Front panels ..........................12

6.1 Front panel P-Synergic / S-Pulse / S-

SpeedPulse 3.0 ..................................12

6.2 Front panel functions S/P ..................12

6.3 Front panel P-basic ............................14

7 Pc-Boards ..............................15

7.1 Pc-board MAPRO05 ............................15

7.2 Pc-board DMR ....................................20

7.3 Pc-board PP90R .................................22

7.4 Pc-board DMRPP04 ............................23

7.5 Pc-board ZVP .....................................26

7.6 Pc-board DS20BF ...............................28

7.7 Pc-board DS21BF ...............................29

7.8 Pc-board DS22BF ...............................29

7.9 Pc-board MAT-BF................................30

7.10 Pc-board DS-VA..................................31

7.11 Pc-board DCDR21 / DCDR23 ..............32

7.12 Pc-board DK-PWRUP / DK-PWRUP02 .35

7.13 Pc-board DK-PWRUP04DKL / DK-

PWRUP05-DKL ...................................36

7.14 Pc-board DP-S3NEFI ..........................37

7.15 Pc-board DK-GLCL3 ............................39

7.16 Pc-board DP-UFI-BO ..........................40

7.17 Pc-board DP-EMV ...............................40

7.18 Pc-board DS-ERW ..............................41

7.19 Pc-board TC21 ...................................43

8 Electrical Components ...........44

8.1 Current Sensor VAC............................44

8.2 Control transformer ...........................46

8.3 TIG Option .........................................47

9 Troubleshooting.....................48

9.1 Monitoring temperature.....................48

9.2 Supply voltages .................................49

9.3 Monitoring welding current................50

9.4 PE-protection / gas pressure switch ..51

9.5 Cooling unit .......................................52

9.6 Monitoring output voltage..................55

9.7 Monitoring wire feed motor ...............56

9.8 Remote control ..................................58

9.9 Monitoring primary input current.......59

9.10 Monitoring bus voltage ......................60

9.11 Encoding power units ........................61

9.12 Testing MOSFETs................................62

9.13 Inside diagram diodes .......................62

9.14 Service Codes ....................................63

9.15 Malfunction Codes..............................64