Distribution Limited

Lumag Servicing and

Maintenance Schedules

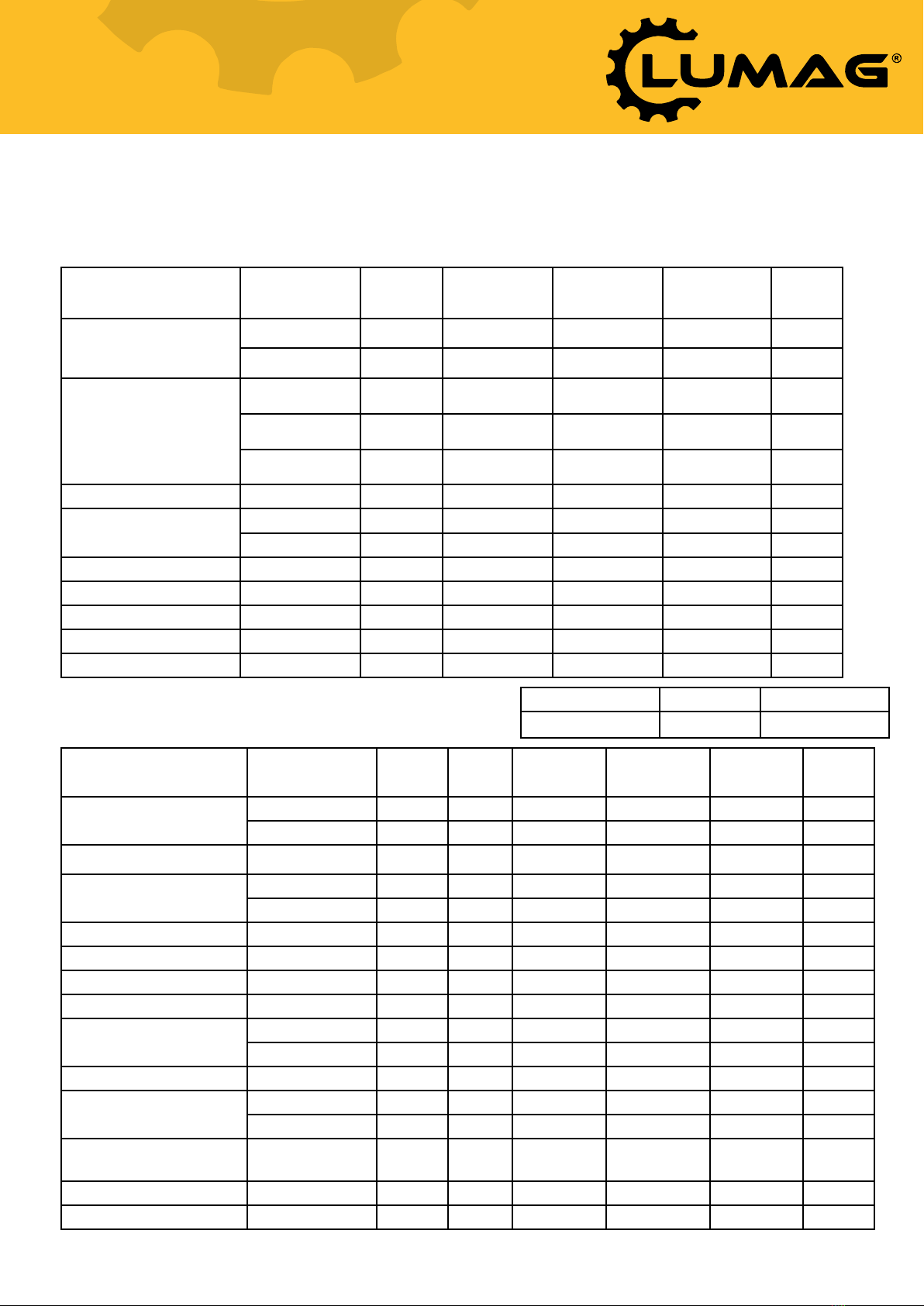

Engine Service & Maintenance Schedule

Machine Service & Maintenance Schedule

Item Checks/Work Each Use 20hrs

(1st Month)

50hrs

(2nd Month)

100hrs

(6th Month)

300hrs

(Yearly)

Engine Oil Check Level X

Change X (1) X

Air Filter Check X

Clean X (3)

Replace X (4)

Sediment Cup Clean X

Spark Plug Check/Clean X

Replace X

Idle Speed Check/Adjust X (2)

Valve Clearance Check/Adjust X (2)

Fuel Tank Strainer Check/Clean X (2)

Combuster Chamber Inspect/Clean X (2)

Fuel Lines Check X (2)

Item Checks/Work Each Use Weekly 20hrs

(1st Month)

50hrs

(2nd Month)

100hrs

(6th Month)

300hrs

(Yearly)

Hydraulic Oil Check Level X

Change X (1) X

Hydraulic Filter Change X (1) X

Transmission Oil Check Level X

Change X (1) X

Fasteners Tension Check Check X

Track Tension Check/Adjust X

Clean Machine Check X

Clutch Adjustment Check/Adjust X

Drive Belt Check/Adjust X

Replace X (2)

Grease Points Grease X

Parking Brake Check/Adjust X

Remove & Inspect X (2)

All Other Moving Parts &

Cables

Lubricate X

Tyres Inspect X

Clutch & Steering Handles Check Funcon X

Engine Oil 600ml Lumag Engine 1

Gearbox 1500ml Lumag Trans 1

1 – First service only, 2 = Should be carried out by your Lumag Dealer, 3 = May need to be done more oen in dusty areas &

4 = Replace paper element only

To maximise the life of your Lumag machine it needs to be serviced and maintained at every indicated month or operang

hour interval, whichever comes rst, in accordance with the below Schedules. Please note that failure to service your

machine on schedule or use genuine Lumag parts and consumables will result in your warranty being void.