N31U Service manual 2

Contents

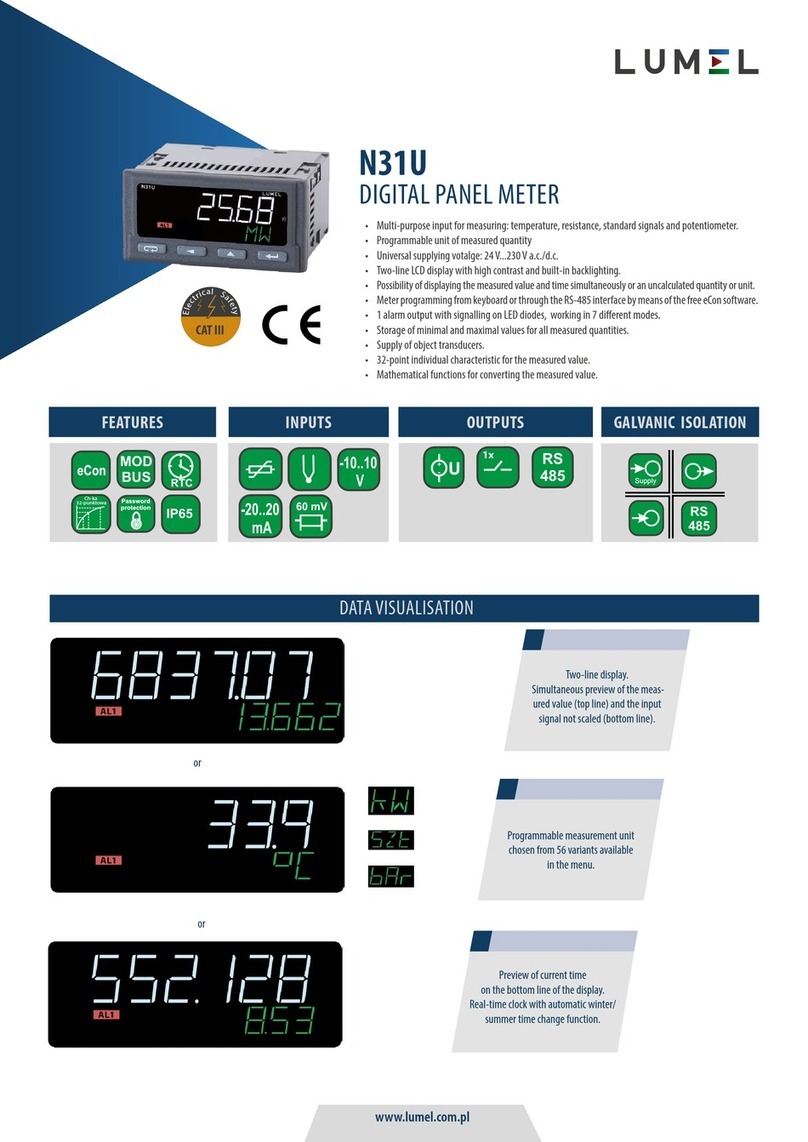

1 Application......................................................................................................................................3

2 Meter set..........................................................................................................................................4

3 Basic requirements, operational safety............................................................................................5

4 Installation.......................................................................................................................................5

4.1 Installation method..................................................................................................................5

4.2 E ternal connection diagram...................................................................................................6

4.3 E amples of connecting the e ternal transducers....................................................................9

5 Service.............................................................................................................................................9

5.1 Description of the frontal plate................................................................................................9

5.2 Buttons' functions...................................................................................................................11

5.3 Programming meter parameters.............................................................................................12

5.3.1 How to change quantity of a selected parameter...........................................................14

5.3.2 Programmable meter parameters, default parameters....................................................15

5.4 Meter functions......................................................................................................................19

5.4.1 Measurement..................................................................................................................19

5.4.1.1 Averaging the measuring quantity..........................................................................20

5.4.1.2 Minimum and ma imum measuring values...........................................................20

5.4.1.3 Mathematical functions..........................................................................................21

5.4.1.4 Individual characteristic.........................................................................................21

5.4.2 Alarm output..................................................................................................................23

5.5 RS-485 interface....................................................................................................................24

5.5.1 Connection.....................................................................................................................24

5.5.2 Description of the MODBUS protocol implementation................................................25

5.5.3 Implemented functions of MODBUS protocol..............................................................25

5.5.4 Map of the registers........................................................................................................26

5.5.4.1 Registers 4000 – 4024............................................................................................26

5.5.4.2 Registers 4200 – 4219............................................................................................29

5.5.4.3 Registers 7500 – 7530 and 7000 – 7030................................................................30

5.5.4.4 Registers 7600 – 7668 and 7200 – 7336................................................................31

6 Error codes.....................................................................................................................................33

7 Technical data................................................................................................................................34

8 Ordering code................................................................................................................................36