NA6Plus-09 User’s Manual 3___________________________________

1. APPLICATION

NA6Plus series meters with a bar graph have a universal input designed to measure temperature,

resistance, voltage from shunts, standard signals, DC voltage and DC current. They can be used in

various industries, such as: food industry, pumping stations and sewage treatment plants, chemical

industry, weather stations, meteorological stations, breweries They are intended for the

visualization of the measured quantity and evaluation of change trends of controlled technological

processes. They can also be used in automation systems where programmed controllers are

applied.

NA6Plus meters have, depending on the version, one or two continuous outputs (voltage or

current), 4 relay outputs or 8 open collector (OC) type outputs, as well as an RS-485 interface. The

meters are programmable via the keyboard and via RS-485.

NA6Plus meters performs the following functions:

measurement of the input quantity and displaying it on the display and the bar graph,

recalculating of the input signal into indication on the base of the individual multipoint

characteristics,

arithmetic on the channels: addition, subtraction, multiplication, division, power and

square root;

programming of colours and bar graph resolutions,

signalling of exceeding the set alarm values;

recording of the measured signal in programmed time intervals,

storage of maximum and minimum values,

programming of the measurement averaging time,

programming of the indication resolution,

deadlock of the parameter introduction by means of a password,

conversion of the measured quantity into a voltage or current output signal,

RS-485 interface support in MODBUS RTU protocol.

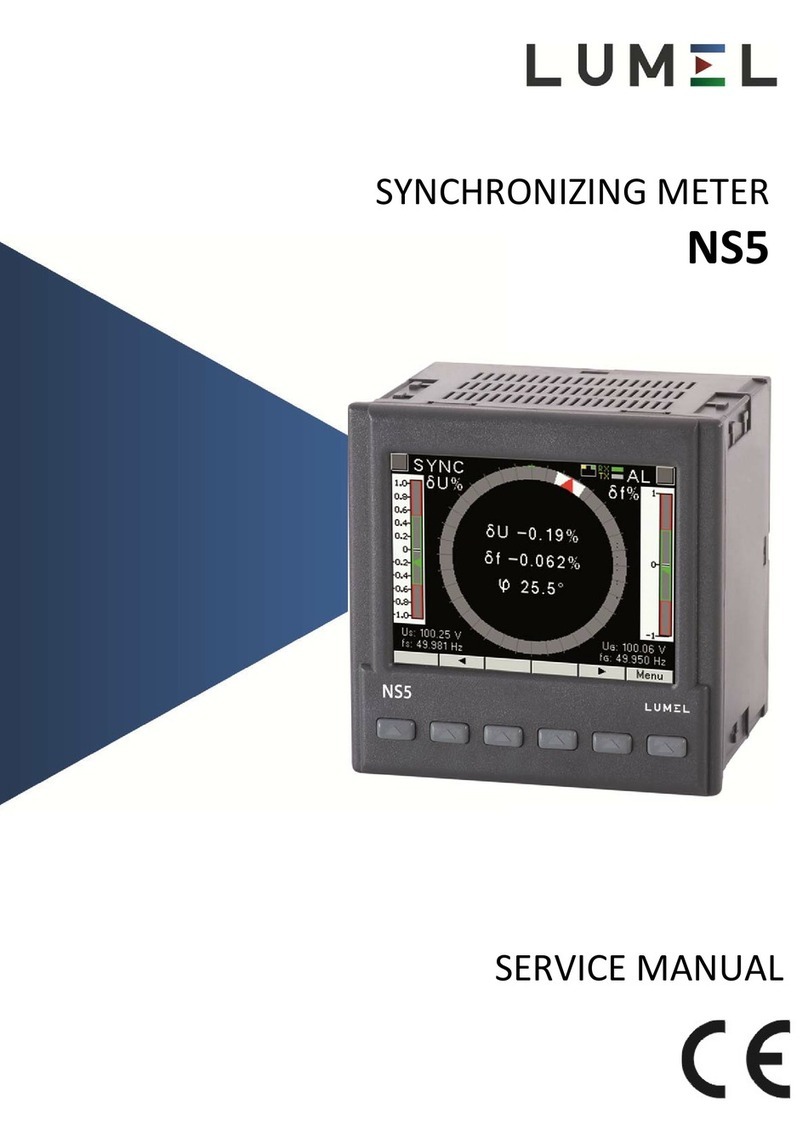

Fig. 1: View of NA6Plus meter.