R3-GD1

P. 1 / 4EM-8465

DeviceNet INTERFACE MODULE MODEL R3-GD1

INSTRUCTION MANUAL

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■ PACKAGE INCLUDES:

Network interface module ........................................... (1)

■ MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■ CONFORMITY WITH EC DIRECTIVES

• The equipment must be mounted inside the instrument

panel of a metal enclosure.

• The actual installation environments such as panel con-

figurations, connected devices and connected wires may

affect the protection level of this unit when it is integrated

in a panel system. The user may have to review the CE

requirements in regard to the whole system and employ

additional protective measures to ensure CE conformity.

■ UNPLUGGING THE MODULE

Before you remove the module from its base or mount it,

turn off the power supply for safety.

■ ENVIRONMENT

• Indoor use

• When heavy dust or metal particles are present in the air,

install the unit inside proper housing with sufficient ven-

tilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -10 to +55°C

(14 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■ WIRING

• Do not install cables (power supply, input and output)

close to noise sources (relay drive cable, high frequency

line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■ AND ....

The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for sat-

isfying complete performance described in the data sheet.

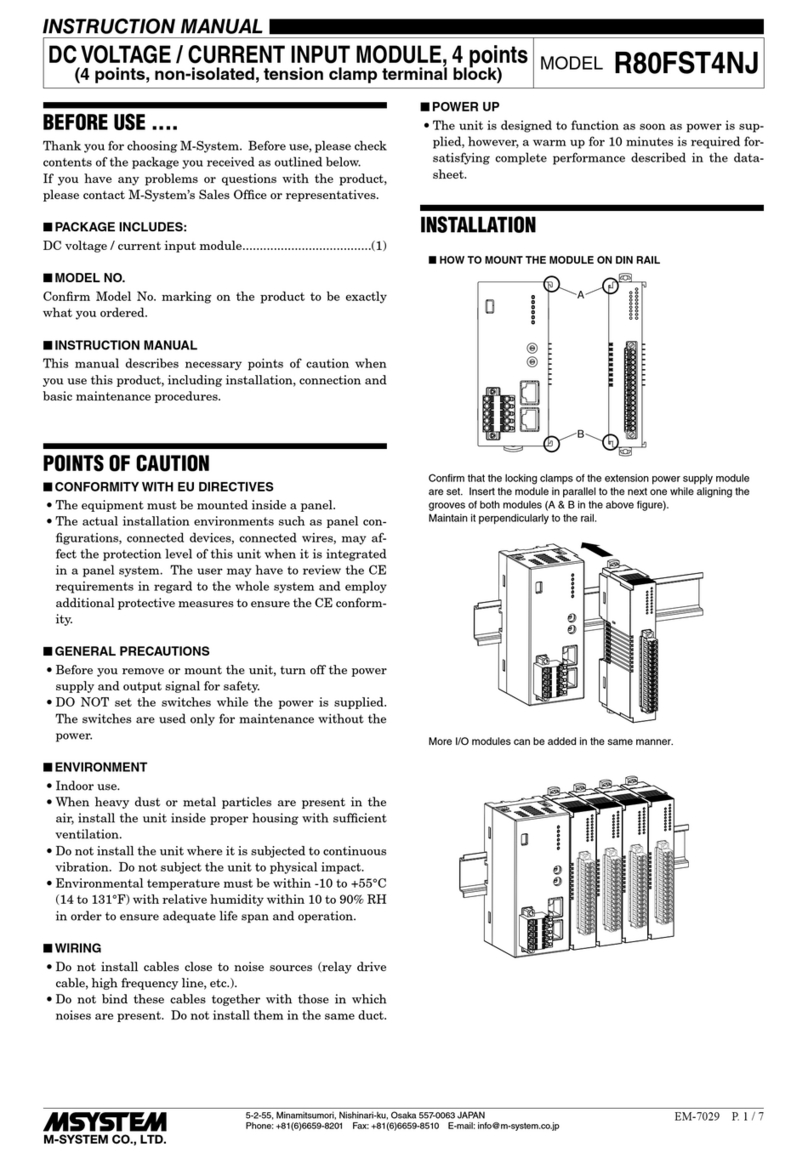

INSTALLATION

Use the Installation Base Model: R3-BSx, or Model: R3-

BSWx for free I/O address capability.

Before mounting the Network Interface Module R3-GD1

onto the base, be sure to configure the module as explained

below.

■ DATA ALLOCATION

Use the side DIP SW1 to set the number of slots which the

module is assigned to.

See “TRANSMISSION DATA DESCRIPTIONS.”

■ NODE ADDRESS & TRANSFER RATE

See “COMPONENT IDENTIFICATION.”

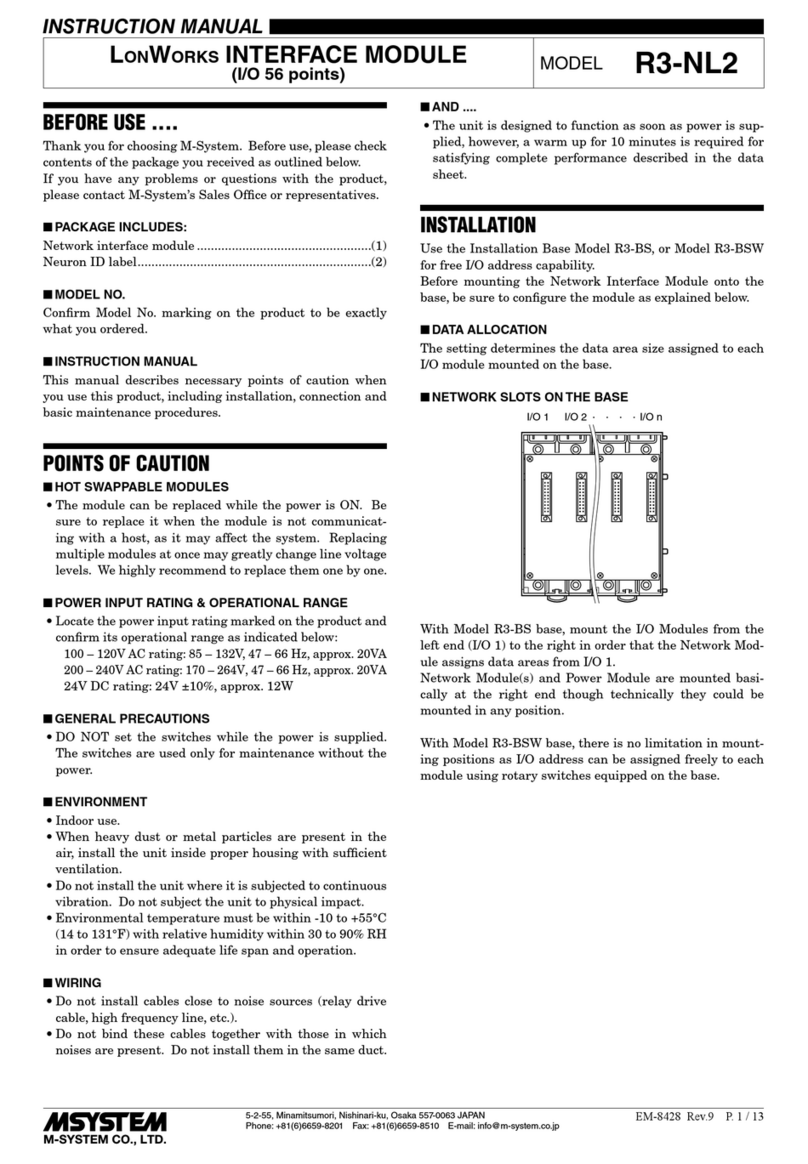

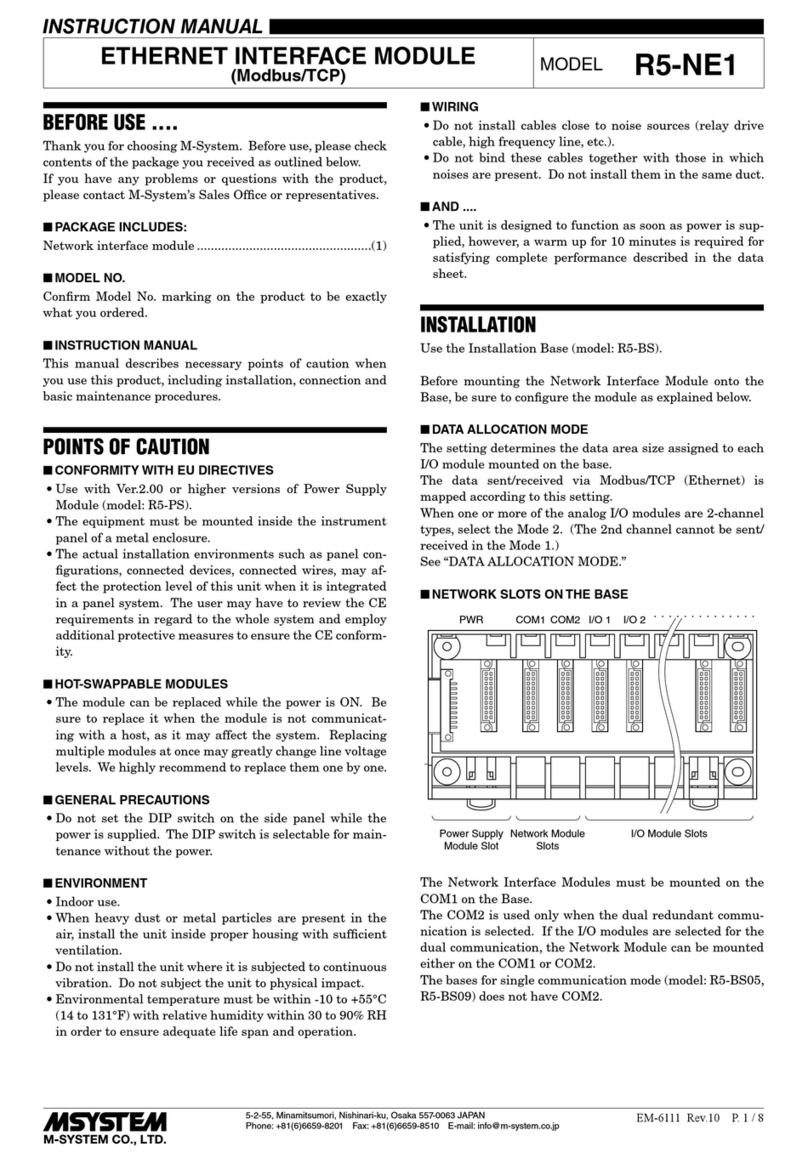

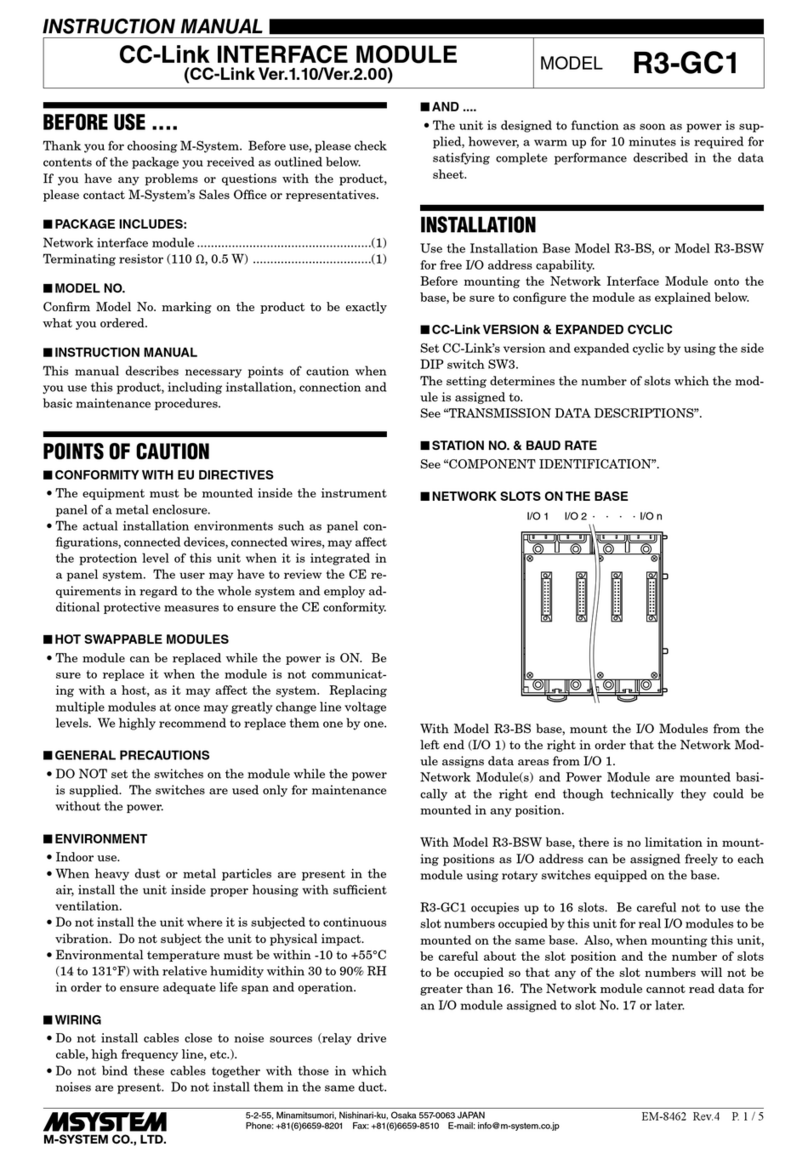

■ NETWORK SLOTS ON THE BASE

With Model R3-BSx base, mount the I/O Modules from the

left end (I/O 1) to the right in order that the Network Mod-

ule assigns data areas from I/O 1.

Network Module(s) and Power Module are mounted basi-

cally at the right end though technically they could be

mounted in any position.

With Model R3-BSWx base, there is no limitation in mount-

ing positions as I/O address can be assigned freely to each

module using rotary switches equipped on the base.

It is available to assign the module to max. 8 slots. The as-

signed slots numbers can not be used again for the real I/O

modules which need to be mounted on the same base. Don’t

set the interface module for more than 16 slots as it can not

read the data for more than 16 modules.

M-SYSTEM WARRANTY

M-System warrants such new M-System product which it manufactures to be free from defects in materials and workmanship during the 36-month period following the date that such

product was originally purchased if such product has been used under normal operating conditions and properly maintained, M-System’s sole liability, and purchaser’s exclusive

remedies, under this warranty are, at M-System’s option, the repair, replacement or refund of the purchase price of any M-System product which is defective under the terms of this

warranty. To submit a claim under this warranty, the purchaser must return, at its expense, the defective M-System product to the below address together with a copy of its original

sales invoice.

THIS IS THE ONLY WARRANTY APPLICABLE TO M-SYSTEM PRODUCT AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. M-SYSTEM SHALL HAVE NO LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR

SPECIAL DAMAGES OF ANY KIND WHATSOEVER.

M-System Co., Ltd., 5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN, Phone: (06) 6659-8201, Fax: (06) 6659-8510, E-mail:

[email protected]