LC / LCS

P. 4 / 4 EM-1355 Rev.3

SIMPLE LOOP TEST OUTPUT Option /E2

Simulated 0% and 100% output is available with Option /E2.

Switch the Loop Test Selector positions.

Top position: 0% fixed

Middle position: 100% fixed

Bottom position: Cancel the loop test mode

(Back to the normal operating mode)

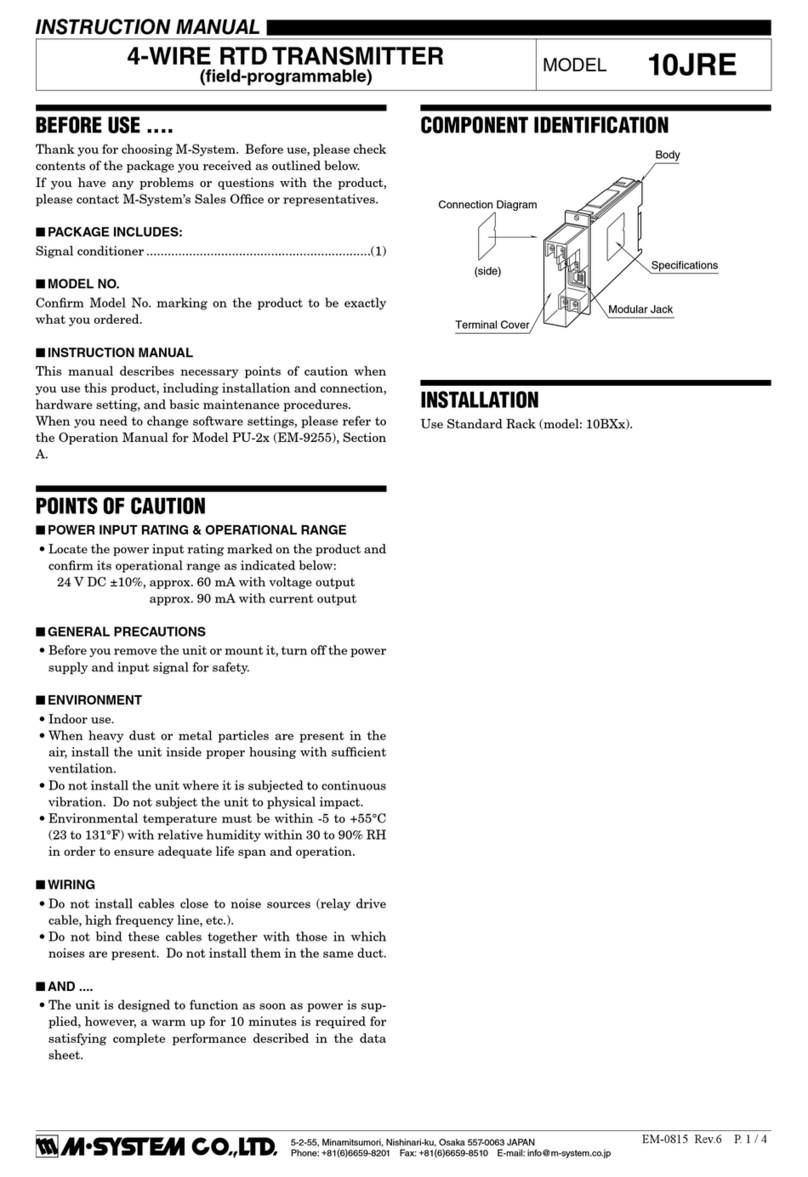

CHECKING

1) Terminal wiring: Check that all cables are correctly

connected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal 7

–8with a multimeter.

3) Input: Check that the input signal is within 0 – 100% of

the full-scale.

4) Output: Check that the load resistance meets the de-

scribed specifications.

ADJUSTMENT PROCEDURE

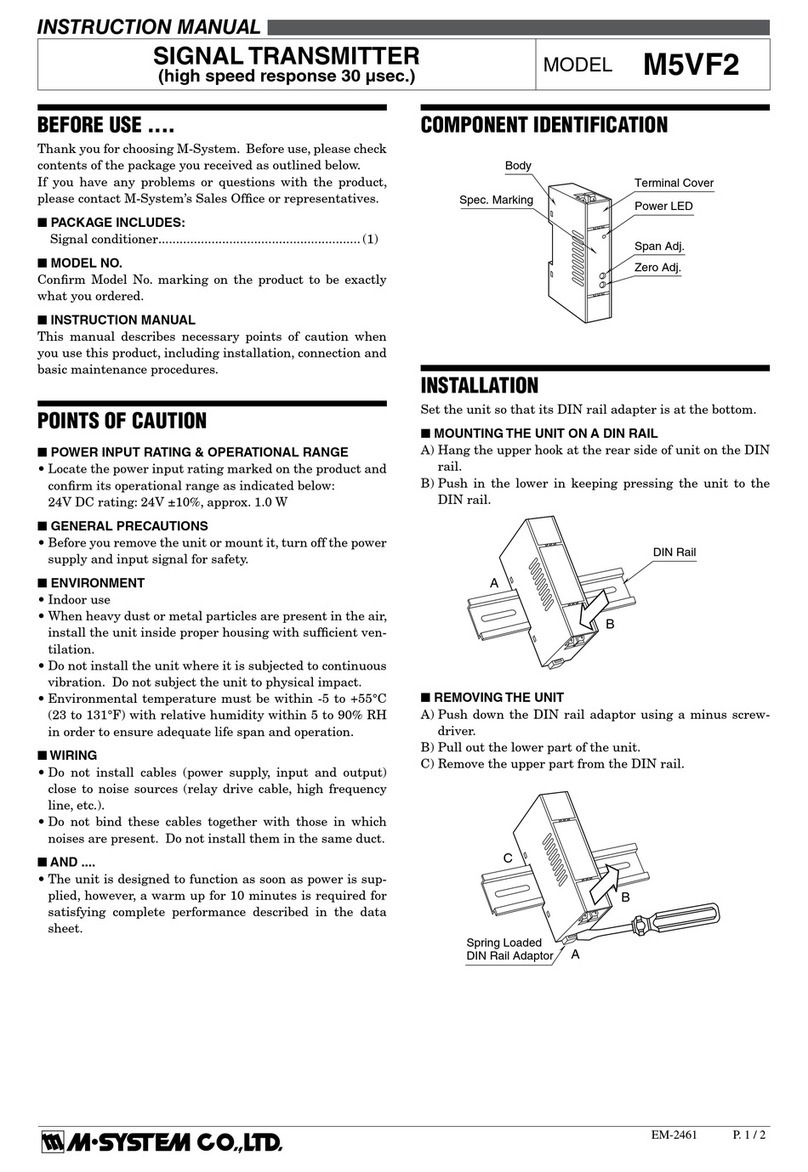

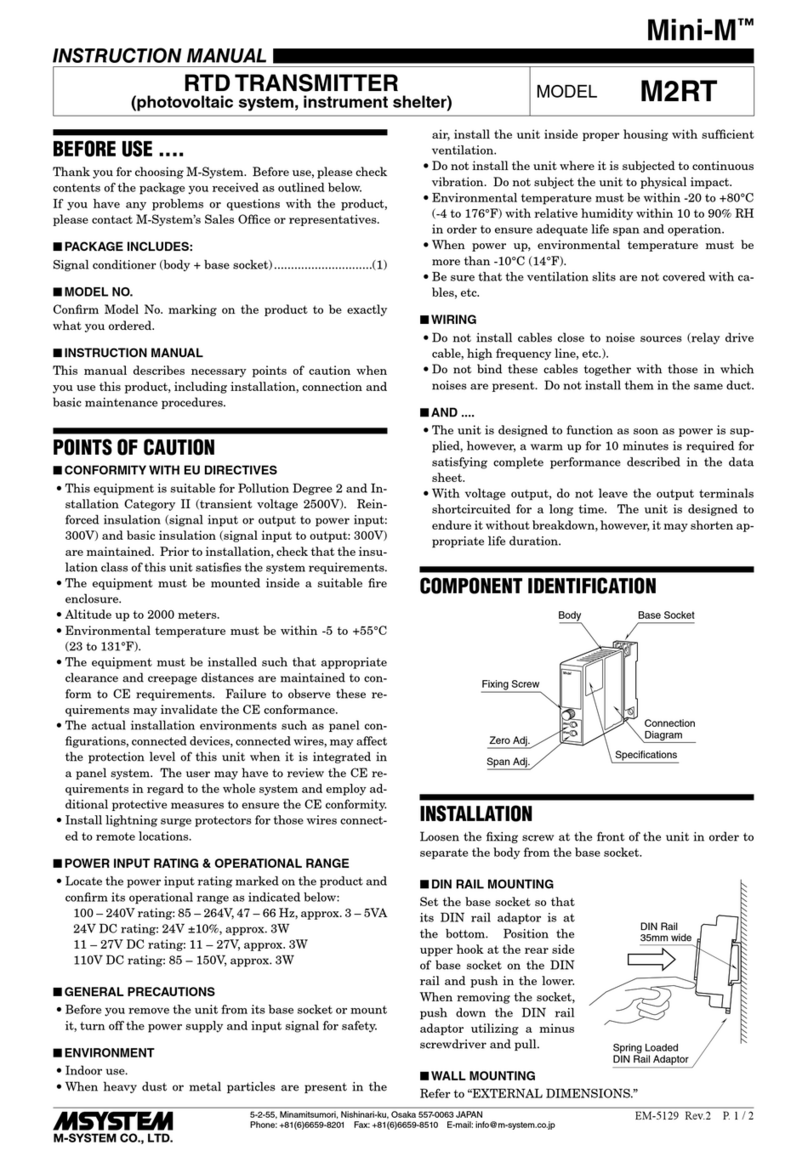

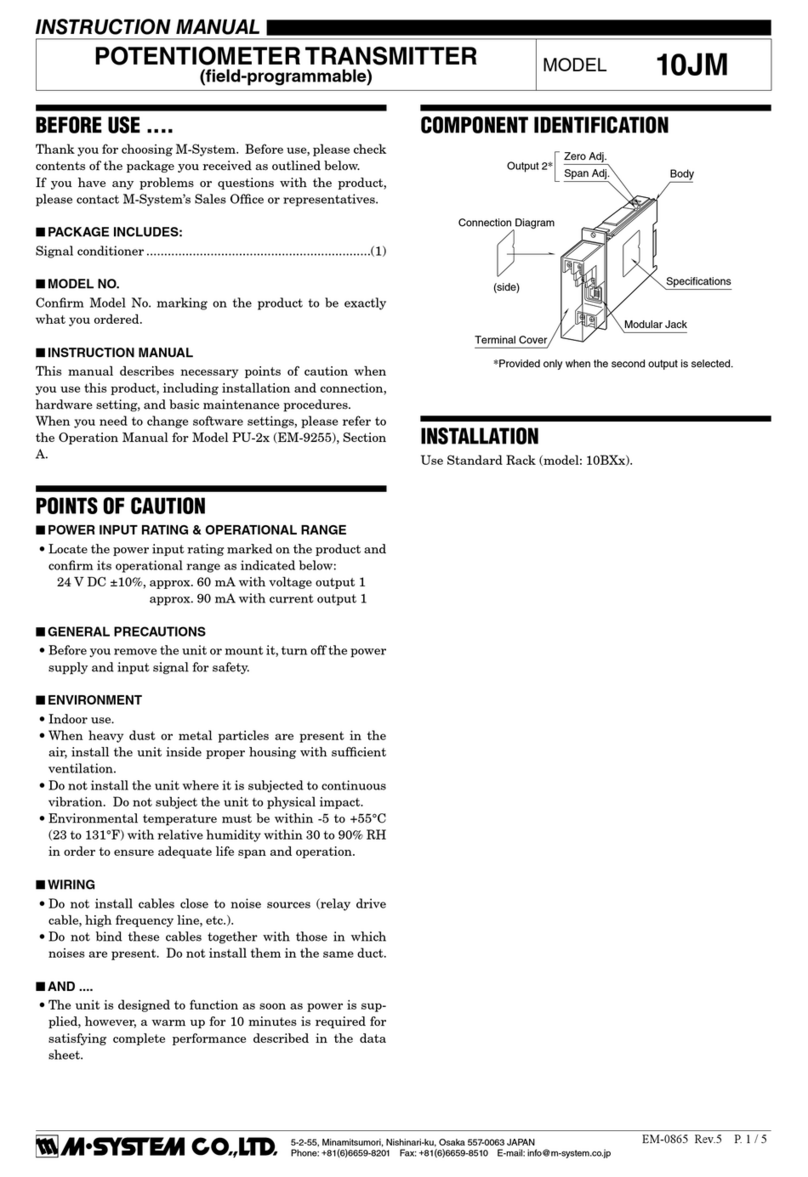

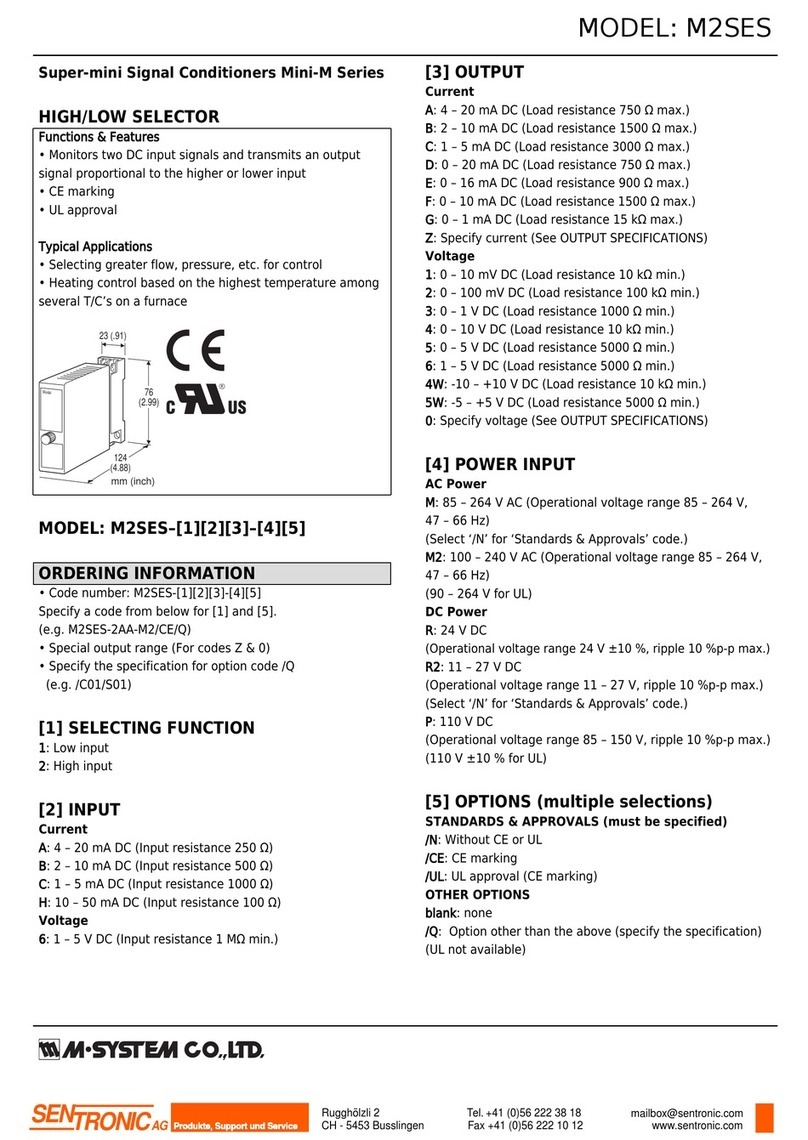

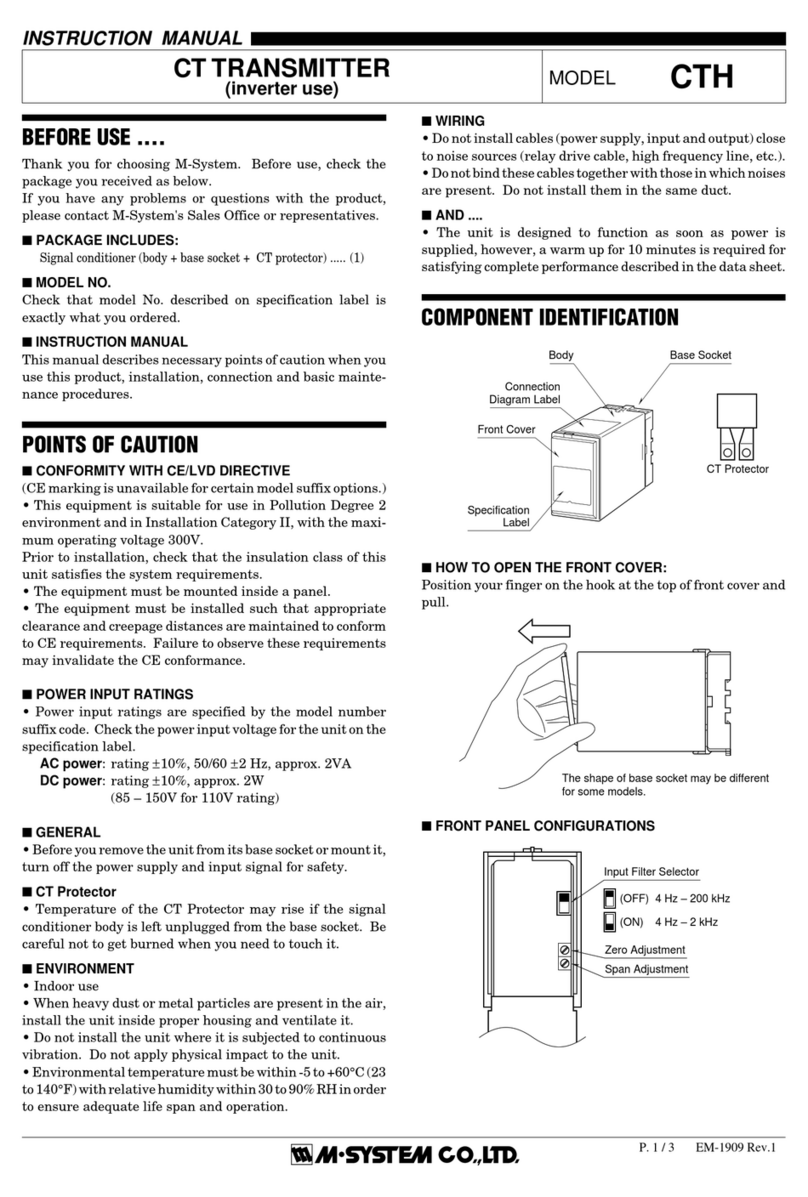

■ FRONT PANEL CONFIGURATION

• Option /E

• Option /E2

M-SYSTEM WARRANTY

M-System warrants such new M-System product which it manufactures to be free from defects in materials and workmanship during the 36-month period following the date that such

productwasoriginallypurchasedifsuchproducthasbeenusedundernormaloperatingconditionsandproperlymaintained,M-System'ssoleliability,andpurchaser'sexclusiveremedies,

under this warranty are, at M-System's option, the repair, replacement or refund of the purchase price of any M-System product which is defective under the terms of this warranty. To

submit a claim under this warranty, the purchaser must return, at its expense, the defective M-System product to the below address together with a copy of its original sales invoice.

THIS IS THE ONLY WARRANTY APPLICABLE TO M-SYSTEM PRODUCT AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. M-SYSTEM SHALL HAVE NO LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR

SPECIAL DAMAGES OF ANY KIND WHATSOEVER.

M-System

Co.,

Ltd.,

5-2-55,

Minamitsumori,

Nishinari-ku,

Osaka

557-0063

JAPAN,

Phone:

(06)

6659-8201,

Fax:

(06)

6659-8510,

E-mail:

[email protected]LCD Meter

Span Adj.

Zero Adj.

Excitation Adj.

Loop Test Selector

Top

Middle

Bottom

: 0% fixed

: 100% fixed

: Cancel

(normal operating mode)

NEXT Key

ENTER Key

Span Adj.

Zero Adj.

Excitation Adj.

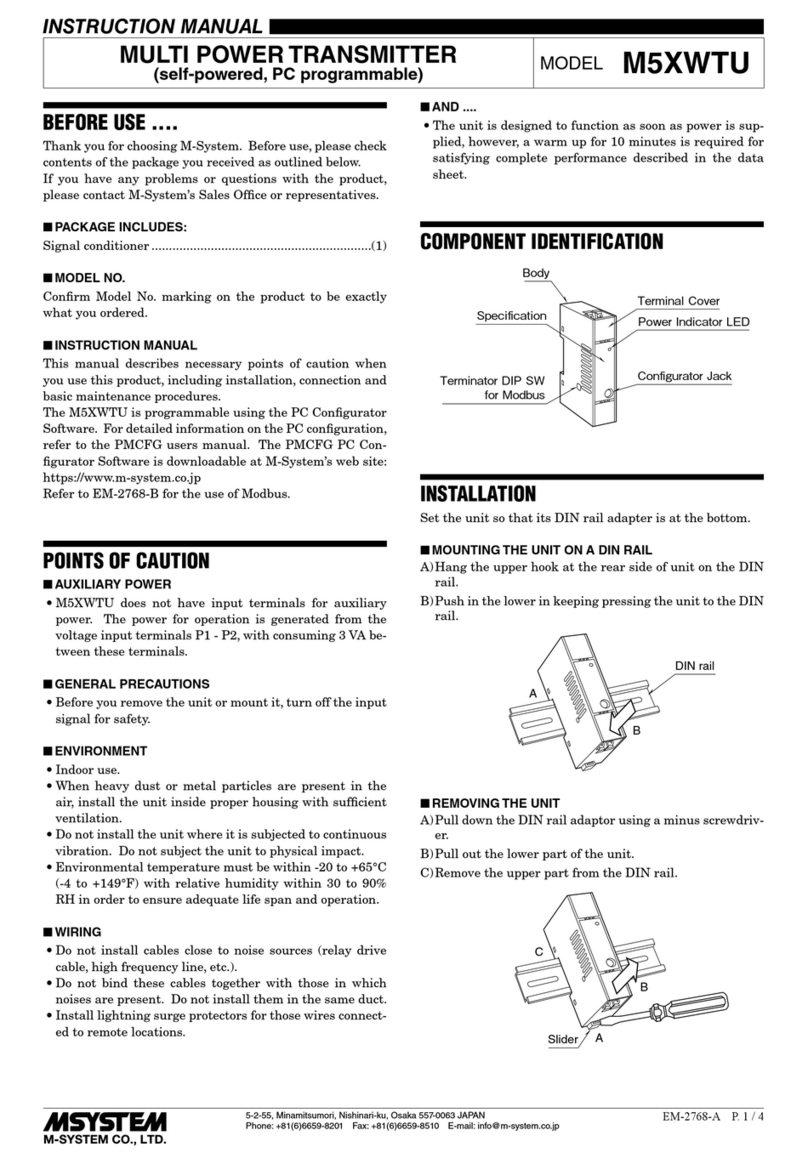

■ EXCITATION

This unit is calibrated at the factory for use with the rating

described on the specification label. However if you need to

adjust it for use with a rating other than the factory setting,

refer to the equation below.

Excitation Voltage = 5 [V] ×a [mV/V] [V]

b [mV/V]

where a : Rating described on specification label

b : Actual rating

With 350Ωbridge resistance, the excitation can be adjusted

from 2V to 10V.

When the result of above calculation exceeds 10V, adjust the

excitation to 10V.

■ ZERO (TARE) ADJUSTMENT

Adjustable from 0 to 80% of the input span (strain gauge

rating). With no load applied, turn the Zero Adjustment until

the output shows 0%.

■ SPAN (SENSITIVITY) ADJUSTMENT

Adjustable from 20 to 100% of the input span (strain gauge

rating). With the full-scale load, turn the Span Adjustment

until the output shows 100%.

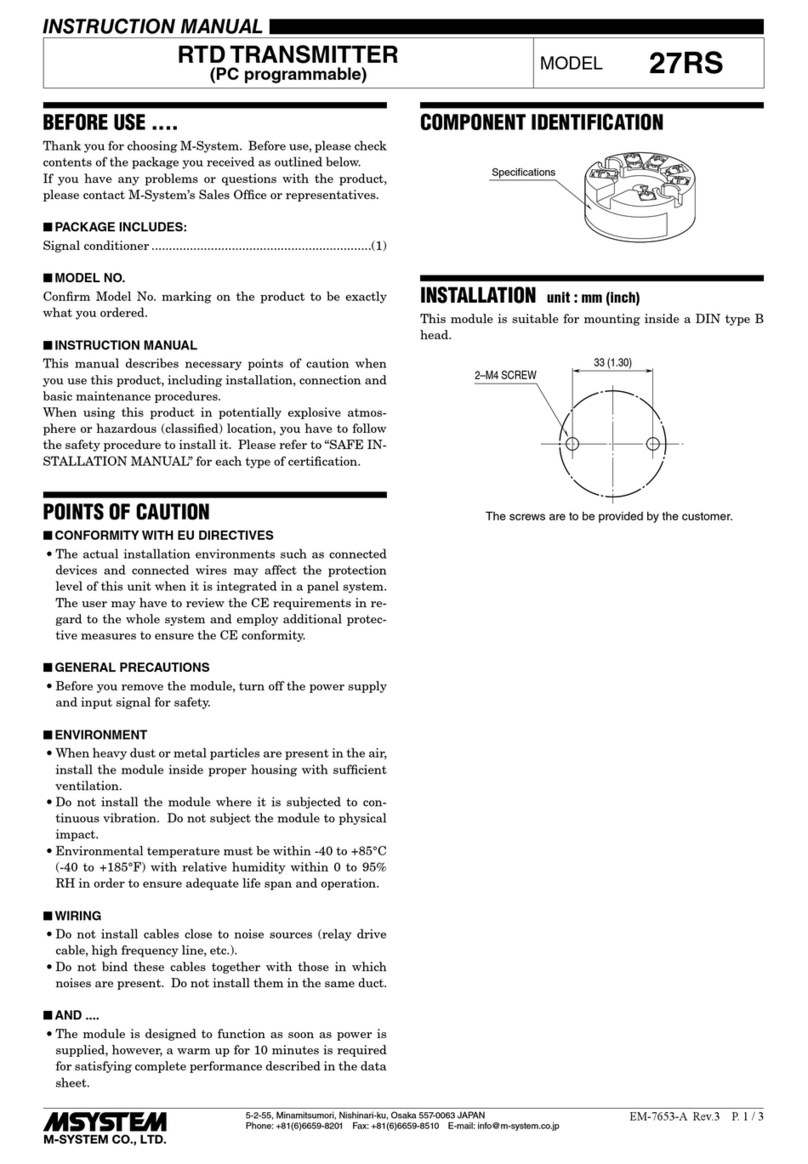

MAINTENANCE

Regular calibration procedure is explained below:

■ CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the "ADJUST-

MENT PROCEDURE" explained earlier.