10JRE

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax:

+81(6)6659-8510 E-mail: info@m-system.co.jp

EM-0815 Rev.6 P. 3 / 4

CHECKING

1 ) Terminal wiring: Check that all cables are correctly

connected according to the connection diagram.

2 ) Power input voltage: Check voltage supplied to the rack

(model: 10BXx). For the DC power source, be sure that

the ripple level is within 10% p-p.

3 ) Input: Check that the input signal is within 0 – 100%

of the full-scale.

(With 20°C or 68°F, approx. 1.1V should read.)

If RTD wires are broken, the output goes over 100% (below

0% with downscale protection) due to burnout protection

function. Check leadwires in such a case.

4 ) Output: Check that the load resistance meets the de-

scribed specifications.

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any cali-

bration, unless you need to match the signal to a receiving

instrument or conduct regular calibration.

Zero and span are adjusted with using the Programming

Unit (model: PU-2x).

Refer to the Operation Manual for Model PU-2x for expla-

nations how to use the programmer.

■WARNING ON USE OF THE PROGRAMMING UNIT

•Be sure to disconnect the Programming Unit before you

turn on/off power supply to the unit.

•The output signal is held when the Programming Unit is

connected. You need to disconnect when confirming cur-

rent output values.

■HOW TO CALIBRATE THE OUTPUT SIGNAL

Use a signal source and measuring instruments of sufficient

accuracy level. Turn the power supply on and warm up for

more than 10 minutes.

• Fine Output Calibration

Using the Programming Unit (ITEM 19, 20)

ITEM 19 is for Zero, and ITEM 20 is for Span.

1 ) Turn the unit into Program mode (ITEM 01).

2 ) Apply simulated 0% input. Increase/decrease values

(default: 0%) at ITEM 19 until the output signal is cali-

brated to actual 0%.

3 ) Apply simulated 100% input. Increase/decrease value

(default: 100%) at ITEM 20 until the output signal is

calibrated to actual 100%.

4 ) Apply simulated 0% input again and check 0% output.

5 ) When 0% value is changed, repeat the above procedure

2) - 4).

The 0% value may be shifted when the output span is

greater than the input span (gain > 1).

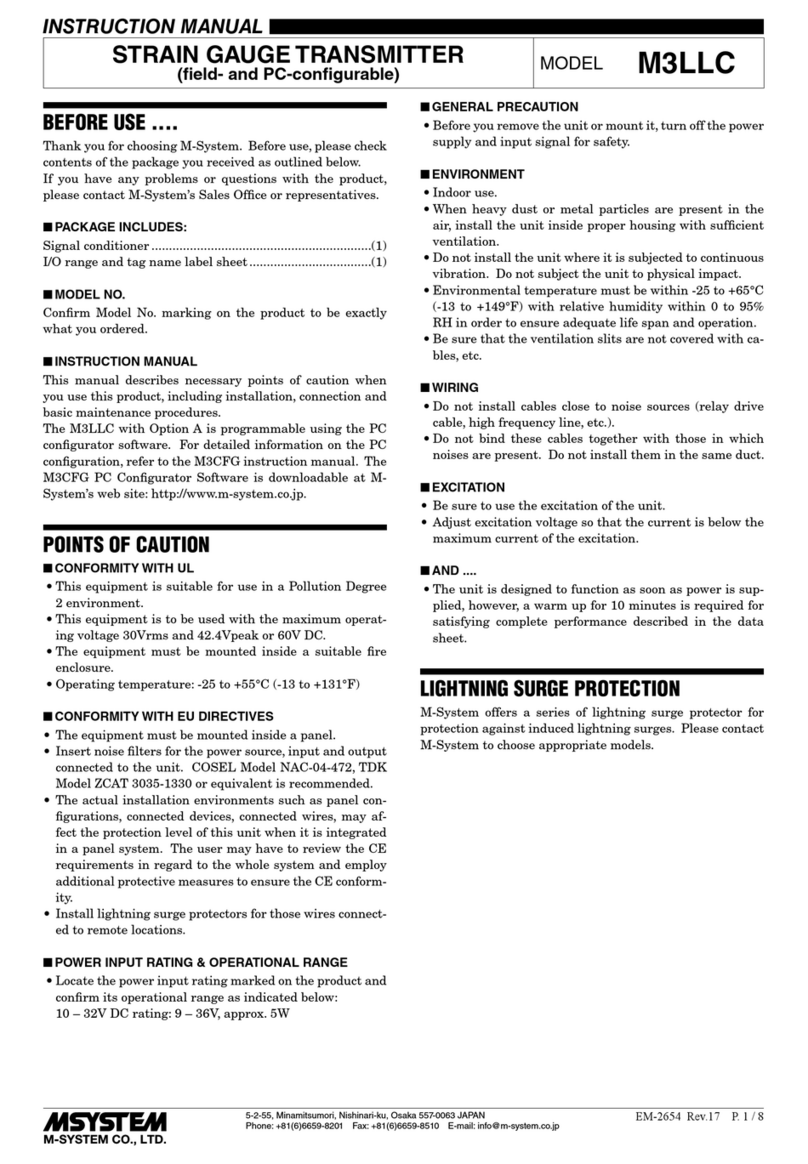

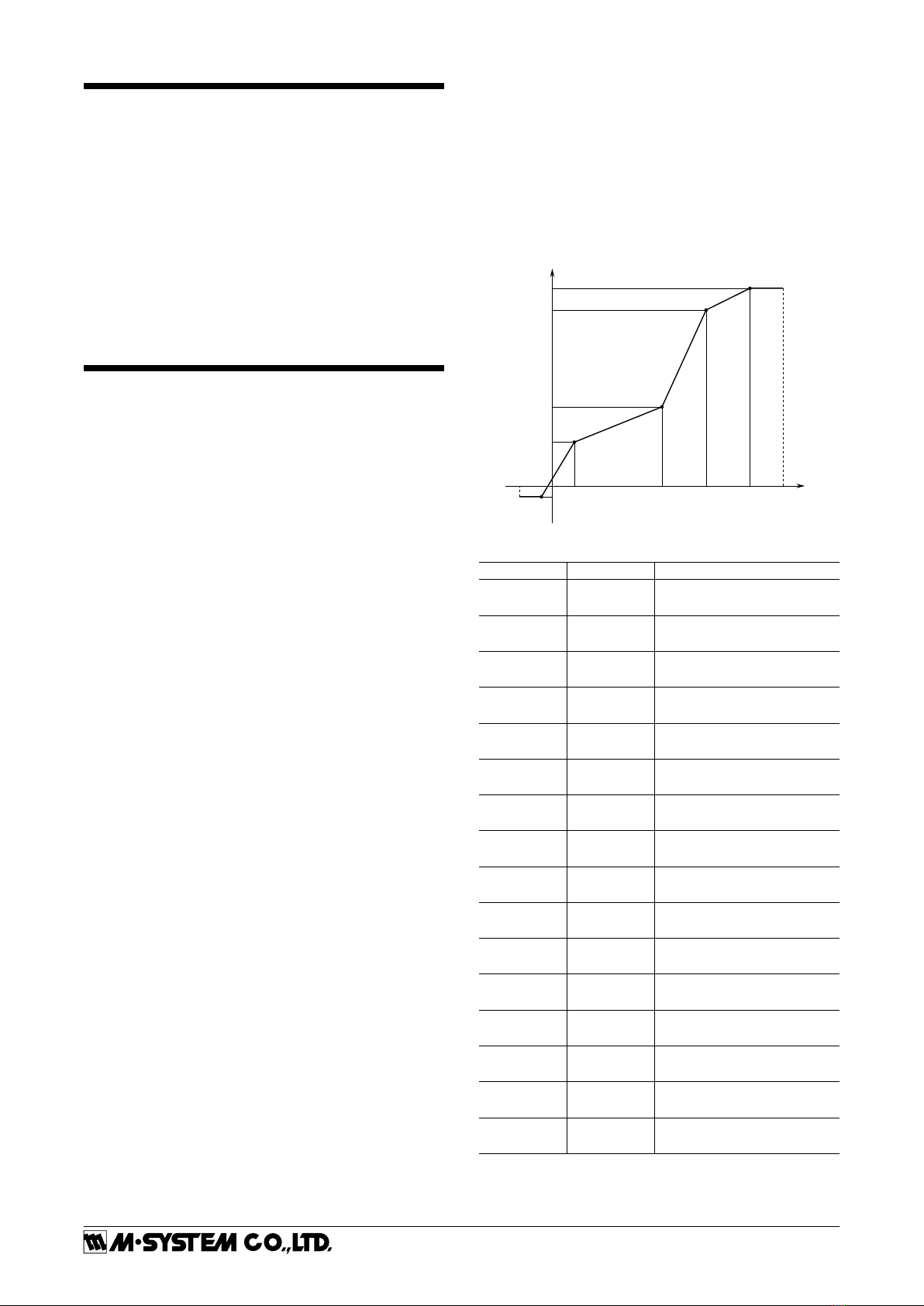

• Using Linearization Table

Please have the PU-2x Operation Manual ready at hand.

Max. 16 calibration points defined by sets of input and out-

put values can be programmed. Use only necessary number

of points, arranged in order from the smallest input value.

Enable use of the linearization table (ITEM 10: Pm-2:

curved) in order to activate the settings.

X (nn) : Input Signal in %

Y (nn) : Output Signal in %

X or Y : -15.00 to +115.00%

-15% 0

X01

X02 X03 X04 X05 +115%

Y01

Y02

Y03

Y04

+100% Y05

INPUT

OUTPUT

[GROUP 01]

ITEM MDFY. DATA EXAMPLE

60 P X (01) : XXX.XX

61 P Y (01) : XXX.XX

62 P X (02) : XXX.XX

63 P Y (02) : XXX.XX

64 P X (03) : XXX.XX

65 P Y (03) : XXX.XX

66 P X (04) : XXX.XX

67 P Y (04) : XXX.XX

68 P X (05) : XXX.XX

69 P Y (05) : XXX.XX

70 P X (06) : XXX.XX

71 P Y (06) : XXX.XX

72 P X (07) : XXX.XX

73 P Y (07) : XXX.XX

74 P X (08) : XXX.XX

75 P Y (08) : XXX.XX

76 P X (09) : XXX.XX

77 P Y (09) : XXX.XX

78 P X (10) : XXX.XX

79 P Y (10) : XXX.XX

80 P X (11) : XXX.XX

81 P Y (11) : XXX.XX

82 P X (12) : XXX.XX

83 P Y (12) : XXX.XX

84 P X (13) : XXX.XX

85 P Y (13) : XXX.XX

86 P X (14) : XXX.XX

87 P Y (14) : XXX.XX

88 P X (15) : XXX.XX

89 P Y (15) : XXX.XX

90 P X (16) : XXX.XX

91 P Y (16) : XXX.XX

Modication Code

S: Modifiable at any time.

P: Modifiable only when the MAINTENANCE SWITCH is in

the “PRG” mode.