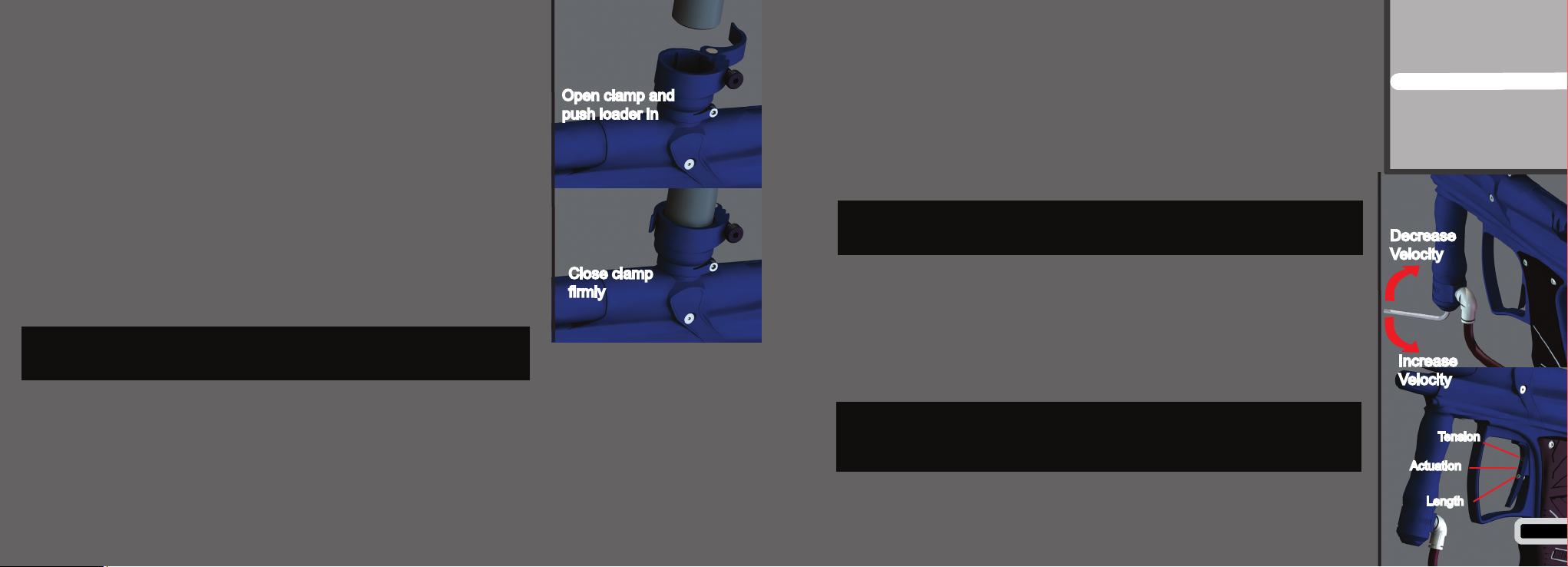

QUICK SETUP

Switching your marker on and off

The on/off button is located on a membrane pad on the rear of the frame. Push

the button with the power symbol ( ), when done correctly, your OLED will

display the MacDev logo and the marker will be set with the beam sensor sys-

tem on and ready to re. Turn your marker off by holding the power button down

until the OLED system goes blank.

Firing your marker

If a paintball is loaded in your marker, and the power is switched on, you may

re the marker by pulling the trigger. If a paintball is not loaded, then you need

to either load one, or read the section below on disabling the beam sensor.

Understanding the beam sensor

Your Cyborg is equipped with a visible light sensor to determine if a paintball is

correctly loaded. This system is used to prevent accidental ball breakage due to

misloaded paintballs. The OLED indicator on the side of your grip will show you

the status of the beam sensor:

Disabling the beam sensor

To disable the sensor (for dry ring), hold the scroll button on the membrane

pad ( )until the beam sensor disabled icon appears on the OLED display. You

can re-enable the beam sensor the same way.

Ball loaded Sensor disabled

No ball loaded Sensor fault

Power button

(for power on/off)

Scroll button

(for eyes on/off and pro-

gramming)

OLED Display

Membrane Pad

Battery meter

Sensor status

Cycle mode

Cycle speed (max)

Lock status

Game timer/

ROF meter

Installing a preset air system

Your Cyborg comes equipped with a high quality venting ASA (Air System Adap-

tor) that is designed for use with commercially available air/nitrogen systems.

The venting ASA included with your Cyborg uses a screw cap to turn the air

from your preset system on or off. Before installing your preset air system, you

must unscrew the ASA cap by approximately 3 turns (do not unscrew it further,

as the cap can come off completely).

Once this is done, carefully screw your air system into the ASA until it stops.

Turning the air on and off

To pressurise your marker, screw the ASA cap down until it stops. This will

depress the pin on the end of your air system and pressurise the marker

(provided you have sufcient air in your air system).

To depressurise your Cyborg, unscrew the ASA cap until you hear the air

being vented from the cap. Your air system is now turned off and safe to

remove.

WHEN SCREWING YOUR AIR SYSTEM INTO THE ASA, THE

THREADS SHOULD BE LOOSE. IF AT ANY POINT THEY BECOME

TIGHT, DO NOT FORCE THE THREADS, THIS MAY CAUSE DAMAGE

TO YOUR AIR SYSTEM OR YOUR MARKER!

NOTE: WHEN YOU UNSCREW THE ASA CAP, YOUR MARKER MAY

STORE ONE SHOT. POINT THE MARKER IN A SAFE DIRECTION AND

FIRE OFF THAT SHOT BEFORE ENTERING A SAFE AREA. 8

Contents

Know your Cyborg

Quick Setup

Using your Cyborg

Advanced Setup

Maintenance

Parts List

Troubleshooting

Turn air on

Turn air off