TABLE OF CONTENTS

Form 169469/169470/169471 4Revision C

6.1 OWNER/OPERATOR RESPONSIBILITIES................................................................................54

6.2 SYMBOL DEFINITIONS ..............................................................................................................54

6.2.1 Engine Functions ................................................................................................................................... 54

6.2.2 Windrower Operating Symbols............................................................................................................... 54

6.2.3 Header Functions................................................................................................................................... 55

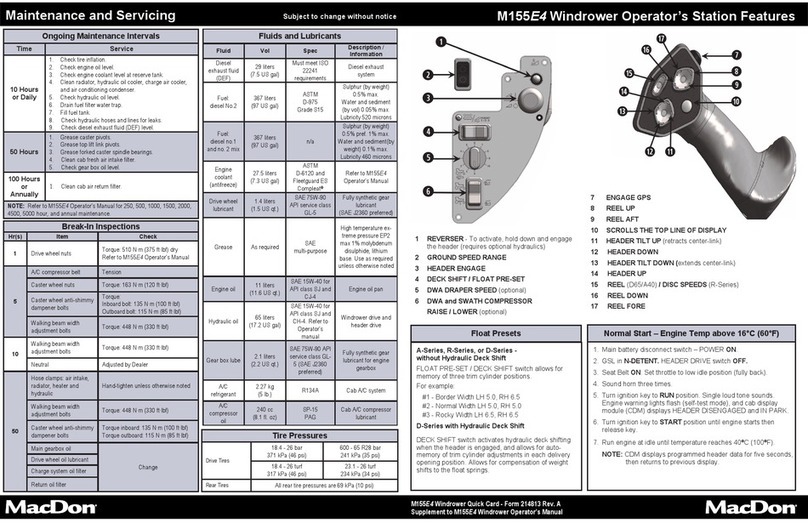

6.3 WINDROWER OPERATION .......................................................................................................56

6.3.1 Operational Safety ................................................................................................................................. 56

6.3.2 Break-In Period ...................................................................................................................................... 56

6.3.3 Pre-Season Check ................................................................................................................................. 57

6.3.4 Daily Check ............................................................................................................................................ 57

6.3.5 Engine Operation ................................................................................................................................... 58

6.3.6 Driving The Windrower........................................................................................................................... 62

6.3.7 Adjustable Caster Tread Width .............................................................................................................. 68

6.3.8 Transporting ........................................................................................................................................... 70

6.3.9 Storage................................................................................................................................................... 79

6.4 HEADER OPERATION................................................................................................................80

6.4.1 Header Lift Cylinder Stops ..................................................................................................................... 80

6.4.2 Header Flotation..................................................................................................................................... 81

6.4.3 Levelling ................................................................................................................................................. 84

6.4.4 Header Drive .......................................................................................................................................... 85

6.4.5 Header Angle ......................................................................................................................................... 86

6.4.6 Cutting Height ........................................................................................................................................ 88

6.4.7 Double Windrowing ................................................................................................................................ 90

6.5 D SERIES HEADER OPERATION..............................................................................................91

6.5.1 Header Attachment ................................................................................................................................ 91

6.5.2 Header Detachment ............................................................................................................................... 95

6.5.3 Header Position...................................................................................................................................... 97

6.5.4 Reel Fore-Aft Position ............................................................................................................................ 97

6.5.5 Reel Height ............................................................................................................................................ 97

6.5.6 Reel Speed ............................................................................................................................................ 98

6.5.7 Draper Speed....................................................................................................................................... 100

6.5.8 Knife Speed.......................................................................................................................................... 102

6.5.9 Deck Shift (Optional) ............................................................................................................................ 103

6.6 A SERIES HEADER OPERATION ............................................................................................104

6.6.1 Header Attachment .............................................................................................................................. 104

6.6.2 Header Detachment ............................................................................................................................. 107

6.6.3 Auger Speed ........................................................................................................................................ 109

6.6.4 Reel Speed .......................................................................................................................................... 110

6.6.5 Knife Speed.......................................................................................................................................... 112

6.7 R SERIES HEADER OPERATION............................................................................................113

6.7.1 Header Attachment .............................................................................................................................. 113

6.7.2 Header Detachment ............................................................................................................................. 116

6.7.3 Disc Speed........................................................................................................................................... 118

7MAINTENANCE/SERVICE ................................................................................................................119

7.1 PREPARATION FOR SERVICING............................................................................................119

7.1.1 Welding Precautions ............................................................................................................................ 119

7.2 RECOMMENDED SAFETY PROCEDURES ............................................................................119

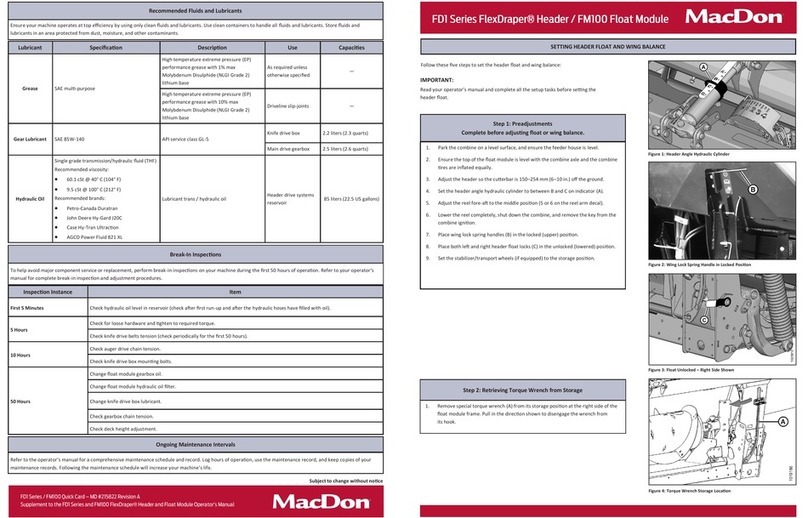

7.3 MAINTENANCE SPECIFICATIONS..........................................................................................120

7.3.1 Recommended Fuel, Fluids And Lubricants......................................................................................... 120

7.3.2 Recommended Torques....................................................................................................................... 121

7.3.3 Conversion Chart ................................................................................................................................. 123

7.4 ENGINE COMPARTMENT HOOD ............................................................................................124

7.5 MAINTENANCE PLATFORMS..................................................................................................125

7.5.1 Opening/Closing Platforms................................................................................................................... 125

7.5.2 Opening/Closing Platform for Major Servicing...................................................................................... 125

7.6 LUBRICATING THE WINDROWER..........................................................................................127

7.6.1 Procedure............................................................................................................................................. 127

7.6.2 Lubrication Points................................................................................................................................. 127

7.7 OPERATOR’S STATION...........................................................................................................129

7.7.1 Seat Belts............................................................................................................................................. 129

7.7.2 Safety Systems .................................................................................................................................... 129

7.7.3 GSL Adjustments ................................................................................................................................. 130

7.7.4 Steering Adjustments ........................................................................................................................... 131