TABLE OF CONTENTS

Introduction...................................................................................................................................... i

List of Revisions ...............................................................................................................................ii

1 Safety.................................................................................................................................................... 1

1.1 Signal Words................................................................................................................................... 1

1.2 General Safety ................................................................................................................................ 2

1.3 Safety Signs.................................................................................................................................... 4

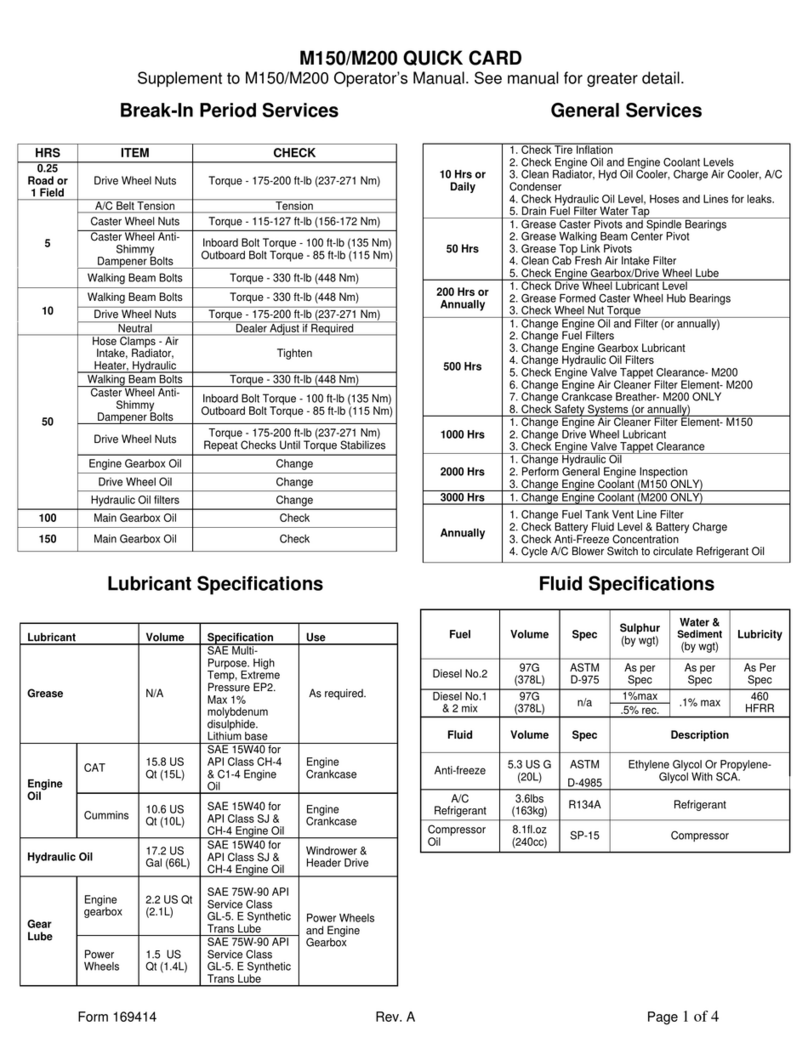

2 Recommended Torques ........................................................................................................................ 5

2.1 Torque Specifications....................................................................................................................... 5

2.1.1 SAE Bolt Torque Specifications................................................................................................. 5

2.1.2 Metric Bolt Specifications.......................................................................................................... 7

2.1.3 Metric Bolt Specifications Bolting into Cast Aluminum............................................................... 10

2.1.4 Flare-Type Hydraulic Fittings................................................................................................... 10

2.1.5 O-Ring Boss (ORB) Hydraulic Fittings (Adjustable)................................................................... 12

2.1.6 O-Ring Boss (ORB) Hydraulic Fittings (Non-Adjustable) ........................................................... 14

2.1.7 O-Ring Face Seal (ORFS) Hydraulic Fittings............................................................................ 15

3 Conversion Chart................................................................................................................................ 17

4Definitions........................................................................................................................................... 19

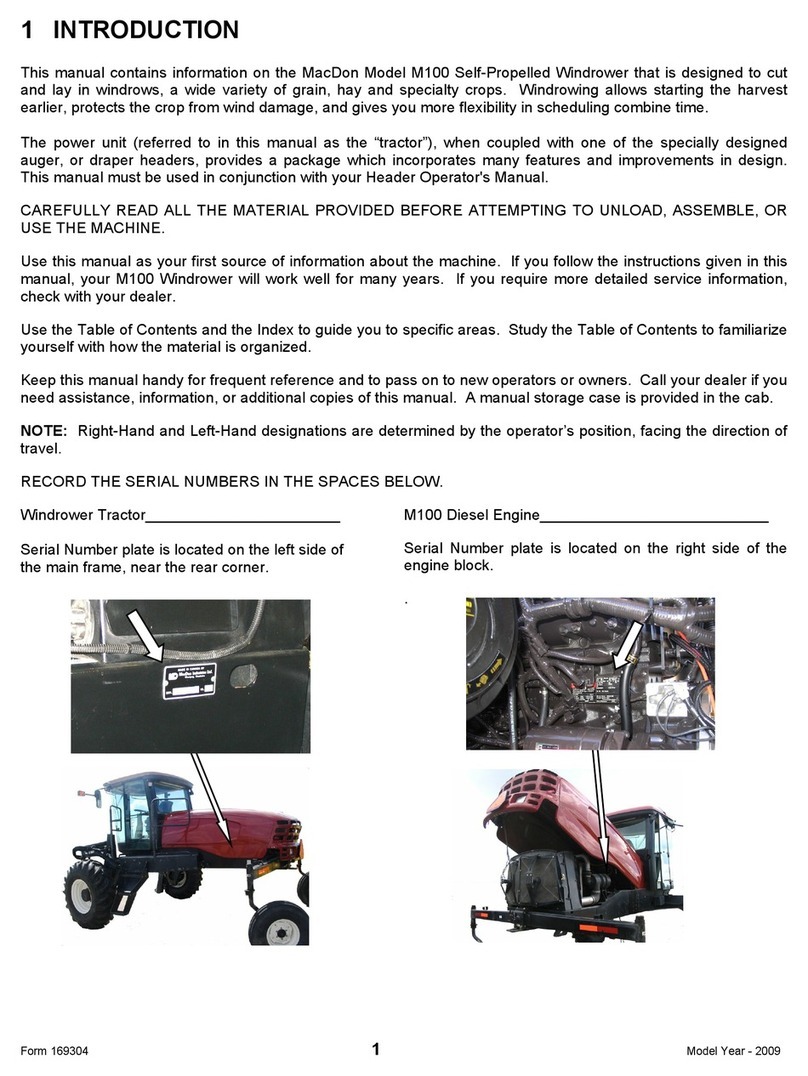

5 Unloading the Windrower.................................................................................................................... 21

5.1 Using Two Forklifts to Unload Windrower ........................................................................................ 21

5.2 Using One Forklift to Unload Windrower.......................................................................................... 23

5.2.1 Method 1 ............................................................................................................................... 23

5.2.2 Method 2 ............................................................................................................................... 24

6 Assembling the Windrower................................................................................................................. 25

6.1 Repositioning Right-Hand Leg........................................................................................................ 25

6.2 Installing Drive Wheel .................................................................................................................... 27

6.3 Repositioning Caster Wheels.......................................................................................................... 28

6.4 Unpacking Ignition Keys................................................................................................................. 30

6.5 Installing Steps.............................................................................................................................. 31

6.6 Connecting Batteries...................................................................................................................... 32

6.7 Starting Engine.............................................................................................................................. 33

6.8 Installing AM/FM Radio.................................................................................................................. 36

6.9 Installing Slow Moving Vehicle (SMV) Sign...................................................................................... 40

6.10 Attaching Header Boots ................................................................................................................. 41

6.11 Attaching Headers......................................................................................................................... 42

6.11.1 Attaching a D-Series Header................................................................................................... 42

Attaching a D-Series Header: Hydraulic Center-Link with Optional Self-Alignment .............. 43

Attaching a D-Series Header: Hydraulic Center-Link without Self-Alignment....................... 49

Attaching a D-Series Header: Mechanical Center-Link...................................................... 54

6.11.2 Attaching an A-Series Header.................................................................................................60

Attaching an A-Series Header: Hydraulic Center-Link and Optional Self-Alignment

Kit .............................................................................................................................. 61

Attaching an A-Series Header: Hydraulic Center-Link without Self-Alignment Kit ................ 66

Attaching an A-Series Header: Mechanical Center-Link .................................................... 72

6.11.3 Attaching an R-Series Header.................................................................................................78

Attaching an R-Series Header: Hydraulic Center-Link with Optional Self-Alignment ............ 79

Attaching an R-Series Header: Hydraulic Center-Link without Self-Alignment..................... 84

Attaching an R-Series Header: Mechanical Center-Link.................................................... 90

6.12 Lubricating the Windrower.............................................................................................................. 96

6.12.1 Lubrication Procedure ............................................................................................................ 96

6.12.2 Lubrication Points................................................................................................................... 97

6.13 Cab Display Module (CDM) Programming....................................................................................... 98

6.13.1 M205 Detailed Programming Menu Flow Chart .......................................................................100

169885 iii Revision A