TABLE OF CONTENTS

6.4 Roll Timing .................................................................................................................................... 71

6.4.1 Checking Roll Timing.............................................................................................................. 71

6.4.2 Adjusting the Roll Timing ........................................................................................................ 72

6.5 Forming Shields ............................................................................................................................ 73

6.5.1 Adjusting the Side Deflectors .................................................................................................. 73

6.5.2 Adjusting the Rear Deflector (Fluffer Shield)............................................................................. 75

6.5.3 Adjusting the Swath Baffle ...................................................................................................... 75

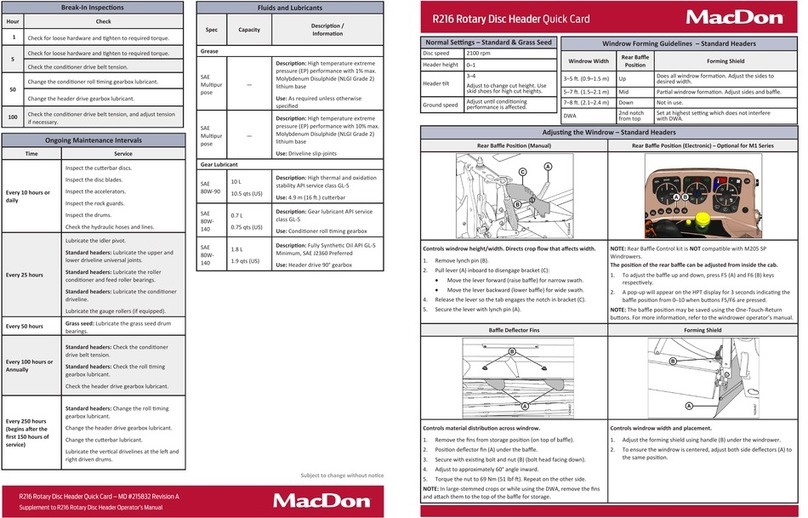

6.6 Header Angle ................................................................................................................................ 77

6.7 Cutting Height ............................................................................................................................... 78

6.7.1 Adjusting Gauge Roller Height ............................................................................................... 78

6.7.2 Adjusting the Skid Shoe Height ............................................................................................... 78

6.7.3 Disc Speed ............................................................................................................................ 79

6.8 Ground Speed............................................................................................................................... 80

6.9 Double Windrowing........................................................................................................................ 81

6.10 Tall Crop Feed Plates..................................................................................................................... 82

6.10.1 Locating Tall Crop Feed Plates for Installation .......................................................................... 82

Installing Tall Crop Feed Plates: Under Driven Deflector.................................................... 83

Installing Tall Crop Feed Plates: Under Driveline Deflector ................................................ 83

6.10.2 Removing Tall Crop Feed Plates ............................................................................................. 84

Removing Tall Crop Feed Plates: Under Driven Deflector.................................................. 84

Removing Tall Crop Feed Plates: Under Driveline Deflector .............................................. 85

6.10.3 Returning Tall Crop Feed Plates to Storage.............................................................................. 85

6.11 Tall Crop Dividers .......................................................................................................................... 87

6.11.1 Removing Tall Crop Divider..................................................................................................... 87

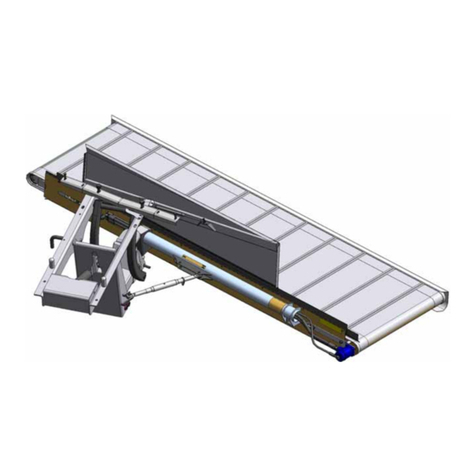

6.12 The Overshot Auger....................................................................................................................... 89

6.12.1 Adjusting the Overshot Auger.................................................................................................. 89

6.13 Stripper Bars ................................................................................................................................. 92

6.13.1 Adjusting the Stripper Bar ....................................................................................................... 92

6.14 Haying Tips ................................................................................................................................... 95

6.14.1 Curing ................................................................................................................................... 95

6.14.2 Topsoil Moisture ..................................................................................................................... 95

6.14.3 Weather and Topography........................................................................................................ 95

6.14.4 Windrow Characteristics ......................................................................................................... 95

6.14.5 Driving On Windrow ............................................................................................................... 96

6.14.6 Raking and Tedding................................................................................................................ 96

6.14.7 Using Chemical Drying Agents................................................................................................ 96

6.15 Unplugging the Header .................................................................................................................. 97

7 Maintenance and Servicing ................................................................................................................. 99

7.1 Preparation for Servicing................................................................................................................ 99

7.2 Torque Specifications....................................................................................................................100

7.2.1 SAE Bolt Torque Specifications ..............................................................................................100

7.2.2 Metric Bolt Specifications.......................................................................................................102

7.2.3 Metric Bolt Specifications Bolting into Cast Aluminum..............................................................105

7.2.4 Flare-Type Hydraulic Fittings..................................................................................................105

7.2.5 O-Ring Boss (ORB) Hydraulic Fittings (Adjustable)..................................................................107

7.2.6 O-Ring Boss (ORB) Hydraulic Fittings (Non-Adjustable) ..........................................................109

7.2.7 O-Ring Face Seal (ORFS) Hydraulic Fittings...........................................................................110

7.3 Conversion Chart..........................................................................................................................112

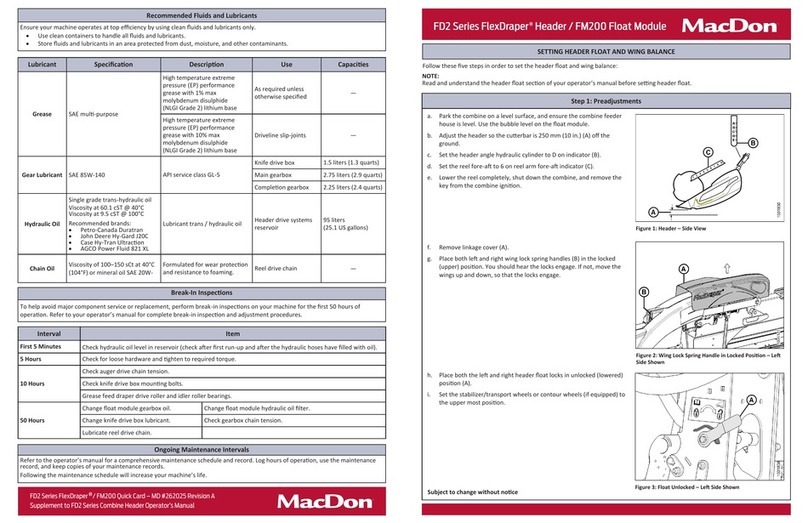

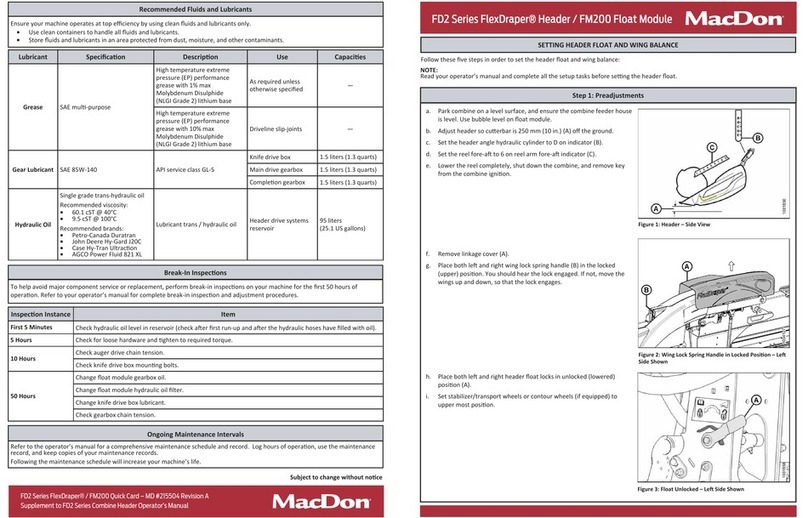

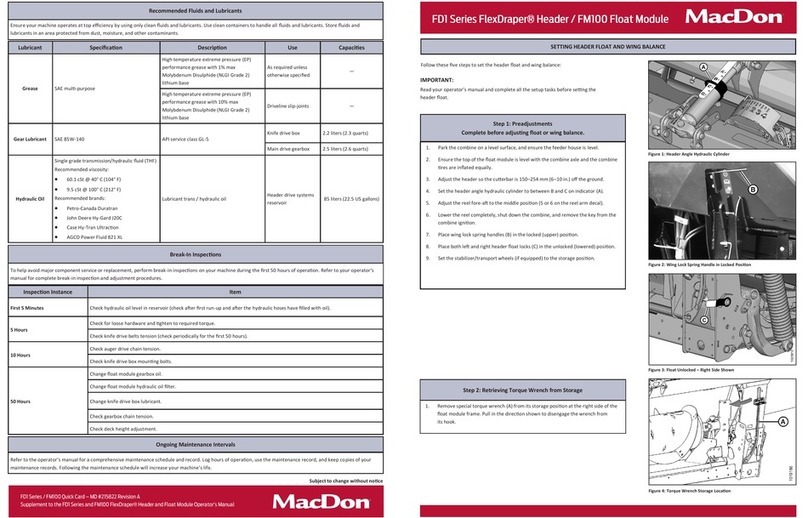

7.4 Recommended Fluids and Lubricants ............................................................................................113

7.5 Maintenance Requirements...........................................................................................................114

7.5.1 Maintenance Schedule/Record...............................................................................................115

7.5.2 Break-In Inspections..............................................................................................................117

7.5.3 Preseason/Annual Service.....................................................................................................117

7.5.4 End-of-Season Service..........................................................................................................118

169457 viRevision G