215953 vRevision A

Introduction ................................................................................................................................................i

Summary of Changes................................................................................................................................... iii

Serial Number............................................................................................................................................ iv

Chapter 1: Safety ........................................................................................................................................ 1

1.1 Safety Alert Symbols ...............................................................................................................................1

1.2 Signal Words .........................................................................................................................................2

1.3 General Safety .......................................................................................................................................3

1.4 Maintenance Safety ................................................................................................................................5

1.5 Hydraulic Safety .....................................................................................................................................6

1.6 Welding Precaution ................................................................................................................................7

1.7 Safety Signs ......................................................................................................................................... 12

1.7.1 Installing Safety Decals.................................................................................................................. 12

1.8 Understanding Safety Signs .................................................................................................................... 13

Chapter 2: Installation Instructions ......................................................................................................... 17

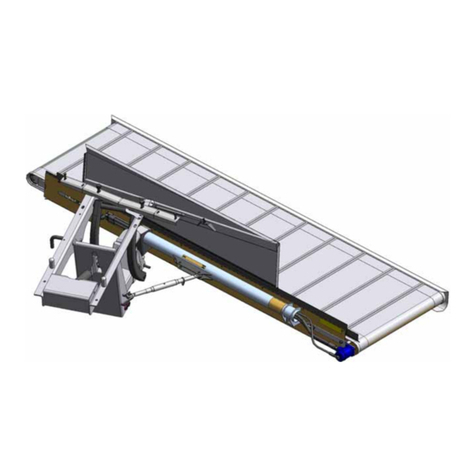

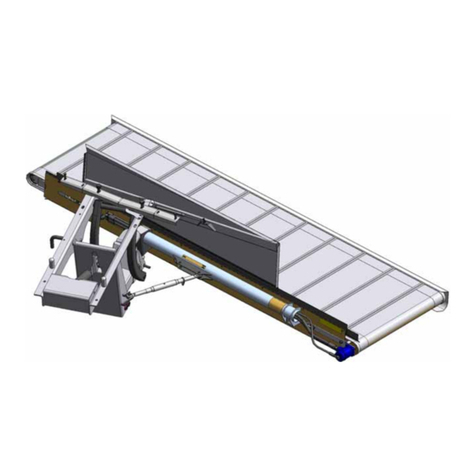

2.1 Removing Swath Compressor from Shipping Crate ..................................................................................... 17

2.2 Installing Swath Compressor................................................................................................................... 20

2.2.1 Installing Frame ........................................................................................................................... 20

2.2.2 Installing Electrical Harness............................................................................................................ 25

2.2.3 Connecting Hydraulics .................................................................................................................. 26

2.2.4 Installing Shield Assembly.............................................................................................................. 28

Chapter 3: Operation................................................................................................................................ 33

3.1 Activating the Swath Compressor ............................................................................................................ 33

3.2 Calibrating Position Sensor..................................................................................................................... 36

3.3 Using Swath Compressor ....................................................................................................................... 40

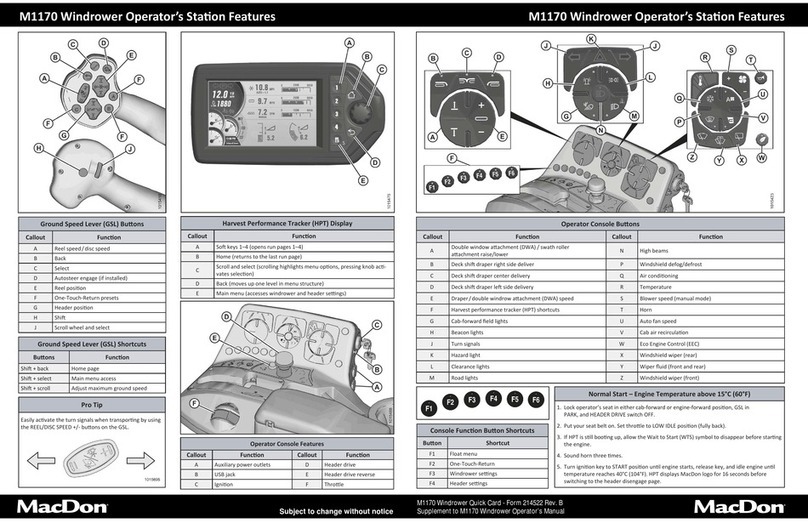

3.3.1 Swath Compressor Controls ........................................................................................................... 40

3.3.2 Setting up Swath Compressor......................................................................................................... 41

3.3.3 Programming One-Touch-Return .................................................................................................... 43

3.3.4 Adjusting Compression ................................................................................................................. 43

3.3.5 Adjusting Side Deflectors............................................................................................................... 44

3.3.6 Locking and Unlocking Swath Compressor ........................................................................................ 44

Chapter 4: Maintenance........................................................................................................................... 45

4.1 Removing Swath Compressor Shield ........................................................................................................ 45

4.2 Electrical System .................................................................................................................................. 47

4.2.1 Rotary Sensor (MD #128994) ......................................................................................................... 47

4.2.2 Swath Compressor Harness (MD #209256) ....................................................................................... 48

Harness Connections................................................................................................................... 49

4.2.3 Electrical Schematic...................................................................................................................... 50

4.3 Hydraulic Schematic.............................................................................................................................. 51

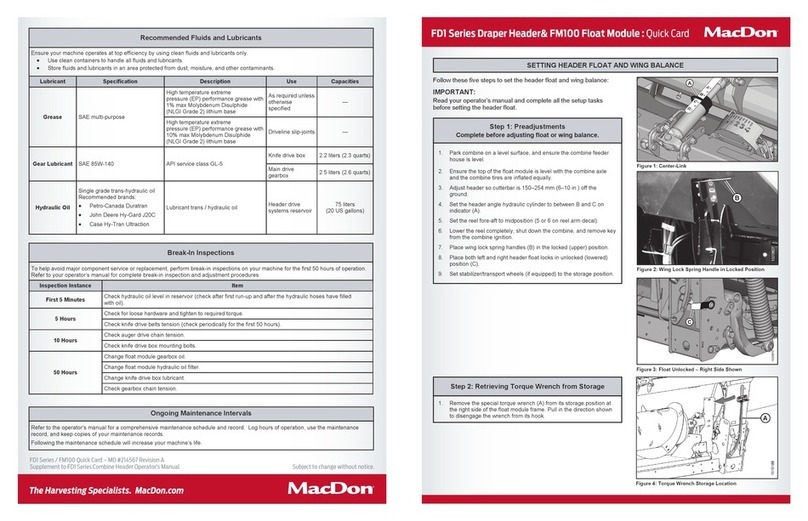

TABLE OF CONTENTS