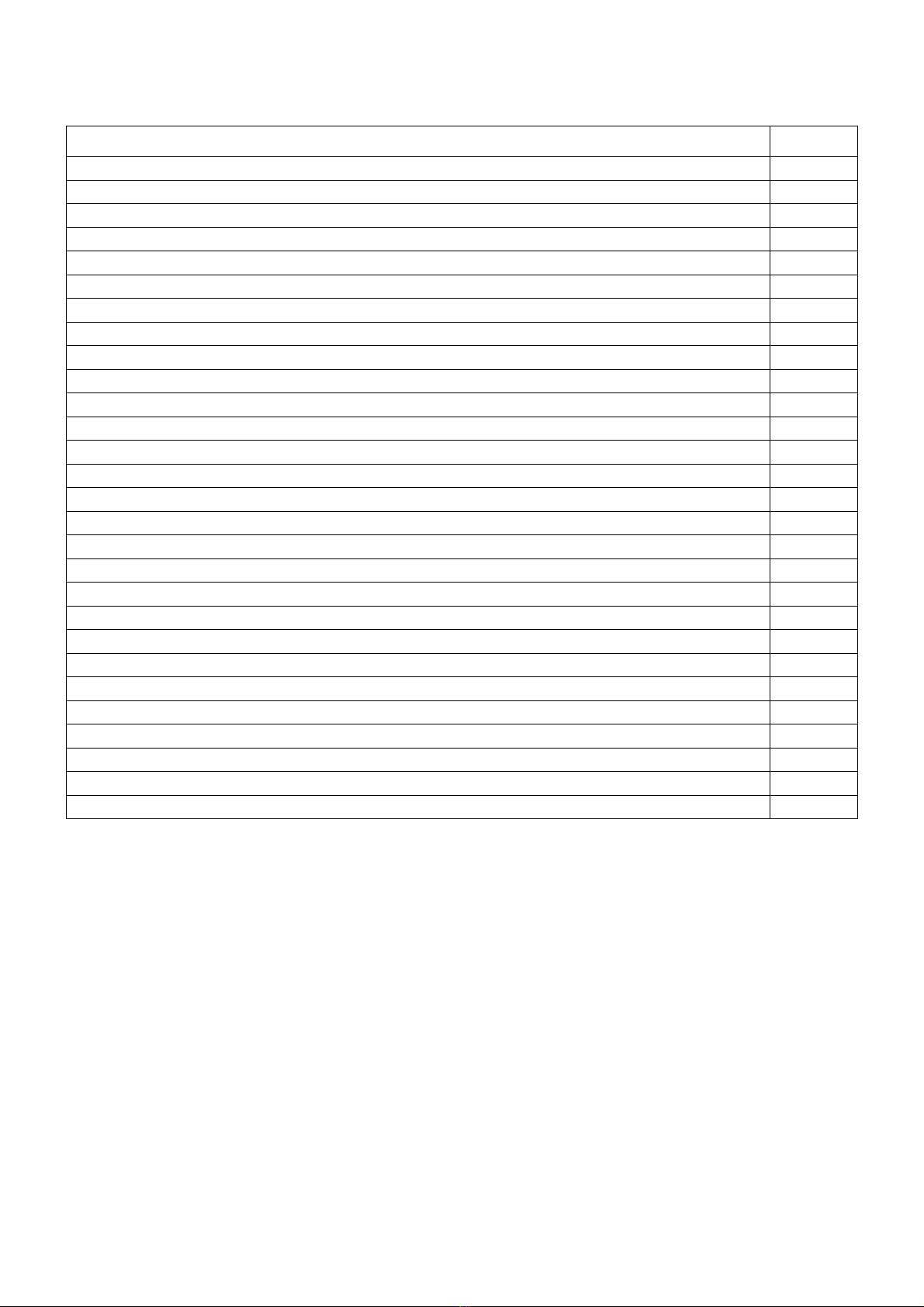

0-3

Item Page

4.13 DERRICK CYLINDER 2-47

4.13.1 DERRICK CYLINDER EXTERNAL VIEW 2-47

4.13.2 DERRICK CYLINDER CONNECTION DESTINATIONS 2-48

4.13.3 DERRICK CYLINDER SPECIFICATIONS 2-48

4.13.4 COUNTERBALANCE VALVE (IDENTIFICATION STAMP “D” FORDERRICKING CYLINDER) 2-49

4.13.5 COUNTER-BALANCE VALVE OPERATING DIAGRAM 2-50

4.14 TELESCOPIC CYLINDER ASSEMBLY 2-51

4.14.1 TELESCOPIC CYLINDER EXTERNAL VIEW 2-51

4.14.2 TELESCOPIC CYLINDER CONNECTION DESTINATIONS 2-52

4.14.3 TELESCOPIC CYLINDER SPECIFICATIONS 2-52

4.14.4 TELESCOPIC CYLINDER CROSS-SECTIONAL DRAWING 2-53

4.14.5 TELESCOPIC CYLINDER HYDRAULIC SYSTEMDIAGRAM 2-54

4.14.6 SEQUENCE VALVE 2-55

4.14.7 MECHANICAL CHECK VALVE 2-56

4.14.8

COUNTER BALANCE VALVE (IDENTIFICATION STAMP “T” FOR TELESCOPING CYLINDER)

2-57

4.15 OUTRIGGER CYLINDER ASSEMBLY 2-58

4.15.1 OUTRIGGER CYLINDER EXTERNAL VIEW 2-58

4.15.2 OUTRIGGER CYLINDER CONNECTION DESTINATIONS 2-59

4.15.3 OUTRIGGER CYLINDER SPECIFICATIONS 2-59

4.15.4 DOUBLE PILOT CHECK VALVE 2-60

4.16 SLIDE CYLINDER ASSEMBLY 2-61

4.16.1 SLIDE CYLINDER EXTERNAL VIEW 2-61

4.16.2 SLIDE CYLINDER CONNECTION DESTINATIONS 2-62

4.16.3 SLIDE CYLINDER SPECIFICATIONS 2-62

4.17 OR SELECT VALVE 2-63

4.18 OIL COOLER 2-64

4.19 RETURN MANIFOLD BLOCK 2-65

4.20 HYDRAULIC PIPING DIAGRAM 2-66

4.20.1 P LINES (PUMP - SHUTTLE MANIFOLD BLOCK LINE) 2-66

4.20.1.1

P LINES (PUMP LINES- SHUTTLE MANIFOLD BLOCK - CHECK JOINT) HYDRAULIC SYSTEM DIAGRAM

2-68

4.20.2

P LINES (SHUTTLE MANIFOLD BLOCK -TRAVELLING / OUTRIGGER CONTROL VALVE LINES)

2-69

4.20.3 T.DR LINES 2-71

4.20.4 TRAVELLING LINES 2-73

4.20.5 OUTRIGGER LINES 2-75

4.20.6 HYDRAULIC PIPING CRANE FIXED PART ASSEMBLY 2-78

4.20.7 HYDRAULIC PIPING ROTATING PART ASSEMBLY (DERRICKING LINES) 2-80

4.20.8 HYDRAULIC PIPING ROTATING PART ASSEMBLY (TELESCOPING LINES) 2-81

4.20.9 HYDRAULIC PIPING ROTATING PART ASSEMBLY (WINCH LINES) 2-82

4.20.10 HYDRAULIC PIPING ROTATING PART ASSEMBLY (WINCHDRAIN LINE) 2-83

4.20.11

HYDRAULICPIPING ROTATINGPARTASSEMBLY (WINCH BRAKERELEASE/2 SPEEDSWITCHINGLINES)

2-84

5. WORK EQUIPMENT 2-86

5.1 BOOM ASSEMBLY 2-86

5.2 HOOK BLOCK ASSEMBLY 2-88

5.2.1 HOOK BLOCK ASSEMBLY 2-88

5.2.2 INSPECTION OF HOOK BLOCK 2-89

6. ELECTRIC CIRCUIT DIAGRAMS (1/3 - 3/3) 2-91

7. ELECTRICAL EQUIPMENT CONNECTION DIAGRAM (1/2 - 2/2) 2-94