Maeda MC-174CRM User manual

Other Maeda Construction Equipment manuals

Maeda

Maeda MC-305C-2 User manual

Maeda

Maeda CC423S-1 User manual

Maeda

Maeda MC-305C-2 User manual

Maeda

Maeda MC815C User guide

Maeda

Maeda CC1908S-1 User manual

Maeda

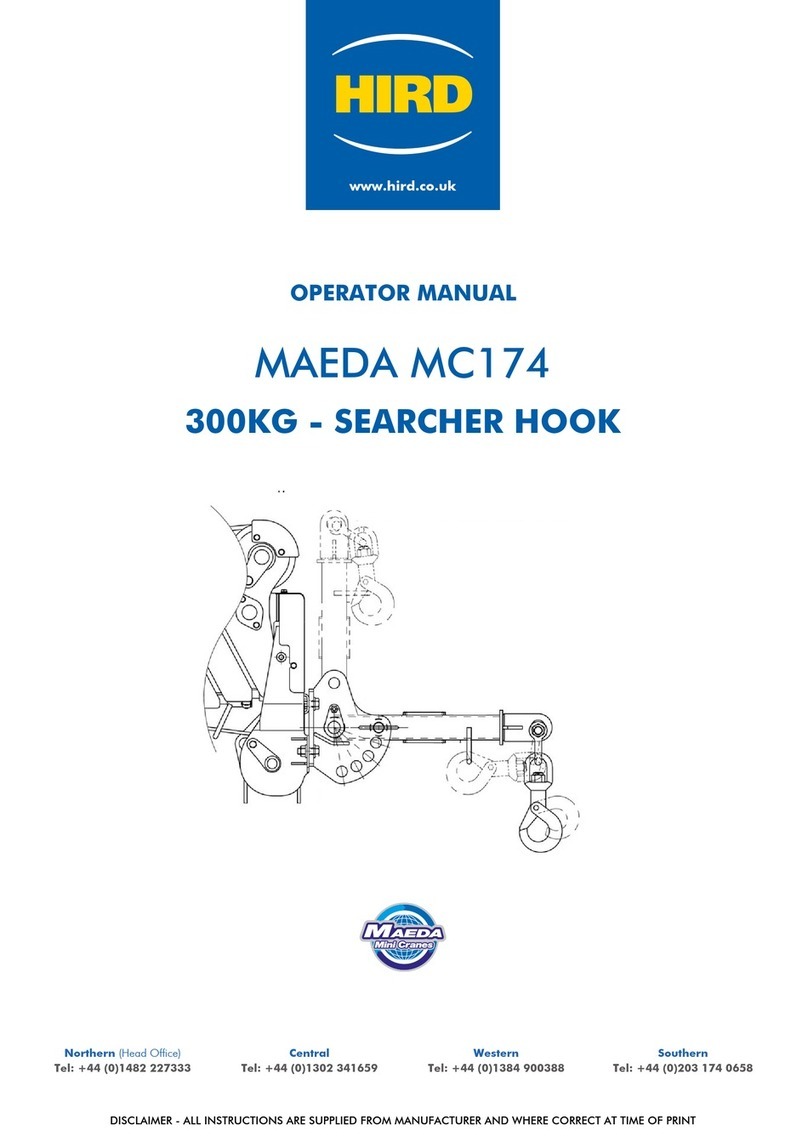

Maeda MC174 User manual

Maeda

Maeda CC1485S-1 Installation manual

Maeda

Maeda MC-104C-2 User manual

Maeda

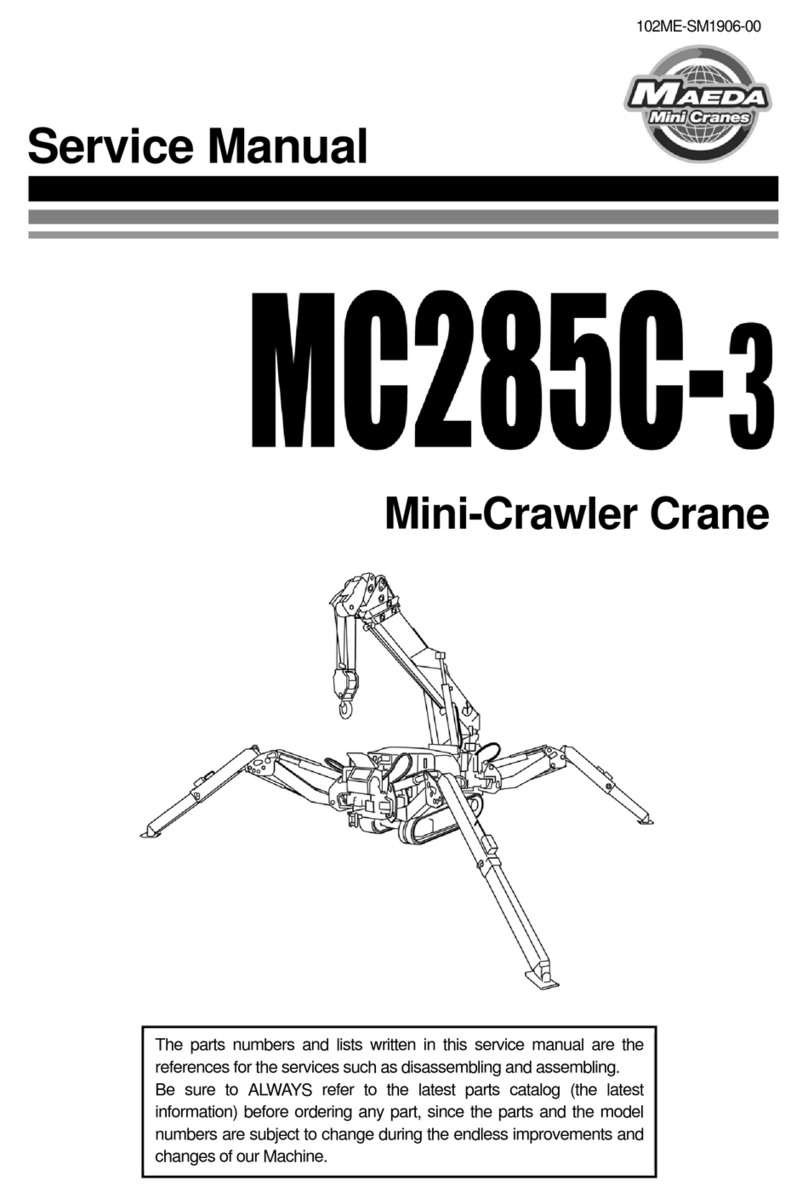

Maeda MC285C-3 User manual

Maeda

Maeda MC815C User manual

Maeda

Maeda MC-285C User guide

Maeda

Maeda LC785M-8B User manual

Maeda

Maeda LC785M-6B User manual

Maeda

Maeda MK1033C-1 User manual

Maeda

Maeda MC285C-2 User manual

Maeda

Maeda MC405C-3 User manual

Maeda

Maeda MC285C-3 User manual

Maeda

Maeda MC-174CRM User guide

Maeda

Maeda HIRD MC815 User manual

Maeda

Maeda CC1908S-1 User manual