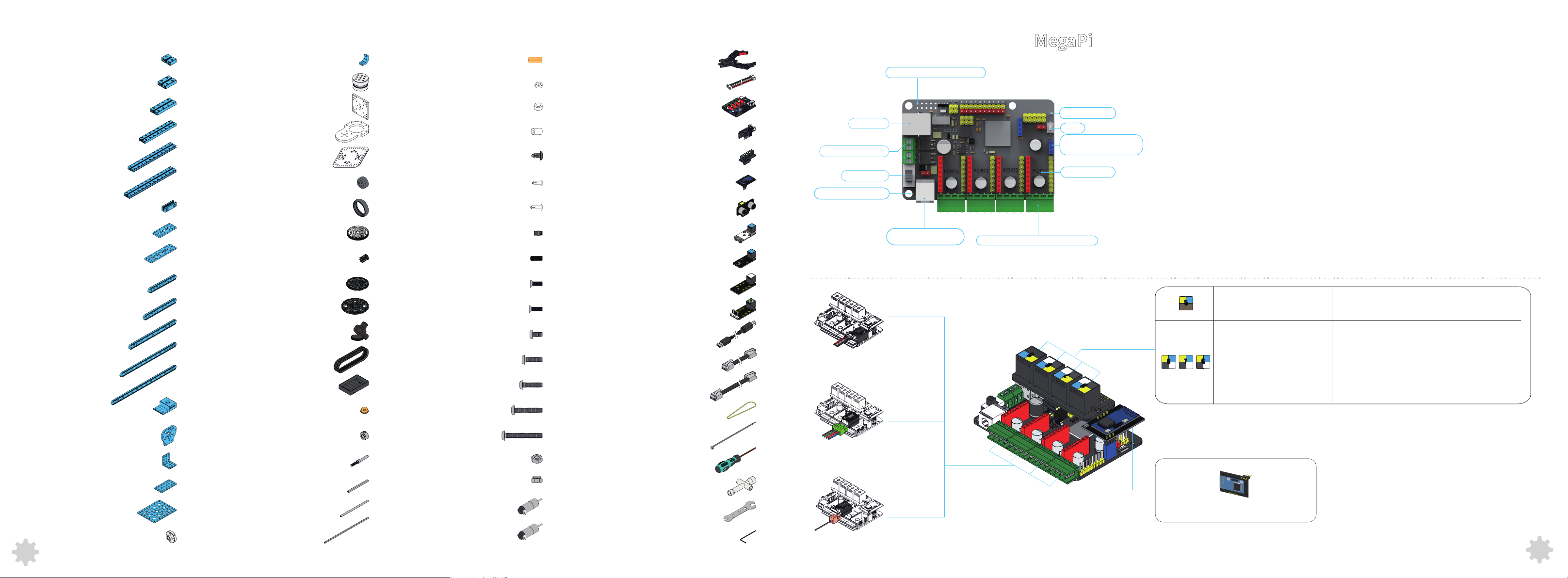

Basic Knowledge -- MegaPi

The various colors on MegaPi represents

specialized functions:

1. Red Pin--power output/motor output

2. Yellow Pin--I/O pin

3. Blue Pin--wireless communication interface

4. Black Pin--power GND

5. Green Interface--

power output/motor output

Technical Specifications

● Microcontroller: ATMEGA2560-16AU

● Input Voltage: DC 6V-12V

● Operating Voltage: DC 5V

● I/O Pins: 43

● Serial Ports: 3

● I

2

C Interface: 1

● SPI Interface: 1

● Analog Input Pins: 15

Bluetooth Communication Module

Hardware serial port Me Bluetooth

Me Bluetooth Module (Dual Mode)

Me Ultrasonic Sensor

Me RGB LED

Me Limit Switch

Me 7 Segment Serial Display

Me PIR Motion Sensor

Me Shutter

Me Line Follower

Me Infrared Receiver Decode

Me 3 Axis Accelerometer

and Gyro Sensor

Me Light and Grayscale

Sensor

Me Potentiometer

Me Joystick

Me 4 Button

Me Sound Sensor

One way digital interface

Dual digital interface

I²C port

Dual & one way analog interface

DC Motor Driver

Encoder Motor Driver

Stepper Motor Driver

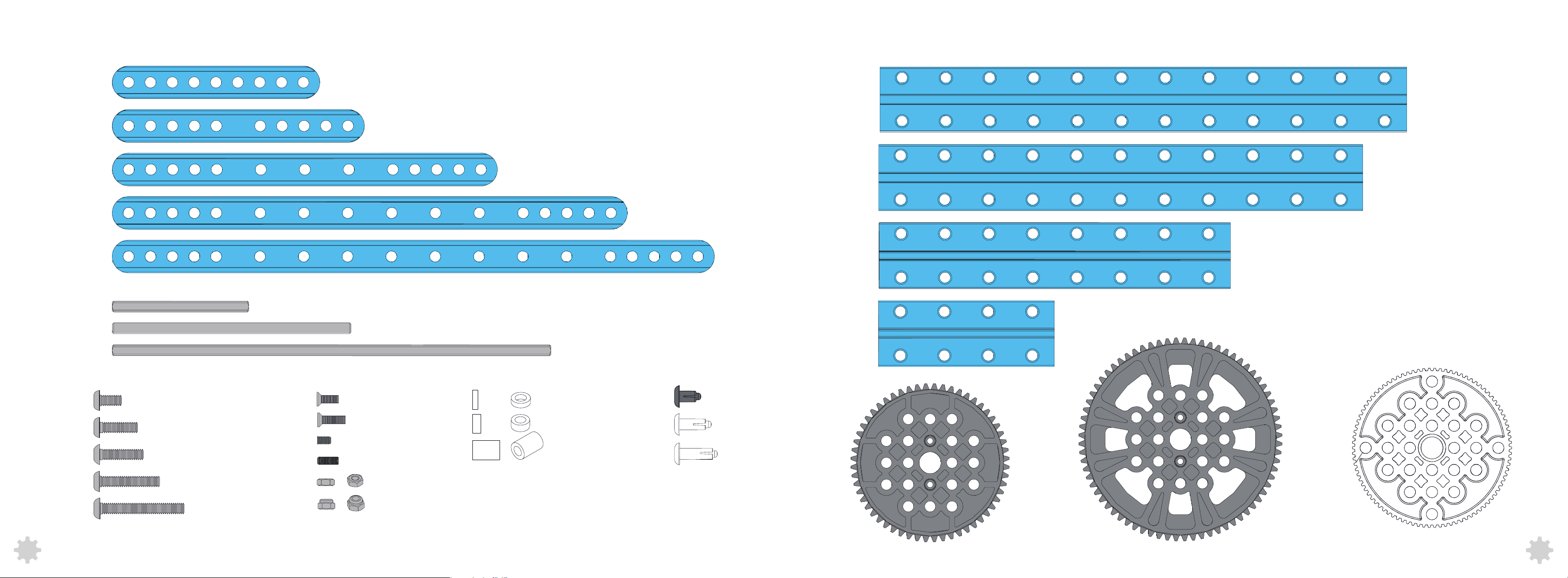

1× Plane Bearing TurntableD34x24mm

1× Quick Release Plate

4× Stiffener1616-08-M4

6× Shaft Connector 4mm

4× Beam0824-016

5× Beam0824-032

3× Beam0824-064

2× Beam0824-128

1× Slide Beam0824-176

2× Slide Beam0824-192

2× Beam0808-024

2× Beam0412-220

6× Beam0412-188

4× Beam0412-140

4× Beam0412-092

4× Beam0412-076

3× Plate0324-088

2× Plate0324-056

2× Bracket P3

1× Plate 7×9-B

2× Plate 3×6

4× Bracket 3×3

3× 25mm DC Motor Bracket

2× 25mm Motor Bracket-72T

2× MegaPi Acrylic Bracket

4× Rubber Blanket

4× Tire 90T B

6× Plastic Timing Pulley 90T

3× Plastic Gear 8T

2× Plastic Gear 56T

6× Threaded Shaft 4×39mm

12× Shaft Collar 4mm

12× Flange Copper Sleeve 4×8×4mm

1× Battery Holder 6AA

2× Track 80×139mm

1× 360° Mobile Phone Bracket

2× Plastic Gear 72T

2× D shaft D4×50mm

20× Plastic Rivet 4060

20× Plastic Rivet 4100

2× Plastic Ring 4×7×10

8× Plastic Ring 4×7×3

4× Plastic Ring 4×7×2

4× Brass Stud M4×16

1× D shaft D4×160mm

2× Shaft D4×88mm

20× Plastic Rivet 4120

12×

Headless Set Screw M3×5

8× Headless Set Screw M3×8

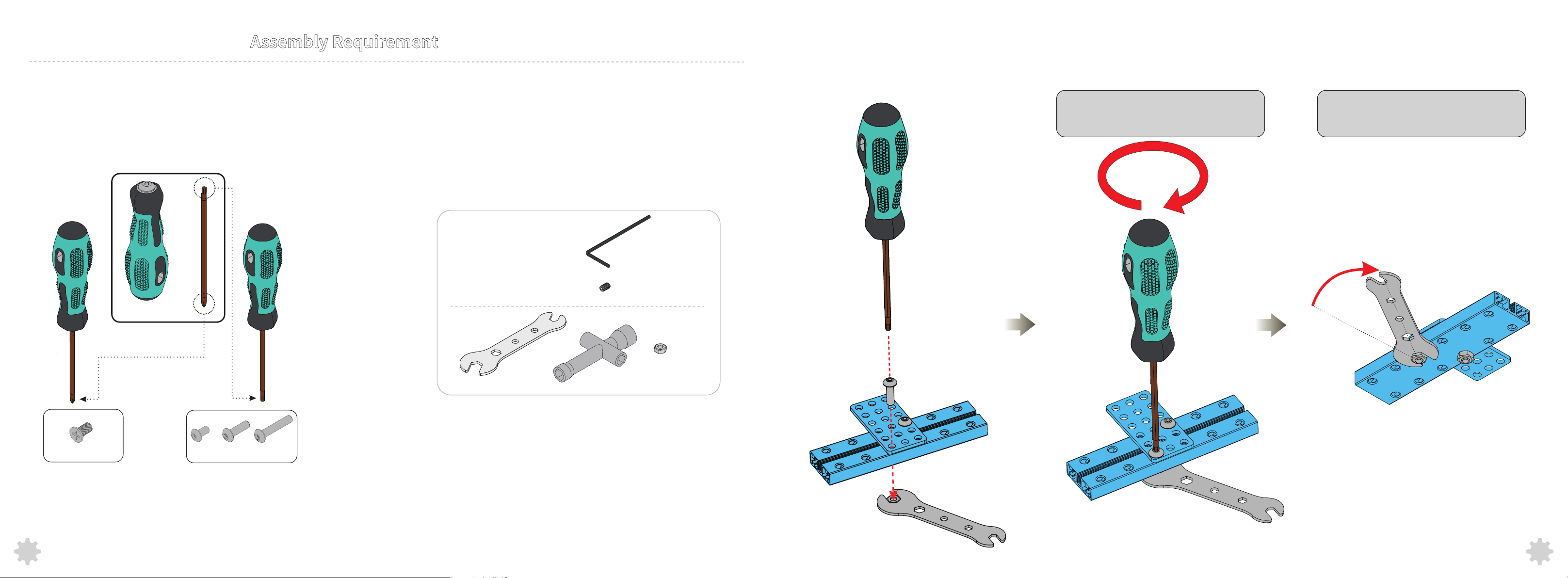

6× Countersunk Screw M3×8

4× Countersunk Screw M3×10

50× Screw M4×8

46× Screw M4×14

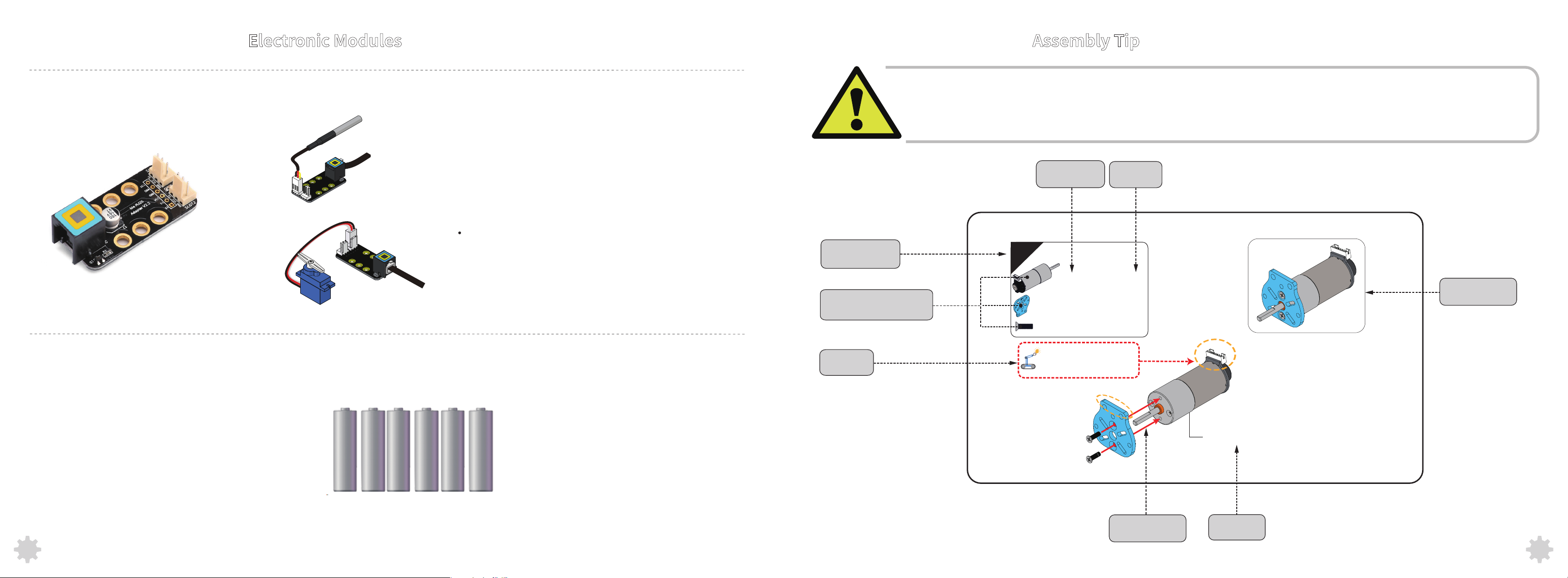

2× 25mm DC Encoder

Motor 9V/185RPM

1× 25mm DC Encoder

Motor 9V/86RPM

10× Nylon Lock Nut M4

47× Nut M4

4× Screw M4×30

4× Screw M4×22

10× Screw M4×16

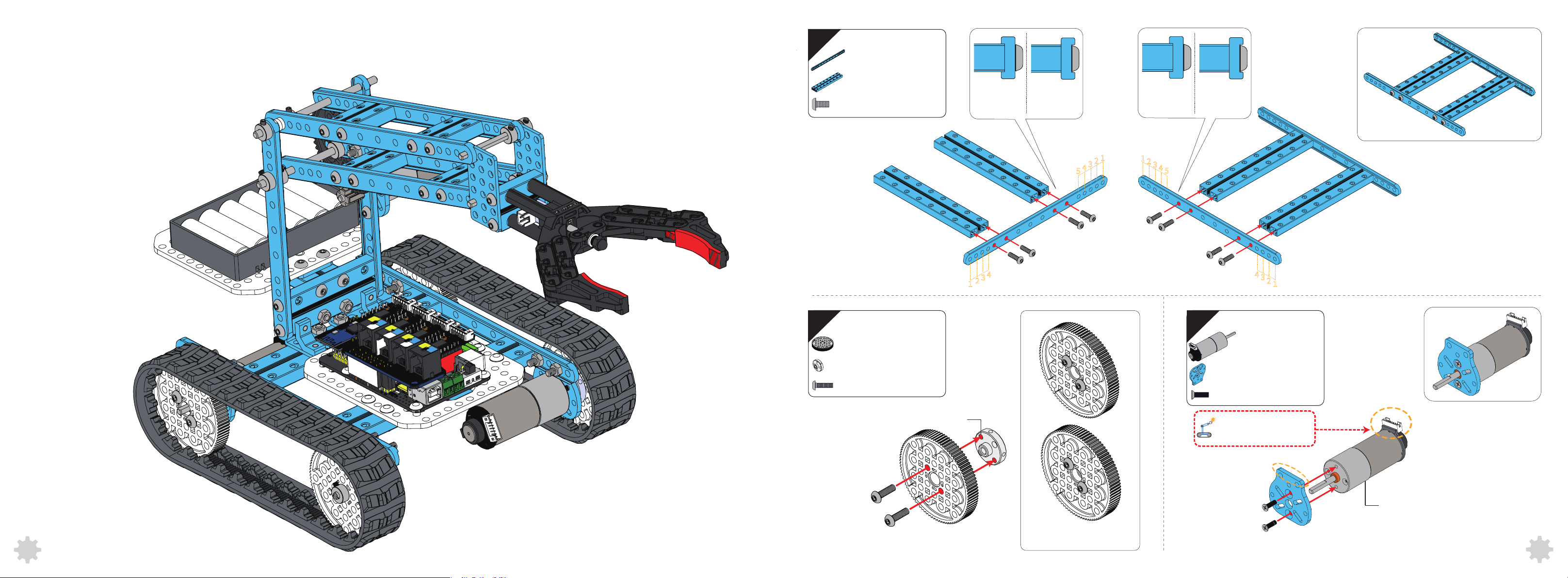

1× Makeblock Robot Gripper

1× Me Line Follower

1× Me Shutter

1× Me Ultrasonic Sensor

1× Bluetooth Module

1× Megapi Shield for RJ25

4× Megapi Encoder/DC Motor Driver

1× MegaPi

3× 25mm DC Encoder Motor Cable

1× Me 3-Axis Accelerometer

and Gyro Sensor

1× Me Adapter

1× USB Cable B-1.3m

2× 6P6C RJ25 Cable-20cm

1× 6P6C RJ25 Cable-35cm

10× Rubber Band

10× Nylon Cable Tie 1.9×100

1× Wrench 5mm&7mm

1× Small Fourway Socket Wrench

1× HEX Key 1.5mm

1× Cross&2.5mm HEX Screwdriver

45

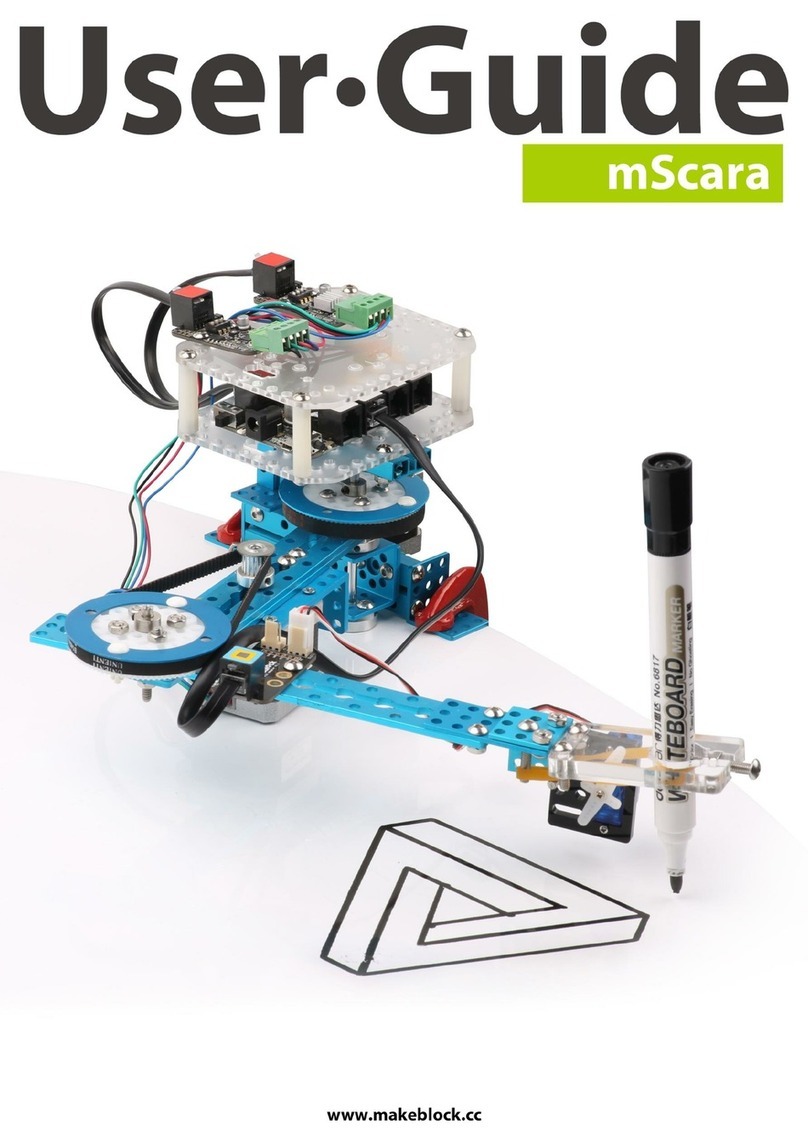

MegaPi is a main control board specially designed for makers and also an ideal option for being applied

to education field and all kinds of matches. It is based on Arduino MEGA 2560 and supports program-

ming with Arduino IDE perfectly. MegaPi can be divided into 6 function area, allowing you to connect

with various plug-in modules to drive motors and sensor and to realize wireless communication. MegaPi

has strong motor-driving ability which is capable of driving 10 servos or 8 DC motors simultaneously. It is

the ideal option for various robotic projects, such as smart robot car and 3D printer.

Power Indicator

USB-B type

Power Switch

High-Power DC

Power Supply (6-12V)

Raspberry Pi Communication

Reset

Wireless

Communication Module

Motor Driver*4

Stepper Motor/DC Motor Interface*4

High-Power Output

M4 Mounting Hole*3