Makita MT M1901 Manual

Other Makita Planer manuals

Makita

Makita KP312 User manual

Makita

Makita KP312S User manual

Makita

Makita DKP181 User manual

Makita

Makita M1902 User manual

Makita

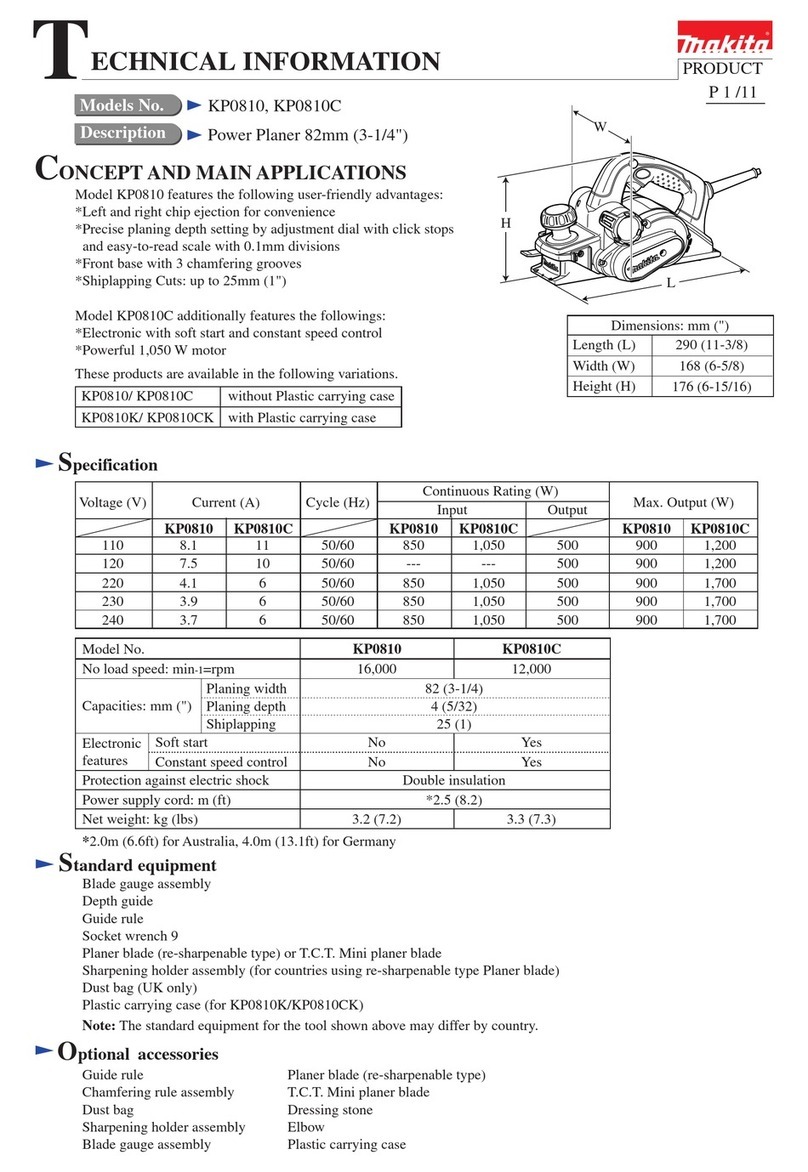

Makita KP0810 User manual

Makita

Makita 1902 User manual

Makita

Makita 1911B User manual

Makita

Makita 1050D User manual

Makita

Makita M1902 User manual

Makita

Makita 1806B User manual

Makita

Makita DKP140 User manual

Makita

Makita KP0800 User manual

Makita

Makita DKP140 User manual

Makita

Makita 1806B User manual

Makita

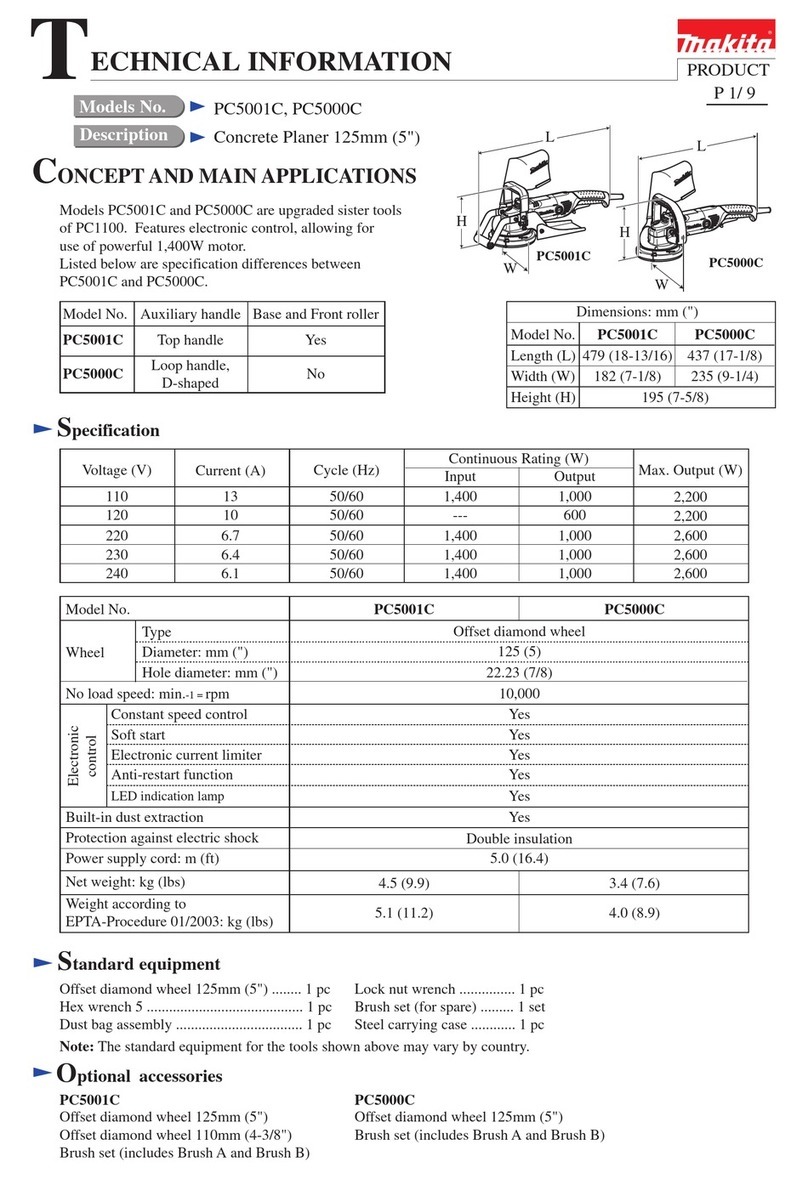

Makita PC5001C Manual

Makita

Makita 1911B User manual

Makita

Makita KP0810 Manual

Makita

Makita HG 1100 User manual

Makita

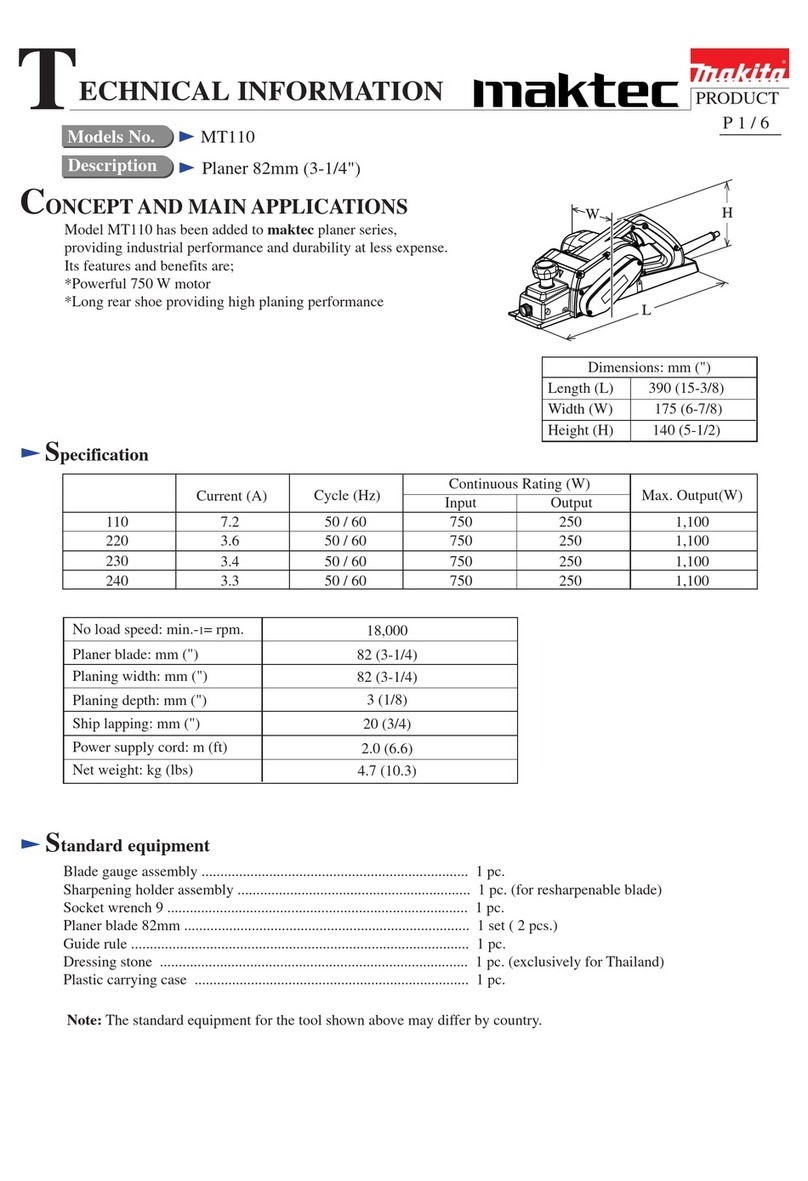

Makita Maktec MT110 Manual

Makita

Makita HG 1100 User manual

Popular Planer manuals by other brands

Felisatti

Felisatti PF180/1500 operating instructions

DeWalt

DeWalt DW 1150 Operation, adjustmants, maintenance, spare parts

Triton

Triton TRP UL Operating and safety instructions

Melbourne

Melbourne MTC-49407 owner's manual

VARO

VARO POWERplus POW1520 manual

Powermatic

Powermatic 209 Operating instructions and parts manual