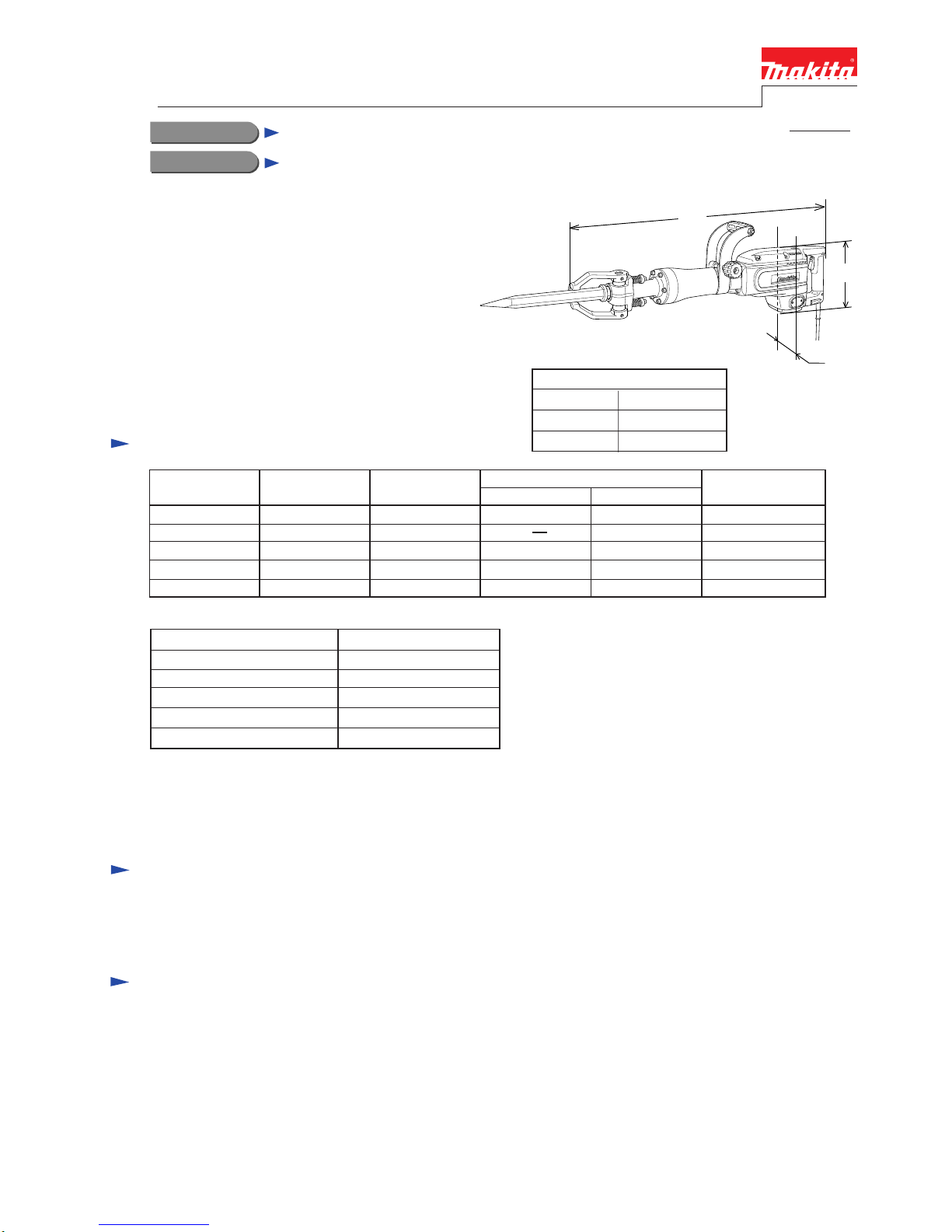

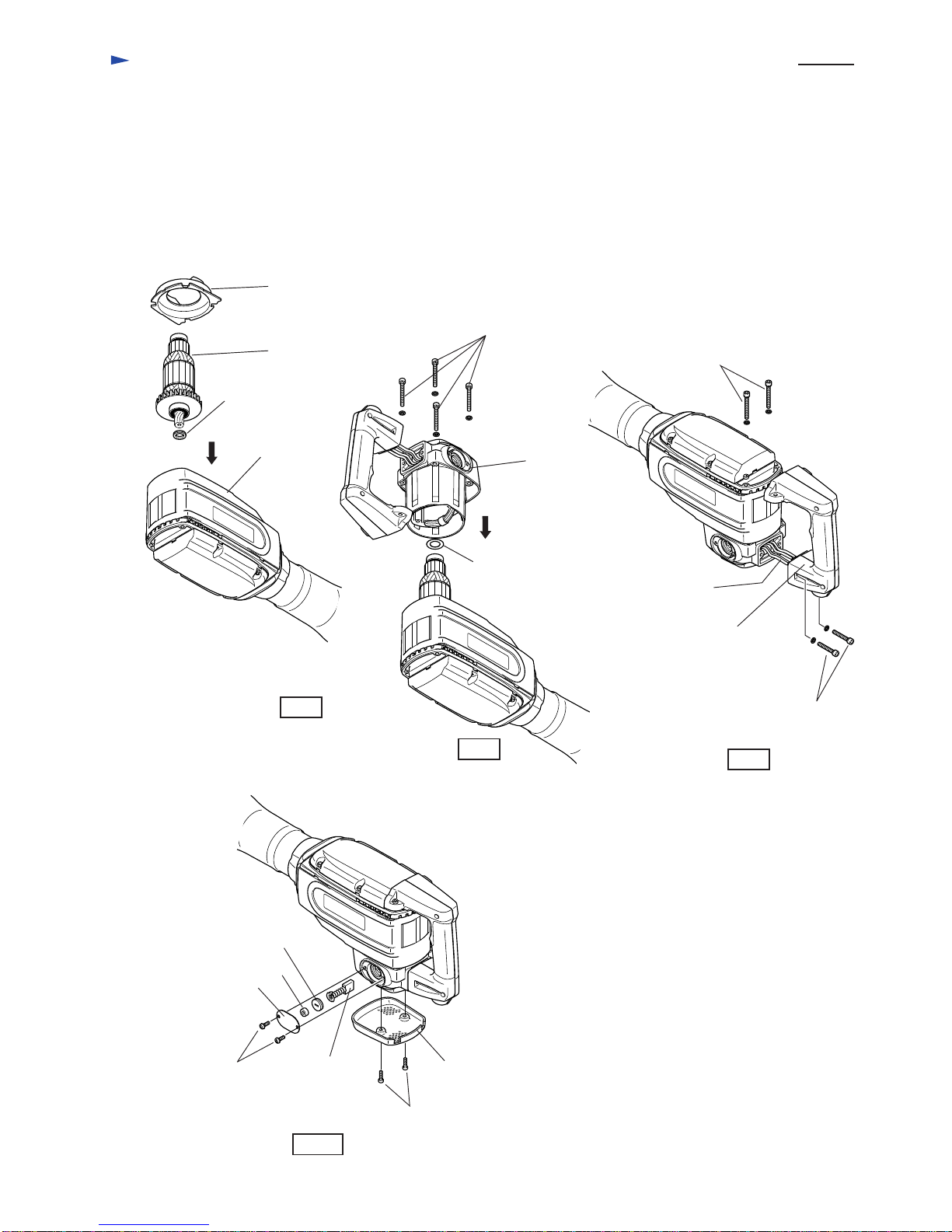

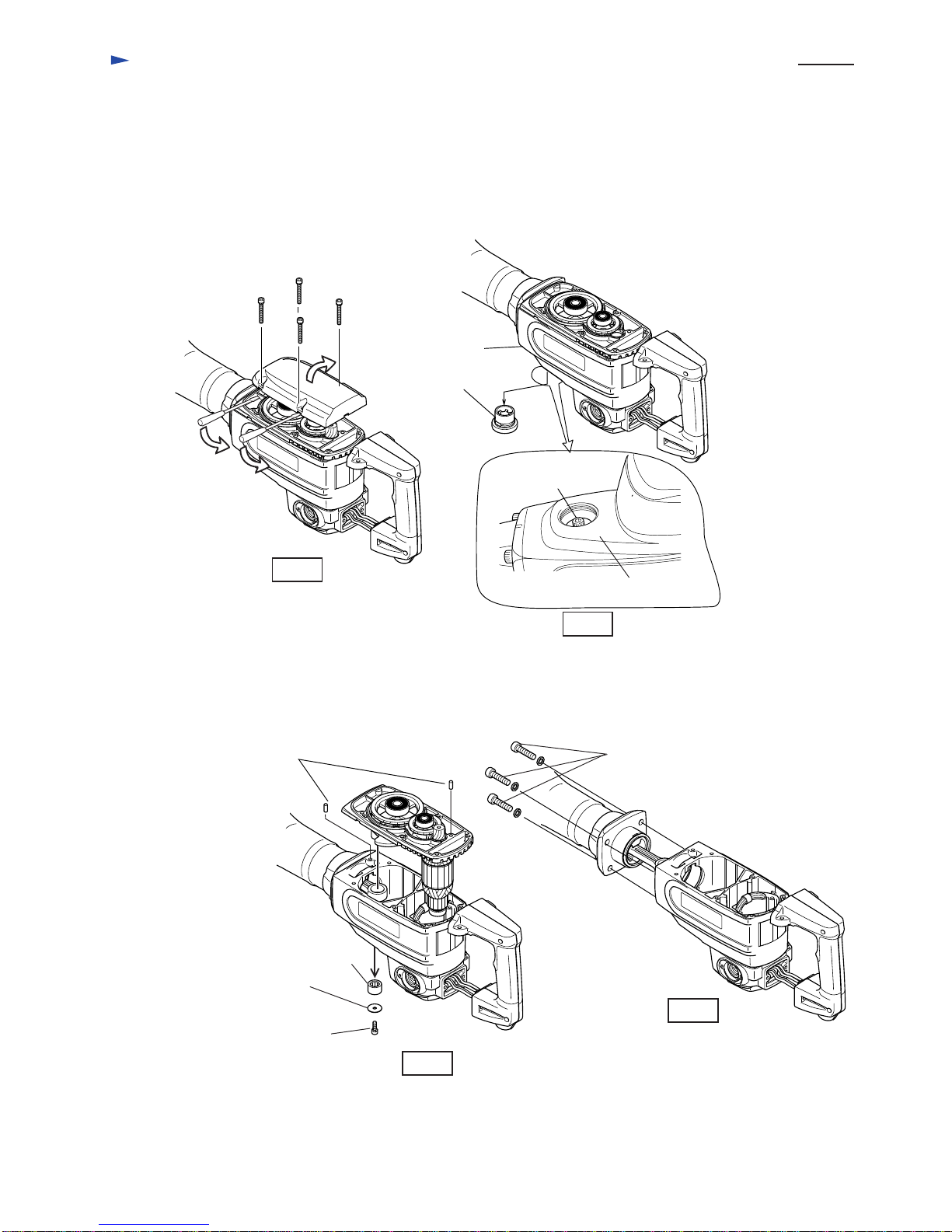

Makita HM1304 Manual

Other Makita Power Hammer manuals

Makita

Makita BHR262TRDJ User manual

Makita

Makita HM1205C User manual

Makita

Makita HM001G User manual

Makita

Makita DHR241RTJ User manual

Makita

Makita GMH02 User manual

Makita

Makita HM0860C User manual

Makita

Makita HM1111C User manual

Makita

Makita HM1200 User manual

Makita

Makita HR2621 User manual

Makita

Makita HM001G User manual

Makita

Makita HM1214C User manual

Makita

Makita HM002G User manual

Makita

Makita M8600 User manual

Makita

Makita M8600 User manual

Makita

Makita HM1213C User manual

Makita

Makita HR2455 Quick start guide

Makita

Makita HM1810 User manual

Makita

Makita HM002G User manual

Makita

Makita DHR243Z User manual

Makita

Makita HM1202 User manual

Popular Power Hammer manuals by other brands

Hitachi

Hitachi H 65SC Instruction manual and safety instructions

Hitachi

Hitachi H 65SB2 Handling instructions

socomec

socomec MDO 6000 TS Use & maintenance

Hitachi

Hitachi H 45MR Technical data and service manual

Atlas Copco

Atlas Copco PB 6S Repair instructions

Pattfield Ergo Tools

Pattfield Ergo Tools PA-1700SH Translation of the original instructions