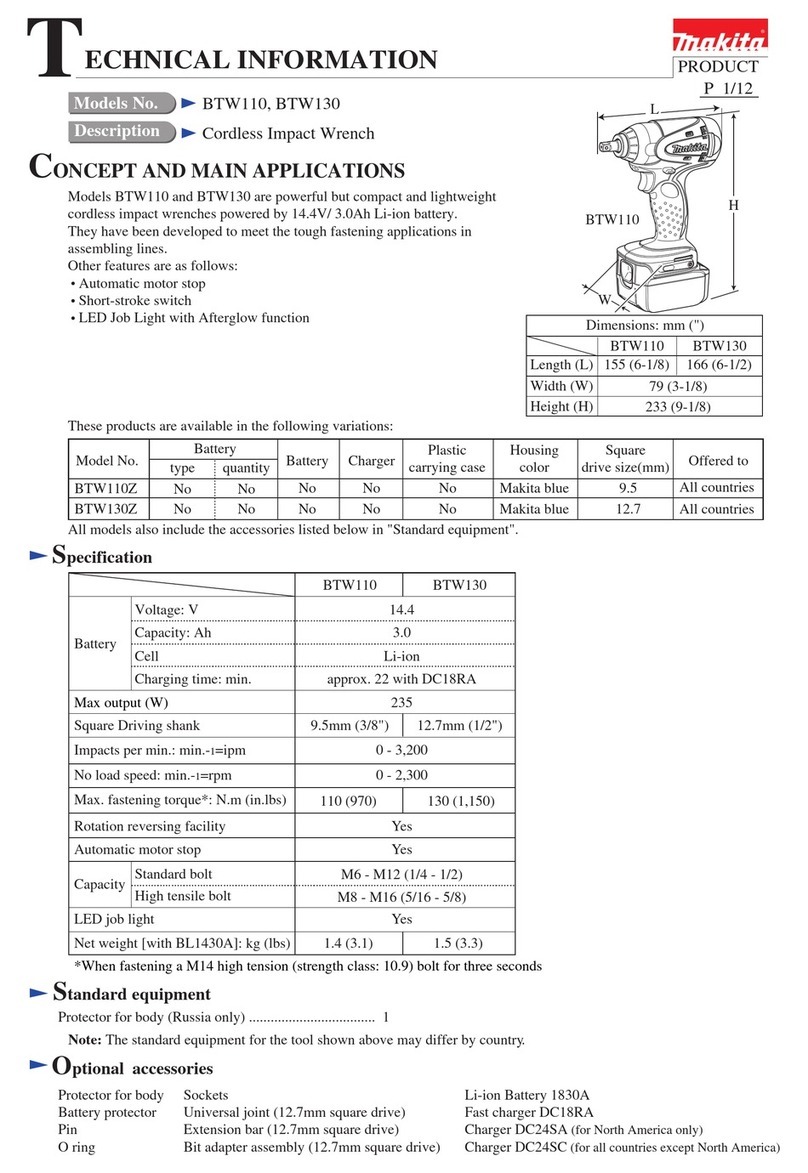

Model No.

Description

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1 /15

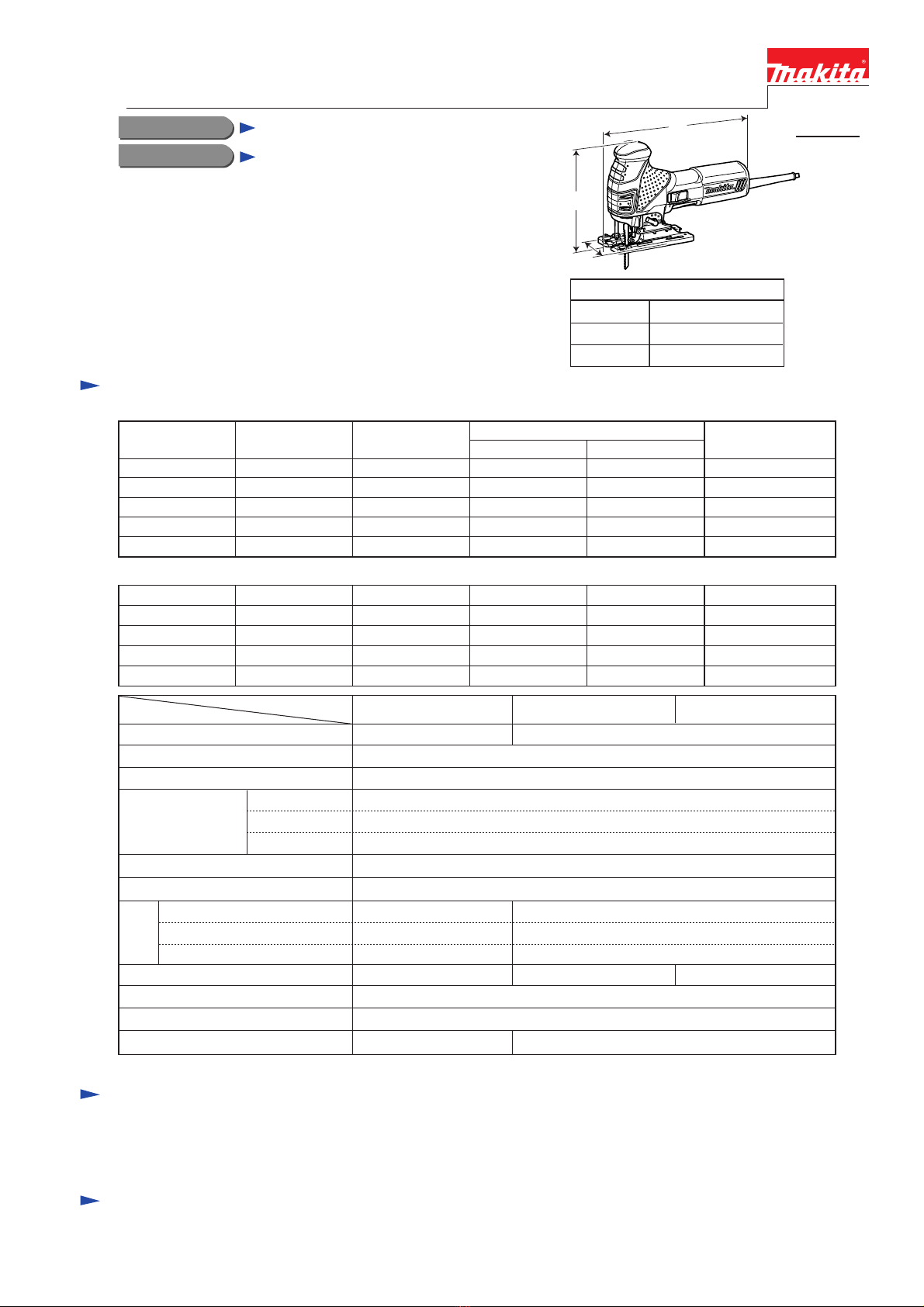

Specification

Standard equipment

Note: The standard equipment for the tool shown above may differ from country to country.

4351T, 4351CT, 4351FCT

Jig Saw

Models 4351T, 4351CT and 4351FCT have been developed

as the successor models of 4341T series models.

In addition to the advantages of the predecessor models,

feature new exterior design with ergonomic rubberized handle.

Top handle type models are also available as 4350T series models.

Optional accessories

Jig saw blades No.51, 58, 59, B-8, B-10 to B-19, B-21 to B-27, B-16L, BR-13

Guide rule, Guide rail, Guide rail adaptor, Anti-splintering device

Hose complete 28-5, Dust nozzle

Specification

Net weight: kg (lbs) 2.4 (5.3) 2.5 (5.5)

Model 4351CT 4351FCT

No load speed: strokes per min.

SteelCapacities: mm (") Wood*1

10 (3/8)

Aluminum 20 (25/32)

135 (5-5/16)

800 - 2,800

Length of stroke: mm (") 26 (1)

Shank type B-type

Protection against electric shock

Power supply cord: m (ft) 2.5 (8.2)*2

Double insulation

*1 when cutting with optional blade No.B-16L *2 Australia, New Zealand: 2.0m (6.6ft)

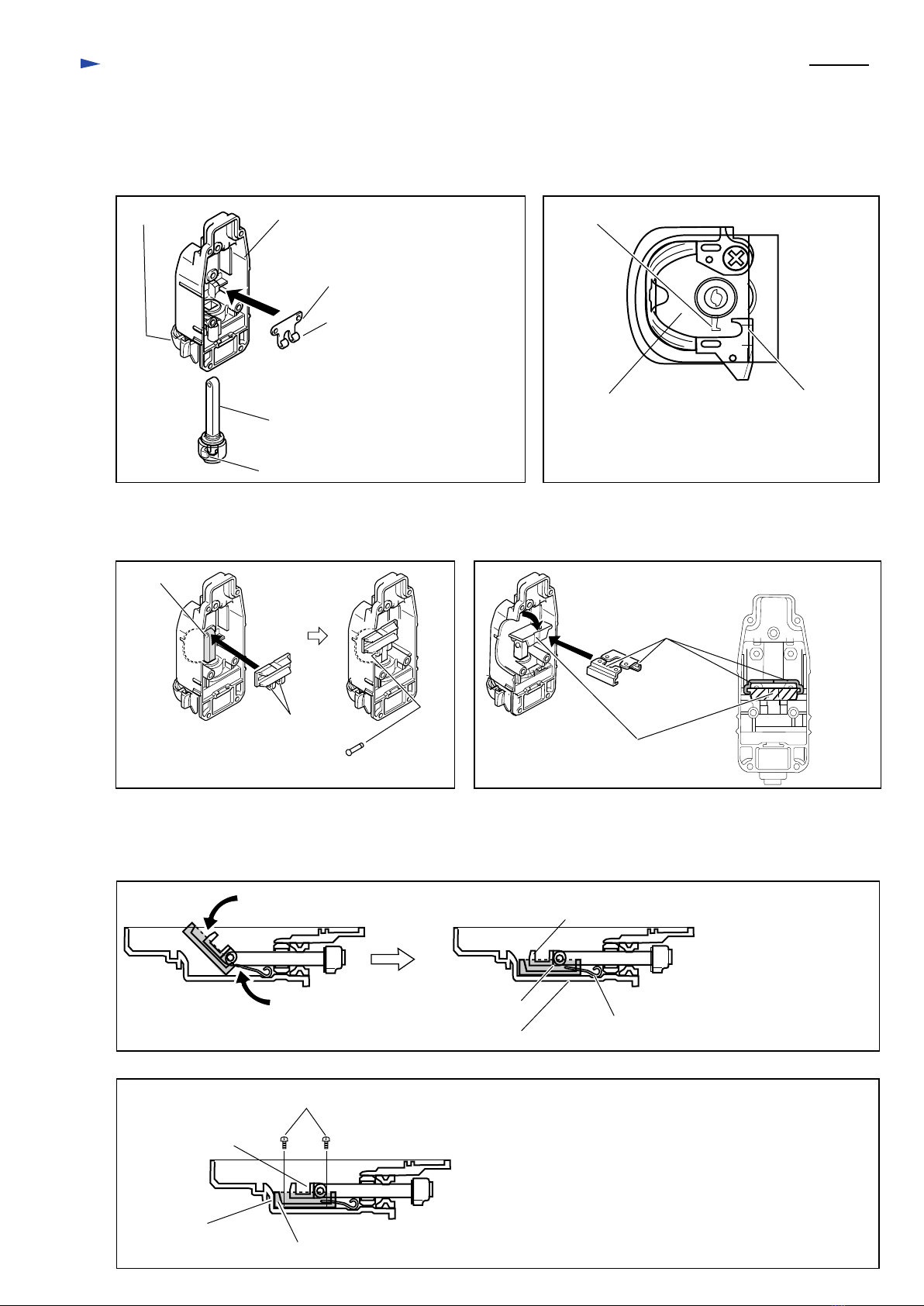

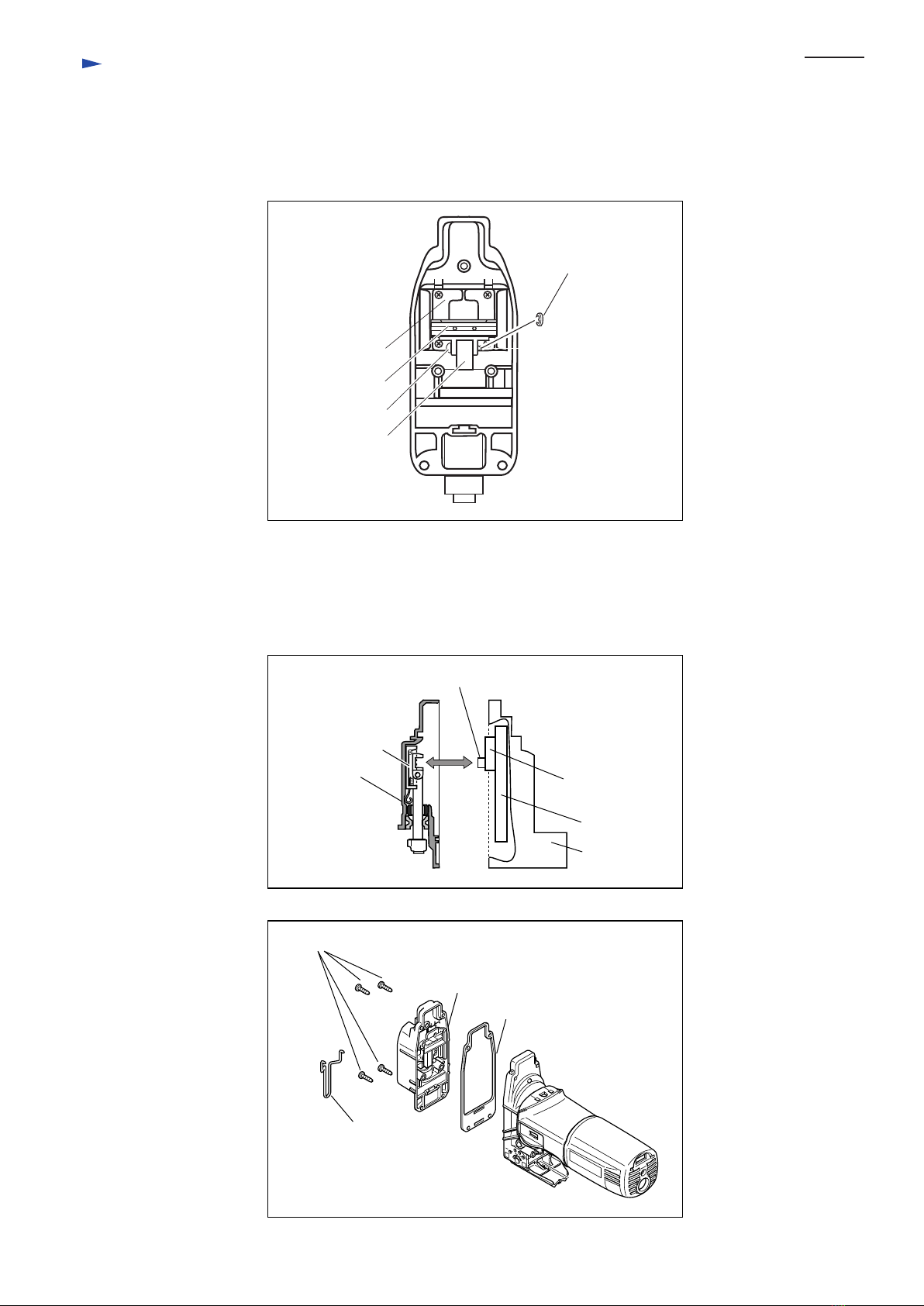

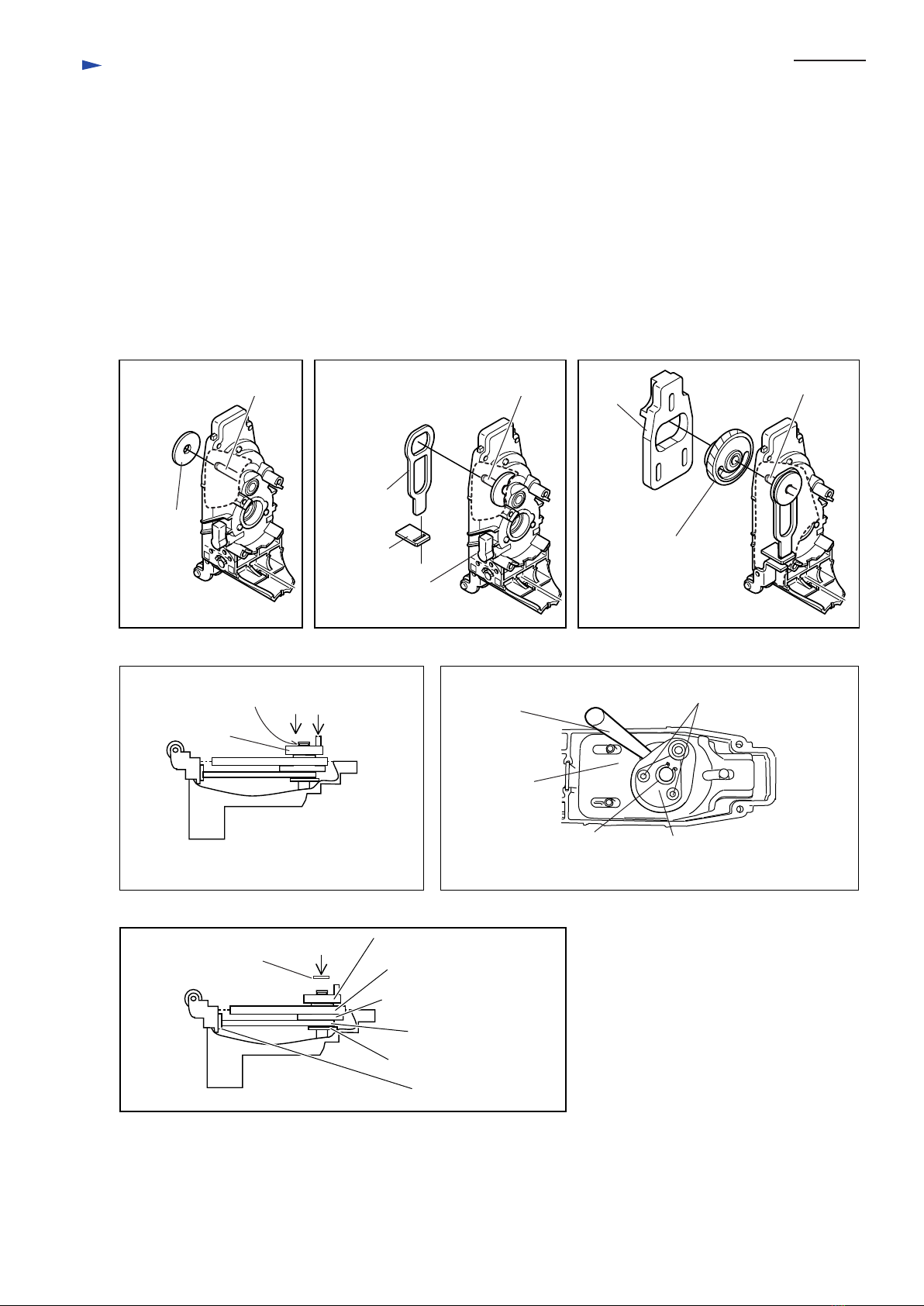

Cut settings 3 Orbital settings + Straight cutting

Yes (Push-in-lock system)

LED Job light

Variable speed control by dial

Soft start

Constant speed control

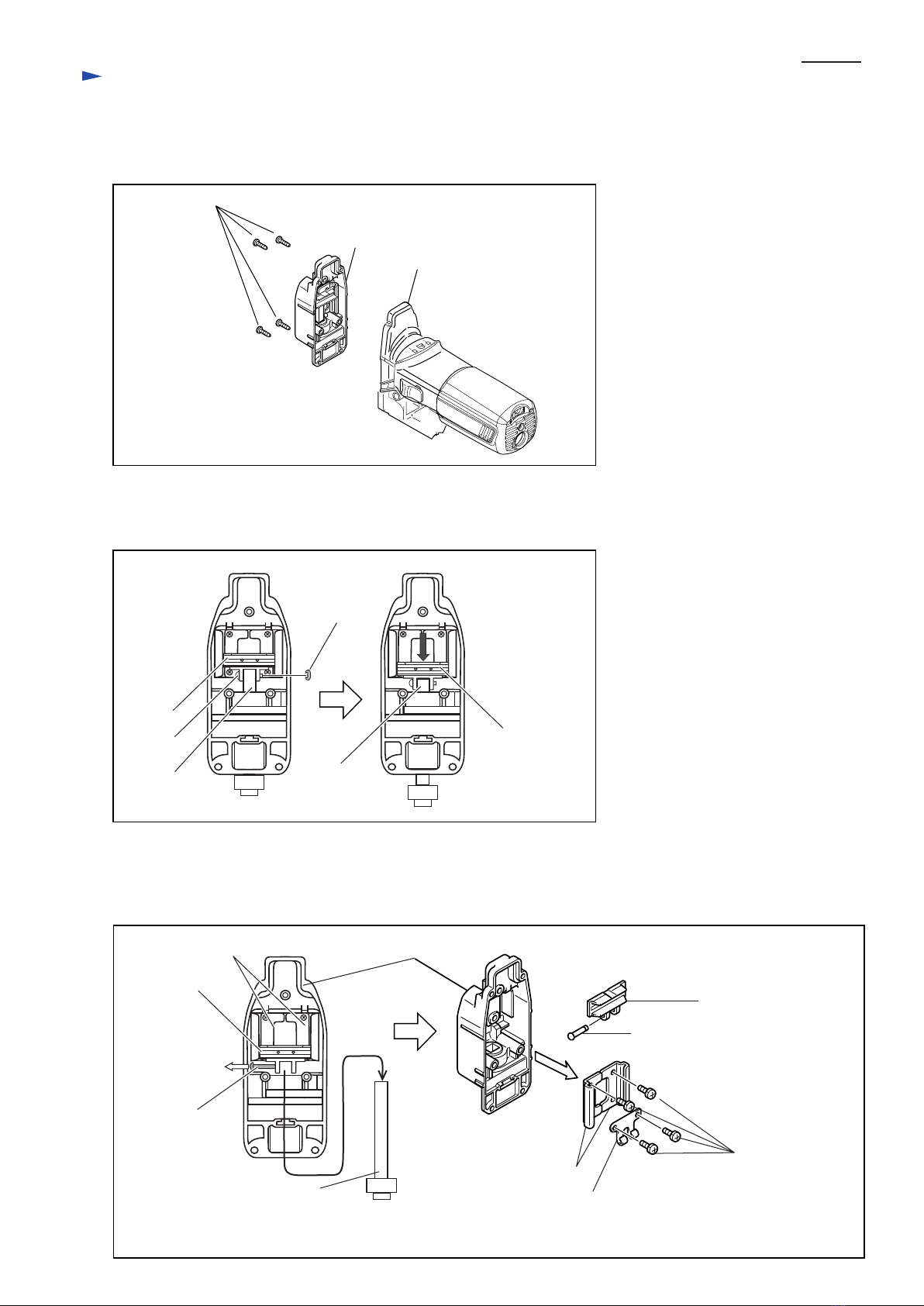

Toolless blade change

Yes

Yes

Yes

No

4351T

2,800

No

No

No

No Yes

Electronic

control

4351CT/ 4351FCT

120

110

220

230

240

6.9 720

--- 320 70050/60

3.4 720 320 70050/60

3.3 720 320 70050/60

3.2 720 320 70050/60

6.3 320 70050/60

4351T

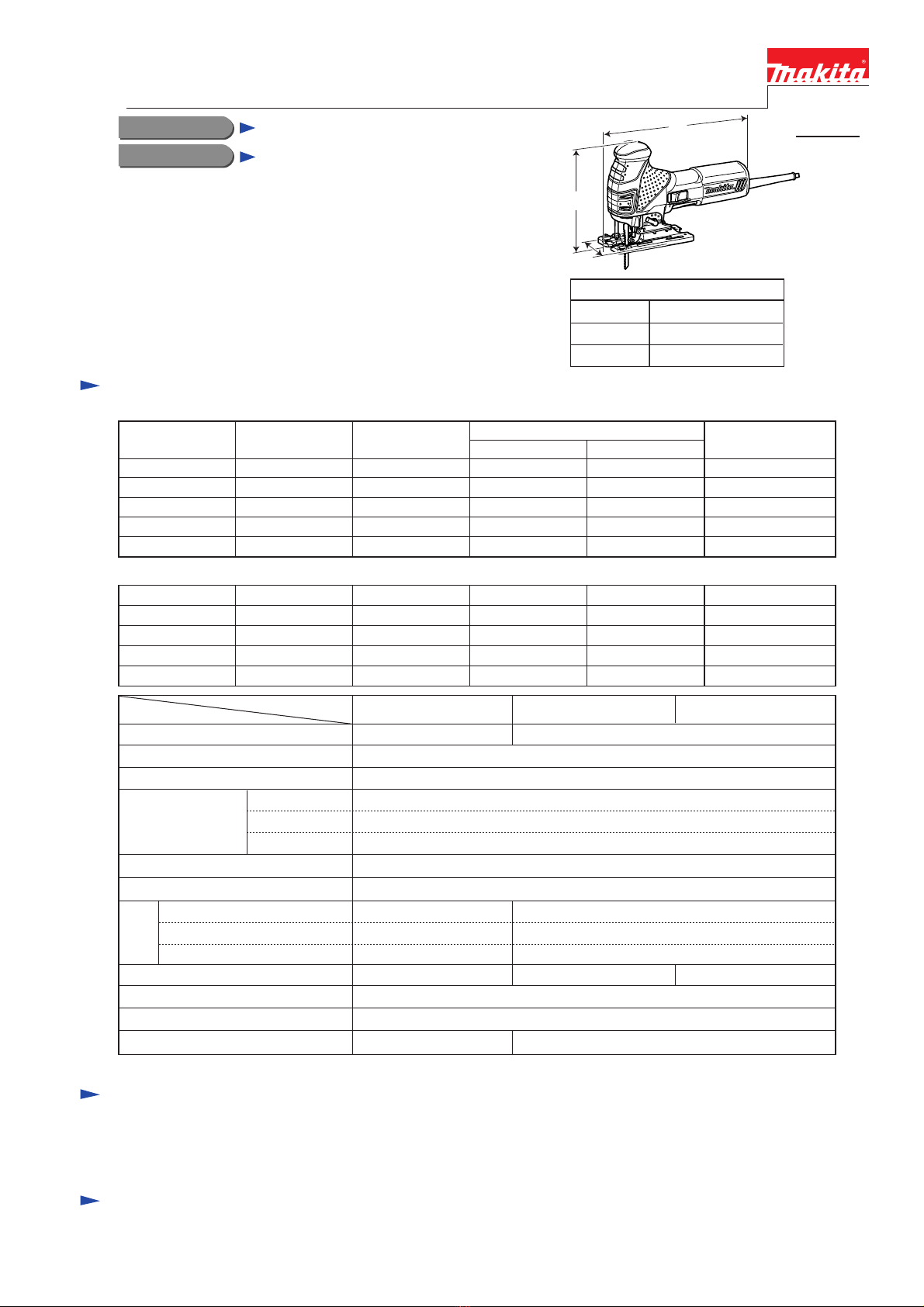

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 271 (10-11/16)

73 (2-7/8)

187 (7-3/8)

L

H

W

TECHNICAL INFORMATION

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output (W)

220

230

240

Current (A)

2.8 580 300 55050/60

2.7 580 300 55050/60

110

120 5.6 580 300 55050/60

5.1 --- 300 55050/60

2.5 580 300 55050/60

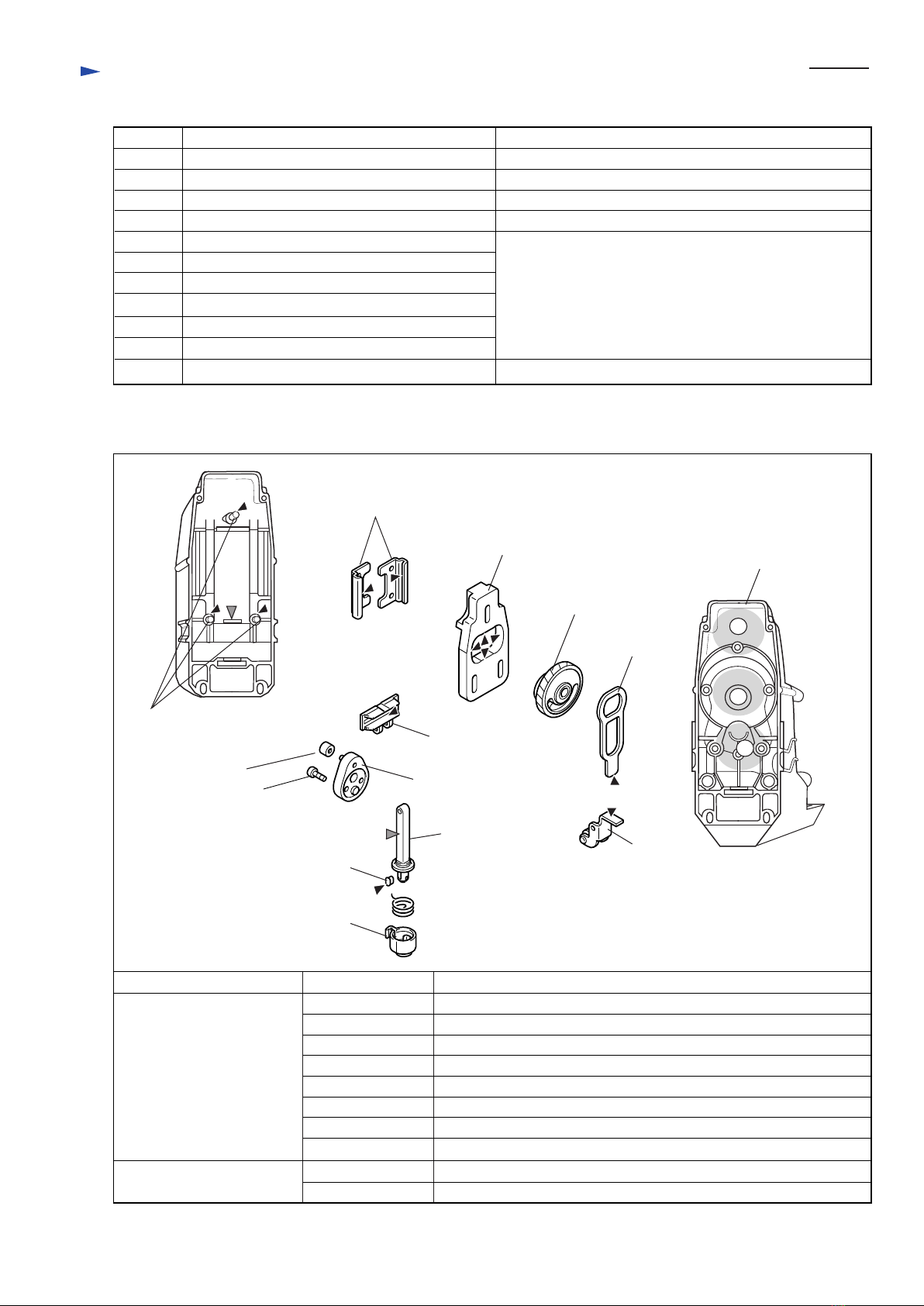

Jig saw blade B-10 ........ 2

Jig saw blade BR-13 ...... 2

Jig saw blade B-22 ........ 2

Cover plate ....................... 1

Anti-splintering device ..... 1

Hex wrench 4 ................... 1

Plastic carrying case ...... 1

Dust nozzle*3................ 1

*3 for European countries only