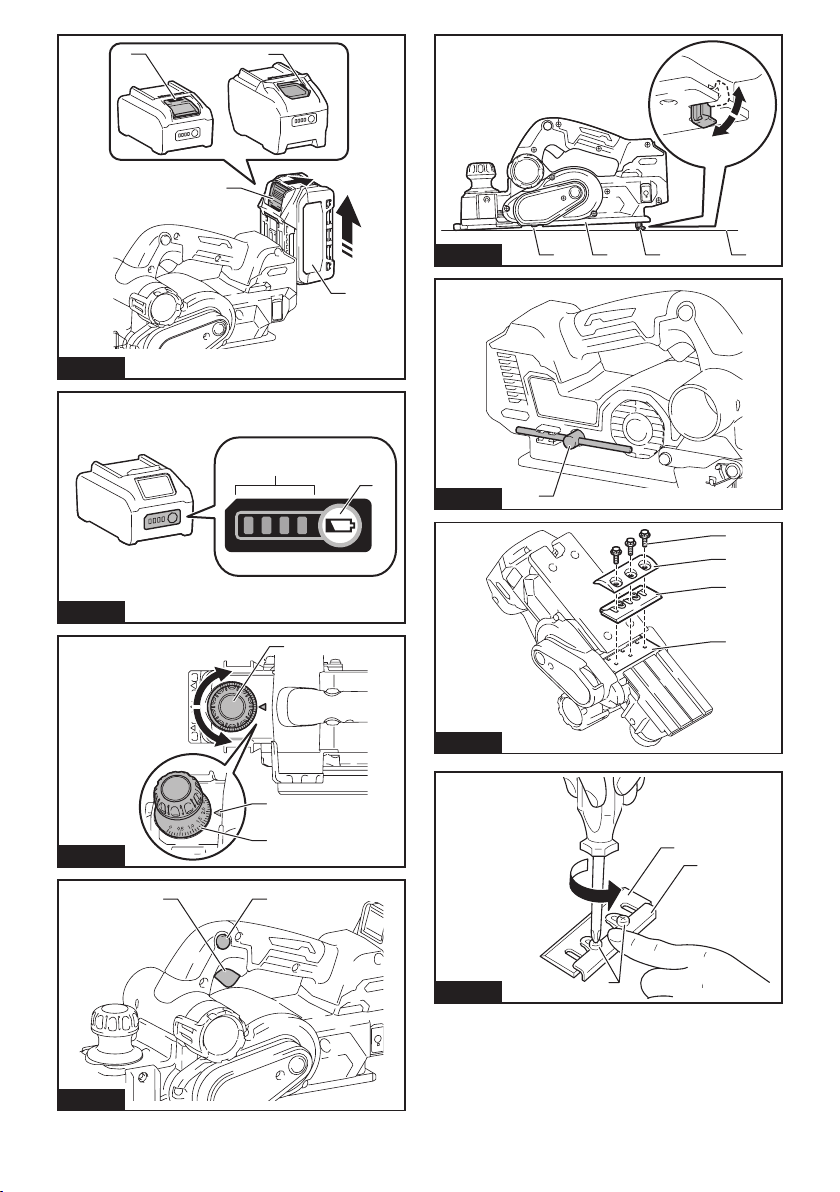

Makita KP001GZ User manual

Other Makita Power Tools manuals

Makita

Makita BSS610SK User manual

Makita

Makita Lithium-ion BDF451RFE Manual

Makita

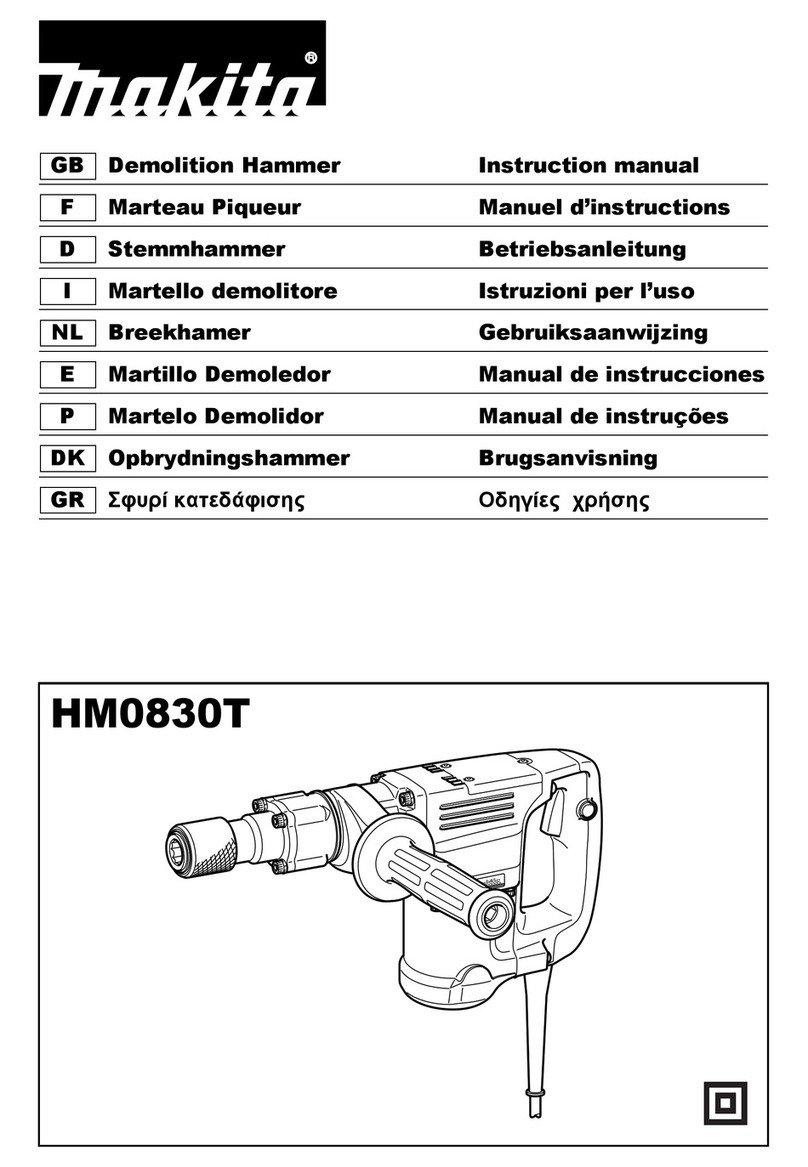

Makita HM0830T User manual

Makita

Makita DUX18 User manual

Makita

Makita DJS200 User manual

Makita

Makita DST221Z User manual

Makita

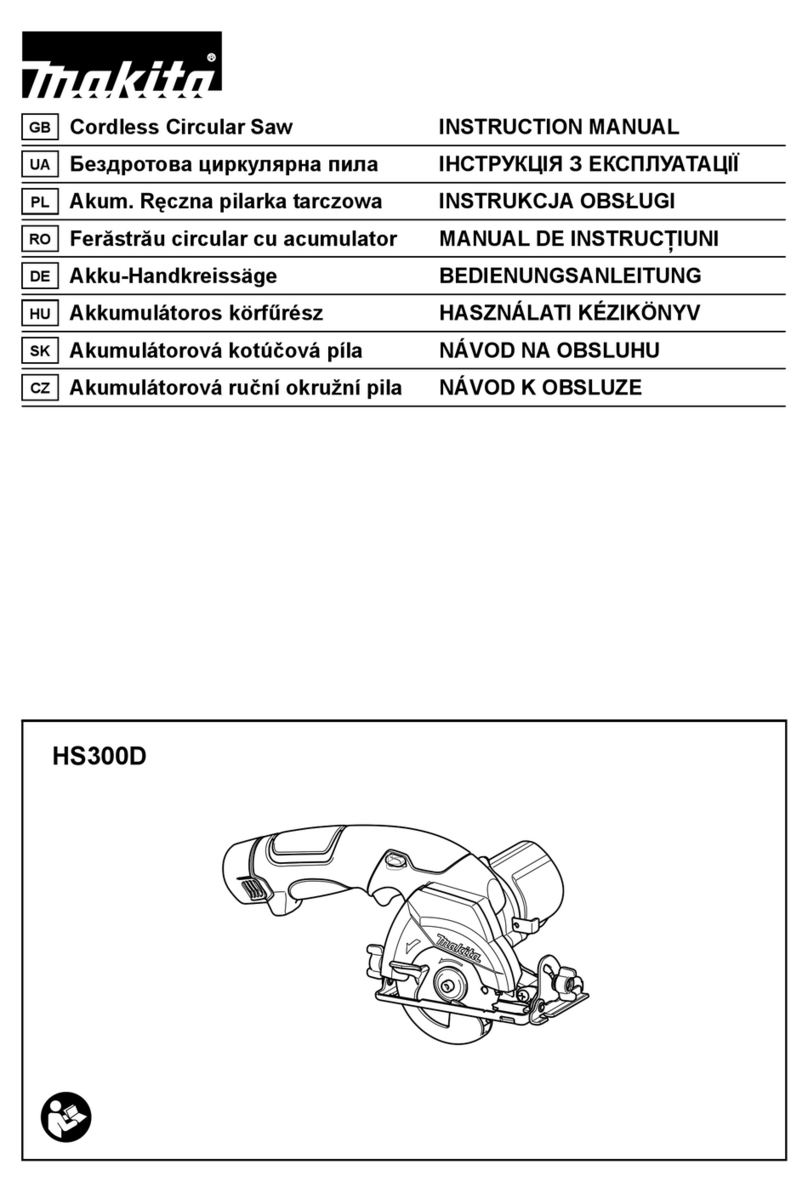

Makita HS300D User manual

Makita

Makita TW161DSAJ User manual

Makita

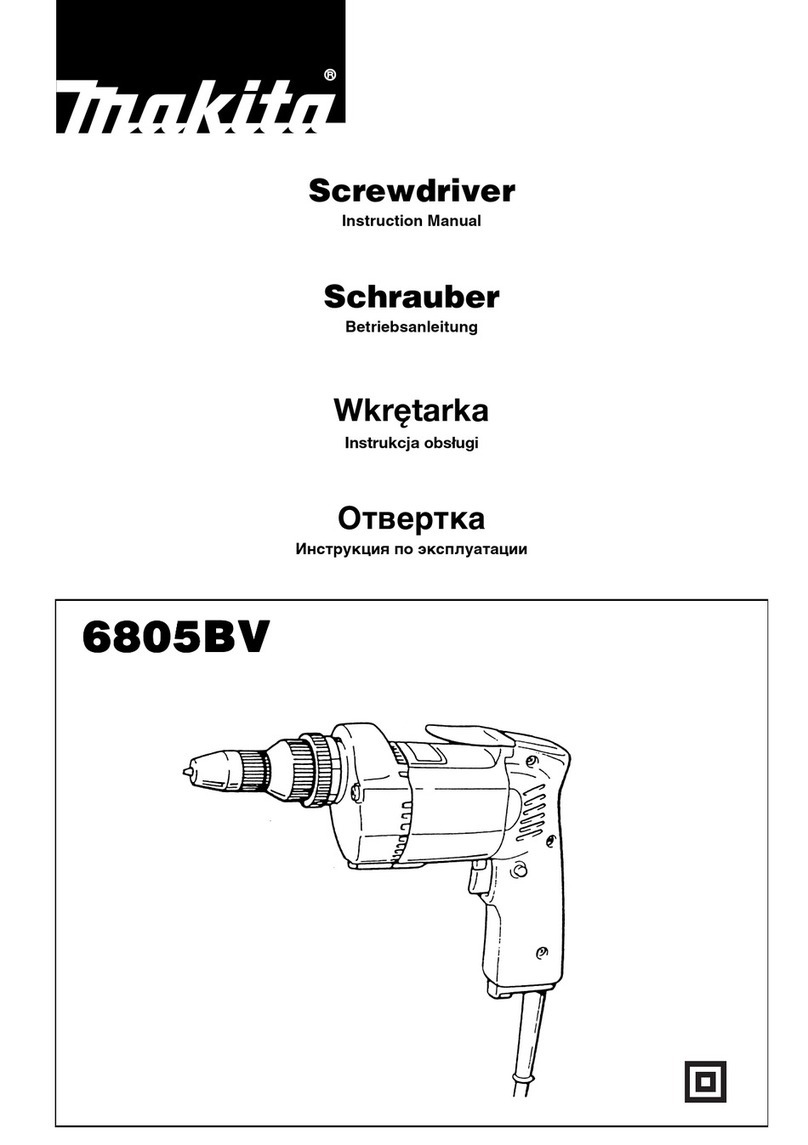

Makita 6805BV User manual

Makita

Makita JS1600 User manual

Makita

Makita HM1500 User manual

Makita

Makita XRV01 User manual

Makita

Makita BFH120F User manual

Makita

Makita HG 1100 User manual

Makita

Makita WT02 User manual

Makita

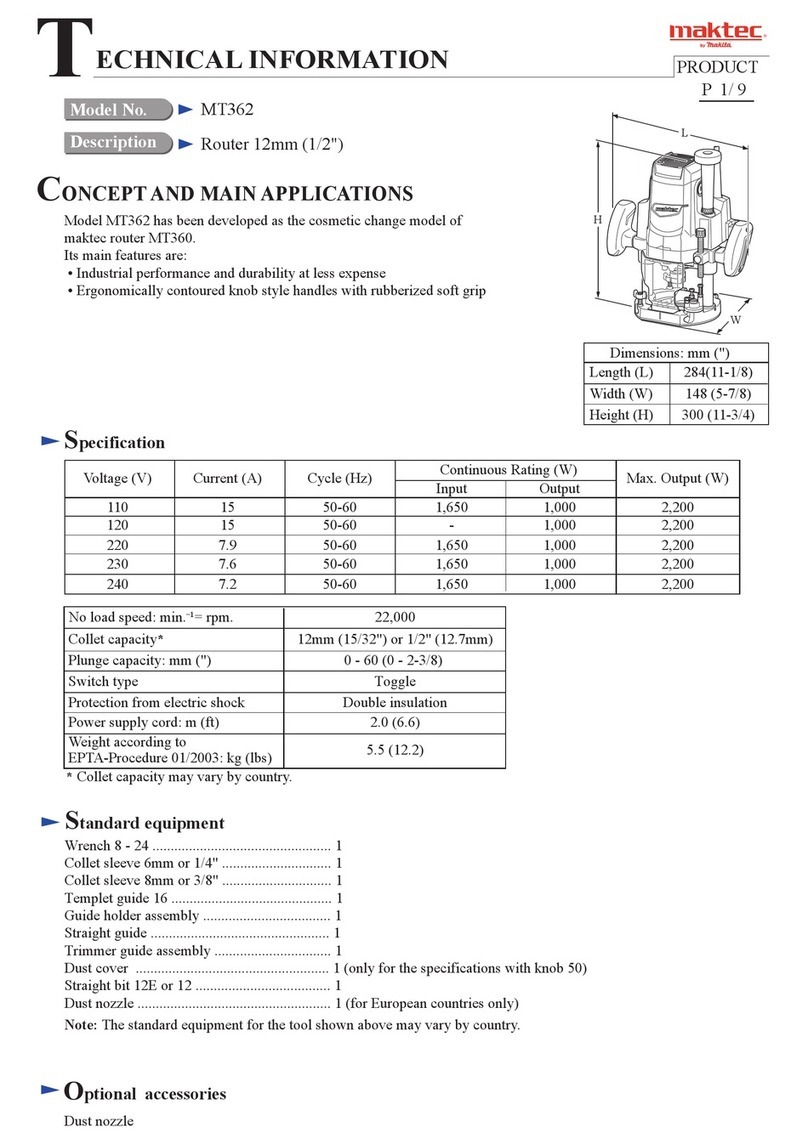

Makita Maktec MT362 Manual

Makita

Makita BJV140 User manual

Makita

Makita TM3010CX5 User manual

Makita

Makita MAKSTAR BTW250 Series User manual

Makita

Makita DJS200 User manual