P 3/ 22

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

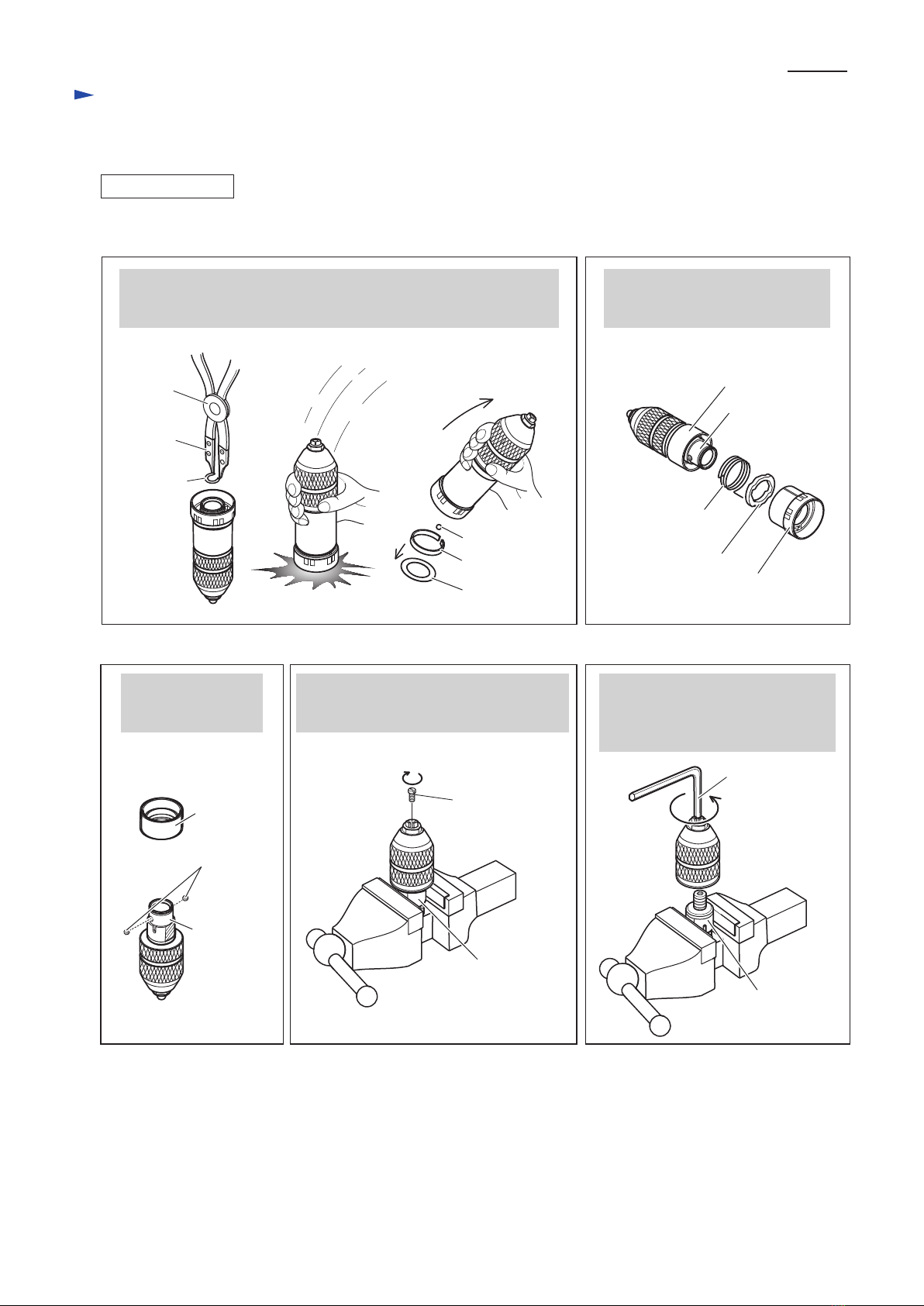

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

Retaining ring pliers ST-2N1R003 removing Ring spring 19 from Tool holder complete/ Tool holder guide complete

1/4” Hex. Shank Bit M81R017 removing Ring spring 28, etc.

removing Ring spring 29

Bearing setting plate 8.21R032 assembling Spiral bevel gear 26

Bearing setting plate 10.21R033

1R045

Ring spring setting tool A1R164 assembling Oil seal 25 to Gear housing complete

Ring spring setting tool B1R165 assembling Needle bearing complete to Gear housing complete

Tip for Retaining ring pliers1R212 attachment of 1R003

T-type hex wrench 3-1271R170 removing two M4x25 hex socket head bolts on Inner support complete

Drill chuck extractor1R139 removing Spiral bevel gear 26

Pipe 301R232 assembling Oil seal 25 to Gear housing complete

Round bar for arbor 24-1001R249 removing Ring spring 29

Round bar for arbor 30-1001R252 removing Oil seal 25 from Gear housing complete

Bearing extractor1R269 removing Ball bearing 608ZZ from Inner support complete

Round bar for arbor 7-501R281 removing Ring 8

1R291 removing Retaining ring S-7

Jig for Spiro lock washer1R369 removing Ring spring 29 from Tool holder complete/ Tool holder guide complete

Ring spring extractor1R388 removing Ring spring 28

Retaining ring S and R pliers

removing Retaining ring WR-12 from Armature shaft

Gear extractor (large)

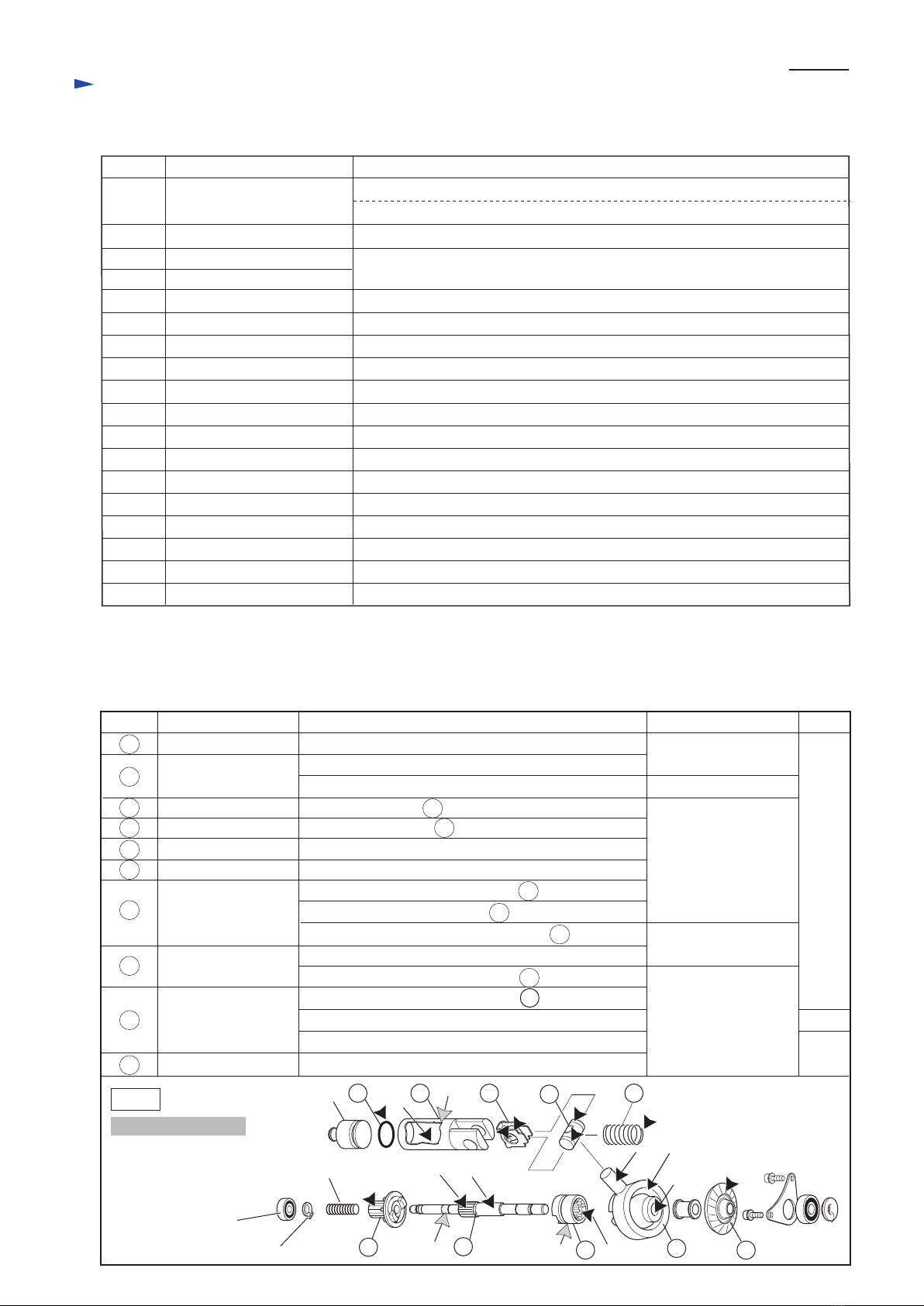

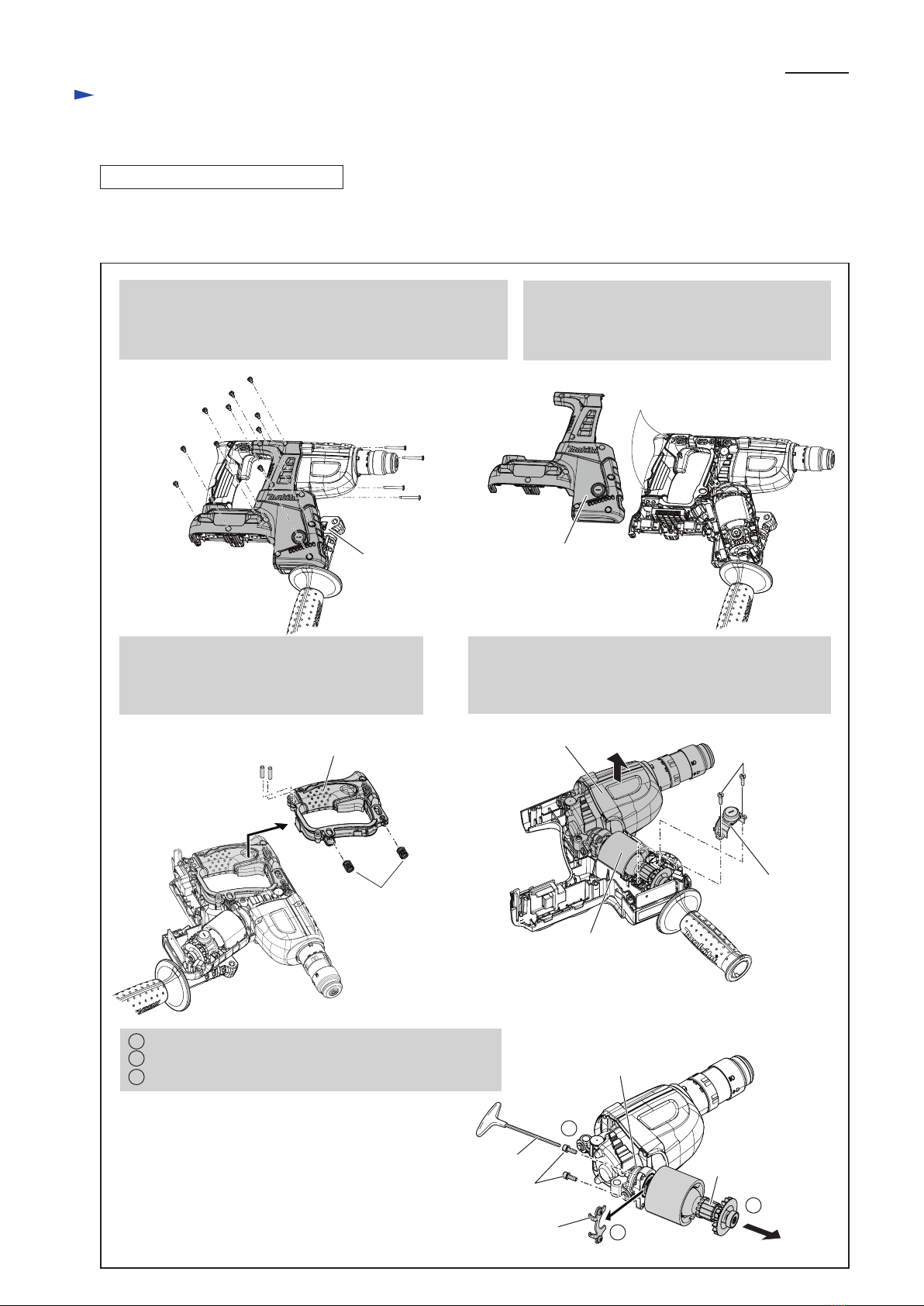

[2] LUBRICATION

Apply the following grease to protect parts and product from unusual abrasion.

* Makita grease RB No.00 to the portions indicated by the black triangle

* Molybdenum disulfide lubricant to the portions indicated by the gray triangle

Fig. 1

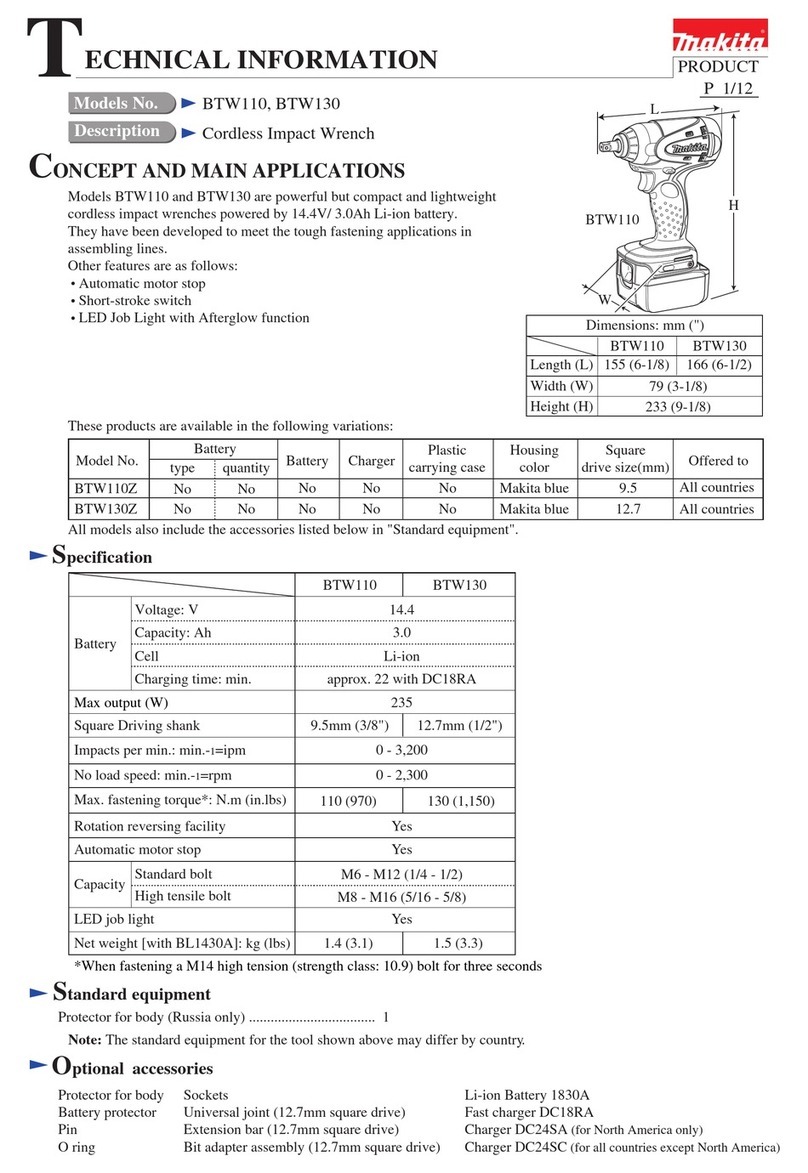

Item No. Description Portion to lubricate Lubricant

Makita grease RB No.00

Makita grease RB No.00

Makita grease RB No.00

4g

Amount

a little

a little

Striker

Compression spring 14 End to be fixed to the boss in Inner housing complete

Ball bearing 606ZZ

Compression spring 7

Retaining ring S-7 (f)

(h) (i)

(j)

42

44

Piston joint Grooves that contact 42 Guide plate

43

50

51

40

41

Clutch cam

Swash bearing 10

O ring 16

Piston cylinder

Guide plate Inside that contacts 43 Piston joint

48 Spur gear 10 Gear portion that engages with Spur gear 51

Whole surface

(h) Pole portion to be inserted into 43 Piston joint

(j) Inside of hole

53 Spiral bevel gear 26 Gear portion that engages with Armature shaft gear

(a) Inside where Striker moves

(b) Outside that contacts Tool holder (guide) complete

49 Cam shaft

(e) Small diameter portion to be inserted into 48 Spur gear 10

(f) Groove for hooking Change plate

(i) Ball bearing portion (See Fig. 3.)

(c) Gear portion that engages with 50 Clutch cam

(d) Portion to be inserted into 51 Swash bearing 10

(g) Gear portion that engages with 49 Cam shaft

40 41

50

48 51 53

49

42 43 44

(a)

(c) (d)

(b)

(g)

Molybdenum disulfide

Molybdenum disulfide

(e)

Transmission parts