Master FPC90 User manual

Other Master Power Tools manuals

Master

Master 10008 User manual

Master

Master BLP 11 Manual

Master

Master PROHEAT STC PH-1600 User manual

Master

Master ULTRATORCH UT-50 User manual

Master

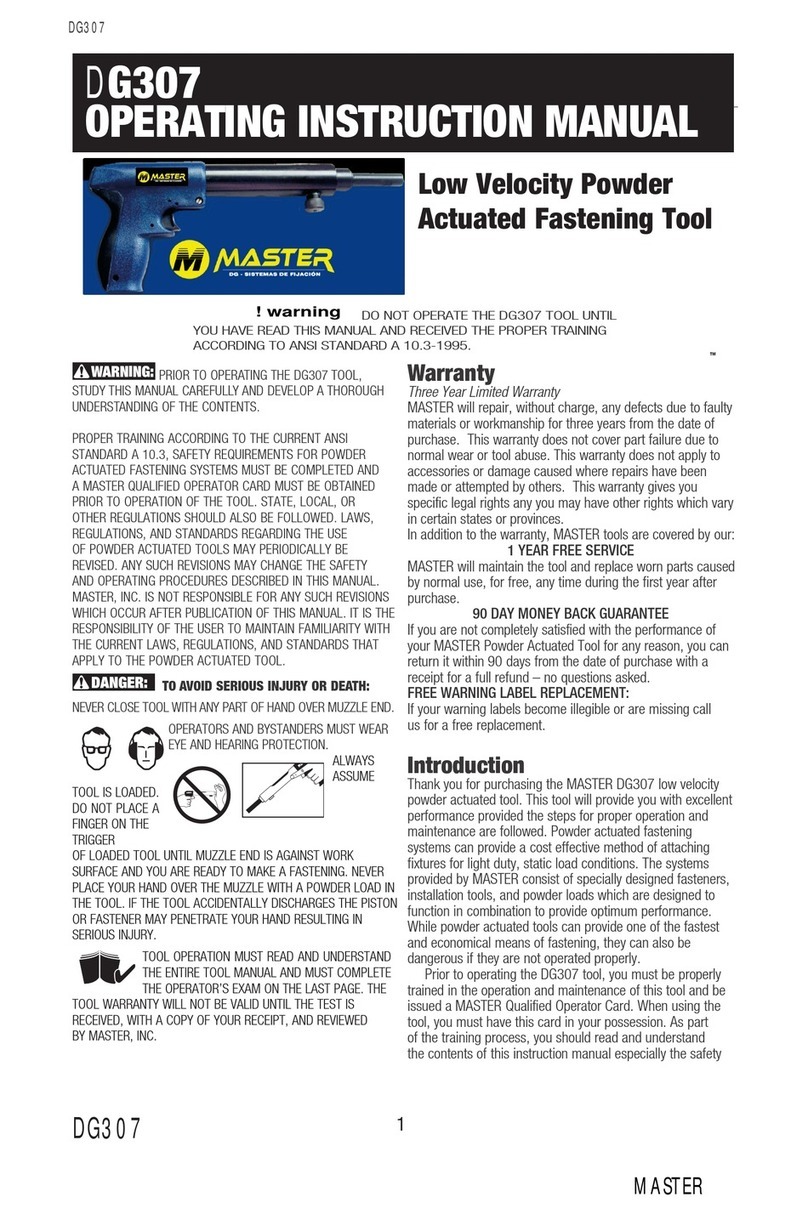

Master DG307 Instruction Manual

Master

Master RS 30 Manual

Master

Master B 45SMS Manual

Master

Master B35CEL Manual

Master

Master BLP 15 kW M User manual

Master

Master Heat Gun HG-801D Series User manual

Master

Master RW 160 User manual

Master

Master VARITEMP VT-752C User manual

Master

Master EC-200 User manual

Master

Master EH 4 User manual

Master

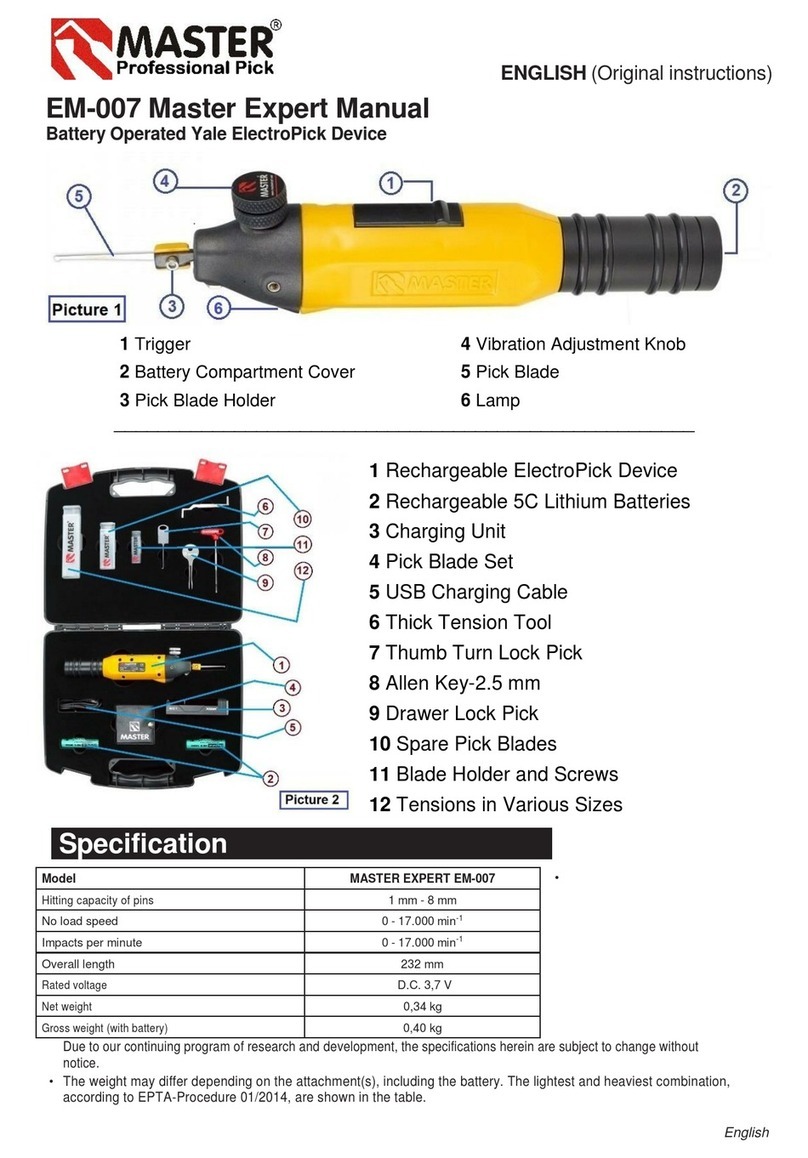

Master EM-007 User manual

Master

Master PROHEAT STC User manual

Master

Master Proheat PH-1000 User manual

Master

Master RS 30 Manual

Master

Master BLP 33E User manual

Master

Master BV 400 Manual