Your butane powered heat tool was carefully lested and Inspected before 11 was

sh~ppedlrom the factory We warrant thls productto be free from defects m

materials

and workmansh~punder normaluseandservlce for one year from date of purchase

Inthe event of a defecttn mater~alsor workmansh~p,we

will

e~therrepalr or replace.

w~thoutcharge, at our optton, any part

which

In our judgement shows evidence of

such defect.

This

warranty does not apply to the attachments. t~ps,burner, or ejector, vhlch are

Items requlnng penodlc replacement, nor does ~tapply ~fthe butane powered heat

tool has been mlsused. abused, altered, tampered wlth, or used with butane fuel

other than MasterAppl~ance

Ultratane butane fuel At the end of the warranty per~od,

Master Appl~anceshall be under no further obl~gation,expressed or ~mpl~ed.Some

states do not allow l~mltat~onson how long an ~mpl~edwarranty lasts, so the above

limltat~onmaynot apply to you

MaslerAppl~anceassumes no responslbllltyfor and thls warranty shall not cover any

tncldental or consequent~aldamages from any defect m

this

productor 11suse

Some slates do not allow the excluston or l~mflat~onof ~nctdentafor consequential

damages,so the above exclus~onmay not apply to you.

This

warranty glves you specrflcnghts and you mayalso have other nghts

which

may

vary

from slate to state For warranty repalr a proof of purchase f&&it%r

dthei

appropriate

proof of date 1s

required

w~thyour retum for warranty repair

to

Master

Appl~anceAll warranty cla~msmust

be

made to Master Appliance and not the

dlstr~butorWe decllne respons~b~lrtywhere repairs have been made or attemptedby

others Any d~tferentguarantee made by others

IS

not

authorized

by us

If

a warranty

clam 1s to

be

made please retum your Master Heat Tool prepa~d,w~thproof of

purchaseand a note descr~b~ngthe problemto our ReparDepartment. See below.

For repalr servlce we charge a flat rate fee Please call Master Appl~ancefor the flat

ratecharge returnyour MasterHeat Toot prepa~d.w~tha notedescrlblngthe problem

to

1

.WARNING.Tha product, when uSed for

soldering

andslmllar appllcat~ons.

produceschemlcelsknownto the State of Calrfom~ato cause cancer

and

birth

defectsor other

reproductive

harm

ADVERTENC1A:EI estadode Callfornlatlene conoclmlentos de que este producto,

cuandose usaen soldaduras o apllcac~onesstmtlares,produce

agentesquunlcos que puedenprovocarcancer, defectosmgenitos

ydanosal sistemareproductor

2.WARNING:By-products of the combust~onof the fuel used by thls product contaln

chernlcals knownto the Stateof Cal~forn~ato cause cancer and repro

dudlve harm,

ADVERTENCIA:EI estadode Callfomiatlene conoclmlentos de que 10s produclos

re~~dualesde lacombus~on

del

combustible usado

por

este

producto,cont~enesubstanc~asquimicasque puedenprovocar

cancery danos alsistema reproductor

3.WARNING:The Departmentof TransportatlooHazardousMater~alRegulat~om

forb~dthe carnageof butane or other flammablegas productson

passengera~rcraflDo not pack thls Itemor any other Hammablegas

Item. Inany checkedor carry-onbaggage

-

----

--

mUSTERR

APPLIANCE

Des~gnersand Manufacturers

of Heat Tool. for Industry

MasterAppl~anceCorp

2420-18thStreet

Raclne.WI

53402

U

S

A

Tel (262)633-7791

Facs~m~te(262)633-9745

web

www

masterappl~ance.com

e-mall sales@masterappllance com Rev 2

Pleasesh~ptool prepa~dEnclosea notedescrlb~ng

your problem Made10Japan

ULTRATORCH

"

UT-50

Please read, understand and keep this

manualfor future reference

OperatingInstructions

Unit operates on butane gas

and creates infrared heat

effectivelyby the use of a catalyst.

Beforefilling, make sure

switch ring is off.

Press the nozzle into the refill

opening. When the unit is full, the

gas will overflow the refill nozzle.

(

OCheck the window for fuel level.

I

N0TICE:Before igniting your Ultratorch the first time, completelyfill the

tank with butane.Then wait

5

minutes. During this time tilt the Ultratorch

upand down several times. This initial waiting period gives the wick inside

the fueltank time to absorb the butane and allows for lubrication of the filter.

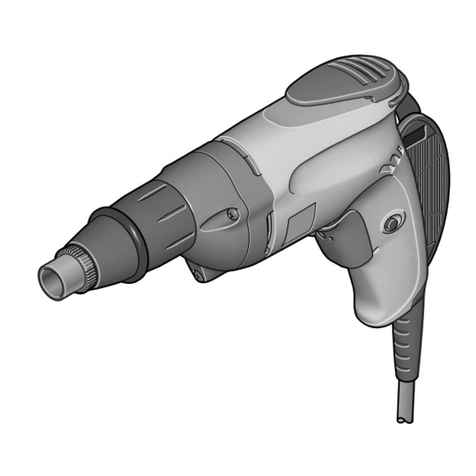

IGNITIONVENT KNURLEDNUT

SWITCH

RING

Ignition hstructions

1.

Pushthe switch ring up andturn to the right. Place

the indicatordot on

1

or lower.

2.

Pushthe knurled nut upward exposingthe

ignition vents.

3.

Ignite

as

shown by Figure

3,

keepingthe vent open.

Holdknurlednut until glow appearsfrom catalyst. Release

the knurlednut, which will returnto its original position.

4.

The heat of the soldering tip can becontrolled by

rotatingthe switch ring between position

1

and

3.