1.1 Introduction ........................................1

1.2 Principles Of Operation .............................1

1.3 Reshaping The Velocity Prole.......................1

2

2.1 High Accuracy ......................................2

2.2 Repeatability .......................................2

2.3 Turndown ..........................................2

2.4 Installation Requirements ...........................3

2.5 Long Term Performance.............................3

2.6 Signal Stability......................................3

2.7 Low Permanent Pressure Loss .......................3

2.8 Sizing ..............................................4

2.9 No Areas of Stagnation..............................4

2.10 Mixing..............................................4

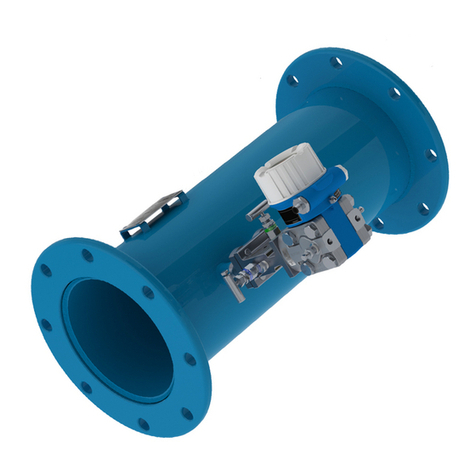

2.11 V-Cone Models .....................................4

5

3.1 Application Data....................................5

3.2 Flow Calculations ...................................5

3.3 Simplied Liquid Calculation . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Application Sizing ..................................8

3.5 Calibration..........................................8

3.6 Materials Of Construction ...........................8

3.7 Valve Manifolds .....................................8

3.8 Secondary And Tertiary Instrumentation.............9

3.9 Meter Tag...........................................9

4.1 Scope .............................................10

4.2 Safety .............................................10

4.3 Unpacking.........................................10

4.4 Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.5 Piping Specication................................10

4.6 Piping Requirements...............................11

4.7 Isolation (Block) Valves .............................11

4.8 Valve Manifolds ....................................11

4.9 Installation ........................................12

4.10 Pressure Taps ......................................12

4.11 Remote Seals or Chemical Seals ....................13

4.12 Impulse Line: General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.13 Impulse Line: Process Industries . . . . . . . . . . . . . . . . . . . .13

4.14 Impulse Line: Steam Applications...................13

4.15 Insulation..........................................13

4.16 Horizontal Piping Installations: Gas .................14

4.17 Horizontal Piping Installations: Liquids..............15

4.18 Horizontal Piping Installations: Condensing Vapors . 15

4.19 Vertical Piping Installations: General ................16

4.20 Vertical Piping Installations: Up Flow ...............16

4.21 Vertical Piping Installations: Gas ...................16

4.22 Vertical Piping Installations: Liquids ................17

4.23 Vertical Piping Installations: Condensing vapors, i.e.

steam .............................................18

4.24 Calibration Compensated Installation...............18

4.25 Vertical Down Flow Piping Installations: General ....18

4.26 Vertical Down Flow Piping Installations: Gas ........19

4.27 Vertical Down Flow Piping Installations: Liquids ....20

4.28 Vertical Down Flow Piping Installations: Condensing

Vapors, i.e. Steam ..................................21

4.29 Supporting Manifold Blocks and Dual Transmitters..22

4.30 Zeroing DP Pressure Transmitters Following

Installation For Steam Flow Applications............23

4.31 Zeroing DP Pressure Transmitters Following Installation

For Ambient Temperature Liquid Applications ......23

4.32 Zeroing DP Pressure Transmitters Following

Installation For Gas Applications....................24

4.33 Zeroing Low Range Transmitters ...................24

4.34 Dierential Pressure Measurement .................25

4.35 Temperature And Pressure Measurement ...........25

5.1 Face To Face Dimensions ...........................26

5.2 Face To Face Dimensions ...........................26

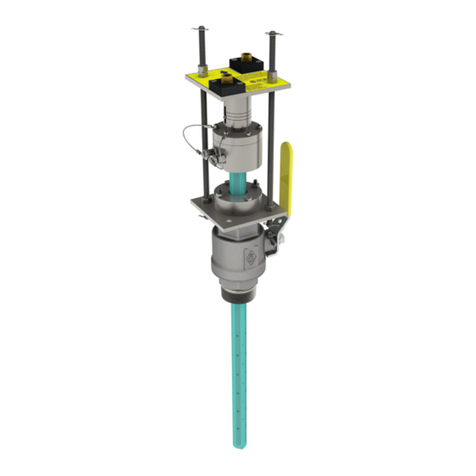

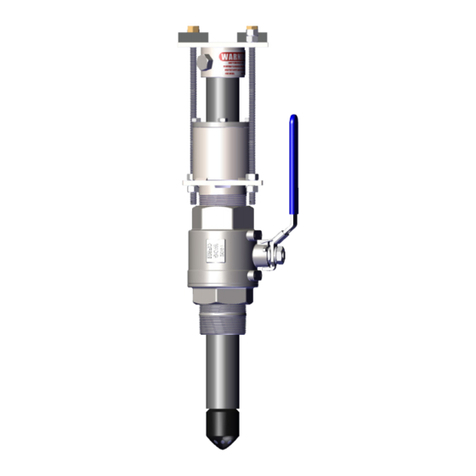

6.1 Wafer-Cone©Model Template ......................27

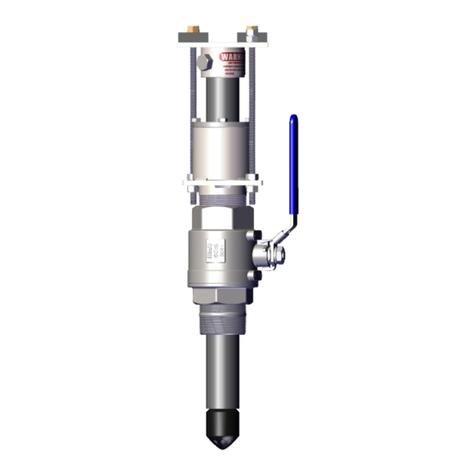

6.2 Precision Tube V-Cone Model Template .............27

6.3 V-Cone Special Models.............................28

6.4 V-Cone Materials...................................28

7.1 Periodic Maintenance ..............................29

8.1 Troubleshooting A V-Cone System On-Site..........29

32

9.1 Conguration Sheets of Various V-Cone Models .....32

33

10.1 V-Cone Installation Guide: Upstream and Downstream

Minimum Straight Pipe Run Recommendations.....33

35