RAW WATER SENSOR POSITION

The operation position for raw waste water and sludge is at sensor

location 0.00 to prevent debris from collecting on the sensor and

aecting velocity readings. To position the sensor at this location

follow the instructions below:

Calculate distance A by subtracting the pipe wall thickness

(WT) and ¾” from length C (Tube Length).

A = C - WT - ¾”

Using the captive nuts, position the top edge of the tube cap so

that its distance from the OD of the pipe is equal to“distance A”

calculated above. See diagram.

12

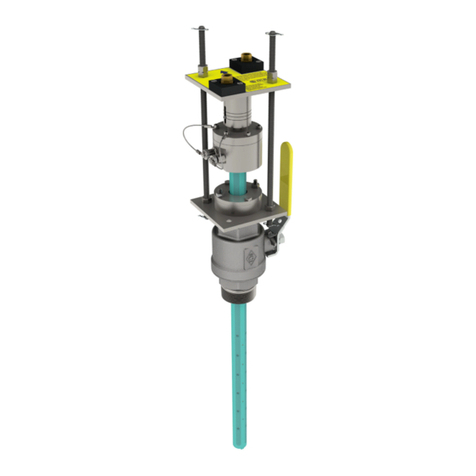

INSERTING THE SENSOR

!

WARNING! The compression seal/sensor assembly may be under

pressure. Serious injury may result if proper procedures are not

followed. Do not attempt to install the sensor without the retaining rods

fully assembled.

Ensure the compression seal is only hand tightened.

Barely crack open the valve and tighten the compression seal as required to minimize

leaks. A towel draped around the compression seal can reduce spray if necessary.

Open the valve completely. Failure to open the valve completely will cause the valve to

scrape the sensor during insertion and may result in permanent damage to the sensor.

Insert the sensor into the pipe by simultaneously

rotating clockwise the two captive nuts on the

top plate for the 2”sensor, and the single captive

nut on the 1” sensor. For the two captive nuts

on the 2” sensor use the two ratchet wrenches

provided. It is recommended that the Sensor

Insertion Tool be used to rotate the captive

nuts on the 2” sensor to ensure the top plate

compresses evenly.

IMPORTANT: If the captive

nuts are not tightened

simultaneously, the top

plate will become crooked

and cause the sensor to

be inserted at an angle

and may cause permanent

damage.

i

11 CLEAN WATER SENSOR POSITION

13

If the ow is clean water, the sensor can be placed at 1/8 of the

inside diameter. To position the sensor at 1/8 of the ID, follow the

instructions below:

• Measure the tube from the top of the cap to the end of the

sensor to nd tube length (TL).

• Calculate (1/8 D): 1/8 D = 0.125 x Pipe ID

• Add wall thickness(WT) to 1/8 D.

• Calculate distance A: A = TL - (1/8 D + WT)

Using the captive nuts,

position the top edge of the

tube cap so that its distance

from the OD of the pipe is

equal to “distance A” calculated

above. See diagram.

If the ow is clean water, the sensor can be left at the 1/8D

position. Do not leave the sensor in this position for raw

waste water because debris could collect on the sensor and

aect the velocity readings. In waste water applications,

position the sensor at location 0.00.

0.00 Position

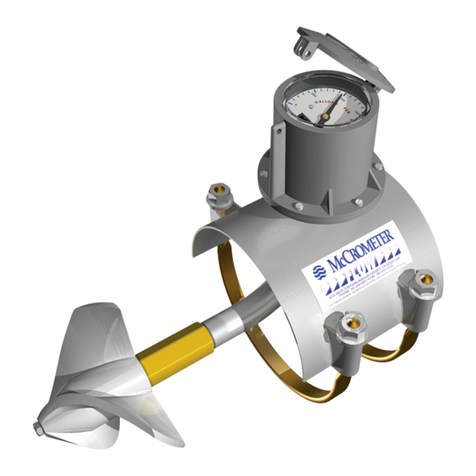

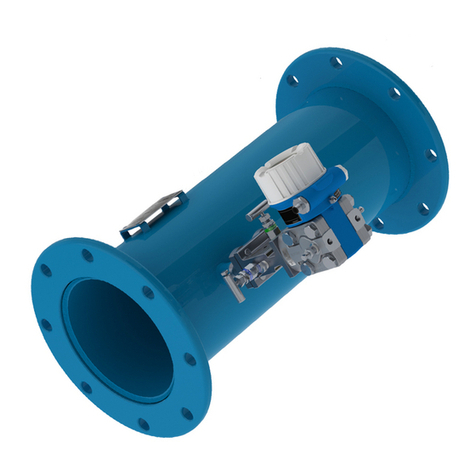

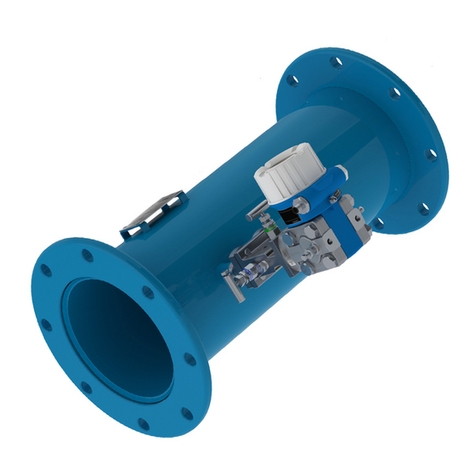

FULL PIPE SENSORS

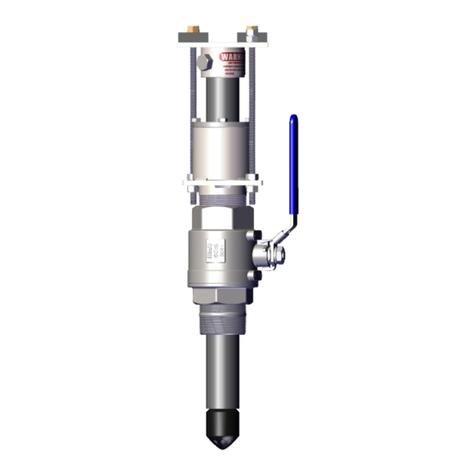

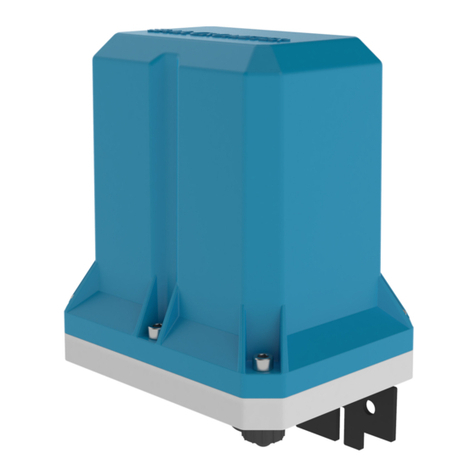

6PARTS DIAGRAM

7

NOTE: Valves are optional or supplied by user.

1 Sensor Assembly

2Bronze Ball Valve

3 Compression Seal Assembly

41" Insertion Tube with cap

2" Insertion Tube without cap

5Insertion Tube Cap

6 3/8" SS Long Threaded Rod

Item No. Part Name

1 2 543

6

282L 1" Sensor

SENSOR ASSEMBLY INSTALLATION

The sensor assembly uses a compression seal, which keeps the sensor

watertight when the pipe is under pressure. Care must be taken when

installing the sensor, to avoid leaks.

Visually inspect all elements of the installation to ensure they are structurally

sound and of high quality materials, including all welds, couplings and

nipples.

Put a generous amount of the supplied pipe sealant on the compression

seal threads. Teon tape may also be used. NOTE: If pipe sealant gets on

the sensor electrodes the velocity signal may be lost.

Place the compression seal threads over the pipe valve. Turn the entire

sensor assembly clockwise to secure the assembly to the valve.

The seal is secure when a large amount of force is required to turn the

assembly. Line up the arrow (on the top plate) with the direction of the ow.

10

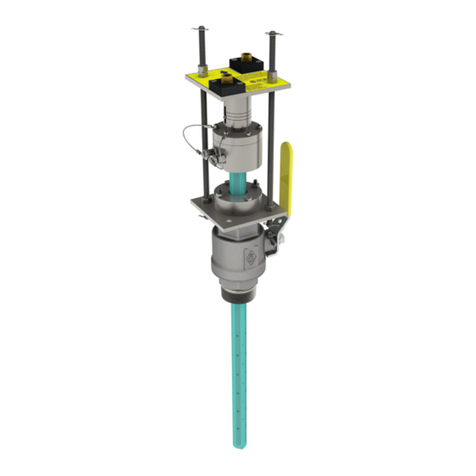

PIPE VALVE INSTALLATION

Install a 2” (50mm) full port valve or corporation stop with a 2”

(50mm) NPT female pipe thread output for the 2” sensor, or a

1” (25mm) full port valve or corporation stop with a 1” (25mm)

NPT female pipe thread output for the 1”sensor.. Follow any and

all installation instructions provided for the valve that you have

chosen. The valve or corporation stop can be installed onto a

welded coupling or pipe saddle

!

WARNING! Pressurized pipes should only be hot

tapped, cut, or drilled by qualied personnel

using high quality saddles, valves and stainless

steel nipples. If possible, depressurize the pipe

before attempting any installation.

9

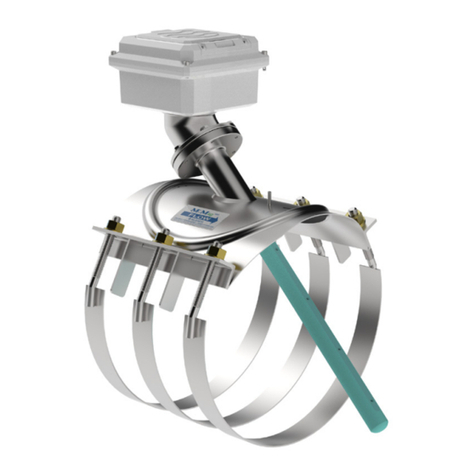

SENSOR CLEARANCE

8

1. the height from the outer pipe wall to the

top of the installation valve

2. the length of the meter (see table)

3. additional 9” of working space

FLOW CALCULATION

5

The full pipe sensor makes use of Faraday’s Law of

Electromagnetic Induction to measure water velocity.

Faraday’s Law states: A conductor, moving through a

magnetic eld, produces a voltage.

Because water is a conductor, water moving through a

magnetic eld produces a voltage. The magnitude of

the voltage is directly proportional to the velocity of

the water. The sensor generates an electromagnetic

eld, creating a voltage in the water. The two velocity

electrodes, along with the ground electrode measure

this voltage. A faster water velocity produces a higher

voltage. By accurately measuring this voltage, the

velocity is determined.

Distance H is estimated by adding three measurements:

Insertion

Tube Length

Overall Sensor

Length

Insertion

Tube Length

Overall Sensor

Length

12” 18.25” 18” 24.25”

24” 30.25” 24” 30.25”

36” 42.25” 30” 36.25”

1” 282L 2” 282L

Pipe Saddle

With Ball Valve

Welded Pipe Nipple

With Ball Valve

Corporation

Stop

Velocity

Electrodes

Ground

Button

2” Sensor

1” Sensor

Velocity

Electrodes

Ground

Button

282L 2" Sensor

5321

6

4

The sensor will protrude from the pipe when

installed requiring sucient clearance from any

obstruction.

Obstruction

H

Compression

Seal Threads

Bottom Plate Compression

Seal Assembly

Compression

Seal

Captive Nuts

TL

Tube Length (TL) 1/8 D

TL

A

WT

1/8 D Position

C

A

WT

3/4”

If the engineering design for this installation

requires that ow in the line be proled, please

refer to the SPI Mag Proling Guides.

SPI Mag 1” Proling Guide: Lit# 24510-58

SPI Mag 2” Proling Guide: Lit# 24510-59

The Proling Guides can be downloaded at:

www.mccrometer.com/Library

To calculate the ow, two things are needed: The

cross-sectional area of the pipe and the average

velocity.

Cross-sectional area is found using the inside

diameter of the pipe. Average velocity is

found using the sensed velocity (measured by

the sensor). A site calibration is performed to

determine the velocity prole. This allows the

ow meter to calculate the average velocity from

the sensed velocity.

Flow is calculated by using the Continuity

Equation: Flow = Average Velocity x Area