30119-03 Rev. 3.8/06-05

McCrometer • Page 5

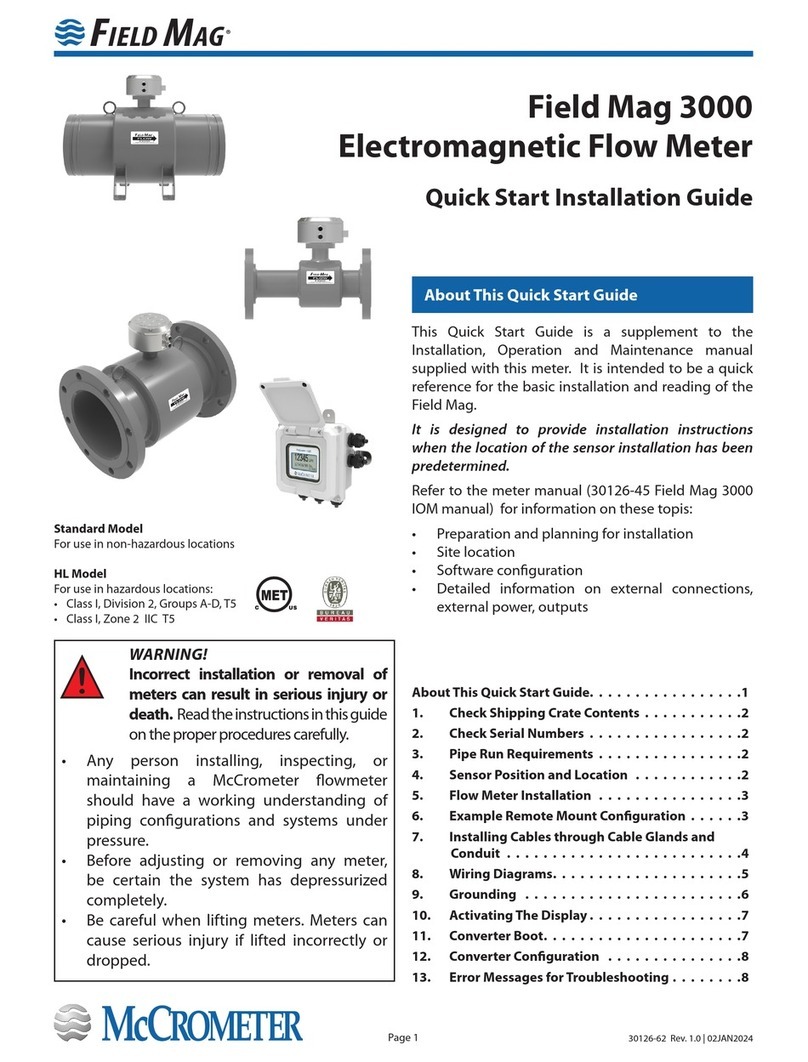

CONFIGURATION METHODS:

All configurations are user defined and password protected.

The configuration is stored in nonvolatile memory with a 10-

year retention. The converter is fully programmed before ship-

ping. Reprogramming can be easily done on site using the fol-

lowing methods:

KEYPAD – can be used to access and change all menu param-

eters using four membrane keys and 3-line display.

RS232 – standard 9-pin data connection for local hand-held

terminal or computer (null modem/Lap Link cable required). Soft-

ware such as ProComm Plus or Microsoft Windows Hyper Ter-

minal is required (see page 29).

HART™Communication – Optional.

DISPLAY:

Back Lit: 3-line, 16-character, read only display for flowrate

(in a choice of engineering units and % of range), forward to-

talizer, reverse totalizer, net totalizer, alarm conditions, flow

velocity, and percent of range.

Internal Totalizer: Resettable 9-digit for forward, reverse

and net totals. Can be programmed to reset via external in-

put.

Test Mode and Output Circuit Loop Verification: After

converter has been programmed, operation of the test mode

will drive all outputs to programmed value to provide total

system test.

INTERCHANGEABILITY: Converters are fully interchangeable with

all sizes of UltraMag sensors and configurable on site. Sys-

tem specification not affected by converters change.

TIME CONSTANT: Fully programmable from 2 to 120 secs

(page 24).

IV. INSTALLATION:

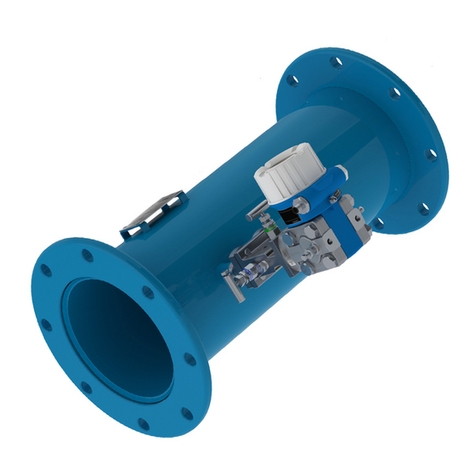

McCrometer's UltraMag Meters are normally supplied as a

calibrated system with the converter factory calibrated to

the supplied sensor. The meter must have a full flow of

liquid for proper accuracy. Installation is made in the fol-

lowing manner:

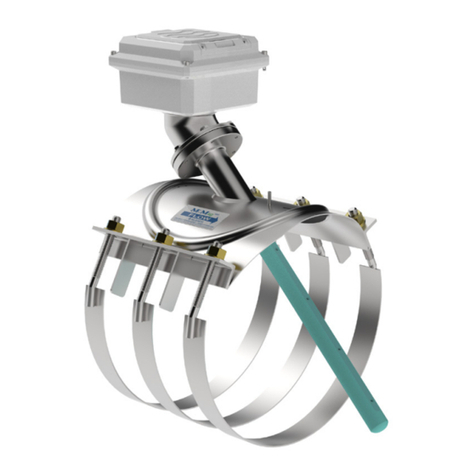

1. POSITIONING THE SENSOR: The following installa-

tion recommendations should be followed (see page 7 for

installation diagrams):

A. In horizontal pipe runs, the electrodes should be

in a horizontal plane to prevent coating by sediments or

loss of electrode contact due to air bubbles.

B. In vertical pipe runs, the flow should be upward.

In slurry application, a vertical position ensures optimal

distribution of solids under all flow conditions.

C. It must be ensured that the sensor is always

completely filled with liquid.

D. For proper accuracies any 90 or 45 degree el-

bows, valves, partially opened valves etc. should be

placed not closer than five to ten pipe diameters up-

stream and two pipe diameters downstream.

E. The flow of the medium should correspond to the

direction shown by the arrow on the sensor.

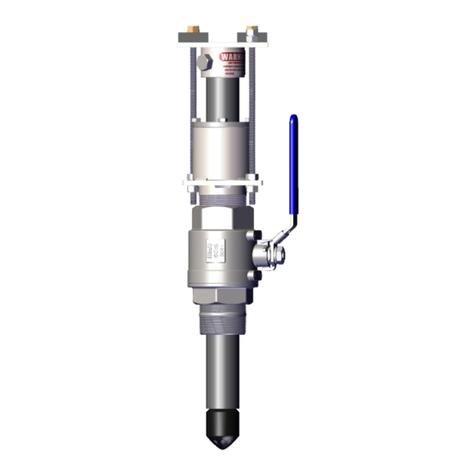

2. ELECTRICAL NOISE AND SENSOR: For flow mea-

surement free of electrical noise interference, the sensor

body must have electrical contact with the media. This is

normally achieved via a required grounding ring (see page 8

for diagram).

3. FLUID CONDUCTIVITY: To eliminate rapid changes in

fluid conductivity, all blending and chemical injecting should

be done early enough so the flow media is thoroughly mixed

prior to entering the measurement area.

4. METER LOCATION: Adjoining pipe must be ad-

equately supported and area around sensor should provide

sufficient drainage to prevent flooding the converter or con-

duits.

The location chosen should provide room to read the display

and be free from harsh electrical noise from adjacent equip-

ment, cables, R.F.I., or E.M.I. The signal converter should not

be subjected to intense, prolonged sunlight, dripping fluids or

spillage, and/or vibrations. Unit should also be shaded from

heat.

5. REMOTE MOUNT SIGNAL CONVERTER may be in-

stalled in the desired place. Providing that free access is

available to allow the display to be viewed as required, the

unit can be either wall mounted or panel mounted with ma-

sonry fixings or nuts and bolts respectively via the fixing

holes provided. Max distance of 300 feet from sensor.

6. GROUNDING RING & GASKETS must be used to en-

sure seal at the flanges and to ensure fluid is properly

grounded to sensor (see page 8).

7. CONVERTER/TRANSMITTER CONNECTIONS to the

sensor must be made with cable supplied by McCrometer

specifically for that purpose. Do not substitute the supplied

cable with other types of cable, even for short runs. For

repairs or added lengths of cable, the entire cable between

the sensor and the converter must be replaced. (Consult

factory for replacement cable and potting compound.)

Power Supply to the converter must be single phase rated at

no more than 265 volts for AC powered converters. This

supply must be fitted with a means of disconnection and be

fused with a fuse suitable for the cable employed but not

exceeding 35 amps.

The converter is not designed to accept rigid conduit direct

entry. If rigid conduit is employed, the first few feet must be

run in flexible conduit and the converter be fitted with face

sealing cable glands. Only 1/2" NPT glands and adapters

may be used.

Only the specified cables and adaptors may be fitted, and in the

manner described elsewhere in this manual. The required NEMA

Enclosure Rating must be maintained. It may be necessary to

seal the conduit entry to prevent moisture entering the terminal

box via the conduit. Potting the junction box is recommended

for remotely mounted converters. Some of these options may

not be suitable for a particular installation. For example, if

mechanical damage to the cable could occur, only armored cable

or conduit should be used. Obey local and national require-

ments for wiring and installation.