Meanwell TDR-480-24 User manual

Other Meanwell Power Supply manuals

Meanwell

Meanwell SHP-10K Series User manual

Meanwell

Meanwell RCP-2000 User manual

Meanwell

Meanwell APV-25 User manual

Meanwell

Meanwell NDR-240 Series User manual

Meanwell

Meanwell DR-RDN20 User manual

Meanwell

Meanwell RST-7K5-HV Series User manual

Meanwell

Meanwell AP User manual

Meanwell

Meanwell RSP-2400-12 User manual

Meanwell

Meanwell LAD Series User manual

Meanwell

Meanwell RCP-1000 Series User manual

Meanwell

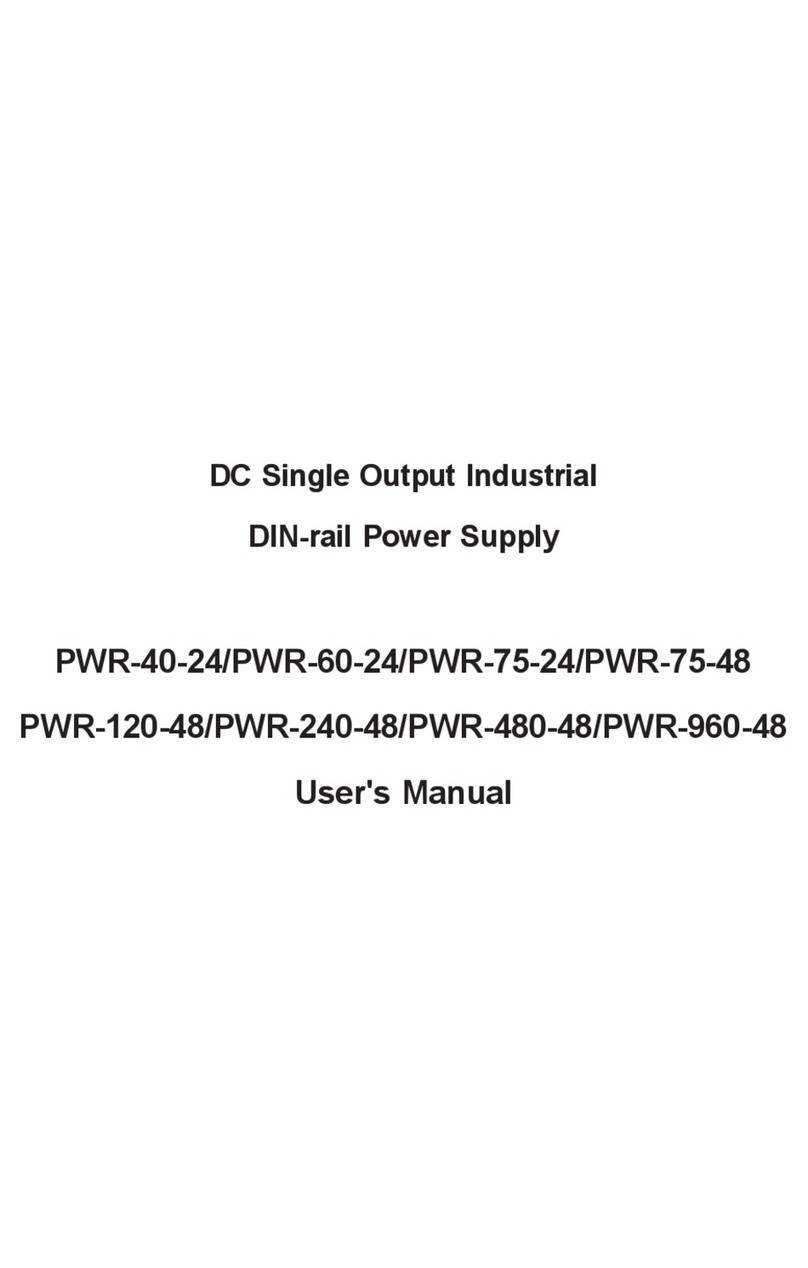

Meanwell PWR-40-24 User manual

Meanwell

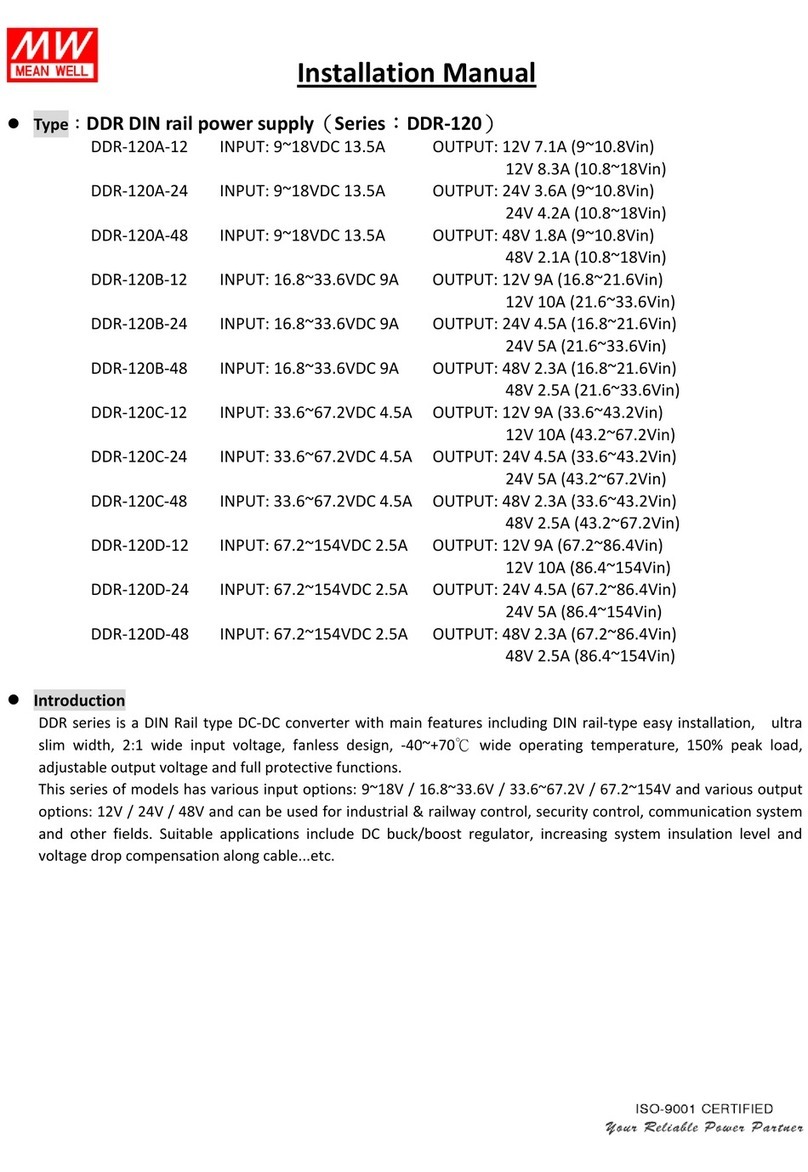

Meanwell DDR-120 Series User manual

Meanwell

Meanwell NDR-75-12 User manual

Meanwell

Meanwell NMP650 User manual

Meanwell

Meanwell DRP-3200 Series User manual

Meanwell

Meanwell DR Series User manual

Meanwell

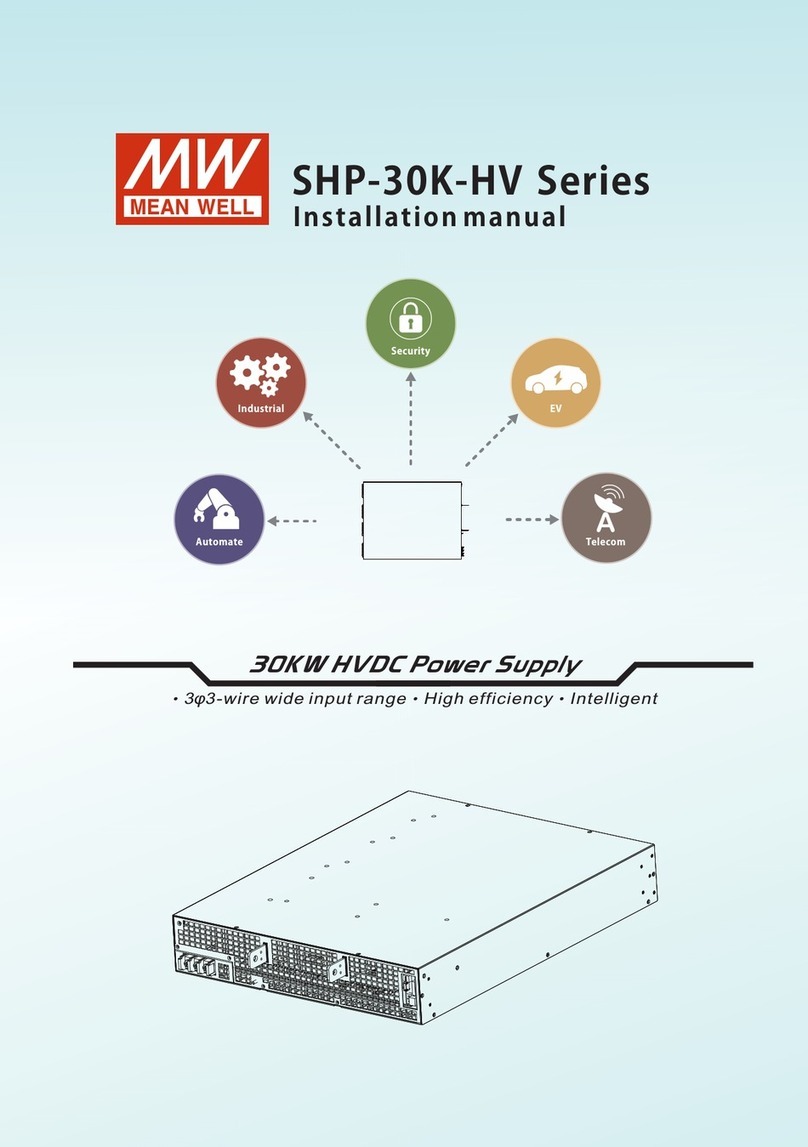

Meanwell SHP-30K-HV Series User manual

Meanwell

Meanwell DDR-15G-3.3 User manual

Meanwell

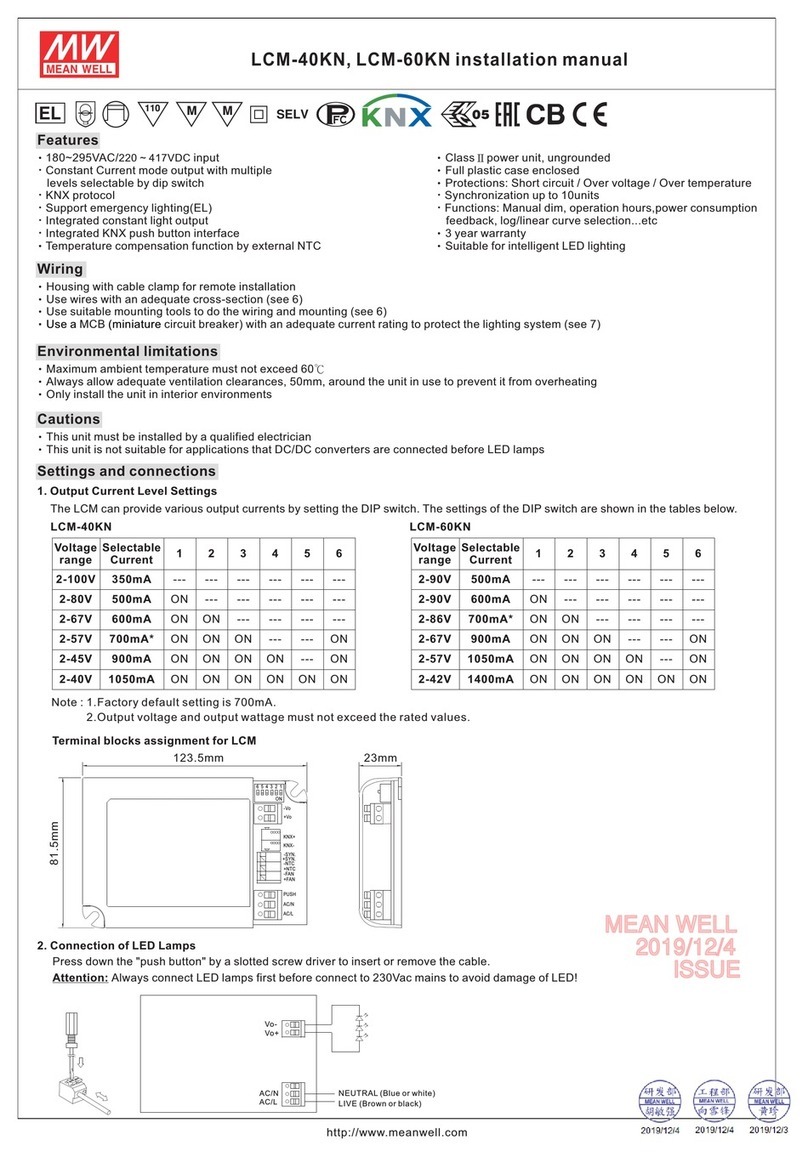

Meanwell LCM-40(DA) User manual

Meanwell

Meanwell RKP-1U User manual

Popular Power Supply manuals by other brands

Videx

Videx 520MR Installation instruction

Poppstar

Poppstar 1008821 Instructions for use

TDK-Lambda

TDK-Lambda LZS-A1000-3 Installation, operation and maintenance manual

TDK-Lambda

TDK-Lambda 500A instruction manual

Calira

Calira EVS 17/07-DS/IU operating instructions

Monacor

Monacor PS-12CCD instruction manual