Meatest 9010 User Manual 4

Resistance.......................................................................................................................................................................................58

Capacitance ................................................................................................................................................................................. 60

Power and energy ..................................................................................................................................................................... 61

Harmonics ...................................................................................................................................................................................... 63

Temperature sensor simulation........................................................................................................................................ 63

SCO 400 MHz scope option ................................................................................................................................................65

MER integrated multimeter option ............................................................................................................................... 67

Certificate of conformity ................................................................................................................................... 69

List of ta les

Table 1 Integrated options ............................................................................................................................................................................11

Table Scope option modes ..................................................................................................................................................................... 31

Table 3 Multimeter SETUP .......................................................................................................................................................................... 39

Table 4 List of main test points ................................................................................................................................................................ 43

Table 5 List of options’ test points .......................................................................................................................................................... 44

Table 6 Calibration points – DC voltage and current ................................................................................................................. 47

Table 7 Calibration points – AC voltage and current ................................................................................................................. 48

Table 8 Calibration points – Resistance ..............................................................................................................................................49

Table 9 Calibration points – Capacitance ..........................................................................................................................................49

Table 10 Calibration points – HVR option ......................................................................................................................................... 50

Table 11 Calibration points – SCO option ........................................................................................................................................... 50

Table 1 Calibration points – MER option ......................................................................................................................................... 50

Table 13 Error code overview ..................................................................................................................................................................... 5

List of figures

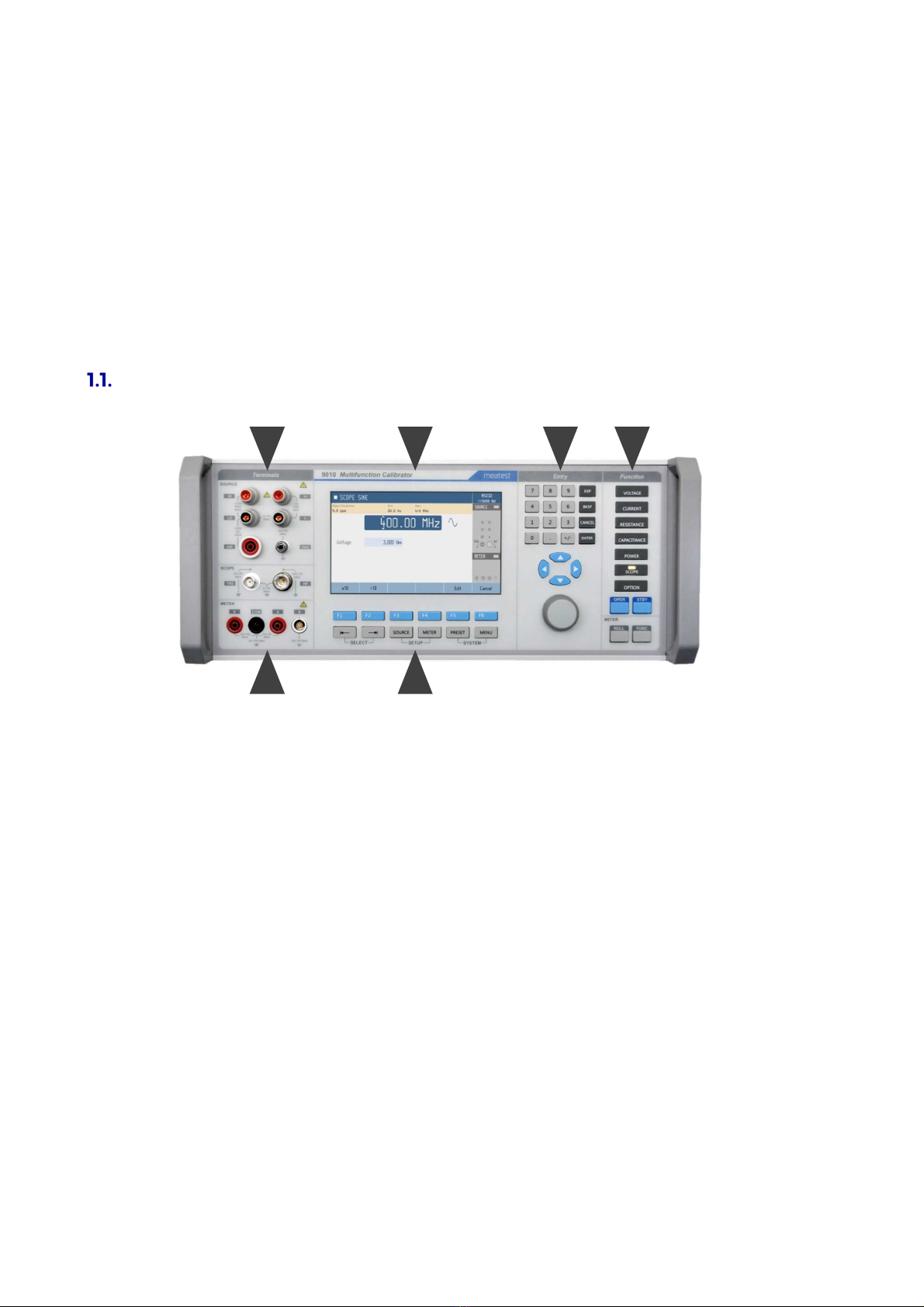

Figure 1 Front panel ........................................................................................................................................................................................... 6

Figure Input/output terminals ................................................................................................................................................................ 7

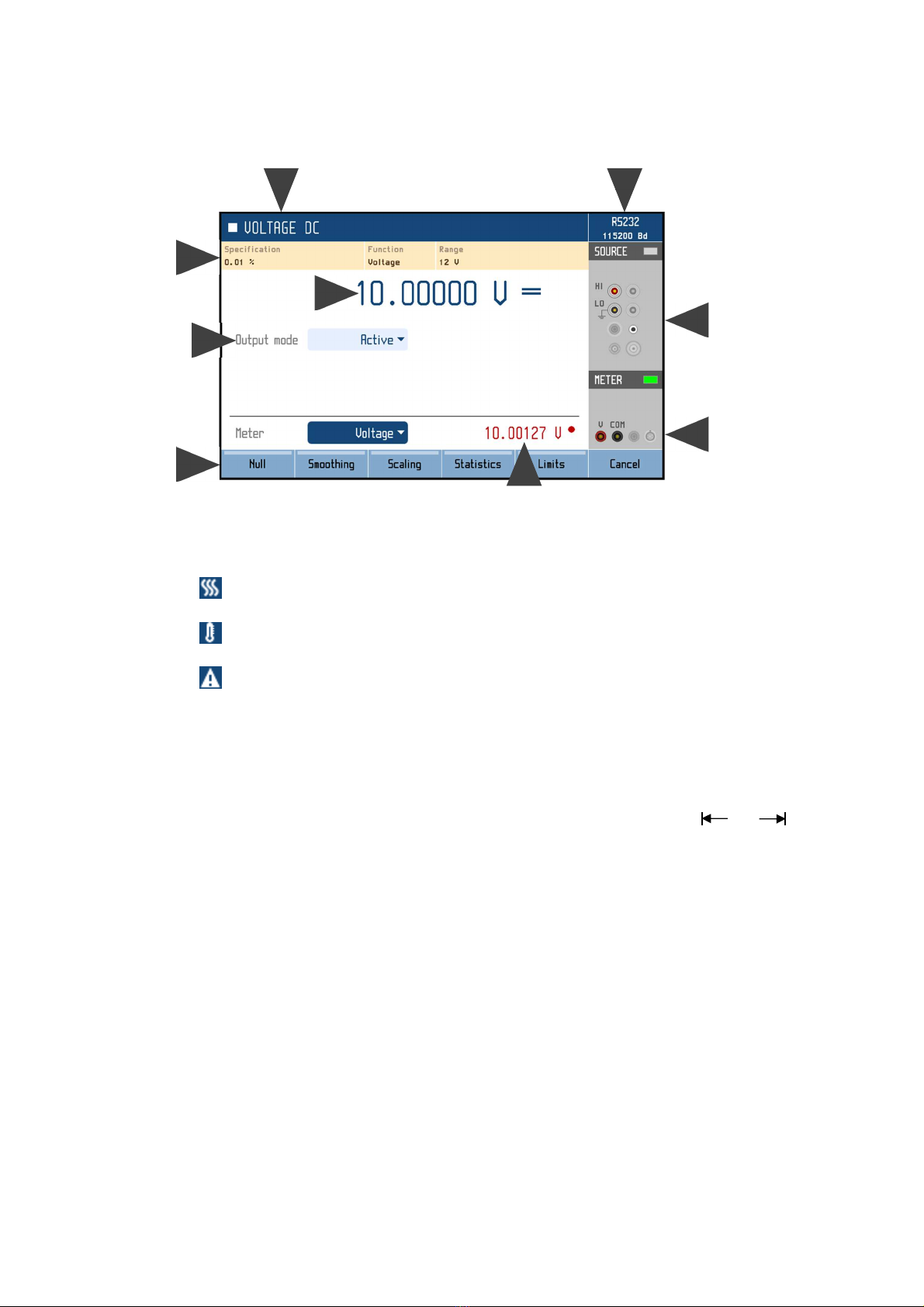

Figure 3 Display .................................................................................................................................................................................................... 8

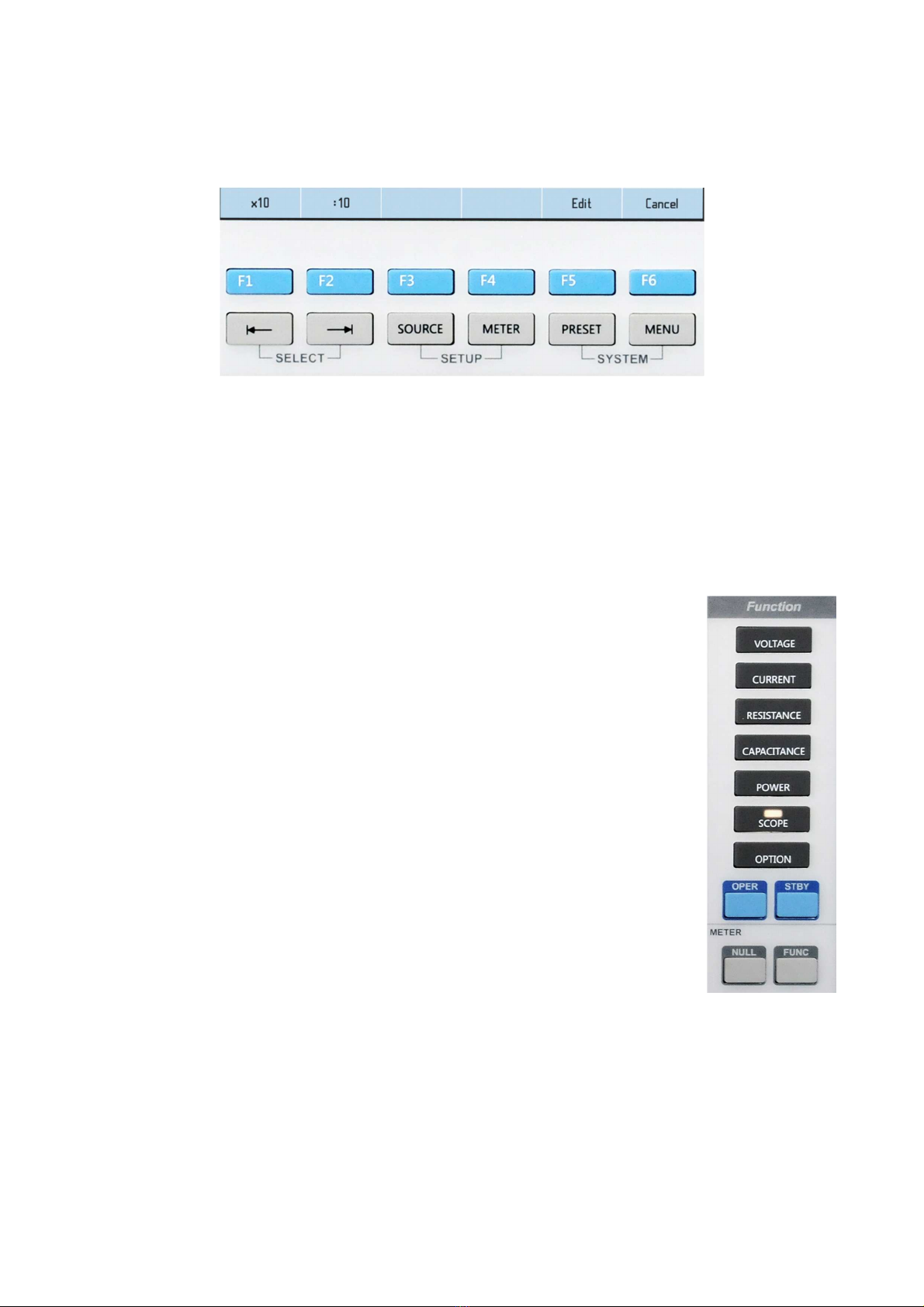

Figure 4 Softkeys and menu buttons ..................................................................................................................................................... 9

Figure 5 Function buttons ............................................................................................................................................................................. 9

Figure 6 Rear panel ......................................................................................................................................................................................... 10

Figure 7 Starting Screen ................................................................................................................................................................................ 13

Figure 8 Factory default screen ................................................................................................................................................................ 13

Figure 9 Main and auxiliary parameters ..............................................................................................................................................14

Figure 10 Main menu ....................................................................................................................................................................................... 15

Figure 11 Device/Setup menu .................................................................................................................................................................... 16

Figure 1 Preset function ............................................................................................................................................................................... 17

Figure 13 Voltmeter calibration ................................................................................................................................................................ 18

Figure 14 Harmonic products setting ................................................................................................................................................... 19

Figure 15 Signal preview ............................................................................................................................................................................... 19

Figure 16 List of preset waveforms ........................................................................................................................................................ 0

Figure 17 Voltage SETUP screen ............................................................................................................................................................... 1

Figure 18 Ammeter calibration ................................................................................................................................................................

Figure 19 Current SETUP screen .............................................................................................................................................................. 3

Figure 0 Two-wire resistance calibration ........................................................................................................................................ 4

Figure 1 Four-wire resistance calibration ......................................................................................................................................... 5

Figure High resistance calibration .................................................................................................................................................. 6