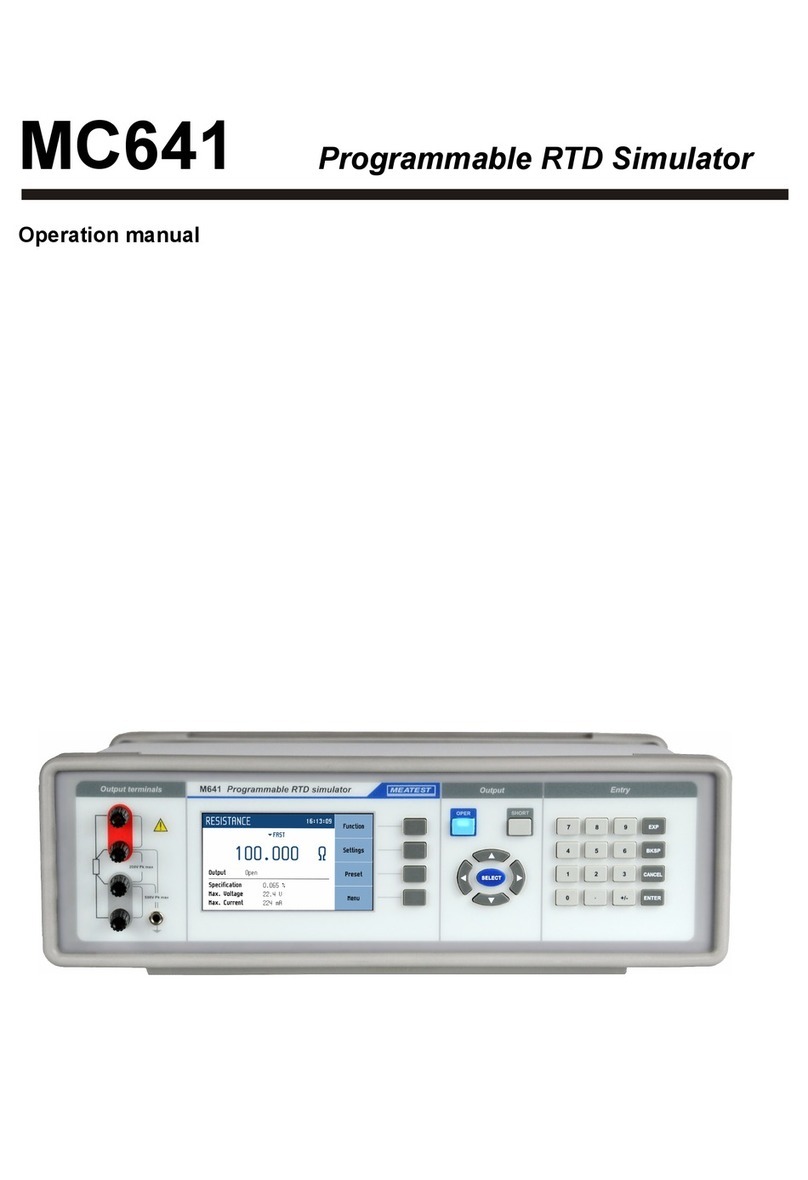

M631 Precision RTD Simulator MEATEST

3 Revision 22, FW 2.000 Operation manual

Content

1. BASIC INFORMATION....................................................................................................................... 5

2. PREPARATION FOR USE .................................................................................................................. 5

2.1. INSPECTING PACKAGE CONTENTS, SELECTING THE INSTALLATION LOCATION ..................................... 5

2.2. POWER ON ...................................................................................................................................... 5

2.3. WAR -UP TI E .............................................................................................................................. 6

2.4. SAFETY PRECAUTIONS ..................................................................................................................... 6

3. DESCRIPTION ..................................................................................................................................... 7

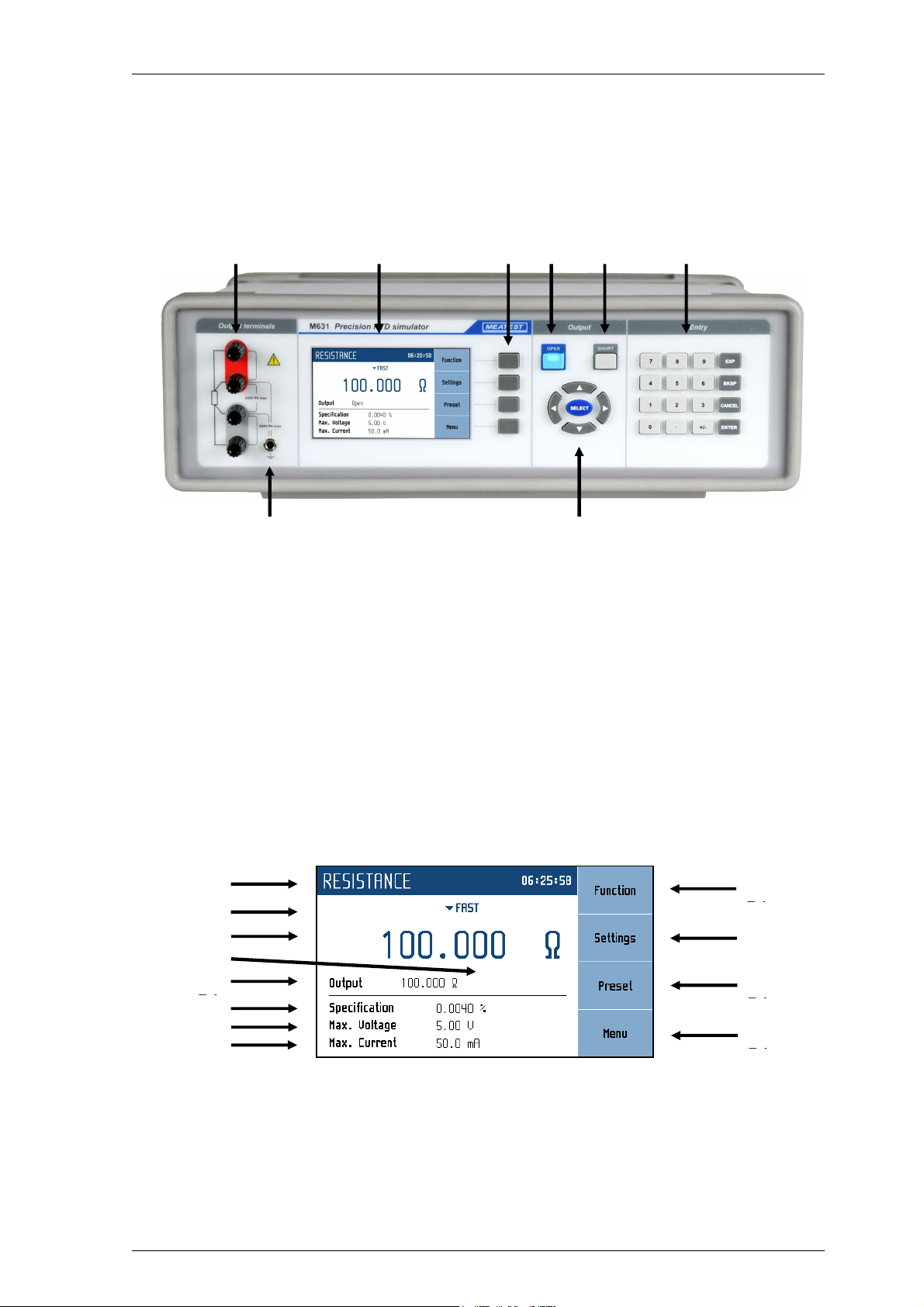

3.1. FRONT PANEL ................................................................................................................................. 7

3.2. REAR PANEL ................................................................................................................................... 9

4. OPERATION .......................................................................................................................................10

4.1. CONNECTION AND DISCONNECTION OF OUTPUT TER INALS .............................................................10

4.2. WIRES CONNECTION .......................................................................................................................10

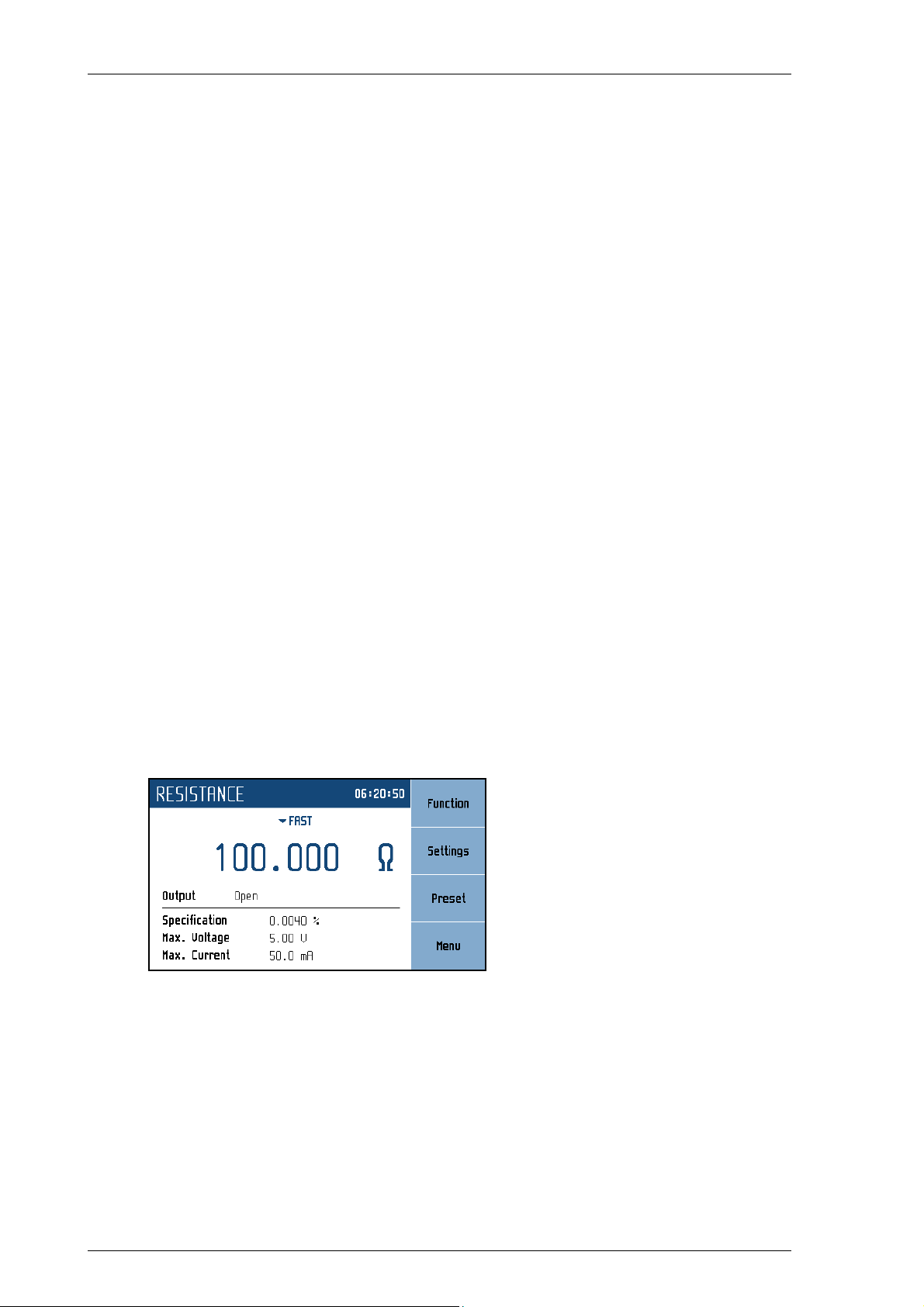

4.3. SETTING THE FUNCTION .................................................................................................................10

4.4. SETTING THE VALUE OF OUTPUT SIGNAL .........................................................................................17

4.5. PARA ETER SETTINGS (SETTINGS ENU) ........................................................................................18

4.6. PRESET ENU ................................................................................................................................18

4.7. AIN ENU ...................................................................................................................................19

4.8. CALIBRATION ODE ......................................................................................................................21

5. PERFORMANCE VERIFICATION TEST ........................................................................................24

6. REMOTE CONTROL .........................................................................................................................25

6.1. RS232 INTERFACE .........................................................................................................................25

6.2. GPIB INTERFACE (OPTION) ............................................................................................................26

6.3. LAN INTERFACE (OPTION) .............................................................................................................27

6.4. USB INTERFACE (OPTION) ..............................................................................................................28

6.5. CO AND SYNTAX .......................................................................................................................29

6.6. SCPI CO AND TREE ...................................................................................................................30

6.7. STANDARD STATUS DATA STRUCTURES .........................................................................................32

6.8. SCPI STANDARD CO ANDS ........................................................................................................34

6.9. SCPI CO ANDS ..........................................................................................................................38

6.10. SCPI ERROR CODES .......................................................................................................................63

6.11. CO PATIBLE CO ANDS ..............................................................................................................64

6.12. DE O PROGRA ............................................................................................................................65

7. MAINTENANCE .................................................................................................................................66

7.1. FUSE REPLACING ............................................................................................................................66

7.2. EXTERNAL SURFACE CLEANING ......................................................................................................66

8. MODULE 19” (VERSION M631 VXX1X)..........................................................................................66

9. TECHNICAL DATA ............................................................................................................................67

10. ORDERING INFORMATION – OPTIONS .......................................................................................69

CERTIFICATE OF CONFORMITY ...........................................................................................................70