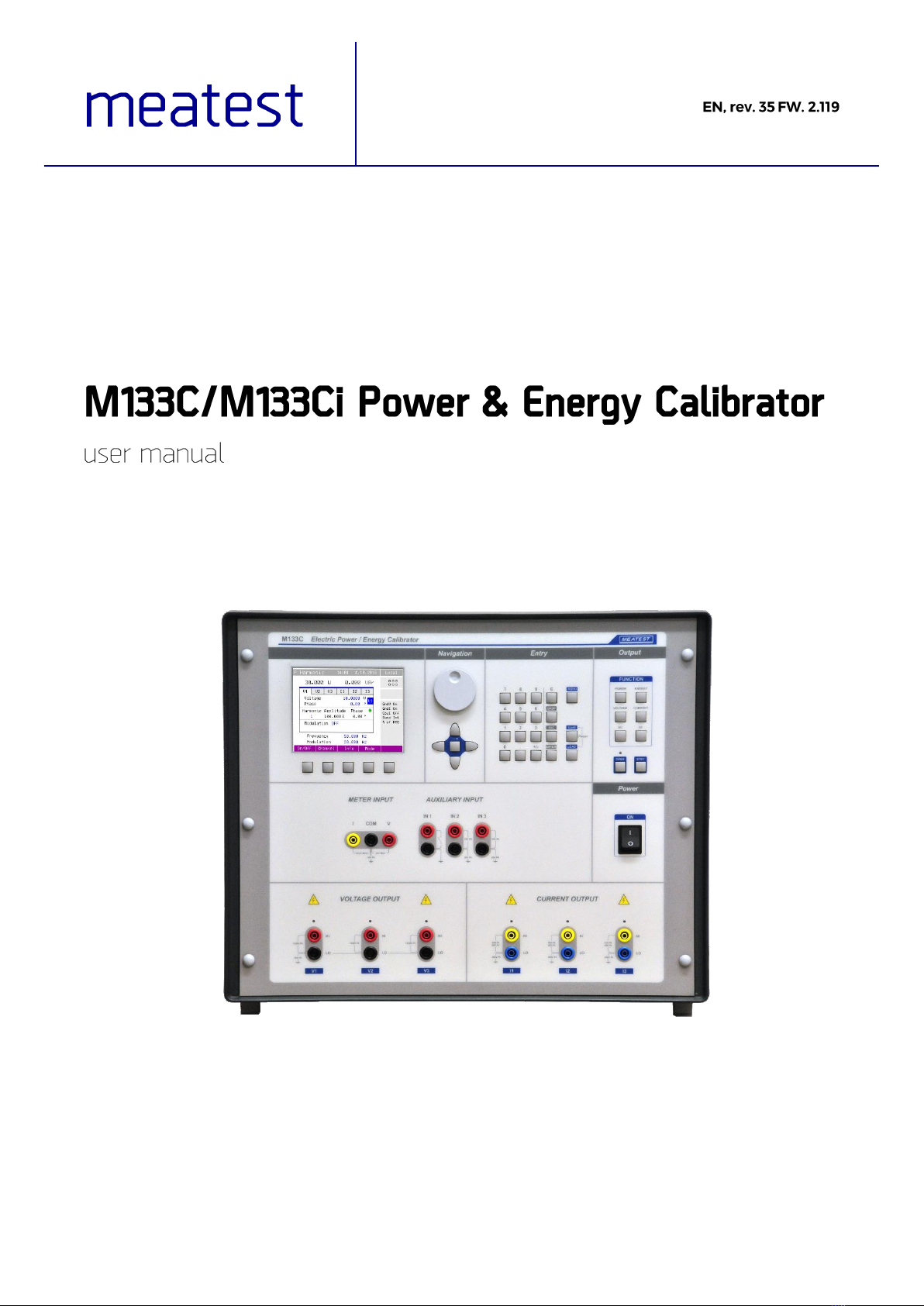

B) Main area - This section displays the set-up values of generated signals and the data related to

the calibrator status. The section includes the following types of data:

1. Main value - There is displayed main output value with the unit and indication of AC or DC

(picture). There is displayed also actual position of cursor if the parameter is in edit mode.

Position of cursor can be changed using keys , and parameter can be changed using keys

, or using the rotary knob. If output voltage exceeds 50V sign of danger voltage is

displayed before main value.

2. Auxiliary parameters - This section displays auxiliary parameters of actually selected function:

-Voltage (functions power and energy)

-Current (functions power and energy)

-Phase / Power factor (functions power and energy)

-Frequency (AC functions)

-Power (energy)

-Dose of energy (energy)

3. Measured value - Value measured using internal multimeter with unit. Value „over“ is displayed

if measured signal is out of range.

4. Outputs state - Window displays which phase units are connected (one phase to three phase),

which terminals are used for signal generation and also informs about output voltage higher

than 50V.

Symbols displayed in window:

- warning, displayed if output voltage is higher or equal 50V.

- phase unit (channel) is connected, output is off

- phase unit (channel) is connected, output is on

- phase unit (channel) is not connected

5. Specification

6. In the field specification of set-up output signal is shown. Uncertainty is related to the main

parameter. Label BUSY instead of uncertainty is displayed, if calibrator is not within specified

parameters or if internal reconnection is in process. This can occur during changing the

functions, changing set parameters, switching output terminals ON and OFF. Specification is

not available in power functions „P Harmonic“ and „P Interharmonic”.

7. Information section

The information section located in the right part of the display and displays additional

information related to the selected function:

-information about the grounding method of output terminals: GndU, GndI as set up

using the menu „Calibrator“.

-information about voltage terminal configuration (2-wire / 4-wire) as set up using the

menu „Calibrator“.

-information about the use of 25-turn coil or 50-turn coil (COIL x50) as set up using the

menu „Calibrator“.

-information about number of controlled output channels (only functions „Power Pac“

and „Energy Eac“).

8. Meter’s information section

C) Display softkeys - The functions of these keys change during operation (depends on actual

display mode).

2. Rotary knob - The rotary knob integrates several functions. By turning the knob to the left or right,

the user can:

-step through the options

-enter numeric values

The function of the rotary knob can usually be performed by the cursor buttons. The central button

is used to confirm the selection (Select) or change the function of the rotary knob (value change or

position change).

3. Numeric keyboard - The keyboard allows the entry of numeric values on the display. ENTER

button is used to confirm the selection. CANCEL button can be used to cancel the entry.

4. Direct keyboard - MENU button is used to open the Main menu of the instrument (parameters

petting). SAVE (RECALL) buttons can be used to save (recall) the actual setting of the instrument