Memjet Printware iJetColor Press Service manual

1 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

Service Station Removal and Cleaning

Summary:

Procedure for removing/re-installing and cleaning the service station

Applicable Products: iJetColor Press

Tools/Parts Required: Small Philips screwdriver

Cleaning/Replacing Service Station Items

The Service Station contains separate areas/devices that are used to perform the following tasks.

Cleaning. The Wiper Roller cleans the Printhead nozzles of excess ink and debris.

Printing/Purging. The Printing Platen acts as a base to support media during printing. It also contains a purging area;

which captures and absorbs ink that is purged, to help keep nozzles clear.

Capping. The Capping Station seals and protects the printhead nozzles when not in use.

Evacuating Waste Ink. In addition to the function of supporting the above items; the Service Station Tray is lined

with wicking material that absorbs the waste ink and transfers it out of the Tray and into the “waste ink trough”.

This waste ink then flows from the “trough” to the “Waste Ink Tray”, which is located behind the Ink Tank Door.

As the above components become worn/dirty, from use, they can lose their ability to perform as intended.

If you experience print quality issues that are not resolved by performing the steps found in the Troubleshooting Section

under “Print Quality Issues”; it may be time to have the Service Station, or components within the Service Station,

cleaned or replaced.

Please use nitrile powder-free gloves and have plenty of paper towels on-hand for these procedures.

CAUTION

THESE PROCEDURES SHOULD ONLY BE PERFORMED BY A

QUALIFIED/TRAINED PERSON.

2 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

Service

Station Slot

Removing the Service Station

1. Open the Top Cover

2. Open the Ink Tank Door (hinged at bottom) to expose the “Service

Station Slot”.

Tip: On older units you will need to

remove the Exit Roller Cover by

removing the four (4) screws. This is

not necessary on newer units.

3. Power-up the printer.

4. Open the Printer Toolbox. In the User Interface window,

press the “Eject Service Station” button.

5. Once the Service Station has ejected; power OFF the printer. Press the ON/OFF button once and wait about 45

seconds for the print engine to power off (all control panel light’s off). Then turn the Main Power Switch OFF.

WARNING

If the Printhead Cartridge is still installed; when you remove the Service Station, the

Printhead will remain un-capped. This can cause dehydration of nozzles and printing

issues. If you want to reduce the chance for printhead nozzle dehydration; it is highly

recommended that you eject the Printhead and follow the procedures described under

“Printhead Cartridge Storage and Handling”, before you begin this process.

Ink Tank

3 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

6. Slide the Service Station out of the Service Station slot. CAUTION: Do not pull

Station all the way out until you disconnect the Ribbon Cable.

NOTE: It is a good idea to place an absorbent towel under the Service Station

as you remove it to prevent any drips or leaks.

7. Disconnect the Ribbon Cable. Slide the Latch open on the Service Station

Circuit Board to release the Ribbon Cable.

CAUTION! This latch can be broken if you pull it out too far. Be careful!

8. Remove the Service Station completely from the print engine and place it on a non-absorbent surface (plastic

bag) to protect the surface you are placing it on.

9. If you are replacing or re-installing the Service Station, please see the

section titled

“Installing the Service Station”.

10. If you are cleaning or replacing items in the service station; please see the next section titled “Cleaning the

Service Station”.

4 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

Cleaning the Service Station

Caution: Please be sure that you are using proper cleaning techniques to clean items that come in contact with the

printhead. Use only distilled or deionized water and lint free cloths. If you don’t follow this rule, you will introduce

contamination into the printhead; which can damage the printhead and ink system.

Wiper Roller Removal and Cleaning or Replacement

Tip: Although the wiper roller can be cleaned; this process is time-consuming. When you factor in labor costs; you may

find it more cost-effective to replace the wiper roller instead. We also recommend that the wiper roller be replaced

whenever a new printhead is installed.

Removal:

1. Lift up, about one inch, on the Wiper Motor Assembly; to expose the latch

retaining screws [C] (one at each end).

NOTE: Early versions of this assembly did not have retaining screws.

2. Carefully loosen the two small screws retaining the wiper roller latches.

Tip: To avoid losing these screws; don’t remove the screws. You only need to back-

out the screws far enough so the latches can be opened.

3. Release the two latches that secure the wiper roller.

4. Remove the Wiper Roller from the Wiper Motor Assembly.

Wiper Motor Assy

5 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

Cleaning/Replacement:

1. Using distilled water; immerse for 10 minutes, then remove and pat dry with absorbent lint free towel.

WARNING! Do NOT rub the roller, when cleaning or drying it. This will cause damage to the roller fabric. Do NOT

use tap/mineral/spring water to clean the wiper roller; doing so will introduce contaminants into the roller. A

contaminated roller will cause damage to the printhead and ink system. Allow the roller to dry completely,

before re-installing it.

2. If the Wiper Roller shows signs of wear (fabric surface torn, un-even or fuzzy), it should be replaced. Be sure to

remove the plastic cover from the new Wiper Roller before installing it.

Install:

1. Re-install the Wiper Roller into the Wiper Motor Assembly. Make sure the gear on the Wiper Roller engages the

gear in the Wiper Motor Assembly.

TIP: If you are planning to clean the Wiper Motor Assembly; don’t re-install the wiper roller until you have

completed the Wiper Motor Assembly cleaning process.

2. Carefully close the latches. Make sure the latches are fully locked and then tighten the latch retaining screws [C]

(don’t over-tighten).

Wiper Motor Assembly Removal and Cleaning

Removal:

1. Disconnect (unplug) the wiper motor cable from the Service Station

Printed Circuit Board [A].

2. Remove the Printed Circuit Board [A] from the Service Station Tray.

Carefully release clips to remove board.

3. Lift out the Wiper Motor Assembly [B].

4. Remove the Wiper Roller from the Wiper Motor Assembly [C] [D]. See

procedure on previous page.

Cleaning:

1. Pour distilled water into a flat-bottom container to the depth of about

17mm.

2. Carefully immerse the Wiper Motor Assembly, motor side up, into the

water.

6 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

WARNING

DO NOT IMMERSE MOTOR OR GET

MOTOR WET; TO AVOID DAMAGE.

3. If vents are showing, carefully add more water until they are covered.

Allow the Wiper Motor Assembly to soak for 10 minutes.

4. Carefully remove the Wiper Motor Assembly. Inspect the vents and

remove any debris with tweezers. Pat dry with an absorbent lint-free

towel.

NOTE: If this assembly shows signs of wear or damage it should be

replaced. If the Service Station is more than one year old, depending on

monthly volume, it may be worthwhile to replace the entire Service

Station instead of replacing components.

5. Lightly lubricate the Wiper Motor Gears (3) with synthetic PTFE grease

(Super Lube 21030 or equivalent).

Install:

1. Allow the Wiper Motor Assembly to dry.

2. Re-install in reverse order.

NOTE: Make sure the wiper roller is re-installed, wiper roller latches are

fully closed/locked and the wiper roller retaining screws are fully

tightened (do not over-tighten).

TIP: If you are planning to clean the Service Station Tray; don’t re-install

this component until you have completed the Service Station Tray

cleaning process.

Printing Platen and Capping Station Removal and Cleaning

Removal:

Both of these items simply lift out for removal from the Service Station.

Cleaning:

1. Rinse off ink using tap water.

Tip: Make sure the valve, located on the bottom of the Capping Station, is clear of debris and working.

2. Pat dry with an absorbent lint-free cloth.

7 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

3. After cleaning the Capping Station; wipe the capping lip with a lint free cloth, dampened with distilled water.

This will help insure that the contaminants on the cap are removed, before the cap makes contact with the

printhead.

NOTE: If either of these items show signs of wear or damage they should be replaced. If the Service Station is

more than one year old, depending on monthly volume, it may be worthwhile to replace the entire Service

Station instead of replacing components.

Install:

1. Allow the Printing Platen and Capping Station to dry.

2. Reinstall Printing Platen and Capping Station into Service Station Tray.

TIP: If you are planning to clean the Service Station Tray; don’t re-install this component until you have

completed the Service Station Tray cleaning process.

Cleaning the Service Station Tray

1. If present; remove the Service Station Printed Circuit Board, Wiper Motor Assembly, Printing Platen and Capping

Station from the Tray; as described on the previous pages.

2. Wipe the Tray with a damp, lint-free cloth to remove the major ink buildup. Be careful not to damage/peel-off

the wicking material; from the surface of the Tray.

3. Then rinse the Tray using tap water.

4. Allow the tray to dry.

NOTE: If the Tray shows signs of wear or damage (wicking material torn or coming loose from surface of tray)

the Tray should be replaced. If the Service Station is more than one year old, depending on monthly volume, it

may be worthwhile to replace the entire Service Station instead of replacing components.

5. Reinstall the Service Station Printed Circuit Board, Wiper Motor Assembly, Printing Platen and Capping Station,

into the Tray; as described on the previous pages.

Suggestion for High Volume Users:

For printers that are being used at high volumes (over 200,000 pieces per month), we recommend purchasing a second

service station to reduce down-time for Service Station Maintenance. The new/clean service station can be swapped

with the dirty one. Then the dirty Service Station can be cleaned according to the above instructions and made ready for

the next time Service Station Maintenance is required.

8 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

Service

Station Slot

Installing the Service Station

CAUTION

THIS PROCESS MUST BE PERFORMED BY A QUALIFIED/TRAINED

PERSON.

Please use nitrile powder-free gloves and have plenty of paper towels on-hand for these procedures.

The Service Station fits in the slot immediately above the Ink Tank slots.

PROCEDURE:

1.

Make sure the printer is powered OFF.

If the printer is not powered off, press the ON/OFF button once and wait about 45 seconds for the print engine

to power off (all control panel light’s off). Then turn the Main Power Switch OFF.

2.

Open the Top Cover.

3.

Open the Ink Tank Door (hinged at bottom) to expose the “Service

Station Slot”.

Tip: On older units you will need to

remove the Exit Roller Cover by

removing the four (4) screws. This is

not necessary on newer units.

4.

If you are installing a New Service Station; carefully remove the Service Station from its packaging.

NOTE: Loose parts may fall out. Keep wiper roller side facing up, when removing the packaging.

5.

Check to be sure that the wiper roller latches are secure.

Check the latch at each end

of the wiper roller.

Ink Tank

9 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

Tighten

6.

Slide the Cable Securing Latch open on the Service Station Circuit Board; as shown below.

7.

Locate the Ribbon Cable (from within the Service Station Slot).

Insert the Ribbon Cable (blue side up) into the space under the Cable

Securing Latch [1].

Make sure the ribbon cable is pushed in all the way and is NOT crooked.

Then close the Cable Securing Latch [2].

CAUTION!

Make sure the latches for the Wiper Roller are fully latched and

secured before installing the Service Station. Current

versions of this assembly also have latch retaining screws

that secure the latches from opening in transit or use. Make

sure theses screws have been tighten (do NOT over-tighten).

NOTE: Early versions of this assembly did not have latch retaining screws.

Closed Opened

Open Close

1 2

Ribbon

Cable

Service

Station

10 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

Wiper Roller end

of Service Station

Ribbon Cable

Connected to Service

Station Circuit Board

8.

Once the Ribbon Cable is properly connected to the Service Station Circuit Board; gently slide the Service

Station, wiper roller end first, into the Service Station Slot until it stops. The Service Station fits into the slot

immediately above the Ink Tank slots.

NOTE: The Ink Tank Door must be open to perform this procedure.

9.

Look down through open area, in the Print Engine, to make sure the

Service Station is aligned with the “Bar”; (Service Station Drive Shaft) as

shown.

If the Printhead Cartridge is not installed (has been removed), you can look

down through the top of the Print-Engine, through the Printhead Cartridge

opening.

If the Printhead Cartridge is still installed,

you must open the Clamshell to see into this

area; as shown.

IMPORTANT!

The Service Station must perfectly aligned with the “Bar” to prevent misalignment and jamming of the service

station.

11 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

You don’t need to open the Print

Engine. Shown for clarification purpose

10.

GENTLY push in on the Service Station with one hand, while slowly turning the “Large Gear” clockwise with the

other hand. It should be easy to turn this gear and the service station should start to drive into the print engine

squarely.

Once the Service Station moves about ¼ inch past the “Bar” (shown in previous step), stop turning the gear. Do

NOT manually drive the Service Station into the print engine beyond this point.

NOTE: The “Large Gear” is located on the non-operator side of Print Engine; as shown below. You don’t need to

open the Print Engine to access this gear.

11.

Turn the printer’s Main Power Switch ON; then press the control panel’s ON/OFF button.

After printer initialization (~45 seconds) the Print Engine will automatically pull the Service Station the rest of

the way in.

NOTICE: If the Service Station should get jammed during this process (you hear motor stall noise or gear slipping

noise); immediately turn OFF the printer’s Main Power Switch. This is one of the only exceptions for turning off

the printer using the main power switch, before properly powering-down the print engine. Remove the Service

station by turning the Large Gear counter-clockwise. Re-check that the Wiper Roller is properly installed and

latched at each end. Then re-install the Service Station starting from step 8 above.

Tip: The “Eject Service Station” button, located in the M Series Toolbox, should be used if the service station

needs to be removed in the future.

12 www.iJetColor.com

Product Technical Bulletin

PTB0625 06.23.14

12.

Verify that the wick, located on the bottom of the Service Station, is hanging into the

waste ink trough; as shown (as viewed looking into the Service Station Slot, from the

exit end of the printer).

13.

Close the Ink Tank Door.

NOTE: If using an older printer you will need to re-install the Exit Roller Cover

plate, using the 4 screws, before closing the Ink Tank Door.

Make sure the cover is installed in the proper orientation.

TIP: Since the Exit Roller Cover is also an integral part of the frame structure;

you may need to push in on the outer frames to get the screw holes in the

Exit Roller Cover to align.

14.

Close the Top Cover

15.

Power the printer on and Test for proper operation.

Still Experiencing Print Quality Issues?

If you still experience print quality issues, after performing all the cleaning processes, outlined in this section, please

refer to the “Troubleshooting Guide” for additional help. If you have exhausted all cleaning and troubleshooting options,

and you have replaced the Printhead Cartridge and Wiper Roller; then this may indicate that the printer requires

technical service.

WARNING

Waste-ink from the Service Station flows through

wicking material and out the hole, located on the bottom

of the service station. If this wicking material is not

directed into the trough; waste-ink will build up on the

base of the Service Station Slot. This misdirected waste-

ink will eventually find its way onto the Ink Tanks, inside

the body of the printer and even under the printer;

causing damage to the system.

Ink Tank

Other Memjet Printer manuals

Memjet

Memjet VIP Color VP5 Series User manual

Memjet

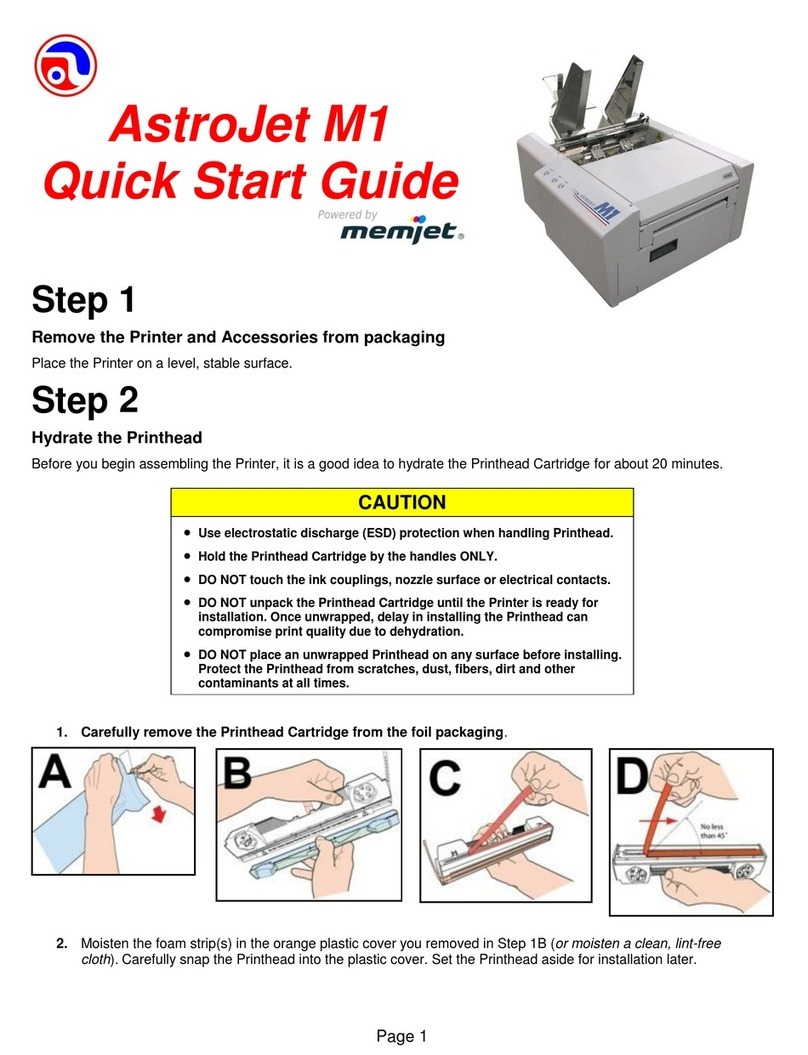

Memjet AstroJet M1 User manual

Memjet

Memjet icube 1-3 Owner's manual

Memjet

Memjet OWN-X Speedstar 1000 Instruction manual

Memjet

Memjet C6010 User manual

Memjet

Memjet SFP User manual

Memjet

Memjet AstroJet M1 User manual

Memjet

Memjet VIPColor VP750 User manual

Memjet

Memjet Quadient Rena MACH 6 User manual

Memjet

Memjet MACH 5 User manual