METER AQUALAB User manual

AQUALAB© VSA

i

TABLE OF CONTENTS

1. Introduction.............................................................................................. 1

2. About the VSA..........................................................................................2

2.1 Moisture Sorption Isotherms ..................................................................... 2

2.2 Measurement Method................................................................................3

2.3 Specifications............................................................................................4

2.4 User Interface and Menus..........................................................................5

2.4.1 Isotherm Tab ....................................................................................6

2.4.2 Measurement Tab ............................................................................7

2.4.3 Configuration Tab.............................................................................7

2.4.4 Data Tab......................................................................................... 15

3. Theory........................................................................................................ 18

3.1 Combining DVS and DDI in One Instrument ............................................. 19

3.2 Hysteresis................................................................................................ 20

3.3 Nonequilibrium........................................................................................ 22

3.4 Matrix Changes........................................................................................ 22

3.5 Working Isotherms................................................................................... 23

3.6 Isotherm Models...................................................................................... 24

3.7 Uses for Moisture Sorption Isotherms ..................................................... 25

4. Installation.............................................................................................. 27

5. Cleaning and Maintenance ............................................................ 31

5.1 Desiccant Replacement........................................................................... 31

5.2 Sample Chamber Cleaning....................................................................... 34

13832-07

2.2022

ii

5.2.1 Cleaning Kit ................................................................................... 34

5.2.2 Cleaning Procedure........................................................................ 35

5.3 Capacitance Filter Replacement.............................................................. 36

5.4 Maintenance Packages............................................................................ 37

6. Verification and Calibration........................................................ 38

6.1 Water Activity Verification ....................................................................... 38

6.1.1 Verification Standards ................................................................... 38

6.1.2 Verification of Calibration .............................................................. 39

6.2 Linear Offset ............................................................................................ 41

6.3 Adjusting for Weight Measurement Offset............................................... 42

6.4 Restore Factory Defaults ......................................................................... 43

6.5 Isotherm Standard Comparison............................................................... 44

7. Running a Test....................................................................................... 46

7.1 Becoming Familiar with Stages................................................................ 46

7.2 Moisture Analysis Toolkit Software.......................................................... 46

7.3 Running a Moisture Sorption Isotherm Test............................................. 46

7.4 Using DDI to Investigate Glass Transition ................................................ 53

7.5 Creating a Working Isotherm ................................................................... 53

7.6 Editing a Running Isotherm Test .............................................................. 54

7.7 Running a Water Activity Test .................................................................. 55

8. Sample Preparation........................................................................... 56

8.1 Coated and Dried Samples....................................................................... 57

8.2 Low Water-Emitting Samples .................................................................. 57

8.3 Volatile Samples ..................................................................................... 58

8.4 Low Water Activity ................................................................................... 58

9. Service....................................................................................................... 59

9.1 Troubleshooting ....................................................................................... 59

9.2 Customer Support.................................................................................... 64

9.3 Repair ...................................................................................................... 65

9.4 Terms and Conditions .............................................................................. 65

Index ................................................................................................................. 67

1

1. INTRODUCTION

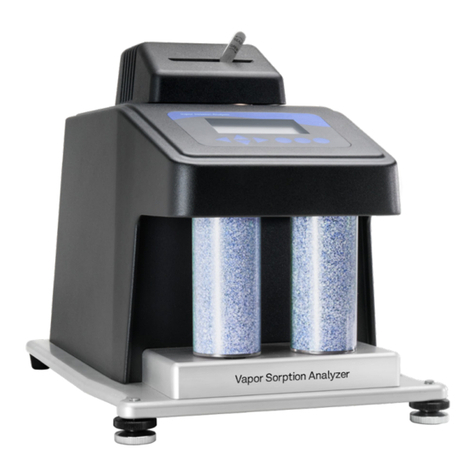

Thank you for choosing the AQUALAB Vapor Sorption Analyzer (VSA) from METER Group.

The VSA is an automatic isotherm generator from the world leaders in water activity

measurement. The VSA is the only automatic isotherm generator that can generate

isotherms using both the Dynamic Vapor Sorption (DVS) method, which generates

equilibrium isotherms, and the Dynamic Dew Point Isotherm (DDI) method, which generates

dynamic isotherms. By combining both methods in one instrument, the VSA makes it

possible to investigate both dynamic matrix changes due to water sorption and the kinetics

of those changes. This manual details VSA operation and provides information on the

capabilities of the VSA.

This manual includes instructions for setting up your VSA which includes setting up an

isotherm test, running a test, collecting data, and analyzing data. Please read the manual

before operating the VSA to ensure the instrument performs to its full potential.

METER provides this manual to aid the end user in understanding the basic concepts of

moisture sorption isotherms, enabling them to use our instruments with confidence. METER

has made every effort to ensure the content of this manual is correct and scientifically sound.

Verify all VSA components are included and appear in good condition:

• AQUALAB VSA Isotherm Generator main unit

• Calibration certificate

• Power cord

• USB cable

• 2 stainless steel sample cups

• 3 refillable desiccant tubes

• 2 bottles (1 for water; 1 for air)

• AQUALAB Cleaning Kit

• Three vials each of the following verification standards solutions:

0.920 aw2.33 mol/kg NaCl

0.760 aw6.00 mol/kg NaCl

0.500 aw8.57 mol/kg LiCl

0.250 aw13.41 mol/kg LiCl

• Moisture Analysis Toolkit Software Package with registration key

• 1 2-g NIST traceable weight

• Tweezers

NOTE: Please keep your original instrument shipping box. If the VSA needs to be returned to METER, it must be

shipped in the original packaging.

2

ABOUT THE VSA

2. ABOUT THE VSA

The VSA Isotherm Generator is an automatic moisture sorption isotherm generator that can

generate both dynamic and equilibrium moisture sorption isotherms.

2.1 MOISTURE SORPTION ISOTHERMS

A moisture sorption isotherm defines the relationship between water activity (aw) and

moisture content at a given temperature. This relationship is complex and unique for each

product due to different interactions (colligative, capillary, and surface effects) between the

water and the solid components at different moisture contents. An increase in awalmost

always accompanies an increase in water content, but in a nonlinear fashion. Moisture

sorption isotherms are sigmoidal in shape for most foods, although foods that contain large

amounts of sugar or small soluble molecules have a J-type isotherm curve shape.

Isotherms provide information about product quality and safety. A few uses for

isotherms include:

1. Monolayer moisture content determination.

2. Determine critical water activity or moisture content.

3. Limits for crispness, hardness, and flow properties.

4. Optimize moisture contents at a safe water activity that maximizes moisture and avoids

over drying.

5. Determine shelf-life and storage stability of a product.

6. Predict packaging requirements based on sorption properties of a product.

7. Determine kinetics of sorption and water vapor diffusion coefficients

8. Determine the equilibrium water activity of a mixture of dry ingredients.

9. Determine the degree of crystallinity of powders.

10. Determine the level of amorphous material in a product.

11. Determine critical water activities for phase transitions.

12. Determine the relationship between water activity and glass transition temperature.

13. Determine the relationship between water activity and crystallization.

14. Determine hysteresis levels for a product.

15. Determine the moisture sensitivity of a product.

16. Determine the equilibrium moisture content at a given water activity.

17. Allow rapid moisture content determination from water activity analysis through an

isotherm curve.

3

AQUALAB VSA

2.2 MEASUREMENT METHOD

The VSA is the only automatic isotherm generator that can create isotherms using both

dynamic and static methods. The VSA uses the Dynamic Dew Point Isotherm (DDI) method

to produce dynamic isotherms and a controlled humidity and balance system, commonly

referred to as Dynamic Vapor Sorption (DVS), to produce static or equilibrium isotherms.

The DDI method for dynamic isotherms is a water activity and gravimetric analysis method

that controls neither water content nor water activity, but dries or wets the sample and

measures water activity and water content during the wetting or drying process. The VSA

determines water content by weighing the sample using a high precision magnetic force

balance and water activity with METER’s patented chilled-mirror dew point sensor. The VSA

imposes drying of the sample by flowing dry air from a desiccant tube across the sample

and wetting of the sample by saturating the air with water before it enters the chamber to

flow across the sample. The VSA water reservoir mounts to the temperature controlled lower

block to ensure humidity saturation and minimize temperature fluctuation.

The DVS method for static or equilibrium isotherms consists of tracking sample weight

change as the sample is exposed to different controlled humidities. The sample is held at

each humidity for a preset time interval or until a steady state weight change is achieved,

the goal being to achieve equilibrium between the sample water activity and the controlled

humidity. Customers typically choose several humidity levels to preset during the set

up process. The instrument then tracks equilibrium progress at each humidity level and

automatically steps to the next humidity when equilibrium requirements are achieved.

Weight change versus time data is recorded allowing for determining kinetics of sorption

for each humidity level. Using less stringent equilibrium settings for weight change or

setting a reduced time interval at each step can speed up the isotherm test, but may give

nonequilibrium results. In addition, setting smaller steps in humidity increase the data

resolution of the isotherm, but at the expense of much longer test times.

The VSA is a stand-alone instrument with an integrated pump system that eliminates the

need for an external gas cylinder, however you can use an external gas source if desired.The

instrument consists of a case which houses the power supply, air pump, balance, temperature

controlled sample chamber, sensor block, sensor and temperature control electronics, water

reservoir, and desiccant supply. Setup is as simple as plugging the instrument in, installing the

desiccant tubes, and filling the water reservoir. Test parameters can be set using an on-board

interface or using a connected computer and VSA software package.

4

ABOUT THE VSA

2.3 SPECIFICATIONS

MEASUREMENT SPECIFICATIONS

Water Activity

Range 0.030–0.95 aw (3%–95% RH)

Resolution 0.0001 aw (0.01% RH)

±0.001 aw(0.1% RH) for volatiles setting

Accuracy ±0.005 at 25 °C

Temperature

Range 15–50 °C

Resolution 0.01 °C

Accuracy ±0.1 °C

Adjustment Increment 1 °C

Read Time

~5 min

Isotherm Methods

Dynamic Dew Point Isotherm (DDI) and Static (DVS)

External Gas

7 psi max

Mass Resolution

0.5 mg

PHYSICAL SPECIFICATIONS

Case Dimensions

Length 38.1 cm (15.0 in)

Width 26.7 cm (10.5 in)

Height 30.5 cm (12.0 in)

Case Material

POLYLAC PA-765 (ABS) with fire retardant

Sample Cup Capacity

14 mL (0.47 fl oz)

5

AQUALAB VSA

Weight

14.9 kg (33.0 lb)

Display

64 × 128 graphical

Operating Temperature

Minimum 4 °C

Typical 23 °C

Maximum 50 °C

Operating Environment

0%–90% RH noncondensing

Data Communications

USB

Power

110–220 VAC 50/60 Hz

COMPLIANCE

Manufactured under ISO 9001:2015

EM ISO/IEC 17050:2010 (CE Mark)

2.4 USER INTERFACE AND MENUS

The AQUALAB VSA is a standalone instrument with arrows and three buttons useful for

navigating menus and beginning tests. There are four tabs at the top of the display screen,

the Isotherm, Measurement, Configuration, and Data tabs. These tabs indicate the four

menus. The button icons on the display change to show the available actions for the screen

(Table1).

6

ABOUT THE VSA

Table1 AQUALAB VSA button icons

Icon Name Action

Enter Accepts the current action

CANCEL Ends the current action

MENU Switches between the Isotherm, Measurement, Configuration, and

Data tabs

SAVE Saves a setting or a reading

OK Accepts the input from the user

GRAPH Shows graph view

WIZARD Brings up Test Setup Wizard

AUDIO OFF Silences beeping

AUDIO ON Enables beeping

2.4.1 ISOTHERM TAB

The Isotherm tab is the main screen and displays each time the VSA turns on. If the Isotherm

tab screen does not appear, refer to Section9.1 for troubleshooting. Operators can initiate

a new test from this screen by pressing the wizard icon (third button from right). If a test is

already running, this screen displays the latest test values including water activity, weight or

% moisture content and temperature. Pressing the second button activates the chart view.

Figure 1 Isotherm tab

7

AQUALAB VSA

2.4.2 MEASUREMENT TAB

The Measurement tab allows you to take water activity readings of the sample in the sample

chamber when not running a test. Pushing the right or left arrow keys changes the display

to a temperature equilibration screen that shows the temperature difference between the

sample temperature and the lid temperature.

Figure 2 Measurement tab

2.4.3 CONFIGURATION TAB

The Configuration tab allows the operator to view various configuration options. Pressing the

up and down arrows moves through the configuration options, while pressing the right and

left arrows allow the operator to page through the options.

Figure 3 Configuration tab menu

8

ABOUT THE VSA

2.4.3.1 CALIBRATION

Highlight “Calibration” and press the Enter button to open the Calibration menu where you

can make either a water activity or weight adjustment.

For more details on weight and water activity calibration procedures refer to Section6. You

may also reset the calibration to the factory defaults by highlighting the Defaults option in

the calibration menu and pressing Enter.

Figure 4 Calibration option

2.4.3.2 VOLATILES

The instrument gives accurate readings on most samples when the default volatiles

setting is “Off.” When reading with volatiles off the chilled mirror method is used by default.

However, samples with certain volatiles in high enough concentrations may give inaccurate

water activity values. This is because the volatiles condense on the mirror during the reading

process, but do not evaporate from the mirror as water does. The concentration of volatiles

that causes interference is variable and matrix dependent.

The most effective method to determine if volatiles are a problem is to compare dew point

readings to capacitance readings. If the dew point readings are more than 0.02 higher than

the capacitance readings, volatiles are likely a problem and it is recommended that the

volatiles setting be switched to On. When you turn the volatiles setting on, the instrument

only uses the capacitive relative humidity sensor for water activities measurements and

isotherm tests. All other operations and features are the same, including measurement

times and adjusting for linear offset. Press Enter to toggle the volatiles setting on and off.

2.4.3.3 WEIGHT REFERENCE

Weight reference is the reference used when calculating the percent change in weight of the

sample. This can be based on the initial weight of the test, the starting weight of the stage

or the minimum weight during the test. Use this reference anytime you are calculating a

percent weight.

9

AQUALAB VSA

2.4.3.4 BASIS

The VSA generates water activity values and corresponding sample weights during moisture

desorption and resorption.To complete the isotherm, the sample weights must be translated

into moisture contents. Moisture content can be calculated in different ways and reported with

a variety of different units. The basis parameter allows the reporting of moisture content in two

different ways, percent moisture on a wet basis and percent moisture on a dry basis.

Equation 1

Equation 2

For food applications, moisture contents are reported on a wet basis.

A simple equation converts between the wet and dry basis.

Equation 3

Equation 4

2.4.3.5 DATE

The VSA has an internal calendar and clock that allow it to record the time and date of each

water activity reading. Press Enter with the Date option highlighted to set the date in the

instrument. Press the left and right arrows to change between the month, day and year. Press

the up or down arrows to change any of the individual values.

Figure 5 Date screen

10

ABOUT THE VSA

2.4.3.6 TIME

Pressing Enter with the Time option highlighted allows you to set the current local time.

Press the up or down arrows to change any of the individual values. Press the left or right

buttons to change between hour and minutes. The hour setting automatically changes

between AM and PM.

Figure 6 Time screen

2.4.3.7 awSETTINGS

Settings related to water activity measurements can be updated here. These include default

system temperature, temperature equilibration tolerance, and beeps.

Figure 7 awSettings screen

2.4.3.8 TEMPERATURE

This setting determines the temperature that the instrument maintains during water activity

measurements. It is also the temperature that the instrument returns to after completing

a test. The default temperature is 25 °C. Press the Enter button to change the temperature

setting. You can set the VSA anywhere between 15 and 60 °C in 0.1 °C intervals. Use the up

and down arrows to set the VSA to your desired temperature.

11

AQUALAB VSA

2.4.3.9 TEMP EQ

Temperature Equilibration Tolerance or “Temp Eq” sets the maximum difference allowed

between the lid and the sample. This lid to sample temperature difference must be less

than the Temp Eq in order to start a water activity measurement. If a sample is out of this

range, the VSA waits for the sample to equilibrate prior to beginning the water activity

measurement. 4 °C is the default setting.

2.4.3.10 BEEPS

Indicates the number of audible beeps after a water activity measurement is completed. You

can set this value to off (0), 4, or infinity (∞).

2.4.3.11 REGIONAL FORMATTING

Allows you to configure how the VSA displays information. You may choose the temperature

scale (Celsius vs Fahrenheit), the date display (mm/dd/yy vs. dd/mm/yy), the hour format

(12 vs 24 hour) and the language. Press Enter to switch the setting.

Figure 8 Regional formatting screen

2.4.3.12 ADMIN SETTINGS

Allows you to create an administrator password as well as add, edit and delete additional

users. The Admin option allows the administrator to grant or block access to some or all of

the configuration options.

For example, if the administrator wanted to make sure that all samples were read at 25 °C

the administrator would set their temperature to 25 °C and then would lock all other users

out of that Configuration screen. This is accomplished by entering the Access function and

selecting the desired option to toggle it on and off. Additionally you can lock and unlock

all of them at once. (For example, if you do not want an individual changing the instrument

measurement temperature, the administrator can lock that function for that individual.)

Administrators can lock the calibration, temperature, temperature equilibration, sensor

selection, mode, date/time, region, password, autosave, number of beeps, contrast, and

delete functions.

12

ABOUT THE VSA

2.4.3.13 USER SETUP

Users can be added, edited or deleted from this screen. To add a user, press the Enter button

with the “New” highlighted. To edit or delete a user, choose the target user and press Enter.

When creating a new user, an alphabet screen appears where you can enter a name using

lower case, upper case and accents.

Figure 9 User screen

NOTE: User setup is not required for instrument operation. It is available for users wanting to be compliant with

21 CFR Part 11 or who want to maintain the settings they have selected.

2.4.3.14 AUTO RESTART

Auto restart enables the instrument to automatically resume the currently running test if

there is a power failure of any kind. Press Enter to toggle auto restart between on and off.

METER recommends this be set to on to prevent data loss. Note: Restart tests with a new

sample if power outages last more than 30 minutes.

2.4.3.15 LIGHTING

Turns the lighting in the desiccant tube area on or off.

2.4.3.16 EXTERNAL GAS

Enables or disables the use of external gas. When External Gas is On, the external gas serves

as the air source for sample desiccation and wetting. When External Gas is Off the internal

pump uses ambient air as the air source.

NOTE: When you use the external gas,it exhausts into the atmosphere.Be sure to provide adequate ventilation and

safety measures while using an external gas supply with the instrument. Do not use combustible or hazardous gases.

To turn external gas on, highlight “External Gas: Off” and press Enter. The External Gas

screen appears.

13

AQUALAB VSA

Figure 10 External Gas screen to turn on gas

To start using external gas, remove the external gas plug from the back of the VSA and insert

the desired gas source. Adjust the external gas pressure until it is between 5 and 35 kPa

(0.7 to 5 psi). The VSA hides the Check Mark until the gas is within the acceptable pressure

range. Press the Check Mark to enable external gas or escape to cancel.

NOTE: When selecting a gas source, choose a gas supply with a filter system that eliminates oil and other

particulates to help prolong the life of your VSA. Make sure to keep the external gas plug to use when you remove

the external gas source.

If the external gas is turned on in the Configuration tab and you want to turn it off, pressing

Enter causes the External Gas screen to appear.

Figure 11 External Gas screen to turn off gas

To stop using external gas, turn off the external gas source and remove the external gas

tubing and adapters from the back of the instrument. Reinstall the external gas plug and

then press the Check Mark to disable external gas or the X to return to the Configuration tab

without changing the setting.

2.4.3.17 CONTRAST

Allows adjustment to the screen contrast. Viewing the screen from a sitting versus a

standing position may require contrast adjustment for the best visibility in that position.

14

ABOUT THE VSA

Figure 12 External Gas screen to turn off gas

2.4.3.18 DIAGNOSTICS

The Diagnostics screen provides you with detailed information about all the sensors in the

instrument. Refer to Section9.1 for details on what kind of values you should expect for each

sensor. Press up or down to page between the different Diagnostics screens.

Figure 13 Diagnostics screen menu

The scale icon on the bottom of the second screen allows you to zero the balance so that

you can take weight readings via the diagnostic screen. The icon labeled “Act” toggles the

actuator system on and off. With the lid open, pressing this button causes the weigh pan and

actuator cylinder to alternatively rise and fall if working properly.

On startup, the pump is turned on and flows dry air into the chamber to monitor the

desiccating capacity of the tubes. The number button on the bottom screen allows you to

switch between the two desiccant tubes. If you press the number button with the arrow

15

AQUALAB VSA

to the left, it switches to the left desiccant tube (#1). If you press the number button with

the arrow to the right, it switches to the right desiccant tube (#2). Any time you press the

desiccant tube button, the pump turns on and blows dry air into the chamber to monitor the

desiccating capacity of the tubes.

The weight calibration value is the current calibration applied to balance readings. A value of

one means no weight calibration is applied. The dew point and capacitance RH sensor offset

values are the current linear offsets applied to water activity readings for the respective

sensor type. A value of zero means that the VSA applied no water activity offset.

2.4.3.19 ABOUT

The About screen provides important information including the serial number and firmware

code version of your instrument.

2.4.4 DATA TAB

The Data tab allows you to view detailed information about the test stored in the memory.

You can view data as a list, view detailed data point information, and graph all or individual

stages. You can also delete the data in the memory.

Figure 14 Data tab

2.4.4.1 VIEW

This selection brings you to a screen where you can decide how to view the data. View the

whole test at once by selecting All or view an individual stage. Once the desired portion of

the test is selected, choose to graph the data by pressing the graph icon or press the Enter

icon to view summary information of each data record. Use the Moisture Analysis Toolkit to

download test data to a computer (Section7.2).

Table of contents

Other METER Measuring Instrument manuals

METER

METER TEROS 06 User manual

METER

METER SC-1 User manual

METER

METER AQUALAB PAWKIT User manual

METER

METER SI-400 Series User manual

METER

METER ACCUPAR LP-80 User manual

METER

METER ATMOS 22 User manual

METER

METER VARIOS User manual

METER

METER G3 User manual

METER

METER PROCHECK User manual

METER

METER AQUALAB TDL User manual