METER WP4C User manual

WP4C

i

TABLE OF CONTENTS

1. Introduction.............................................................................................. 1

2. Operation ...................................................................................................2

2.1 Installation ................................................................................................2

2.2 Preparing Samples.....................................................................................3

2.3 Checking Sample Temperature ..................................................................4

2.4 Taking a Reading........................................................................................ 4

3. System......................................................................................................... 6

3.1 Specifications............................................................................................6

3.2 Components ..............................................................................................8

3.2.1 Sample Chamber.............................................................................. 9

3.2.2 LED ................................................................................................ 10

3.2.3 Buttons.......................................................................................... 10

3.2.4 Display Screen ............................................................................... 11

3.2.5 Reading Modes .............................................................................. 14

3.2.6 Computer Interface........................................................................ 15

3.3 Theory...................................................................................................... 16

3.3.1 Defining Water Potential ............................................................... 16

3.3.2 Measuring Water Potential ............................................................ 17

4. Service....................................................................................................... 19

4.1 Calibration ............................................................................................... 19

4.1.1 Verification Standards ................................................................... 19

4.1.2 Calibration Process........................................................................ 19

4.2 Maintenance............................................................................................ 21

4.3 Cleaning................................................................................................... 21

13588-06

4.30.2019

ii

4.4 Repair ...................................................................................................... 25

4.5 Troubleshooting ....................................................................................... 26

4.6 Customer Support.................................................................................... 28

4.7 Terms and Conditions .............................................................................. 28

Further Reading.......................................................................................... 29

Index ................................................................................................................. 32

WP4C

Dewpoint PotentiaMeter

1

1. INTRODUCTION

Thank you for choosing the WP4C Dewpoint PotentiaMeter from METER Group.

WP4C is a fast, accurate, and reliable way to measure water potential using the chilled-

mirror dew point technique. This manual includes instructions for setting up, calibrating, and

maintaining the WP4C. This manual also explains the basic concepts of water potential.

Verify all WP4C components are included and appear in good condition:

• WP4C unit

• Power cord

• RS-232 to USB cable

• 25 plastic sample cups and lids

• 10 stainless steel sample cups

• 12 vials of 0.50 mol/kg potassium chloride (KCl) verification standard

• Cleaning kit

2

OPERATION

2. OPERATION

Please read all instructions before operating the WP4C to ensure it performs to its full

potential.

PRECAUTIONS

METER instruments are built to the highest standards, but misuse, improper protection,

or improper installation may damage the sensor and possibly void the manufacturer’s

warranty. Before setting up the WP4C, follow the recommended installation instructions

and arrange proper protections to safeguard the instrument from damage.

2.1 INSTALLATION

Follow the steps listed in Table 1 to set up the WP4C.

Table 1 Installation

Tools Needed Portable 12-V power inverter (field installation)

Preparation

Select Clean, Level Location

Select a location where the temperature remains fairly stable to avoid

temperature changes that can affect accuracy (away from air conditioner and

heater vents, open windows, etc.). If in the field, a Styrofoam box, for example,

can help minimize temperature effects.

Observe clean practices to prevent contamination of the sample chamber.

Maintain a level surface to reduce the chance of spilling sample material and

contaminating the sample chamber.

Remove Sample Cup

Pull open the sample drawer by turning the knob to the OPEN/LOAD position.

Remove the empty upside-down disposable sample cup (used to protect the

drawer during shipment) and set aside.

Installation

(continued)

Plug In Instrument

Plug the power cord into the back of the WP4C unit and an outlet. Use only the

supplied power cord.

If in the field, plug the instrument into a 12-V portable power inverter that plugs

into the 12 V output of a vehicle.The inverter should have a continuous output of

at least 140 W.

NOTE: When the instrument is on, it draws up to 1 A. Check the battery rating to determine

how long it will power the instrument (for example, if the battery is rated for 60 Ah, it will

work for 60 h when the vehicle is not running).

WARNING: An incorrect main power voltage can damage the instrument.

Turn the Unit ON.

The ON/OFF switch is located on the lower right corner of the WP4C back panel.

Allow the WP4C a 15- to 30-min warm-up period to ensure accurate readings.

Check the calibration of the instrument (Section4.1).

3

WP4C

2.2 PREPARING SAMPLES

Proper sample preparation is important to keep the WP4C internal sensors clean and

achieve repeatable results. Carefully prepare and load samples to lengthen the time

between cleanings and help avoid downtime. Be consistent in sample preparation methods

to obtain reproducible results.

Considerations regarding sample temperature are discussed in Section2.3.

NOTE: Calibrate the WP4C (Section4.1) using the same type of sample cup that will be used for subsequent

measurements.

Follow the steps listed below to prepare samples.

1. Choose an appropriate sample cup.

METER recommends using stainless steel cups because stainless steel cups come to

temperature equilibrium with the sample block more quickly, leading to a more accurate

measurement. Only use disposable plastic cups for dry samples.

NOTE: Soil samples can be oven dried directly in the stainless steel cups to determine water content

gravimetrically, which is convenient if generating soil moisture characteristic curves.

2. Place the sample in the sample cup.

a. Completely cover the bottom of the cup, if possible, to provide enough sample to get

an accurate reading.

The WP4C may not be able to accurately measure a sample that does not (or cannot)

cover the bottom of the cup. A larger sample surface area speeds up the reading by

shortening the time needed to reach vapor equilibrium. It also increases instrument

accuracy by providing more stable infrared sample temperature measurements.

b. Do not fill the sample cup more than half full.

Overfilled cups may contaminate the sensors in the chamber.

3. Wipe any excess sample material from the rim of the cup with a clean KIMWIPES®tissue.

Material left on the rim or the outside of the cup will prevent a vapor seal with the

sensor block and will contaminate subsequent samples.

4. If a sample cannot be read immediately, put the disposable sample cup lid on the cup to

restrict water transfer.

For longer term storage, seal the lid by placing tape or Parafilm®laboratory film

completely around the cup to lid junction.

Thoroughly clean the stainless steel cups using deionized water between uses to prevent

solutes from contaminating subsequent samples and causing artificially negative osmotic

potential.

The WP4C can be used to measure the water potential of leaves and plant material. Refer

to the application note Easy, accurate measurement of leaf water potential using the WP4C

(metergroup.com/environment/articles/measurement-leaf-water-potential-using-wp4c/).

4

OPERATION

2.3 CHECKING SAMPLE TEMPERATURE

For an accurate measurement, the sample temperature (Ts) should be close to the

sample block temperature (Tb). WP4C displays the temperature difference in the sample

temperature screen.

If a sample is warmer than the sample chamber (Ts-Tb is a positive number), condensation

may occur and moisture may condense inside the block, which will adversely affect readings.

If a sample is colder than the sample block temperature (Ts-Tb is a negative number), the

WP4C will wait to start a reading until its temperature increases to 1 °C below sample block

temperature. The closer the sample temperature is to the sample block temperature (i.e.,

closer to equilibrium), the less time is need for a reading.

To ensure the sample is at the correct temperature, use the following steps.

1. Place the sample in the chamber and close the drawer.

2. Press the lower right button to access the sample temperature screen and view the

temperature difference.

3. If the sample temperature difference is between −0.5 and 0, the sample can be used to

begin a reading (Section2.3).

If the sample temperature difference is a positive number, remove the sample

immediately.

4. Set the sample on a cold surface and cover with the cup lid to preserve the moisture.

Leave for approximately 1 min.

Do not cool the sample too much or the equilibrium time will be lengthened.

5. Place the sample back in the chamber and note the temperature difference again.

If it is between −0.5 and 0, begin the reading (Section2.4).

2.4 TAKING A READING

Observe the following cautions and use the following steps to take a reading.

CAUTIONS

• Ensure that the physical temperature of the WP4C is between 5 °C and 40 °C.

• Do not measure a sample that has a temperature greater than the WP4C chamber

(Section2.3). Remove the sample until it is at room temperature.

• Do not move the sample drawer too quickly when loading or unloading samples to avoid

spilling.

• Never try to move the instrument after a sample is loaded. Movement may cause the

sample material to spill and contaminate the sample chamber.

• Never leave a sample in the WP4C after a reading has finished. The sample may spill and

contaminate the instrument chamber if the instrument is accidentally moved or jolted.

5

WP4C

• Consult troubleshooting (Section4.5) if the triangular warning symbol appears in the top

right corner of the display (Figure1).

Figure1 Triangular warning sign

Perform the following steps to take a reading.

1. Turn the drawer knob to OPEN/LOAD and pull the drawer out.

2. Place the sample in the sample drawer and carefully slide the drawer closed to avoid

spilling solution and contaminating the chamber.

3. Check to be sure the sample temperature is below chamber temperature (lower right

button).

4. Turn the drawer knob to the READ position.

A notification that the measurement is starting will appear (Figure2).

Figure2 Measurement starting notification

Values display the initial measurements being taken and the Main screen will update

values throughout the reading. WP4C signals when it reaches the final values by a green

LED flash and an audible notification (if enabled). The WP4C will display the final water

potential and temperature of the sample (Figure3).

Figure3 Results screen

6

SYSTEM

3. SYSTEM

This section describes the specifications, components, and theory of the WP4C instrument.

3.1 SPECIFICATIONS

MEASUREMENT SPECIFICATIONS

Water Potential

Range 0 to –300 MPa

Resolution NA

Accuracy ±0.05 MPa from 0 to –5 MPa

1% from –5 to –300 MPa

NOTE: All vapor pressure instruments (including the WP4C) are limited by accuracy in the wet end of the water

potential range. The range of 0 to −5 MPa has an accuracy of ±0.05 MPa. For example, a measurement of −0.1 MPa

has an accuracy of ±50% of the measurement and a measurement of −1 MPa has an accuracy of ±5%.The WP4C will

not measure water potential accurately near field capacity (-0.033 MPa).

Temperature

Range 15-40 °C

Resolution 0.1 °C

Accuracy ±0.2 °C

Read Time

Soil sample

~10–15 min (precise mode)

<5 min (fast mode)

NOTE: WP4C will display updated measurements approximately every 5 min until

stopped.

Plant sample ~20 min

PHYSICAL SPECIFICATIONS

Case Dimensions

Length 24.1 cm (9.5 in)

Width 22.9 cm (9.0 in)

Height 8.9 cm (3.5 in)

Case Material

Powder painted aluminum

7

WP4C

Sample Cup Capacity

15 mL (0.5 oz) full

7 mL (0.25 oz) recommended

Weight

3.2 kg (7.1 lb)

Display

20 x 2 alphanumeric LCD with backlighting

Sensor Types

Chilled-mirror dew point sensor

Infrared temperature sensor

Operating Temperature

Minimum 5 °C

Typical NA

Maximum 40 °C

Data Communications

RS-232A serial

8-data bit ASCII code

9,600 baud, no parity

1 stop bit

Interface Cable

Standard RS-232 to USB cable (included)

Power

110–220 VAC

50/60 Hz

COMPLIANCE

Manufactured under ISO 9001:2015

EM ISO/IEC 17050:2010 (CE Mark)

Compatible standard: ASTM D6836-07

8

SYSTEM

3.2 COMPONENTS

The WP4C uses the chilled-mirror dew point technique to measure the water potential of

a sample. In an instrument that uses the dew point technique, the sample is equilibrated

with the headspace of a sealed chamber that contains a mirror and a means of detecting

condensation on the mirror. At equilibrium, the water potential of the air in the chamber is

the same as the water potential of the sample.

The WP4C main components include the display screen and sample chamber (Figure4 and

Figure5). A power cord and RS-232 communication cable can be plugged into the back of the

unit.

OPEN/LOAD

READ

LED

Function keys

Sample drawer

LCD screen

WP4C

Dewpoint PotentiaMeter

Figure4 Front view

9

WP4C

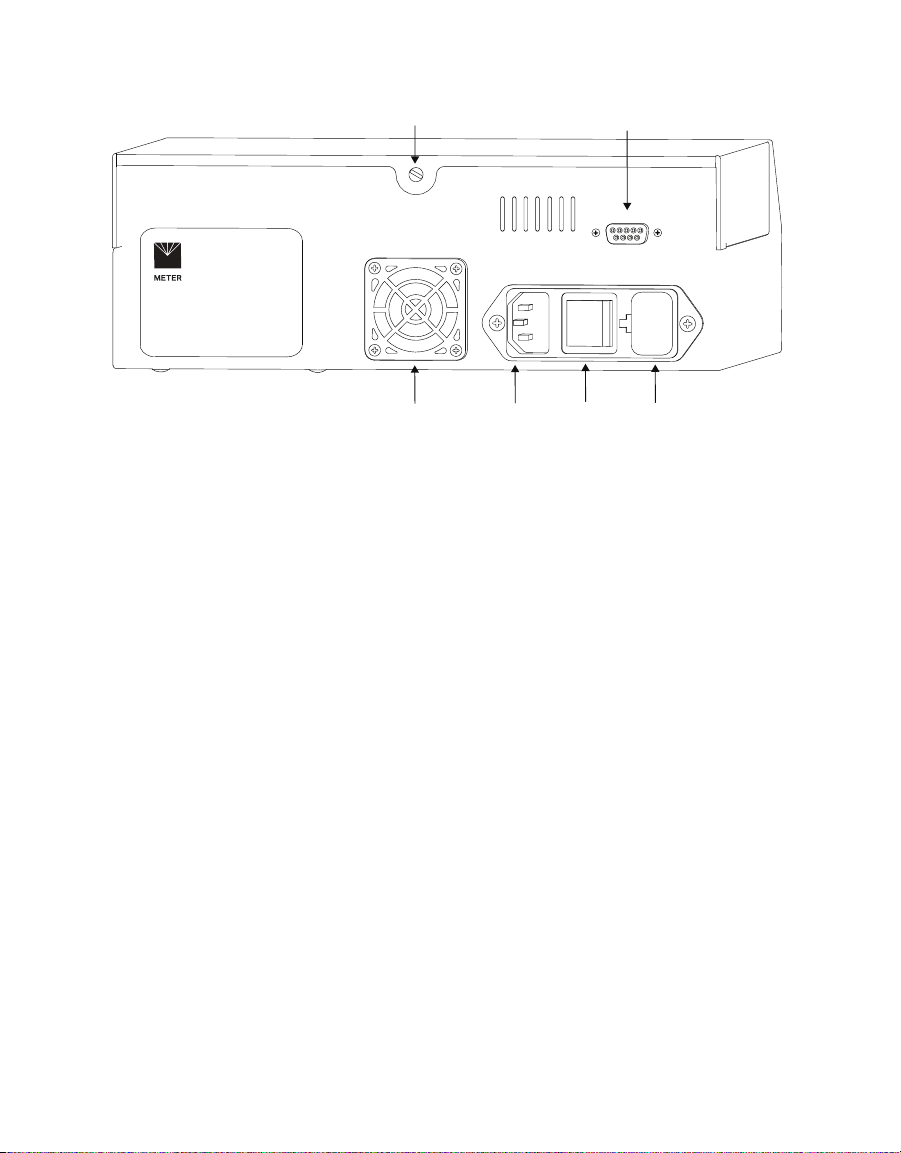

FanFuse well

ON/OFF

switch

Power

cord plug

Lidscrew RS-232 connection

Figure5 Back view

3.2.1 SAMPLE CHAMBER

The sample chamber has many components (Figure6). An internal thermoelectric module

equilibrates the sample temperature to the headspace of the chamber.

A thermoelectric (Peltier) cooler controls the mirror temperature. A photoelectric cell detects

the exact point when condensation first appears on the mirror by measuring a reflected

beam of light with a photodetector. The photodetector senses the change in reflectance

when condensation occurs on the mirror. A thermocouple attached to the mirror records the

temperature when condensation occurs.

An internal fan circulates the air within the sample chamber to reduce time to equilibrium.

Both dew point and sample surface temperatures are simultaneously measured, eliminating

the need for complete thermal equilibrium.

10

SYSTEM

Fan

IR thermometer

Optical sensor

Mirror

Locking levers

20-pin socket

Figure6 Sample chamber

3.2.2 LED

A flashing green LED, located on the left front corner of the WP4C case, blinks to notify the

user of different settings.

The LED flashes once when a sample reading starts. In Fast and Precise reading modes, the

LED will flash continuously when the sample reading is finished until the sample drawer

knob is moved to the OPEN/LOAD position. The LED settings cannot be changed or turned off.

3.2.3 BUTTONS

Four buttons flank the LCD screen (Figure7). The function of each button changes

depending on the current screen (Section3.2.4).

WP4C

Dewpoint PotentiaMeter

Figure7 Buttons

11

WP4C

3.2.4 DISPLAY SCREEN

The WP4C has five different screens to display data and change settings.

3.2.4.1. MODEL INFORMATION SCREEN

The Model Information screen (Figure8) will appear for approximately 3 s after turning the

WP4C on, immediately followed by the Main screen.

Figure8 Model Information screen

3.2.4.2. MAIN SCREEN

The Main screen (Figure9) displays the water potential in both megapascals and log-scaled

pF values. The sample temperature is displayed in degrees Celsius. The values on this

screen will update during measurements. A small letter in the top left indicates the reading

mode.

Reading mode Language screen

System Setup screen Sample Temperature screen

WP4C

Dewpoint PotentiaMeter

Figure9 Main Menu screen and button functions

Pressing the upper left button will change the reading mode (Section3.2.5). The symbol on

the screen will toggle between p, c, or fto indicate if WP4C is reading in Precise, Continuous,

or Fast mode.

Press the upper right button to change the WP4C language (Section3.2.4.3).

Press the lower right button to show sample temperature information (Section3.2.4.4).

Press the lower left button to bring up system setup options (Section3.2.4.5).

NOTE: WP4C will not allow button selections while the unit is reading a sample.

12

SYSTEM

3.2.4.3. LANGUAGE SCREEN

The Language screen shows the current selected language for the unit. English is the WP4C

default on-screen language. The on-screen user language can be changed to any one of the

following languages: German, French, Spanish, Italian, Swedish, Danish, Norwegian, Czech,

Portuguese, Japanese, Polish, or Finnish.

From the Main screen, press the upper right button.The Language screen (Figure10) with

default English will appear. Continue pressing the upper right button to scroll through the

language options. When the preferred language is reached, press the lower left button to exit.

Figure10 English screen

3.2.4.4. SAMPLE TEMPERATURE SCREEN

The Sample Temperature screen (Figure11) displays the sample temperature (Ts) and the

temperature difference between the WP4C sample and the sample block (Ts - Tb). Use this

screen to quickly check if the sample is too hot, which may cause condensation inside the

chamber.

NOTE:It is important that Ts−Tb is negative in order to prevent condensation inside the sample chamber.

From the Main screen, press the lower right button to bring up the Sample Temperature

screen. Press either of the lower buttons to exit.

NOTE:The sample drawer knob must be in the OPEN/LOAD position to access the Sample Temperature screen.

Figure11 Sample Temperature screen

3.2.4.5. SYSTEM SETUP SCREEN

The System Setup screen is used to change how the WP4C signals after each reading, enter

the Calibration Menu, and set the Temperature (set T) (Figure12).

Figure12 System Setup screen

13

WP4C

From the Main screen, press the bottom left button to access this menu. Use the buttons to

select the desired setting to configure: audible notification, calibration, and temperature.

Press the upper left button to toggle adjust the audible notification at the end of a reading.

Three icons represent the three options: no notification (0x), beep momentarily before

stopping (4x), or beep continuously until the sample drawer knob is turned to the OPEN/

LOAD position.

NOTE: The audible notification is not changed by turning the instrument off and on.

Press the upper right button to go to start calibration (Section4.1).

Press the lower right button to set WP4C temperature (Section3.2.4.6)

Press the lower left button to exit back to the Main menu at any time.

3.2.4.6. TEMPERATURE SET SCREEN

The default temperature of the WP4C sample block temperature is 25 °C. The Temperature

Set screen allows the sample block temperature to be set manually (Figure13). The sample

block temperature roughly corresponds to the temperature needed to read the sample.

To access this screen from the Main menu, press the lower left button, followed by the lower

right button (next to set T) on the System setup screen.

Figure13 Temperature Set screen

The index number can be adjusted between 15 and 40 °C. Use the right buttons next to the +

and −symbols to adjust the sample block temperature value in increments of 0.1 °C.

NOTE:Holding down the button will rapidly increment the value.

The temperature control can be disabled by pressing the −button after reaching 15 °C.

Reenable temperature control by pressing the +button to bringing the sample block

temperature back into its controllable range.

After adjusting the sample block temperature, wait 15 min before taking a measurement to

allow the sample block to reach the new temperature.

3.2.4.7. PERFORMANCE EVALUATION SCREEN

The Performance Evaluation screen needs to be accessed only if one of the components

of the WP4C may be causing a measurement error. Before accessing this screen, ensure

the instrument has been cleaned (Section4.3) and other troubleshooting steps have been

14

SYSTEM

reviewed (Section4.5). Values on this screen cannot be changed, but they will indicate

component performance. If any of these values are not what they should be, contact

Customer Support.

To access this screen, hold down the lower right button while turning on the instrument.

After the instrument initializes, the Performance Evaluation screen will appear, providing

four values (Figure14).

Figure14 Example Performance Evaluation screen

• The top left value is the value the thermocouple is reading—the temperature difference

between the sample block and the mirror. If this is 0, there is something wrong with the

thermocouple.

• The top right value is the value read by the thermopile—the temperature difference

between the sample block and the sample. This value is variable but should never be 0.

• The bottom left value is the sample block temperature. This value should be around

ambient temperature.

• The bottom right value is the mirror reflectance voltage, in volts. This value should normally

be around 0.5 or above, but if it drops below 0.3, there is something wrong.

Press the button next to –Exit– to bring up the Main menu.

3.2.5 READING MODES

WP4C has three reading modes: precise, continuous, or fast. The display will show a small

p, c, or fto the left of the water potential readings (Figure15) indicating which mode is

selected. To change the mode, navigate to the Main screen and press the upper left button.

NOTE: WP4C will not allow button selections while the unit is reading a sample.

Figure15 Main Menu with Continuous mode enabled

PRECISE MODE

Precise mode is the default WP4C mode. WP4C repeats sample measurements until

successive readings agree within a preset tolerance (0.03 MPa for Ψ> −40 MPa; otherwise

0.3 MPa). For most accurate results, run most soil samples in Precise mode. Typical read

times are within 10 to 15 min.

15

WP4C

CONTINUOUS MODE

Continuous mode measures the water potential of the sample continuously until the drawer

knob is turned back to the OPEN/LOAD position. The WP4C will measure the sample, display

the water potential and sample temperature, then begin another read cycle. WP4C will

signal the end of a reading with an LED flash and audible notification (if enabled).

Continuous mode is recommended for samples that take a long time (20 to 30 min) to come

to vapor equilibrium, such as plant samples and wet soil samples with water potential

>−0.5 MPa. METER recommends using Continuous mode and logging data to determine when

equilibrium conditions are reached. It may be helpful to connect the WP4C to a computer

while in Continuous mode in order to log and store data over time (Section3.2.6).

FAST MODE

Fast mode measures the sample once. Read time is typically 3 to 5 min. Readings are less

precise, particularly in the wet range.

Fast mode is recommended for dry soil samples with water potential <−40 MPa. For samples

with very little water holding capacity (i.e., dry sand samples), small leaks in the sample

chamber can cause water potential to drift down over time.

3.2.6 COMPUTER INTERFACE

The WP4C can connect to a computer to send water activity data to a computer for further

analysis and storage. An RS-232-to-USB serial cable is included for this purpose. The

interface is run through the AquaLink 4 Software or a terminal communication program.

NOTE:If the computer does not have a USB port, use a USB-to-RS-232 adapter.

There are several terminal program options. METER has its own terminal program (DecaTerm)

that can be downloaded from metergroup.com/wp4c-support. Two other options are

TeraTerm, a free program that can be found on the internet, and Hyperterminal, the standard

program with Microsoft®Windows®prior to Windows 7 software.

To integrate a terminal program with WP4C, use the following steps:

1. Power on the WP4C.

2. Connect the USB interface cable to the computer.

3. Follow the instructions for the program with the following settings:

c. Choose correct COM Port.

d. Set or verify COM Properties.

e. Bits per second (Baud rate): 9,600

Data: 8 bit

Parity: none

Stop: 1 bit

Flow control: none

16

SYSTEM

Upon successful completion of a water activity reading, the data in the terminal program

displays measurement time (in minutes), sample temperature, and water potential (in both

megapascals and picofarad). Figure16 shows a sample return.

Figure16 Sample data return

3.3 THEORY

Water potential is a measurement of the energy status of the water in a system. It

indicates how tightly water is bound, structurally or chemically, within a substance.

Water potential is defined as the potential energy per unit volume of water in a sample.

3.3.1 DEFINING WATER POTENTIAL

The total water potential of a sample is the sum of four component potentials:

gravitational, matric, osmotic, and pressure. Gravitational potential depends on the

position of the water in a gravitational field. Matric potential depends on the adsorptive

forces binding water to a matrix. Osmotic potential depends on the concentration of

dissolved substance in the water. Pressure potential depends on the hydrostatic or

pneumatic pressure on the water.

The WP4C measures the sum of the osmotic and matric potentials in a sample. Often

one or the other of these potentials will be the dominant factor in determining the total

potential. For example, solutions like the KCl calibration standard have only an osmotic

component. Soils bind water mainly through matric forces and therefore have mainly a

matric component (though salt-affected soils can have a significant osmotic component).

Table of contents

Other METER Measuring Instrument manuals

METER

METER PROCHECK User manual

METER

METER AQUALAB PAWKIT User manual

METER

METER SI-400 Series User manual

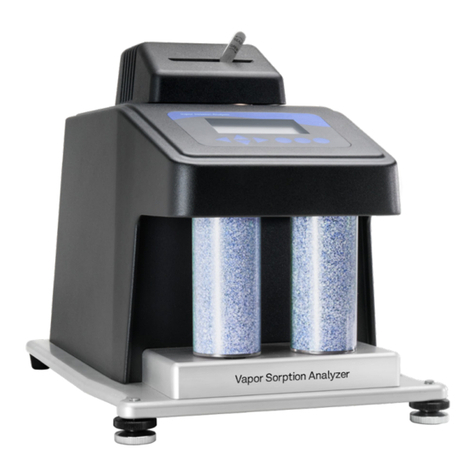

METER

METER AQUALAB VSA User manual

METER

METER AQUALAB TDL User manual

METER

METER AQUALAB User manual

METER

METER TEROS 54 User manual

METER

METER ACCUPAR LP-80 User manual

METER

METER TEROS 06 User manual

METER

METER THERMOLINK User manual

METER

METER APOGEE SU-221 User manual

METER

METER AQUALAB TDL User manual

METER

METER TEROS 11 User manual

METER

METER ROS 1 User manual

METER

METER TEMPOS User manual

METER

METER TEROS 32 User manual

METER

METER ATMOS 22 User manual

METER

METER AQUALAB PAWKIT User manual

METER

METER APOGEE SQ-521 User manual

METER

METER SC-1 User manual