METER ROS 1 User manual

ROS 1

i

TABLE OF CONTENTS

1. Introduction.............................................................................................. 1

2. Operation ...................................................................................................2

2.1 Installation ................................................................................................2

2.2 Sample Preparation ................................................................................... 3

2.3 Taking a Reading........................................................................................ 4

3. System......................................................................................................... 6

3.1 Specifications............................................................................................6

3.2 Components ..............................................................................................8

3.3 Theory...................................................................................................... 11

3.3.1 Introduction to Moisture Content .................................................. 11

3.3.2 Analysis of the Drying Process....................................................... 12

3.3.3 Temperature Dependence of Water Activity................................... 13

4. Service....................................................................................................... 14

4.1 Calibration ............................................................................................... 14

4.2 Maintenance and Cleaning....................................................................... 14

4.3 Repair ...................................................................................................... 18

4.4 Troubleshooting ....................................................................................... 19

4.5 Customer Support.................................................................................... 20

4.6 Terms and Conditions .............................................................................. 20

Index ................................................................................................................. 21

18459-00

11.2021

1

ROS 1

1. INTRODUCTION

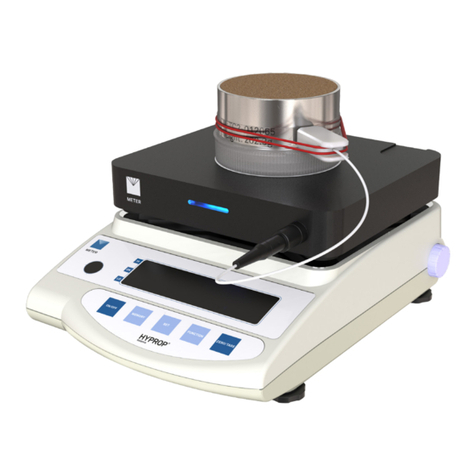

Thank you for choosing the ROS 1 Moisture Analyzer from METER Group. The ROS 1 utilizes a

unique design combined with a sound scientific understanding of moisture loss to create the

ideal loss-on-drying moisture analyzer.

This manual includes instructions for setting up, verifying the scale calibration, preparing

samples, taking readings, and maintaining the ROS 1.

Verify all ROS 1 components are included and appear in good condition:

• ROS 1 Moisture Analyzer

• Certificate of calibration (factory temperature)

• Power cord

• METER USB A to USB A cable (1.28 m, 6 ft)

• 100 sample cups

• Filter papers

• 2.0000-g NIST traceable standard weight

• USB drive with ROS 1 Bridge app

2

OPERATION

2. OPERATION

Please read all instructions before operating the ROS 1 to ensure it performs to its full potential.

PRECAUTIONS

METER instruments are built to the highest standards, but misuse or neglect may damage

the device and possibly void the manufacturer’s warranty. Before using the ROS 1, follow the

recommended user instructions and arrange proper protections to safeguard the instrument

from damage.

2.1 INSTALLATION

Follow the steps listed in Table 1 to set up the ROS 1 and start collecting data.

Table 1 Installation

Tools Needed Microsoft®Windows®computer for ROS 1 Bridge app

Preparation

Select Stable Location

Select a location where the temperature remains fairly stable to avoid

temperature changes that can affect accuracy (i.e., away from air conditioner

and heater vents, open windows).

Select a stable surface free from vibration.

NOTE: Always ensure the sample chamber is empty prior to moving the instrument.

Installation

Plug In Instrument

Plug the power cord into the back of the ROS 1 unit and into an outlet.

Only use the supplied power cord or one rated for ROS 1 and certified for the

country of use. The cord must be a minimum of 18 AWG and have a rating for 10A

or greater.

WARNING: An incorrect main power voltage can damage the instrument.

Turn the Unit ON

Allow the ROS 1 a 2-h warm-up period to bring the scale into constant operating

temperature and ensure accurate readings.

Leave the ROS 1 powered on when not in use to maintain optimal instrument

speed and performance. When not in use, the ROS 1 will automatically enter

standby mode.

Connecting

Download ROS 1 App

Copy the Bridge app from the included USB drive to the computer.

Open the Bridge app.

Connect the USB cable to a USB port on the ROS 1 and a USB port on the computer.

Select the METER USB COM port from the dropdown menu.

Click Connect .

NOTE: If METER USB is not shown, install the included driver software.

3

ROS 1

Table 1 Installation (continued)

Calibration

Calibrate the Scale

Navigate to the Settings menu in the Bridge app.

Click on the Calibrate Scale button from the Settings menu.Follow the prompts

to complete the calibration. Section4.1 contains more details about calibrating

the scale.

To print a certificate of calibration, click the Generate Calibration Certificate

button from the Settings menu.

WARNING: The 2.0000-g standard weight must be handled only with clean lab utensils

such as tweezers. Mishandling the standard weight nullifies the calibration.

2.2 SAMPLE PREPARATION

Proper sample preparation is important to keep the ROS 1 clean and achieve repeatable

results. Carefully prepare and load samples to lengthen time between ROS 1 cleanings

and to help avoid downtime. Be consistent in sample preparation methods (e.g., crush,

grind, slice the sample) to obtain reproducible results. Exposure of samples to the ambient

atmosphere should be minimized since this will affect the measured moisture content.

Place a representative selection of the material in each cup. When adding the sample to the

cup, spread it out over the bottom of the cup as much as possible to ensure good contact

with the heating surface.

The nature of some samples results in longer reading times and may require additional

preparation to ensure accurate readings. Crush, slice, or blend coated or dried samples

before testing to increase the surface area of the sample, thus decreasing testing times.

Follow the steps listed below to prepare samples:

1. Make sure the sample to be measured is representative.

Multicomponent samples (e.g., muffins with raisins) or samples that have outside

coatings (like deep-fried, breaded foods) can be measured, but they need to have

representative portions in the cup. The moisture is not distributed uniformly among the

components, so getting an accurate moisture content depends on the operator’s ability

to choose a sample that accurately represents the product.

2. Place the sample in a disposable sample cup.

a. Completely cover the bottom of the cup, if possible.

The ROS 1 is also able to accurately measure a sample that does not (or cannot)

cover the bottom of the cup. For example, raisins only need to be placed in the cup

and do not need to be flattened to cover the bottom. A larger sample surface area

increases instrument efficiency by providing more area for evaporation per unit

sample volume. It also speeds up the reading by shortening the time needed for the

sample to get to its drying temperature.

4

OPERATION

b. Do not fill the sample cup more than half full.

Overfilled cups slow down the readings.

3. Wipe any excess sample material from the rim and outside of the sample cup with a

clean KIMWIPES®tissue.

Material left on the rim or the outside of the cup can contaminate the carousel and be

transferred to adjacent samples.

4. If a sample cannot be measured immediately, put it in a sealed container until it can be

measured to avoid water loss.

2.3 TAKING A READING

The ROS 1 can test one to nine samples simultaneously. The sample type will determine the

desired test settings: drying temperature, timed test or constant-weight test, and constant-

weight test parameters. Several presets are available. Customer Support can help select the

appropriate settings for the sample and a video tutorial is also available at metergroup.com/

ros1-training.

Use the following steps to take a reading with the ROS 1.

1. Ensure the ROS 1 is plugged in and turned on.

2. In the Bridge app, select the METER USB COM port.

3. Click Connect .

4. Select sample test settings in the Bridge app.

5. Open the ROS 1 sample chamber lid.

6. Verify that the sample chamber is clean and free from debris.

If the sample chamber is dirty, please follow the cleaning steps listed in Section4.2.

7. Place empty sample cups in the sample chamber in any of the positions.

NOTE: When drying liquid samples, filter paper may be added to the empty sample cup before taring.

The ROS 1 can take between one and nine sample test at one time. Any position without

a sample cup will be disregarded, meaning all positions on the carousel do not have to

contain a sample cup.

8. Close the sample chamber lid.

NOTE: More accurate weight readings can be achieved by closing the sample chamber lid while weight

measurements are being taken.

9. Click Next in the Bridge app window.

The ROS 1 will move the carousel around to detect sample cups and take accurate tare-

weight readings.

NOTE: Both the tare-weight measurement and the sample-weight measurement are critical values for the

calculation of moisture content.

5

ROS 1

After an empty sample cup has been tared, the LED on the ROS 1 will turn green, and a

prompt in the Bridge app will appear instructing the user to add a sample.

10. Add a sample.

NOTE: For samples prone to spilling, remove the sample cup and add the sample to ensure the drying chamber

stays clean.

A rough weight will appear at the bottom of the Bridge app window.

11. Close the sample chamber lid.

12. Follow the onscreen prompts in the Bridge app.

The ROS 1 will move the sample cups into the weight position and take tare-weight readings.

When the sample weight has been recorded, the LED for that sample position on the

ROS1 will turn white and the image on the Bridge app window will show a blue circle around

thatsample position.

The LED for any unused sample positions will not light up.

If a sample needs to be replaced, click on the blue sample cup image that is to be

replaced shown in the Bridge app. Follow the prompts in the Bridge app to tare a new

sample cup and replace the sample.

13. Once the last sample has been weighed, all of the LEDs on the ROS 1 will pulse and the

internal air flow and heating process will begin automatically.

During the test, the ROS 1 Bridge app window will display the in-process readings

(clicking the Graph button will show the same data in graph format).

When a sample has dried, the corresponding LED on the front of the ROS 1 will turn blue.

The light turns blue on the Bridge app window. Sample Drying window, and the moisture

content result shown in the % Moisture column will stop changing.

14. Click the OK button on the Test complete message that appears in the Bridge app when

the test is complete.

Export data or click on the New test button.

The testing data can be exported at any time during or after a test by clicking the Export

data button.

NOTE: If on the Bridge app Test Prep screen,click the Previous test results button to recall previous tests and export

previous test data.

6

SYSTEM

3. SYSTEM

This section describes the specifications, components, and theory of the ROS 1.

3.1 SPECIFICATIONS

MEASUREMENT SPECIFICATIONS

Moisture Range

Range 0.1−100%

Accuracy

Repeatability

(4-g samples)

0.05%

Repeatability

(10-g samples)

0.01%

Method Loss-on-drying using any standard method

Scale

Readability 0.0001 g

Minimum 0.0 g

Maximum 50.0 g

Calibration Performed in Bridge app

Samples

Number 1–9

Weight range 500 mg–20 g

COMMUNICATIONS SPECIFICATIONS

Data Communications

Serial over USB

7

ROS 1

PHYSICAL SPECIFICATIONS

Dimensions

Length 38.1cm (15.0 in)

Width 30.5 cm (12.0 in)

Height 20.3 cm (8.0 in)

Case Material

Powder-coated steel

Sample Cup Capacity

33.173 mL (1.124 fl oz)

ROS 1 Weight

12.5 kg (27.6 lb)

Operating Temperature Range

Minimum 4 °C

Typical NA

Maximum 50 °C

NOTE: Sensors may be used at higher temperatures under certain conditions; contactCustomer

Supportfor assistance.

Operating Environment

0%–90% noncondensing

Power

110–220 VAC

50/60 Hz

COMPLIANCE

Manufactured under ISO 9001:2015

EM ISO/IEC 17050:2010 (CE Mark)

8

SYSTEM

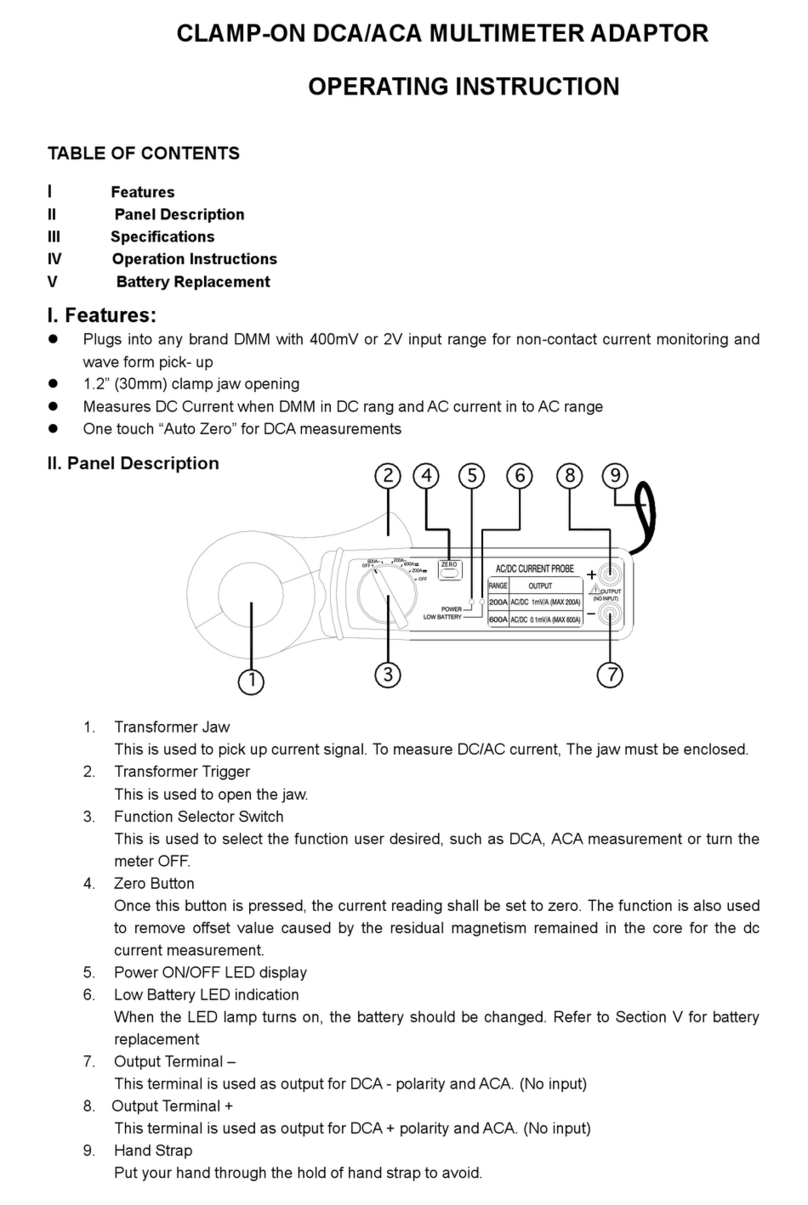

3.2 COMPONENTS

The ROS 1 is a loss-on-drying moisture analyzer with the ability to run multiple samples.

A carousel enables high-sample throughput by analyzing as many as nine samples

simultaneously using primary reference methods. The ROS1 controls the temperature of each

sample position individually using controlled contact drying and tracks the weight loss of each

sample over time. The instrument consists of an enclosure that houses the power supply, air

flow control, the sample chamber, and scale.The power switch and communications ports are

located on the rear of the ROS 1. There are LEDs on the front of the ROS 1 that correspond to

each of the nine sample positions on the carousel (Figure1).

Figure1 Enclosure

IN

OUT OUT

OUT

OUT OUT

OUT

Figure2 Air Flow Control

9

ROS 1

Carousel

(sample chamber)

Figure3 Sample chamber

Scale pan

Figure4 Scale and scale pan

10

SYSTEM

COM port

USB ports

Power

switch &

cable plug

Figure5 Power Switch and COM ports

Figure6 Front panel

11

ROS 1

3.3 THEORY

The Bridge app user matches any reference moisture method without the need to use

extreme temperatures to predict the moisture content. ROS 1 has a growing list of standard

configurations based on AOAC, AACC, and Swiss Food Manual standards. The ROS 1 calculates

moisture on a dry basis.

Percent Moisture on a Wet Basis (% wb, g/100 g total)

Percent Moisture on a Dry Basis (% wb, g/100 g solids)

% Moisture

=x100 =

initial weight – dry weight

initial weight

grams of water

100 grams total

% Moisture

=x100 =

initial weight – dry weight

dry weight

grams of water

100 grams total

Many food applications report moisture contents on a wet basis. A simple equation converts

between the wet and dry basis.

% moisture wet

=x100

% moisture dry

100 – % moisture dry

% moisture dry

=x100

% moisture wet

100 – % moisture wet

3.3.1 INTRODUCTION TO MOISTURE CONTENT

Two measures are required to completely describe the state of water in a product: water

activity and moisture content. Water activity is a measure of the water’s energy. It has a

sound thermodynamic basis and can be exactly specified and measured. Moisture content,

on the other hand, must be defined operationally, since there is no way to actually determine

the exact amount of water in a sample.

One way to determine moisture content is to measure the difference between the mass of

a sample and its mass in a reference state. The reference state is generally specified as the

state of the sample after it is placed in an oven at a specified temperature for a specified

time. This state is often assumed to be a state of 0 moisture content, but it is not. Increasing

the oven temperature or decreasing the oven vapor pressure will result in additional mass

loss from the sample, and some of that mass loss will be water. Some mass loss may be from

vaporization of other volatiles present in the sample or oxidization of sample constituents.

The uncertainty from these two sources (tightly bound water remaining in the dry sample

and nonwater mass loss from the sample) leads some to use the term moisture content

rather than water content to describe the result of the measurement. Whatever it is called,

the measurement provides valuable information about the state of the water in the product

and the product yield, quality, and purity. It is, therefore, important to make the measurement

as precisely as possible. The reference state needs to be carefully specified, and the

conditions that affect it must be well controlled.

12

SYSTEM

3.3.2 ANALYSIS OF THE DRYING PROCESS

Drying occurs when a sample loses water. When water loss stops, under a specified set of

conditions, the sample is said to be dry. Heating is often assumed to be necessary for drying,

but high temperatures are only peripherally related to drying.

The integrated form of the Fick equation (Equation 1) gives the rate of water loss from a sample:

Equation 1

where:

E

=the evaporation rate (g×m-2s-1)

When the sample is dry, Ebecomes 0

NOTE: The sample and air-vapor pressures are equal.

gv= the vapor conductance of the sample surface and the air surrounding the sample

(g×m-2s-1)

pa= the atmospheric pressure (kPa)

eaand es=the vapor pressures of the air (kPa) and of water at the sample surface, respectively.

d= the characteristic dimension

In a well-ventilated oven, the vapor pressure of the air in the oven (ea

) equals the vapor

pressure of the air in the laboratory where the oven resides. The vapor pressure of air is

theproduct of the air humidity (expressed as a fraction) and the saturation vapor pressure

atair temperature. In a typical laboratory, it is assumed that the relative humidity is 0.4 and

the air temperature is 25 °C, the vapor pressure of the oven air would be 1.27 kPa (0.4 ×

3.17 kPa = 1.27 kPa, where 3.17 is the saturation vaporpressure (kPa) of air at 25 °C).

The vapor pressure of the sample (es) is the product of its water activity and the saturation

vapor pressure at sample temperature. A typical standard drying oven temperature is

105 °C. The saturation vapor pressure of water at that temperature is 121 kPa. Knowing

the saturation vapor pressure of water and the vapor pressure of the oven air can be used

to calculate the water activity of a dry sample. Equation 2 shows the calculation for the

specified conditions:

Equation 2

The sample dry water activity can be computed for any vapor pressure that might exist in the

oven as shown in Figure7.

13

ROS 1

0.025

0.02

0.015

0.01

0.005

0

010.5 1.5

Oven Vapor Pressure (kPA)

2.5

23

Dry Sample Water Activity

Figure7 Water activity of a dry sample in an oven

This analysis should make several things clear:

1. Dry does not mean there is no more water in the sample.

There is always more water in the sample. The amount of water that is removable by

the drying process depends on the vapor pressure of the air around the sample and the

sample temperature.

2. Anything that alters the oven vapor pressure will alter the dry water activity of the

sample, which, in turn, will alter the dry weight of the sample.

So, increased laboratory humidity or lack of proper oven ventilation will result in an

increase in oven dry weight and a decrease in apparent moisture content.

3. Moisture content measurements will be most accurate if there is a specified dry water

activity and a requirement that drying methods bring samples to that water activity.

The challenge is to find a method that rapidly dries samples to a specified water activity

while minimizing sample oxidation and volatile loss that occurs with heating in an oven.

3.3.3 TEMPERATURE DEPENDENCE OF WATER ACTIVITY

The water activity of all products changes with temperature. Generally, an increase in

temperature results in an increase in water activity. At intermediate water activity, the water

activity change is around 0.003 awper °C. This effect results in additional drying of a typical

product at high temperature compared to drying at lower or room temperature, even if the

high- and low-temperature samples are at the same final water activity. A precise moisture

content measurement, therefore, requires accurate control of both sample temperature and

oven vapor pressure.

14

SERVICE

4. SERVICE

This section describes the scale calibration and maintenance of the ROS 1. Troubleshooting

solutions and customer service information are also provided.

4.1 CALIBRATION

Frequent scale calibration is not necessary for ROS 1 moisture content measurements.

METER recommends, at a minimum, calibrating the ROS 1 after a thorough cleaning.

Operators can calibrate the scale with the included 2.0000-g NIST traceable standard.

WARNING: The 2.0000-g standard weight must be handled only with clean lab utensils such as tweezers.

Mishandling the standard weight nullifies the calibration.

To begin the scale calibration, use the following steps.

1. Ensure the ROS 1 sample chamber is empty and the lid is completely closed.

2. Connect to the ROS 1 using the Bridge app.

3. Open the Bridge app Settings menu.

4. Click on the Calibrate Scale button.

5. Select Next to begin tarring the scale.

NOTE: Do not touch the table or ROS 1 during calibration to prevent disturbing the calibration routine.

6. When prompted in Bridge, open the sample chamber lid.

7. Add an empty sample cup to sample position 1 on the carousel.

8. Shut the lid.

9. Select Next from Bridge.

10. When prompted, open the sample chamber lid.

11. Add the 2.0000-g standard to the empty sample cup.

12. Shut the lid.

13. Select Next from the Bridge.

The weight offset value will display on the Bridge app window.

14. Select Next again to accept and store the weight offset or Cancel to abort.

4.2 MAINTENANCE AND CLEANING

ROS 1 may be returned to METER for maintenance in the following areas: system inspection,

parts replacement, and instrument cleaning. Replacement parts can also be ordered from

METER. Contact Customer Support for more information.

Keeping the ROS 1 sample chamber clean is an important part of regular instrument care

and maintenance. Dust, debris, and spills can interfere with the sample cup rotation, disrupt

conductance between the heating surface and the samples, and alter weight measurements.

15

ROS 1

General cleaning procedures that should be performed after each test are listed below:

• Blow out the sample chamber with compressed air between tests.

• Remove spills prior to starting a test.

Spills left in the sample chamber during a test can burn and become difficult to remove

after the test is complete.

• If a spill occurs near the scale pan, remove the scale pan and soak up any liquids or debris

in the reservoir under the scale pan Figure8.

WARNING: Keep liquid and debris out of the highlighted area in Figure8. Failure to keep this area free of

liquid and debris may result in degraded performance and/or costly repairs.

Area below scale pan

Sample reservoir

Keep this area

free of liquid

and debris

Figure8 Sample reservoir

• Use a moist towel, sponge, or KIMWIPE tissue and a gentle liquid detergent or isopropyl

alcohol to remove most (nonburnt) debris.

• To remove burnt or dried substances, try gently scrubbing using a very fine (scratch free)

cleanser (METER has successfully tested Bon Ami cleaner).

• Rinse the surfaces using a moist towel, sponge, or KIMWIPE.

WARNING: Do not use anything abrasive! Scouring pads, sandpaper, and coarse cleansers wear down the

surface of the sample chamber. Kitchen degreasers containing methylene chloride will strip the surfaces of

the chamber.

16

SERVICE

METER recommends checking the ROS 1 daily to see if a more thorough cleaning is needed. For a

more thorough cleaning, use the following steps to wash, rinse, and dry each area.

1. Turn the ROS 1 power off.

2. Open the sample chamber lid to expose the sample chamber.

3. Clean, rinse, and dry the sample chamber lid.

4. Remove the carousel by removing the two thumb screws in the center of the carousel

(Figure9 and Figure 10).

Figure9 Remove Thumb Screws

Table of contents

Other METER Measuring Instrument manuals

METER

METER AQUALAB TDL User manual

METER

METER ATMOS 22 User manual

METER

METER THERMOLINK User manual

METER

METER TEROS 11 User manual

METER

METER TEMPOS User manual

METER

METER VARIOS User manual

METER

METER WP4C User manual

METER

METER ACCUPAR LP-80 User manual

METER

METER G3 User manual

METER

METER SATURO User manual

METER

METER SC-1 User manual

METER

METER TEROS 32 User manual

METER

METER PROCHECK User manual

METER

METER AQUALAB PAWKIT User manual

METER

METER SI-400 Series User manual

METER

METER ATMOS 22 User manual

METER

METER TEROS 54 User manual

METER

METER MW04 User manual

METER

METER AQUALAB VSA User manual

METER

METER AQUALAB 3 User manual