MINN KOTA MKA-16-03 User manual

1 | minnkotamotors.com ©2022 Johnson Outdoors Marine Electronics, Inc.

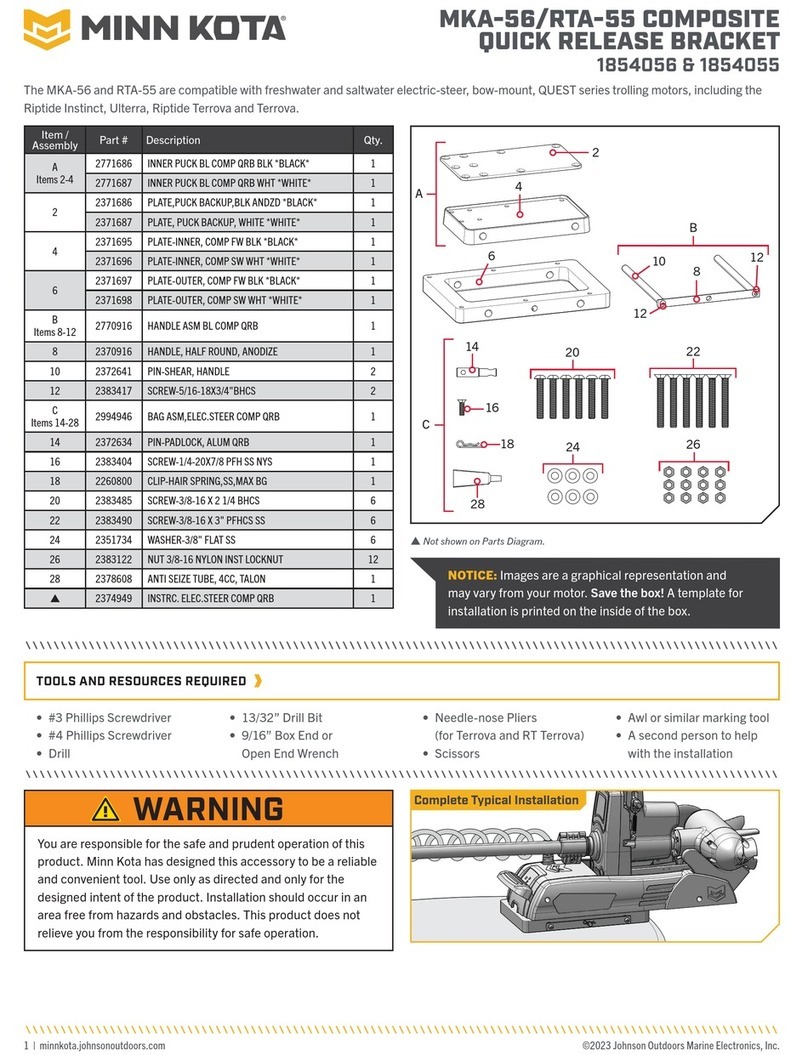

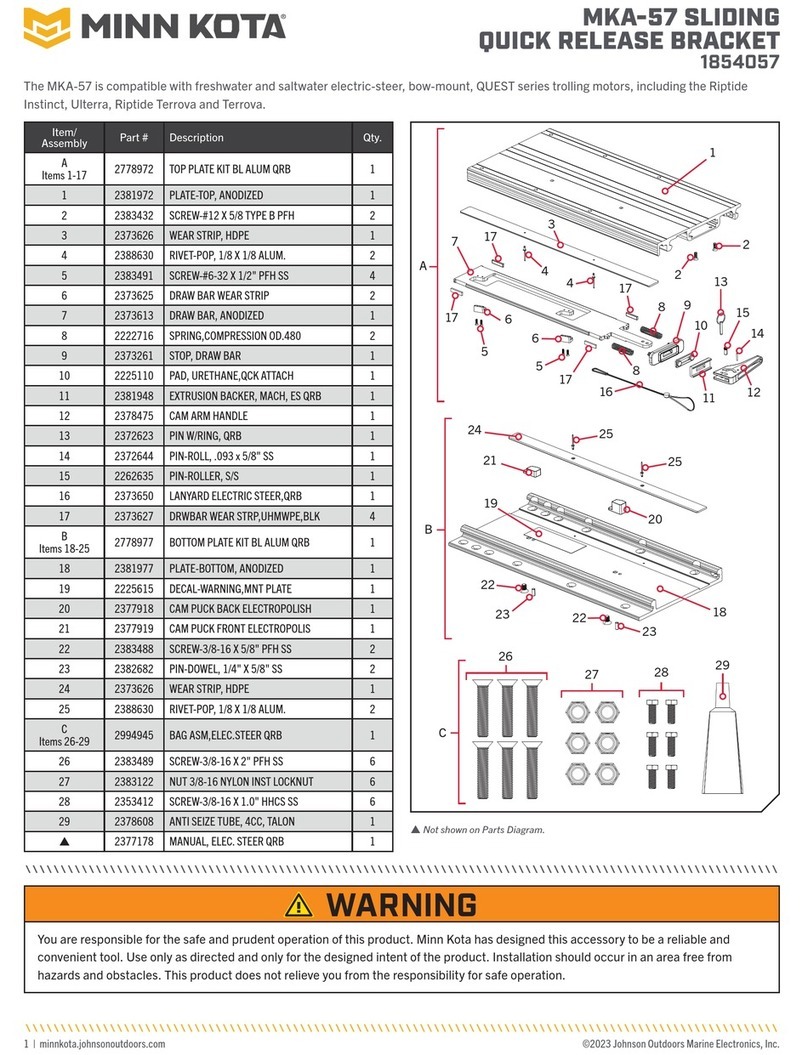

MKA-16-03 ELECTRIC-STEER

QUICK RELEASE BRACKET

1854035

MOUNTING CONSIDERATIONS

TOOLS AND RESOURCES REQUIRED

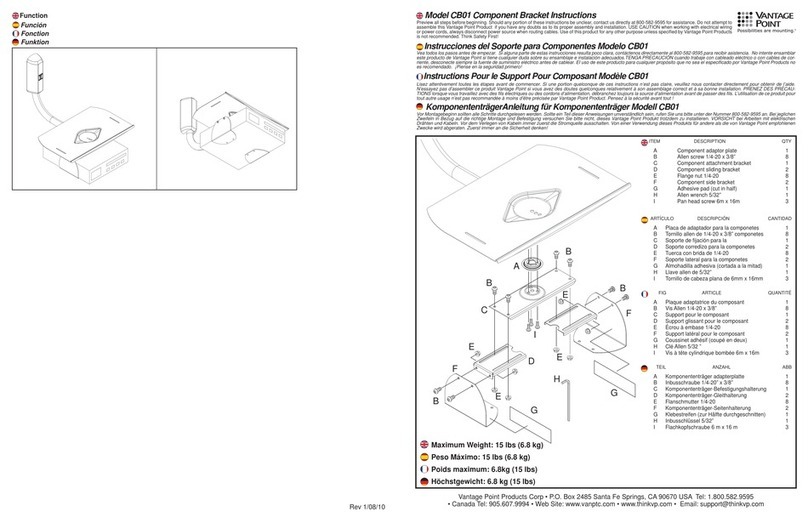

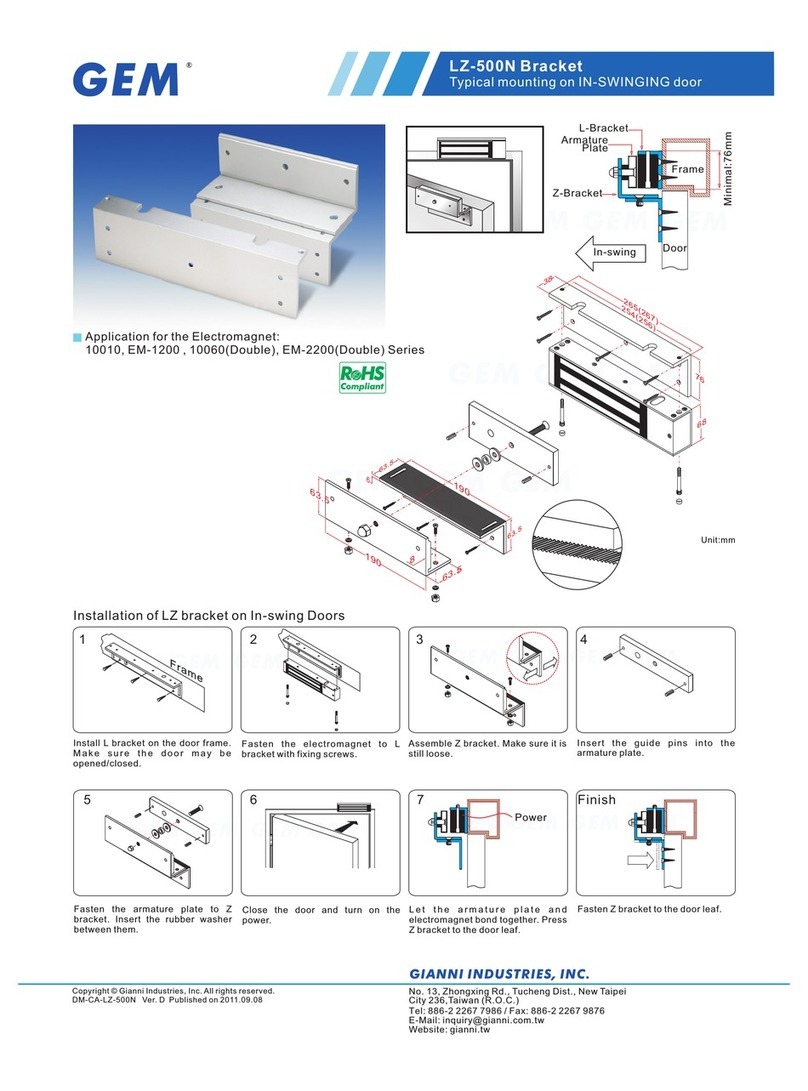

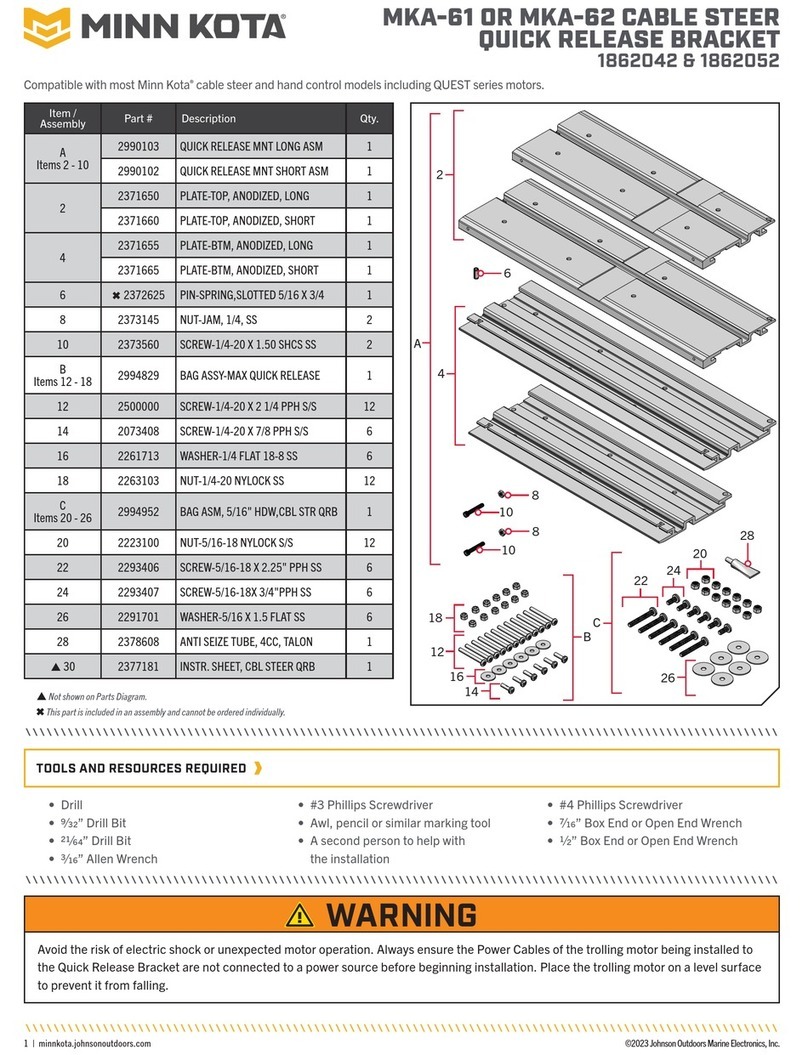

Item /

Assembly Part # Description Qty.

A

Includes

2-10

2990114 QCK REL PLATE/THUMB SCREW ASM 1

2✖PLATE-MNT,TOP PD QUICK RELEASE 1

4✖PLATE-MNT,BTM PD/AP QK/RL 1

6 2373421 SCREW-5/16-18 X 3/8 SHCS S/S 1

8 9951778 LOCKWASHER-1/4" ZINC 1

10 2011385 SCREW-TENSION/NEW KNOB 1

p2374914 INSTR SHEET-PD/AP QK RL BRK 1

B

Includes

12-18

2994932 BAG ASM, ELEC. STEER QRB 1

12 2371728 WASHER-FENDER 1/4 X 1 1/4 ZP 4

14 2373413 SCREW-1/4-20 X 7/8 HHCS ZP 4

16 2263104 NUT-1/4-20 NYLOCK ZP 8

18 2373516 BOLT-1/4-20 X 2" HHC ZP 4

22

66

88

1010

44

AA

BB

1414

1818

1212

1616

• #3 Phillips Screwdriver

• Drill

• 9/32” Drill Bit

• Awl or similar marking tool

• 7/16” Box End or

Open End Wrench

• A second person to help

with the installation

It is recommended that the motor be mounted as close to the

centerline or keel of the boat as possible. The motor must not

encounter any obstructions as it is lowered into the water or raised

into the boat when stowed and deployed. Make sure the motor rest

is positioned far enough beyond the edge of the boat. Make sure

the area under the mounting location is flat, clear to drill holes and

install nuts and washers. Recruit a second person to help with the

installation, as an unsecured motor will tip when deployed and

when left unattended.

pNot shown on Parts Diagram.

✖This part is included in an assembly and cannot be ordered individually.

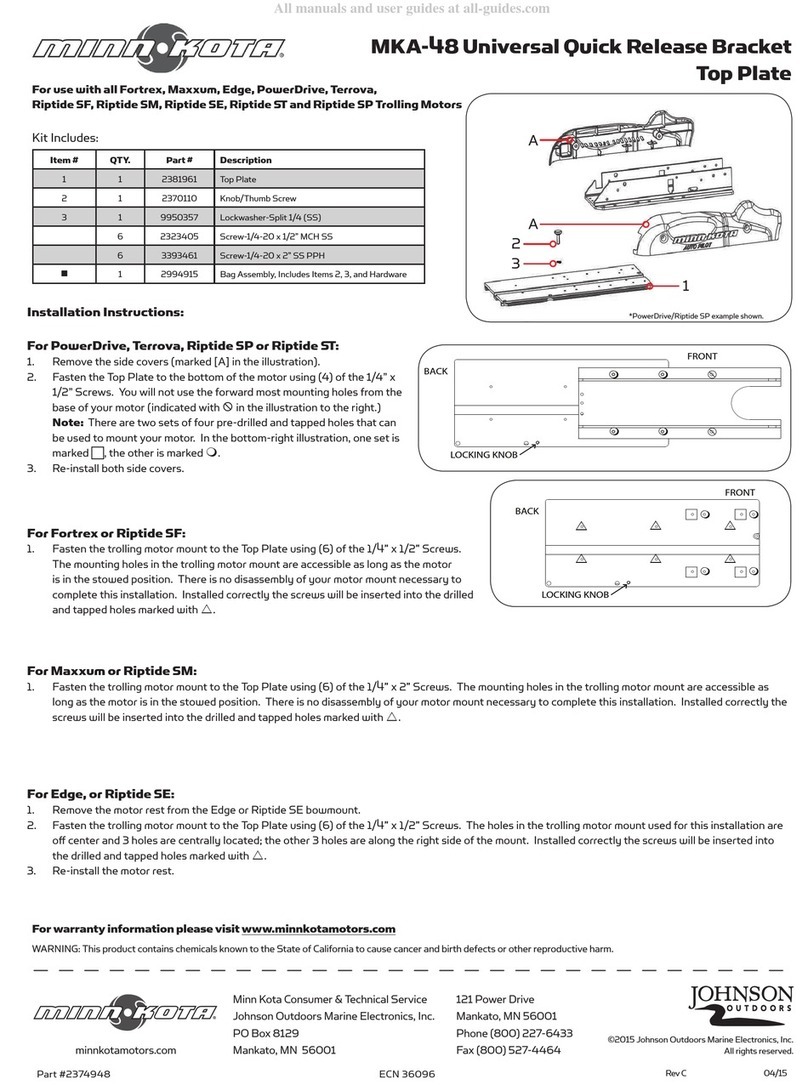

For use with all Minn Kota® PowerDrive™, Pontoon PowerDrive™, Ulterra™ and Terrova® freshwater trolling motors, the PowerDrive™ Pontoon

Hand Control Bracket and the DeckHand 40.

NOTICE: Images are a graphical representation and may

vary slightly from your motor.

NOTICE: In order for the MKA-16-03 bracket to be engaged

and disengaged, the motor must be in the stowed position.

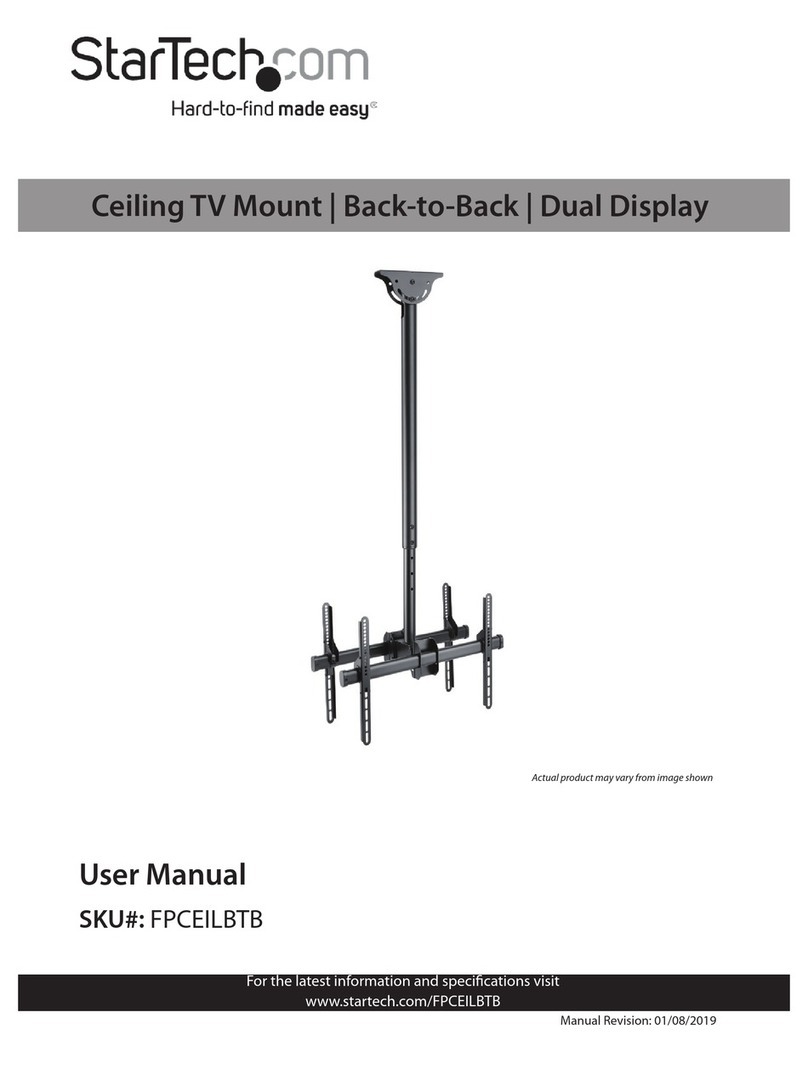

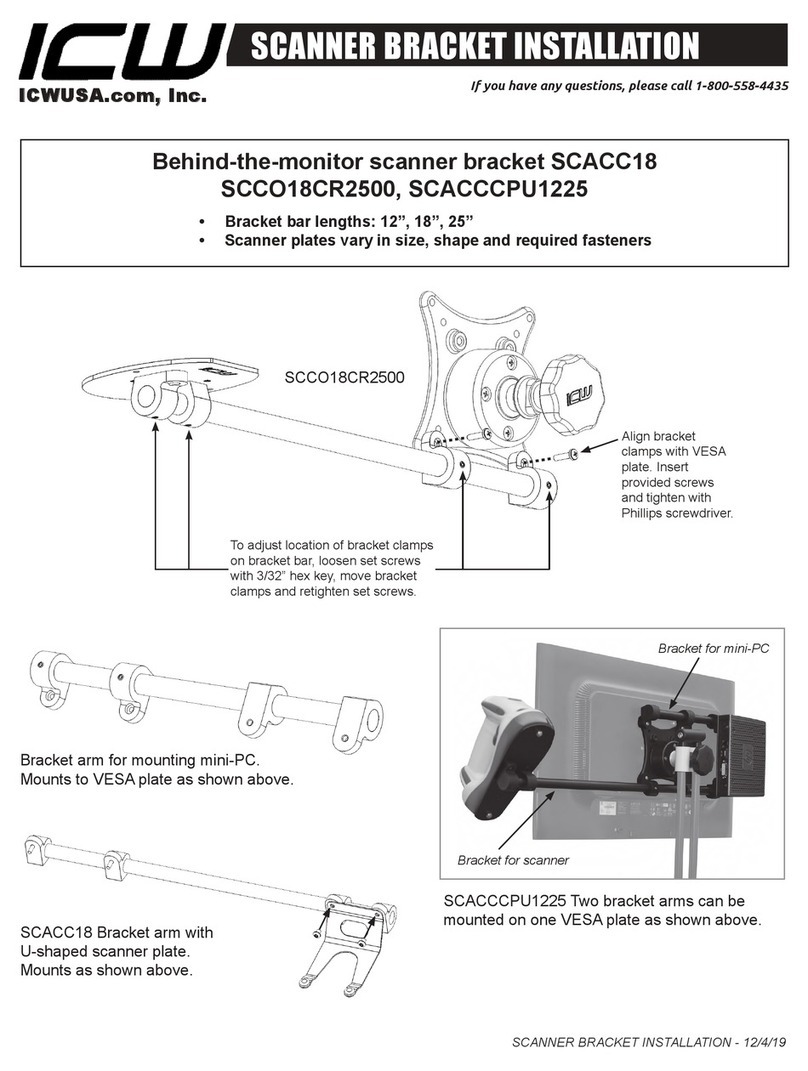

Complete Typical Installation

NOTICE: The mounting surface for the Bottom Plate must

be completely flat. Rubber Washers can be used to shim

the Bottom Plate flat before hardware is tightened.

2 | minnkotamotors.com ©2022 Johnson Outdoors Marine Electronics, Inc.

The MKA-16-03 Electric Steer Quick Release Bracket is designed to work on a number of Minn Kota trolling motors. The base extrusion

or mounting bracket of the trolling motors may vary. Please note the appearance of the applicable trolling motors and mounting brackets.

UlterraUlterraPowerDrivePowerDrive TerrovaTerrova PowerDrive PontoonPowerDrive Pontoon

Hand ControlHand Control DeckHand 40DeckHand 40

InboardInboard InboardInboardInboardInboard InboardInboard InboardInboard

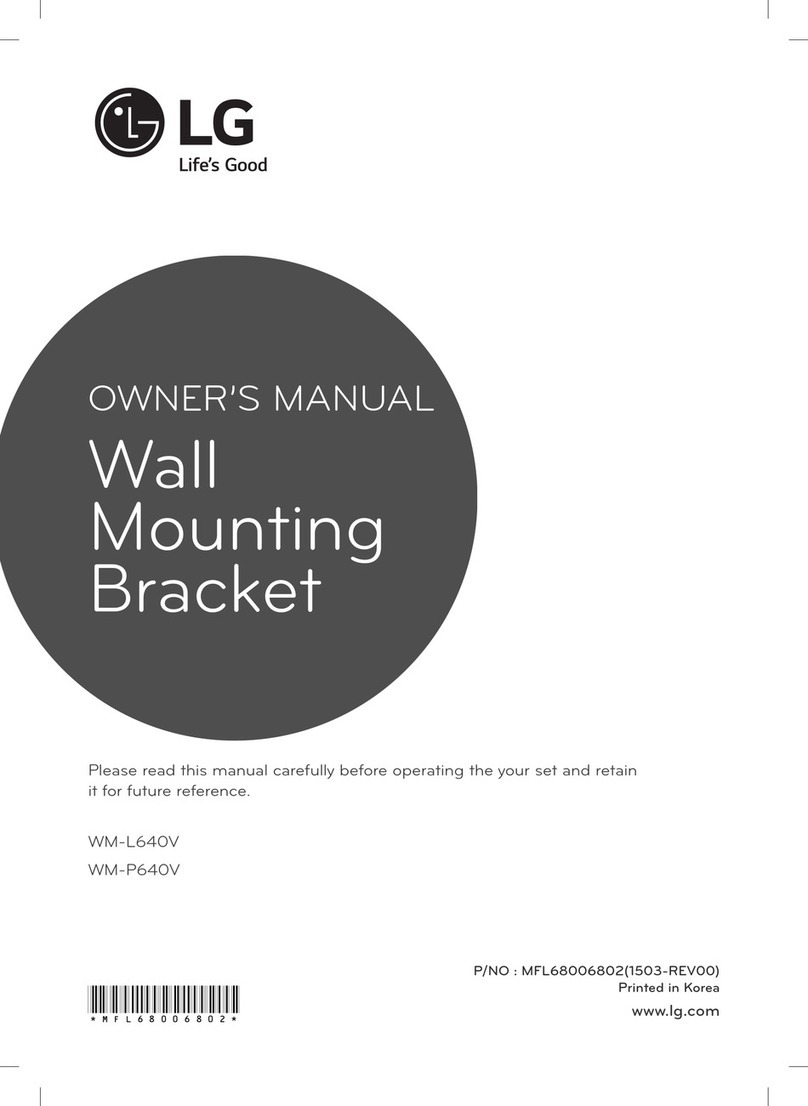

The mounting location of the Quick Release Bracket will vary

depending on the motor that will be mounted:

1. For PowerDrive or Terrova motors: Fully deploy the motor and

position the mount on the bow of the boat to check for proper

clearance. The motor must not encounter any obstructions

as it is lowered into the water or raised into the boat. When

the motor is deployed, there must be a minimum required

distance of 1½" between the Gunwale and the Shaft.

2. For Ulterra Motors: Position the mount so the Slot in

the Base Extrusion is positioned beyond the gunwale of the

boat. For proper clearance, the entire Slot must be visible

beyond the gunwale. When the motor is deployed, there must

be a minimum required distance of 1½" between the Gunwale

and the Shaft. The Ulterra motor cannot be deployed before

mounting and connecting to a power source.

3. For the DeckHand 40: The Davit must always be mounted

so it overhangs the bow by approximately nine inches. This

leaves room for the anchor to clear the boat and properly

pivot in the Davit. For more information, refer to the

DeckHand 40 owner's manual online at minnkotamotors.com.

Mount the bracket using only the four holes that are farthest

outboard. The two holes closest inboard are not used to

install the bracket.

4. For the Pontoon Hand Control Bracket: Mount the bracket

using only the four holes that are farthest outboard. The two

holes closest inboard are not used to install the bracket.

InboardInboard

Pontoon Hand Control

InboardInboard

DeckHand 40

Ulterra

1-1/2"1-1/2"

MinimumMinimum

GunwaleGunwale

ShaftShaft

PowerDrive or Terrova

SlotSlot

GunwaleGunwale

3 | minnkotamotors.com ©2022 Johnson Outdoors Marine Electronics, Inc.

INSTALLATION

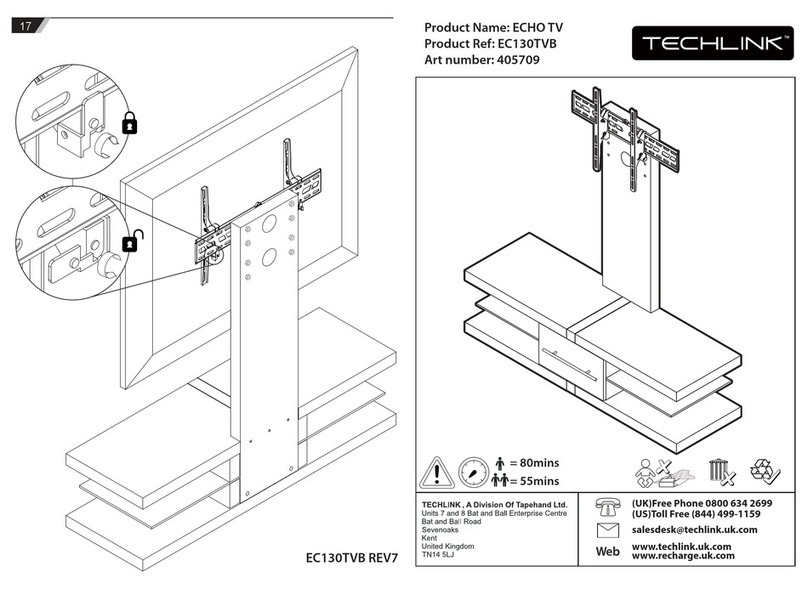

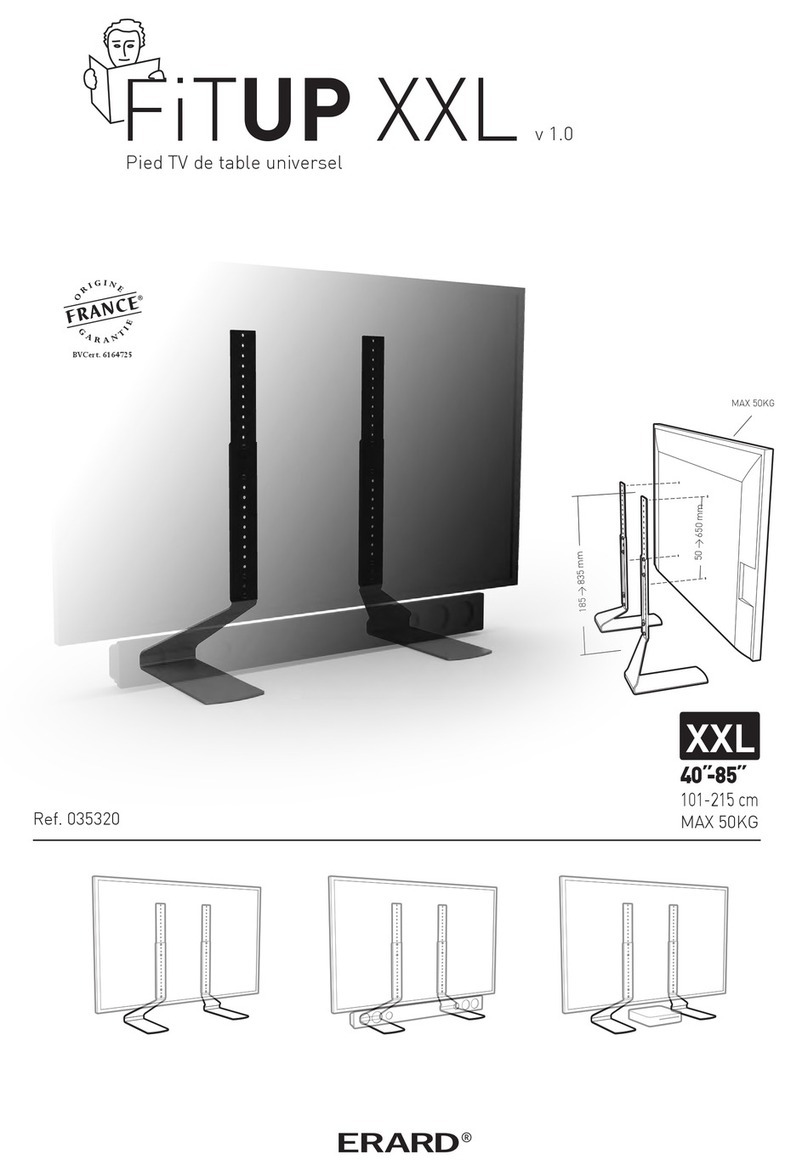

Opening the Bracket

a. Take the Quick Release Bracket Assembly

(Assembly #A) and remove the Tension Screw Knob

and Lock Washer. Set the Tension Screw Knob and

the Lock Washer aside to reassemble later.

b. Slide the Top and Bottom Plates and take notice of

the range of motion allowed in the bracket, as well

as the position of the bracket when it is completely

closed. The Socket Head Cap Screw stops the

motion of the brackets when closed.

c. Slide the Plates completely apart and set the Bottom

Plate aside. The Top Plate will be installed first.

d. On the Top Plate, take note of the Padlock Slot on

the side of the Plate, near the Socket Head Cap

Screw. When the Top Plate is installed to the Base

Extrusion, the Padlock Slot should face inboard.

#A x 1

CAUTION

Watch for pinch points when sliding the Top and Bottom

Plates of the MKA-16-03.

TensionTension

Screw KnobScrew Knob

Top PlateTop Plate

SlideSlide

SlideSlide

Top PlateTop Plate

BottomBottom

PlatePlate

Lock WasherLock Washer

Socket HeadSocket Head

Cap ScrewCap Screw

Padlock SlotPadlock Slot

Quick Release Bracket AssemblyQuick Release Bracket Assembly

ITEM(S) NEEDED

1

InboardInboard

Padlock SlotPadlock Slot

4 | minnkotamotors.com ©2022 Johnson Outdoors Marine Electronics, Inc.

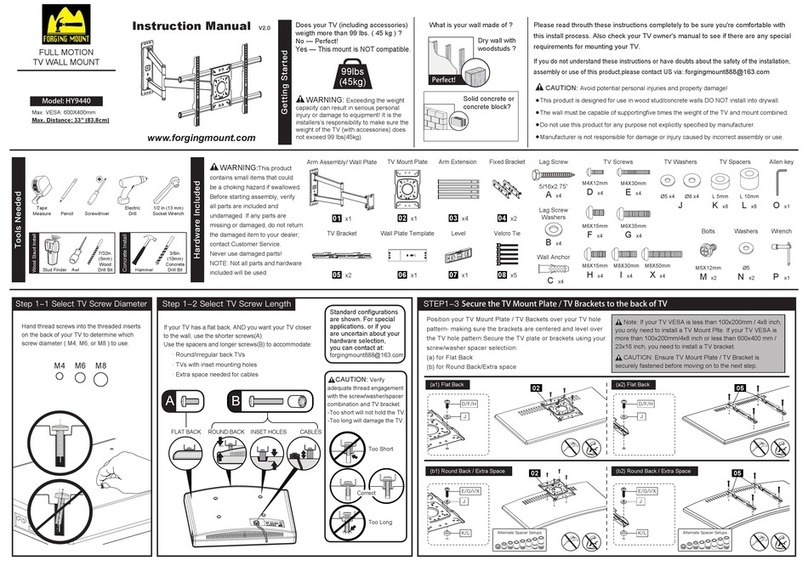

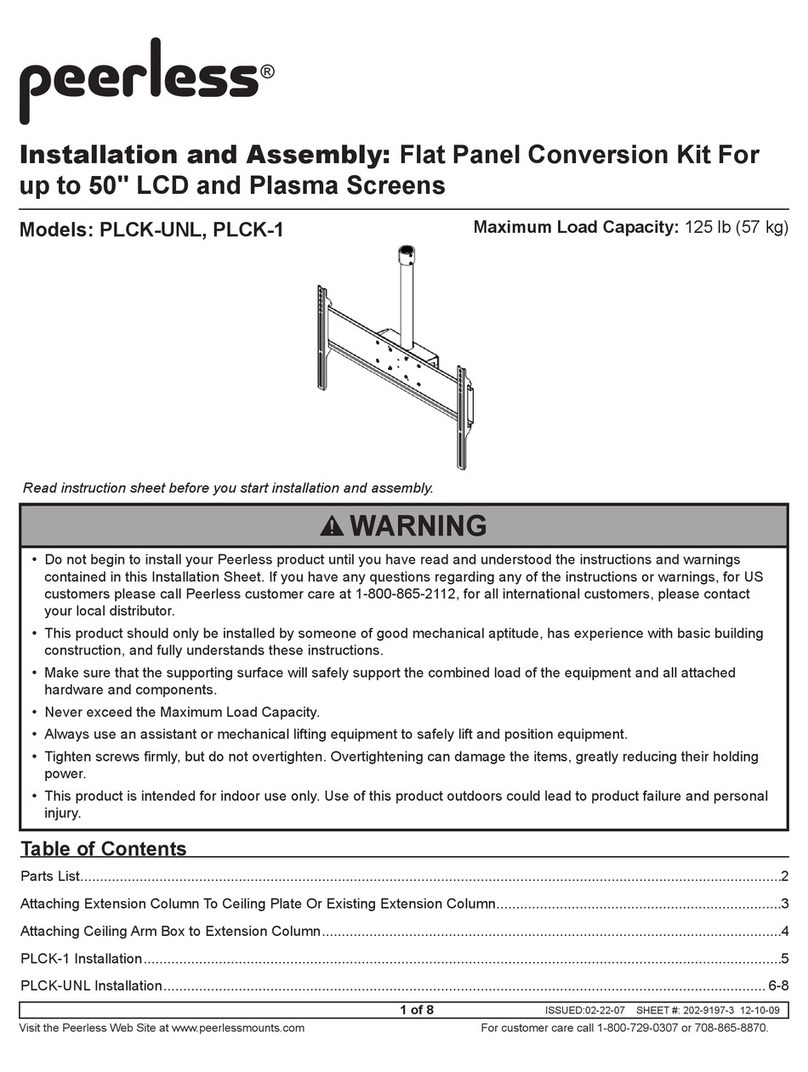

a. Make sure that the Power Cables from the battery

are disconnected or that the breaker, if equipped,

is "off." Power CablesPower Cables

WARNING

Make sure the motor is mounted on a level surface and is not

connected to a power source.

b. Place the mount on an elevated, level surface such

as a workbench or the tailgate of a pickup. The

motor should be in the stowed position.

c. Remove the four Sideplate screws using a #3 Phillips

Screwdriver. Two of these screws will be located on

each side of the mount.

NOTICE: A motor may weigh up to 65lbs. Minn Kota

recommends having a second person help with the installation.

DeployedDeployed StowedStowed

Sideplate ScrewSideplate Screw

1

22c

Installing the Top Plate to a PowerDrive or Terrova

d. Remove the Right Sideplate.

e. Swing the Left Sideplate out and away from the Base

Extrusion. Removing the sideplates exposes the

mounting holes in the Base Extrusion.

Right SideplateRight Sideplate

Mounting HolesMounting Holes

Left SideplateLeft Sideplate

Base ExtrusionBase Extrusion

33e

3d

5 | minnkotamotors.com ©2022 Johnson Outdoors Marine Electronics, Inc.

f. Place the flat side of the Top Plate (Item #2) against

the bottom of the Base Extrusion. The Padlock Slot

on the Top Plate should face inboard. Align the

Mounting Holes in the Top Plate with the Mounting

Holes in the Base Extrusion that were exposed when

the sideplates were removed. The appearance of your

Base Extrusion may vary depending on motor type.

#14 x 4#2 x 1 #16 x 4

Top PlateTop Plate

Mounting HolesMounting Holes

MountingMounting

HolesHoles

BaseBase

ExtrusionExtrusion

Padlock SlotPadlock Slot

Hex HeadHex Head

Cap ScrewCap Screw

Nylock NutsNylock Nuts OutboardOutboard

InboardInboard

4ITEM(S) NEEDED

h. With the Top Plate attached to the Base Extrusion,

Replace the Right Sideplate.

i. Swing the Left Sideplate back into its correct

position on the Base Extrusion.

j. Replace the four sideplate screws using a #3 Phillips

Screwdriver. Two of these screws will be located on

each side of the mount.

Right SideplateRight Sideplate

Left SideplateLeft Sideplate

Base ExtrusionBase Extrusion

Sideplate ScrewSideplate Screw

55i

5j

5h

NOTICE: To prevent seizing of the stainless steel

hardware, do not use high-speed installation tools.

Wetting the screws or applying an anti-seize may help

prevent seizing.

g. Use four Hex Head Cap Screws (Item #14) and four

Nylock Nuts (Item #16) to secure the Top Plate to the

Base Extrusion. Install the Screws using only the four

corner mounting holes, with two Screws on each side

of the Base Extrusion. The center mounting holes

will not be used. The Screws should pass from the

bottom up, through the Top Plate and into the Base

Extrusion. Place a Nylock Nut on the end of each

Screw and tighten with a 7/16” Box End or Open End

Wrench. Make sure all hardware is secure.

Other manuals for MKA-16-03

1

This manual suits for next models

1

Table of contents

Languages:

Other MINN KOTA TV Mount manuals

MINN KOTA

MINN KOTA MKA-51 User manual

MINN KOTA

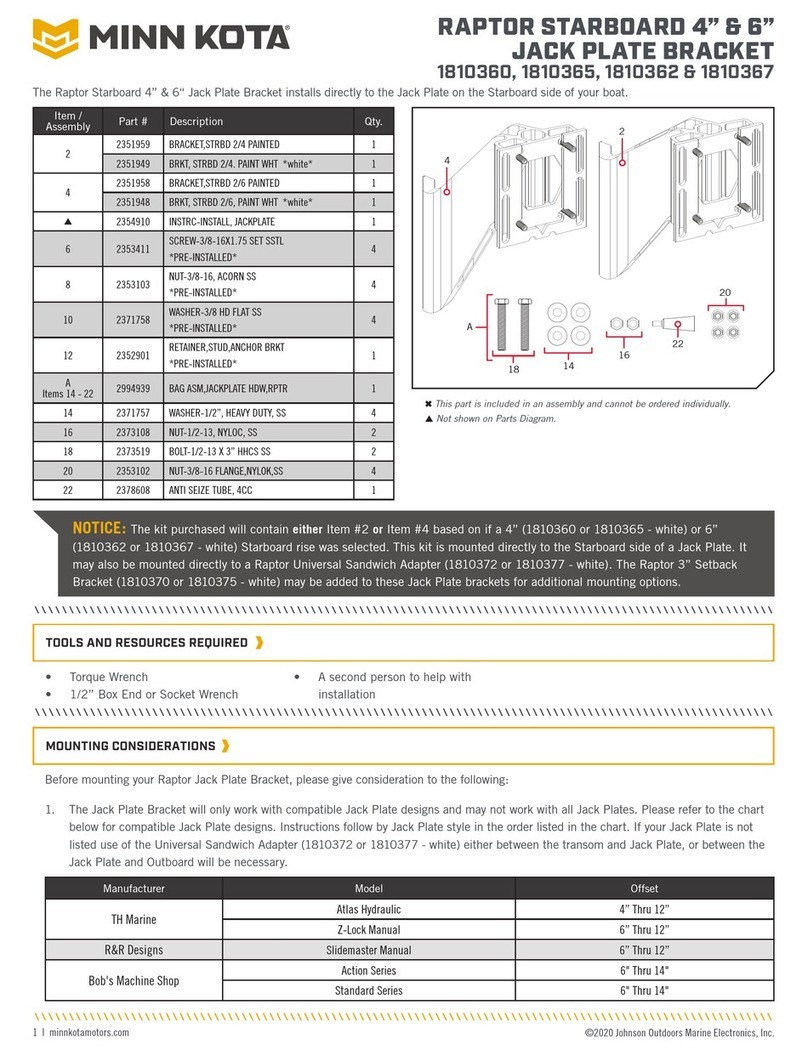

MINN KOTA 1810360 User manual

MINN KOTA

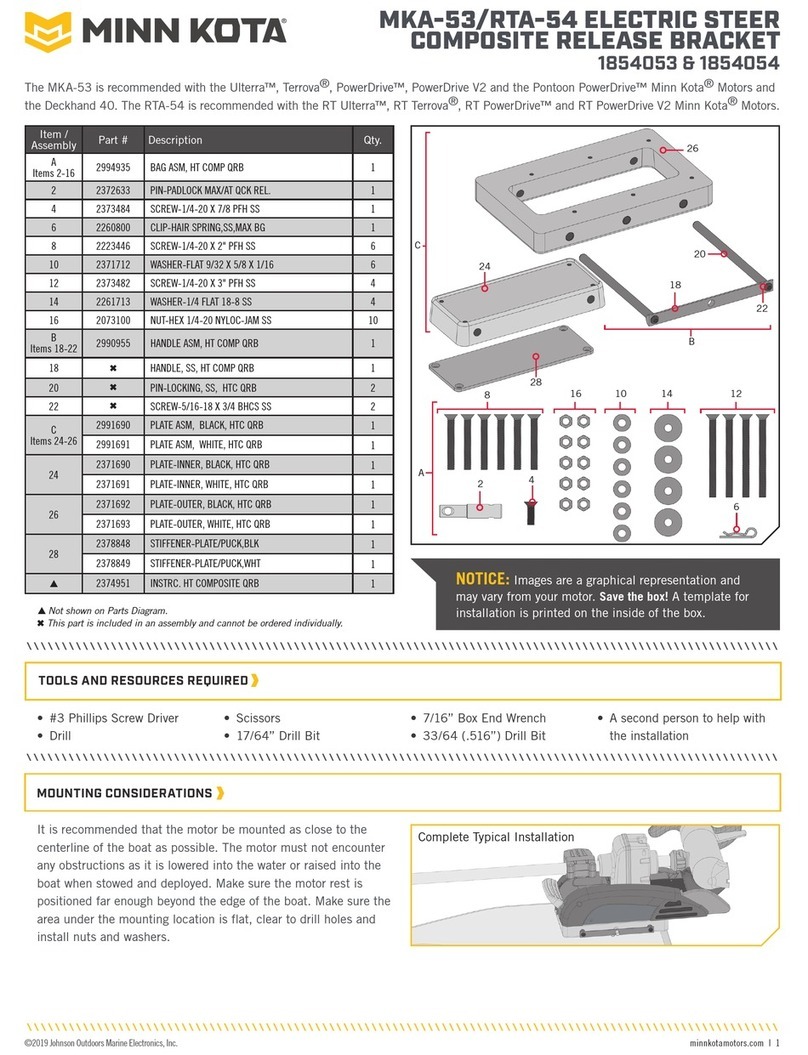

MINN KOTA MKA-53 User manual

MINN KOTA

MINN KOTA MKA-23 User manual

MINN KOTA

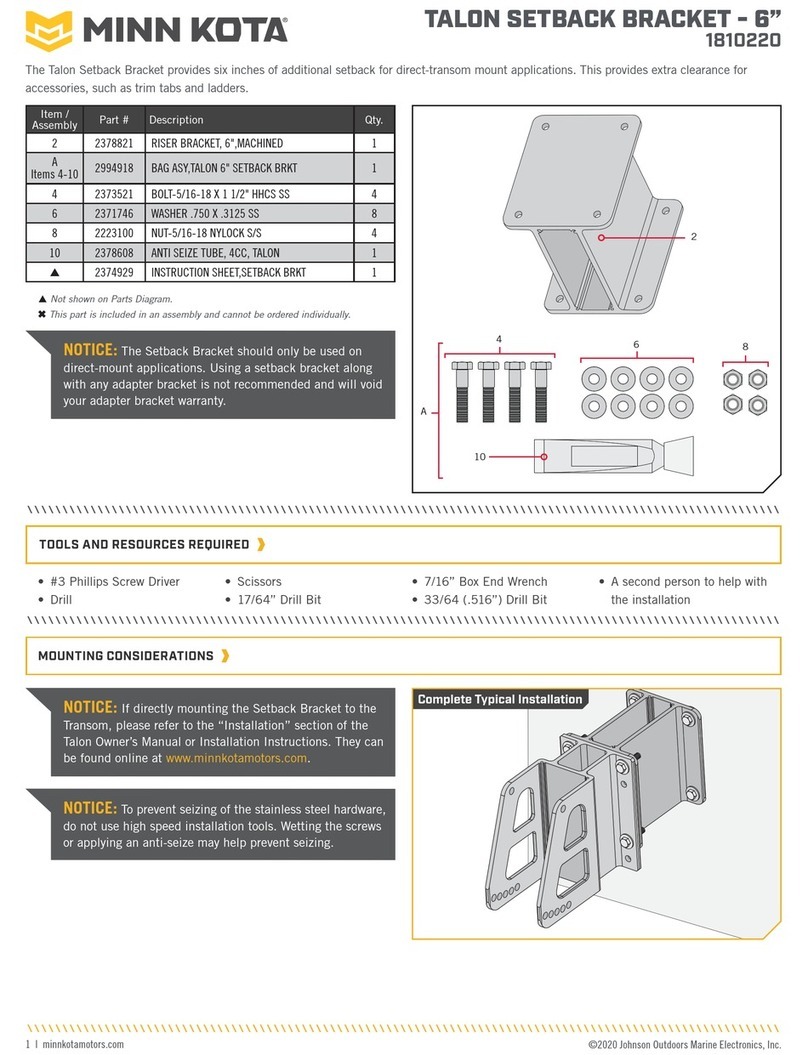

MINN KOTA 1810220 User manual

MINN KOTA

MINN KOTA MKA-61 User manual

MINN KOTA

MINN KOTA MKA-48 User manual

MINN KOTA

MINN KOTA MKA-47 User manual

MINN KOTA

MINN KOTA TALON User manual

MINN KOTA

MINN KOTA MKA-16-03 User manual