Printed in Japan

Mitutoyo Corporation, 1-20-1 Sakado, Takatsu-ku, Kawasaki City, Kanagawa 213-8533, Japan

Tips

Use a sub-anvil as well when the micrometer head only is insufcient for the required adjustment

range.

3. Reference Point Setting

• A reference gage is required for reference point setting.

• Dirt on the reference gage may lead to an error. Clean before reference point setting.

• Be sure to set the reference point before measurement and after measured dimension setting.

Even during continuous measurement, set the reference point as often as possible.

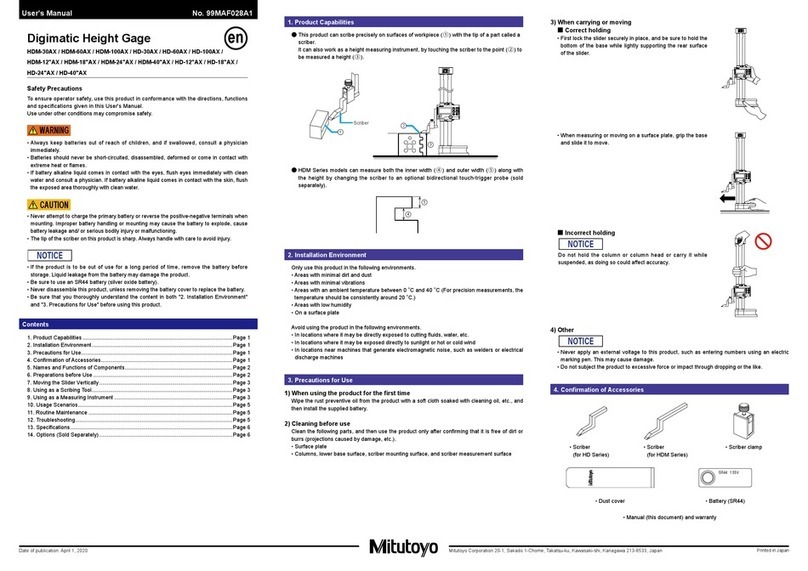

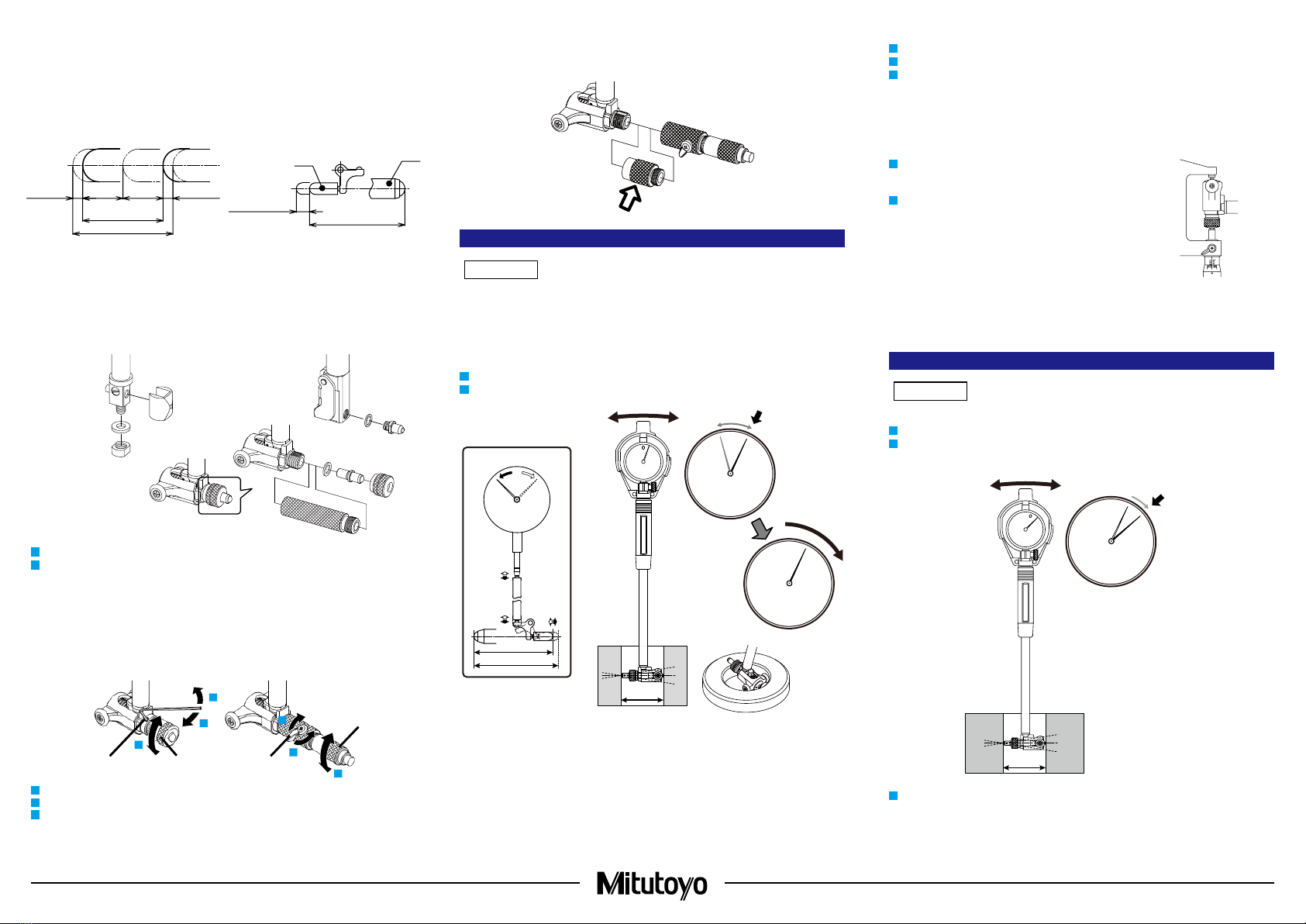

1) Reference point setting with a set ring or cylindrical master gage

1Insert the bore gage into the reference gage (set ring or cylindrical master gage).

2Oscillate the bore gage. The reference point is where the contact point is pushed deepest.

0

10

20

30

0

10

20

30

0

A

B

B

A

60.00

Tips

• Setting the indicator to the reference point.

• Turn the bezel when the indicator is a dial gage.

• Perform presetting when the indicator is a Digimatic indicator.

• When inserting the bore gage into a reference gage, insert the contact point/guide side rst.

After that, insert the anvil side while pressing the guide to the reference gage.

2) Reference point setting with outside micrometer and gauge block

1

Measure the gauge block corresponding to the reference dimension by inserting it into the micrometer.

2Clamp the micrometer and then remove the gauge block.

3Insert the bore gage instead into the micrometer, and then oscillate the bore gage. The

reference point is where the contact point is pushed deepest.

3) Reference point setting with outside micrometer only

Notices

Do not clamp the micrometer.

1 Fix the micrometer vertically with the head (spindle) portion

downward and align the opening of the measuring surfaces

to the reference dimension.

2Insert the bore gage to the measuring surfaces of the

micrometer and then oscillate the bore gage. The reference

point is where the contact point is pushed deepest.

Tips

• Reference point setting with the outside micrometer requires expertise, since centripetal effects

by the guides cannot be utilized.

• Reference point setting can be performed in the same way as with an outside micrometer even

with another reference gage (gauge block, height master, bore gage checker).

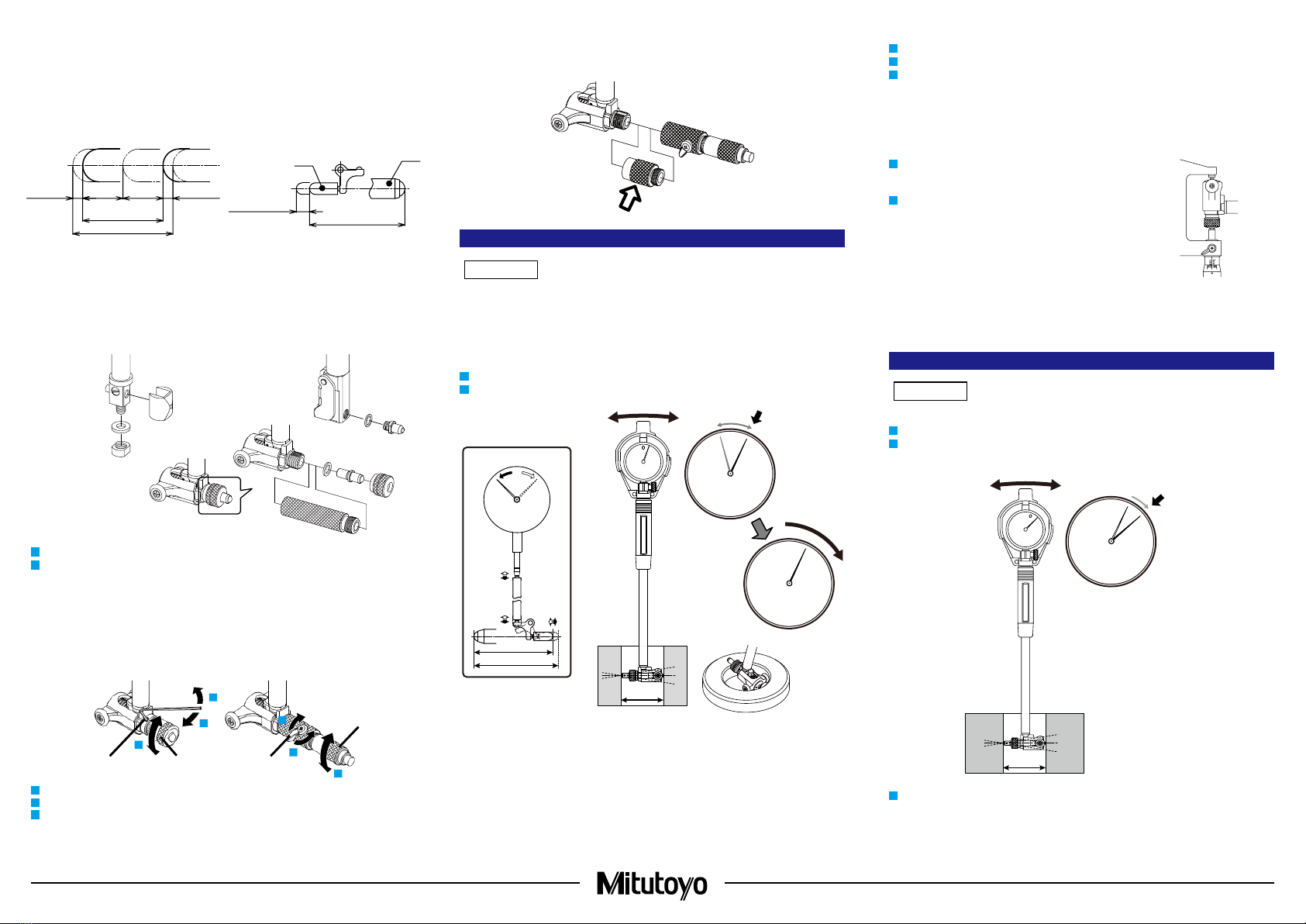

4. Measurement Method

Dirt on the workpiece may lead to an error. Clean before measurement.

1Insert the bore gage into the workpiece to be measured.

2Oscillate the bore gage and read the indicated value. If the indicator is a dial gage, read the

value when the needle swings widest clockwise.

0

59.93

10

20

30

3Calculate the measured value by adding the read value (difference) to the dimension of the

reference gage.

Tips

When inserting the bore gage into the workpiece to be measured, insert the contact point/guide

side rst. After that, insert the anvil side while pressing the guide to the workpiece.

2) Adjusting the nominal size

Adjust the nominal size according to the dimensions to be measured by attaching an anvil,

adjustment washer, or sub-anvil, or adjusting the micrometer head.

We recommend using a central value of the measured dimensions as nominal size L.

For instance, if the measured dimensions are 100 ±0.05 mm, the nominal size is set to 100 mm.

Similarly, if the measured dimensions are 100.5 +0.02/-0.08 mm, nominal size L should ideally be

set to 100.47 mm. However, except for CGM-X, settings in 0.01 mm increments are not possible.

Therefore, set to 100.5 mm, the nearest possible value to the central value.

A

L

Po

S

R

R/2R/2

0.1 mm + R/2

(0.004 in + R/2)

0.1 mm

(0.004 in)

0.1 mm

(0.004 in)

A:

Contact point

B: Anvil

L: Nominal size (length from the anvil tip to P0 which is the center of effective measurement range)

R:

Effective measurement range

S:

Movable range

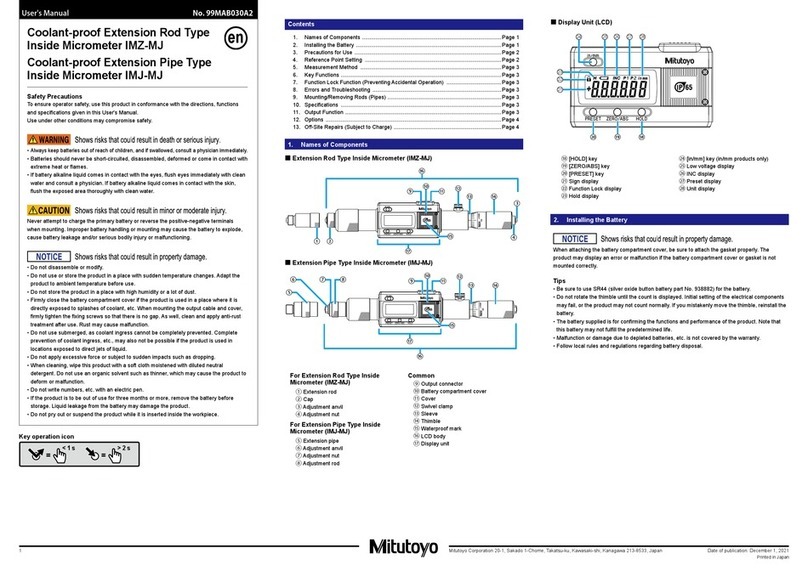

■ Adjusting the nominal size with anvils, adjustment washers, or sub-anvils.

CG-S10A,

CG-S.4”A

CG-S18A, CG-S.7”A,

CG-35AX, CG-1.4”AX,

CGB-35X, CGB-1.4”X,

CGF-35X - CGF-150X,

CGF-1.4"X - CGF-6"X

CG-60AX - CG-400AX,

CG-2.5”AX - CG-16”AX,

CGB-60X - CGB-160X,

CGB-2.5”X - CGB-6.5”X

1Select an anvil, adjustment washers, etc. according to the measured dimensions.

2Mount securely, making sure there is no looseness or play.

Tips

• If attaching multiple adjustment washers, attach as few as possible.

• Except for models where an anvil is xed with a supporting nut, use the provided wrench when

attaching or removing the anvil.

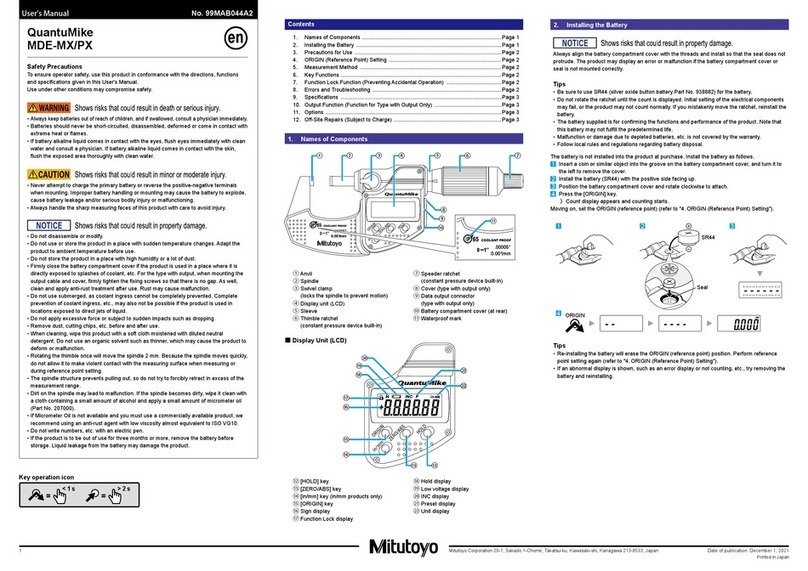

■ Adjusting the nominal size with micrometer head

1

3

1

3

2

1

3

Hex socket head set screw Thimble

Thimble

Clamp

1 Turn the hex socket head set screw or clamp to release the micrometer head.

2Turn the thimble to adjust the length of the micrometer head.

3 Turn the hex socket head set screw or clamp to x the micrometer head.