Mitutoyo Corporation 20-1, Sakado 1-Chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213-8533, Japan Date of publication: April 27, 2022

Printed in Japan

4

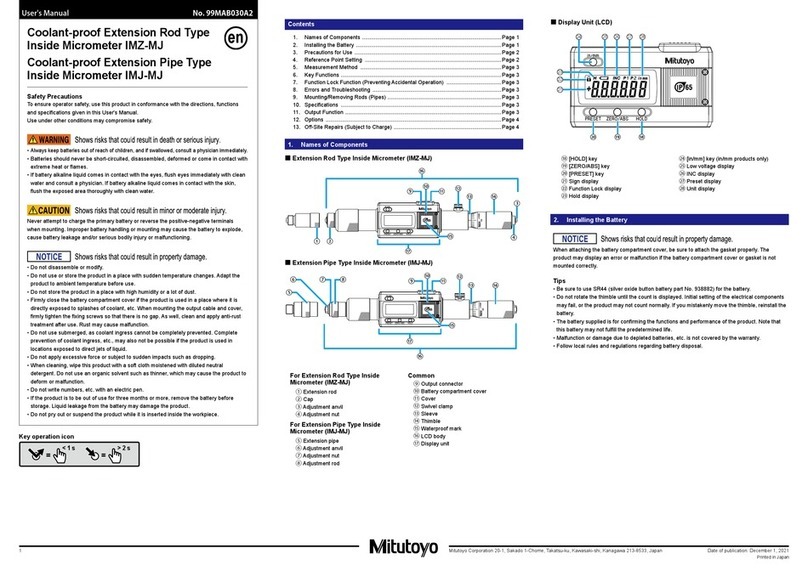

Key icon operation

=

< 1 s

=

> 2 s

F2 F3F1

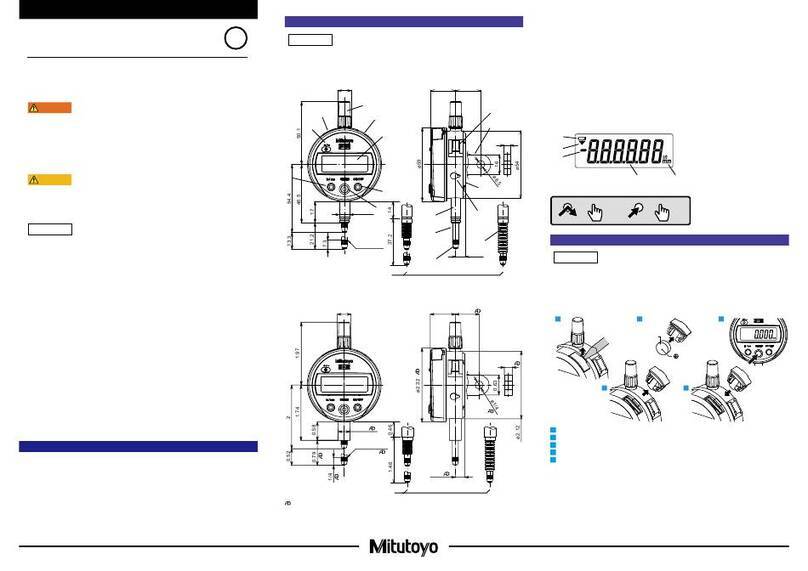

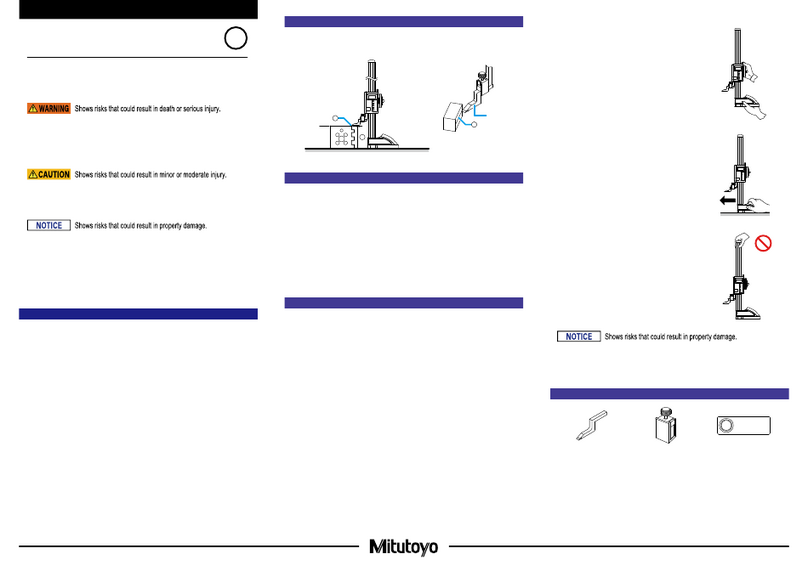

1) For incremental measurement (INC)

Zeros the dimensions of the master to use as reference and measures the dimensional difference with the workpiece.

1

Confirm that the product is in incremental measurement (INC display is turned on), and check the counting direction.

Tips

• If set to absolute measurement, switch the measurement system to incremental measurement.

Refer to "7. Switching Measurement Systems" for details.

• Negative counting is normally used. Refer to "11. Setting Parameters" - "4) Selecting the

counting direction" for details.

2Press the base surface against the reference plane (a scale or other surface guaranteed to be

flat) and slide it horizontally several times.

3Press the [F2] key.

⇨The displayed value is set to zero.

4Repeat step 2 several times to confirm that the reference point is not misaligned.

5Replace the master with the workpiece and perform incremental measurement.

F2

2

1

3

5

4

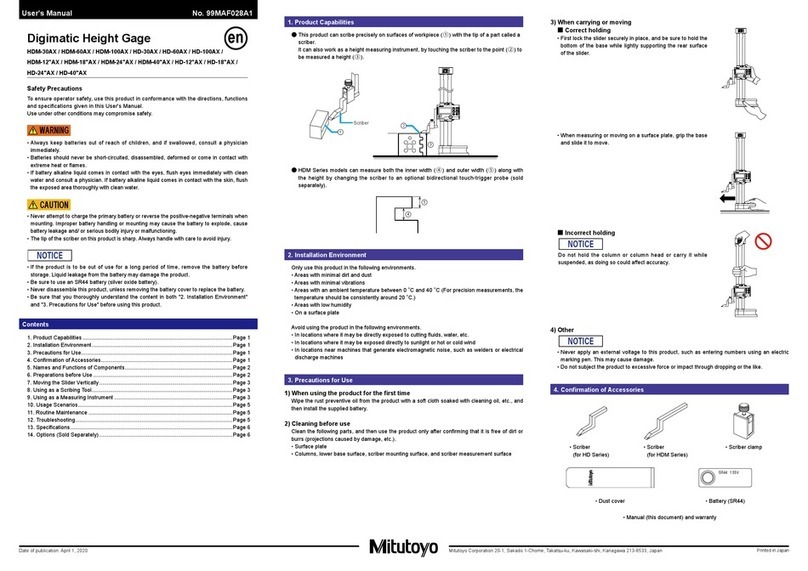

2) For absolute measurement (ABS)

Sets (presets) the measurement origin and measures the dimensions of the workpiece.

3-4

3-5

1 2

3-1 3-2

3-3

3-6

4

F2 F2

F2

F2

F2 F1/F3

F1 F3

F1 F2

F3

1 Confirm that the product is in absolute measurement (INC display is turned off), and check the

counting direction.

Tips

• If set to incremental measurement, switch the measurement system to absolute measurement.

Refer to "7. Switching Measurement Systems" for details.

• Negative counting is normally used. Refer to "11. Setting Parameters" - "4) Selecting the

counting direction" for details.

2Press and hold the [F2] key to start setting (presetting) the measurement origin.

⇨Preset display ([P]) will blink and the previous preset value will be displayed.

3Set the preset value.

1 Press and hold the [F2] key.

⇨The sign will blink and the preset value can be changed.

2 Press the [F1] key or [F3] key.

⇨Each time the key is pressed, it will switch the sign.

3 Press the [F2] key.

⇨ The sign is confirmed and the neighboring digit blinks.

4 Press the [F1] key or [F3] key.

⇨Each time the key is pressed, the value will change by one.

5 Press the [F2] key.

⇨ The number is confirmed and the neighboring digit blinks.

⇨Each time the key is pressed, the blinking digit moves to the right.

6 Repeat steps 4 to 5 above until the numbers for all digits are confirmed.

⇨ Confirming the last digit will cause preset display ([P]) to blink.

4Press the [F2] key to exit the origin setting (presetting).

⇨ The preset display turns off and the setting is concluded.

Tips

• Press and hold the [F1] key to cancel the preset setting.

• If the preset value is incorrect, press and hold the [F2] key and redo from step 3.

5Press the base surface against the master and slide it horizontally several times.

5

6Set the origin.

6-1 -26

1 Press and hold the [F2] key.

⇨

Preset display ([P]) will blink and the previous preset value (example: 3.00 mm) will be displayed.

2 Confirm the preset value, and then press the [F2] key.

⇨The measurement origin is set as the preset value and it becomes measurable.

7Replace the master with the workpiece and perform absolute measurement.

7

Tips

• The set preset value and origin are retained even when the power is turned off. However, the

preset value is cleared when All Reset is performed and must be reset.

• The preset value is automatically converted when the unit system or resolution is changed. In

this case, however, a conversion error may be produced. It is therefore recommended to check

the preset value after changing the unit system or resolution.

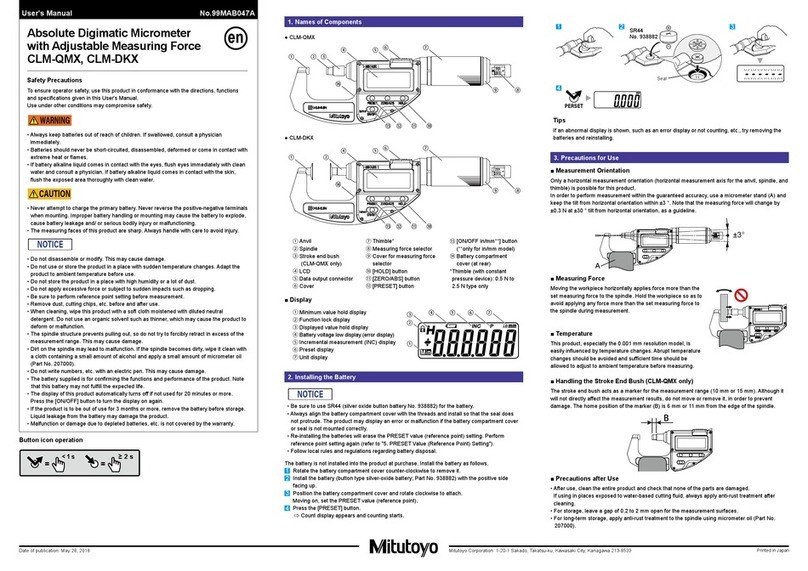

3) Detecting peaks

During peak detection, measurement is performed by moving and rotating the workpiece while it is

gripped. The displayed value can be switched between the runout width (TIR), the maximum value

(Max), and the minimum value (Min) detected as the displacement peak value.

●Current value display

Current measurement value is always displayed.

●Runout width (TIR) display

The runout width (maximum value - minimum value) is always displayed relative to the displacement

of the measured value. [Max] or [Min] blinks when the maximum and minimum values are updated.

Tolerance judgment results are displayed with respect to the runout.

Tips

• When [Auto] is selected in "Analog bar display selection" in the parameter setting mode, the

analog bar scale automatically changes so that the pointer of the analog bar is always within

the display range with respect to the displacement of the measured value.

•

For tolerance judgment, the set upper/lower limit width is compared with the measured runout width.

● Maximum value (Max) display

The maximum value is always displayed relative to the displacement of the measured value.

[Max] blinks when the maximum values are updated.

Tolerance judgment results are displayed with respect to the maximum value.

Tips

•

In absolute measurement, it is possible to preset any maximum value and perform measurement

based on that position. Refer to "9. Measurement Method" - "2) For absolute measurement

(ABS)" for preset settings.

• If the pointer on the analog bar exceeds the display range with respect to the displacement of

the measured value, the pointer automatically returns to the center position.

● Minimum value (Min) display

The minimum value is always displayed relative to the displacement of the measured value.

[Min] blinks when the minimum values are updated.

Tolerance judgment results are displayed with respect to the minimum value.

Tips

•

In absolute measurement, it is possible to preset any minimum value and perform measurement

based on that position. Refer to "9. Measurement Method" - "2) For absolute measurement

(ABS)" for preset settings.

• If the pointer on the analog bar exceeds the display range with respect to the displacement of

the measured value, the pointer automatically returns to the center position.