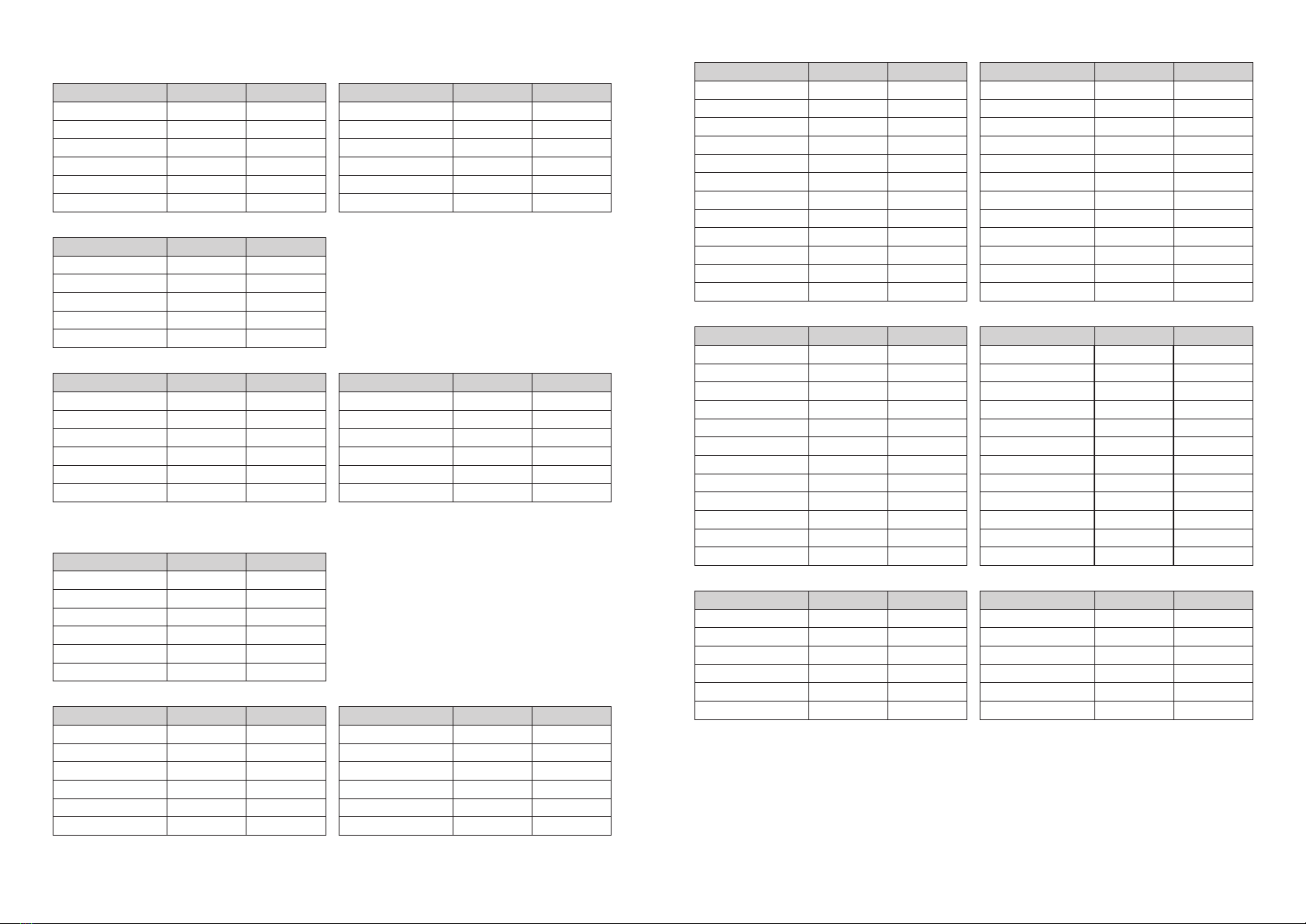

0.05 mm / 1/128 in

*L (mm) EMPE (mm) SMPE (mm) *L (inch) EMPE (inch) SMPE (inch)

0 ≤ L ≤ 50 ±0.04 ±0.04 0 ≤ L ≤ 2 ±0.5/128 ±0.5/128

50 < L ≤ 100 ±0.04 ±0.04 2 < L ≤ 4 ±0.5/128 ±0.5/128

100 < L ≤ 200 ±0.04 ±0.04 4 < L ≤ 8 ±0.5/128 ±0.5/128

200 < L ≤ 300 ±0.04 ±0.04 8 < L ≤ 12 ±0.5/128 ±0.5/128

300 < L ≤ 400 ±0.06 ±0.06 12 < L ≤ 16 ±0.5/128 ±0.5/128

400 < L ≤ 500 ±0.06 ±0.06 16 < L ≤ 20 ±0.5/128 ±0.5/128

500 < L ≤ 600 ±0.08 ±0.08 20 < L ≤ 24 ±1/128 ±1/128

600 < L ≤ 700 ±0.08 ±0.08 24 < L ≤ 28 ±1/128 ±1/128

700 < L ≤ 750 ±0.08 ±0.08 28 < L ≤ 30 ±1/128 ±1/128

750 < L ≤ 800 ±0.10 ±0.10 30 < L ≤ 32 ±1/128 ±1/128

800 < L ≤ 900 ±0.10 ±0.10 32 < L ≤ 36 ±1/128 ±1/128

900 < L ≤ 1000 ±0.10 ±0.10 36 < L ≤ 40 ±1/128 ±1/128

0.02 mm / 0.001 in

*L (mm) EMPE (mm) SMPE (mm) *L (inch) EMPE (inch) SMPE (inch)

0 ≤ L ≤ 50 ±0.04 ±0.04 0 ≤ L ≤ 2 ±0.0015 ±0.0015

50 < L ≤ 100 ±0.04 ±0.04 2 < L ≤ 4 ±0.0015 ±0.0015

100 < L ≤ 200 ±0.04 ±0.04 4 < L ≤ 8 ±0.0015 ±0.0015

200 < L ≤ 300 ±0.04 ±0.04 8 < L ≤ 12 ±0.0015 ±0.0015

300 < L ≤ 400 ±0.06 ±0.06 12 < L ≤ 16 ±0.0025 ±0.0025

400 < L ≤ 500 ±0.06 ±0.06 16 < L ≤ 20 ±0.0025 ±0.0025

500 < L ≤ 600 ±0.08 ±0.08 20 < L ≤ 24 ±0.0030 ±0.0030

600 < L ≤ 700 ±0.08 ±0.08 24 < L ≤ 28 ±0.0030 ±0.0030

700 < L ≤ 750 ±0.08 ±0.08 28 < L ≤ 30 ±0.0030 ±0.0030

750 < L ≤ 800 ±0.10 ±0.10 30 < L ≤ 32 ±0.0040 ±0.0040

800 < L ≤ 900 ±0.10 ±0.10 32 < L ≤ 36 ±0.0040 ±0.0040

900 < L ≤ 1000 ±0.10 ±0.10 36 < L ≤ 40 ±0.0040 ±0.0040

0.001 in

*L (inch) EMPE (inch) SMPE (inch) *L (inch) EMPE (inch) SMPE (inch)

0 ≤ L ≤ 2 ±0.0015 ±0.0015 20 < L ≤ 24 ±0.0030 ±0.0030

2 < L ≤ 4 ±0.0015 ±0.0015 24 < L ≤ 28 ±0.0030 ±0.0030

4 < L ≤ 8 ±0.0015 ±0.0015 28 < L ≤ 30 ±0.0030 ±0.0030

8 < L ≤ 12 ±0.0015 ±0.0015 30 < L ≤ 32 ±0.0040 ±0.0040

12 < L ≤ 16 ±0.0025 ±0.0025 32 < L ≤ 36 ±0.0040 ±0.0040

16 < L ≤ 20 ±0.0025 ±0.0025 36 < L ≤ 40 ±0.0040 ±0.0040

*L

jp 測定長さ sv Mätlängd zh-CN 实测长度

en Measured length pt Comprimento medido zh-TW 實測長度

de Messlänge cs Měřená délka th ความยาวที่วัดได้

es Longitud medida pl Długość pomiaru vi Chiều dài đo được

fr Longueur mesurée ru Длина измерения ms Panjang yang diukur

nl Gemeten lengte tr Ölçme uzunluğu id Panjang terukur

it Lunghezza misurata ko 측정 된 길이

App-2 No. 99MAC002

533 Series

0.05 mm

*L (mm) EMPE (mm) SMPE (mm) *L (mm) EMPE (mm) SMPE (mm)

0 ≤ L ≤ 50 ±0.05 ±0.05 500 < L ≤ 600 ±0.10 ±0.10

50 < L ≤ 100 ±0.05 ±0.05 600 < L ≤ 700 ±0.12 ±0.12

100 < L ≤ 200 ±0.05 ±0.05 700 < L ≤ 750 ±0.12 ±0.12

200 < L ≤ 300 ±0.08 ±0.08 750 < L ≤ 800 ±0.15 ±0.15

300 < L ≤ 400 ±0.08 ±0.08 800 < L ≤ 900 ±0.15 ±0.15

400 < L ≤ 500 ±0.10 ±0.10 900 < L ≤ 1000 ±0.15 ±0.15

0.02 mm: 533-503

*L (mm) EMPE (mm) SMPE (mm)

0 ≤ L ≤ 50 ±0.02 ±0.02

50 < L ≤ 100 ±0.03 ±0.03

100 < L ≤ 150 ±0.03 ±0.03

150 < L ≤ 200 ±0.03 ±0.03

200 < L ≤ 300 ±0.04 ±0.04

0.02 mm: 533-504, 533-505, 533-506

*L (mm) EMPE (mm) SMPE (mm) *L (mm) EMPE (mm) SMPE (mm)

0 ≤ L ≤ 50 ±0.02 ±0.02 500 < L ≤ 600 ±0.05 ±0.05

50 < L ≤ 100 ±0.03 ±0.03 600 < L ≤ 700 ±0.06 ±0.06

100 < L ≤ 200 ±0.03 ±0.03 700 < L ≤ 750 ±0.06 ±0.06

200 < L ≤ 300 ±0.03 ±0.03 750 < L ≤ 800 ±0.06 ±0.06

300 < L ≤ 400 ±0.04 ±0.04 800 < L ≤ 900 ±0.07 ±0.07

400 < L ≤ 500 ±0.05 ±0.05 900 < L ≤ 1000 ±0.07 ±0.07

534 Series

0.05 mm

*L (mm) EMPE (mm) SMPE (mm)

0 ≤ L ≤ 50 ±0.07 ±0.07

50 < L ≤ 100 ±0.07 ±0.07

100 < L ≤ 200 ±0.07 ±0.07

200 < L ≤ 300 ±0.07 ±0.07

300 < L ≤ 400 ±0.13 ±0.13

400 < L ≤ 500 ±0.13 ±0.13

0.02 mm

*L (mm) EMPE (mm) SMPE (mm) *L (mm) EMPE (mm) SMPE (mm)

0 ≤ L ≤ 50 ±0.04 ±0.04 500 < L ≤ 600 ±0.08 ±0.08

50 < L ≤ 100 ±0.04 ±0.04 600 < L ≤ 700 ±0.08 ±0.08

100 < L ≤ 200 ±0.04 ±0.04 700 < L ≤ 750 ±0.08 ±0.08

200 < L ≤ 300 ±0.04 ±0.04 750 < L ≤ 800 ±0.10 ±0.10

300 < L ≤ 400 ±0.06 ±0.06 800 < L ≤ 900 ±0.10 ±0.10

400 < L ≤ 500 ±0.06 ±0.06 900 < L ≤ 1000 ±0.10 ±0.10