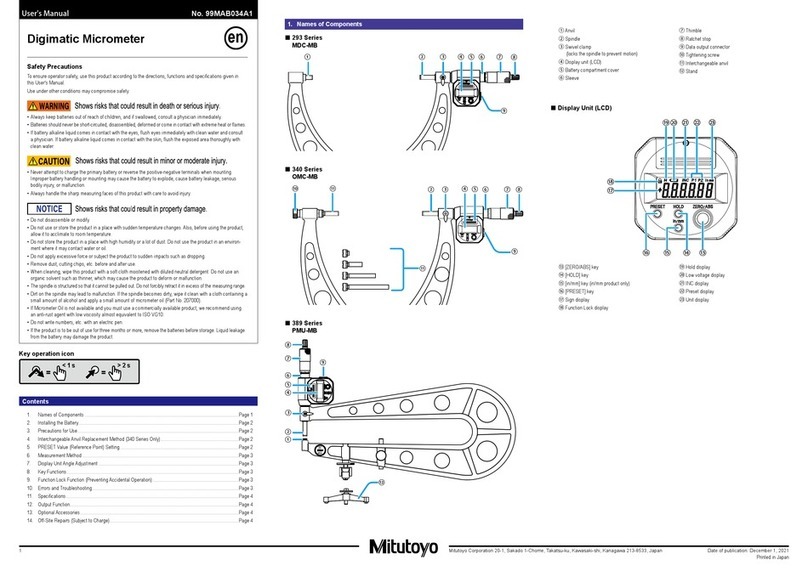

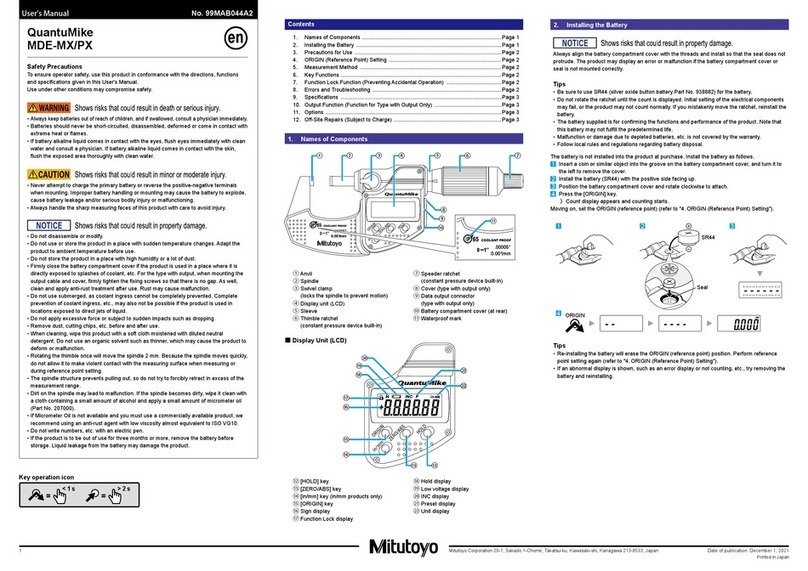

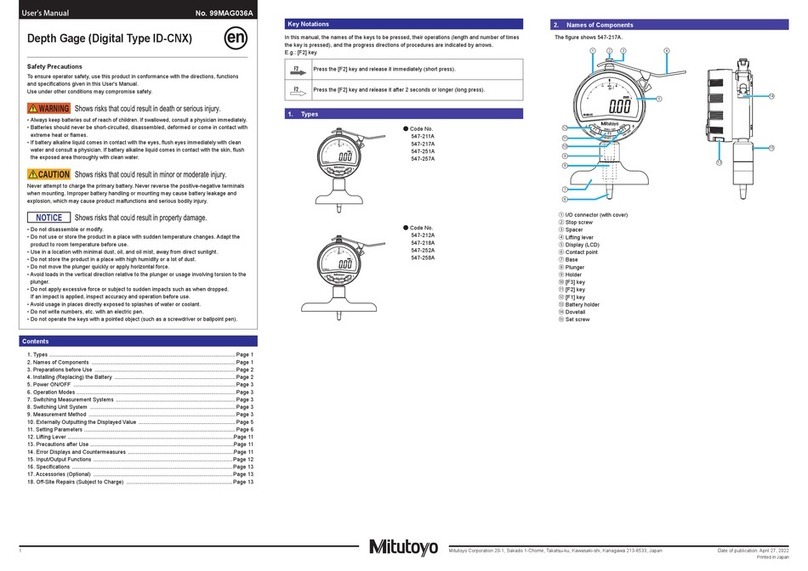

Mitutoyo Corporation 20-1, Sakado 1-Chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213-8533, Japan Date of publication: December 1, 2021

Printed in Japan

2

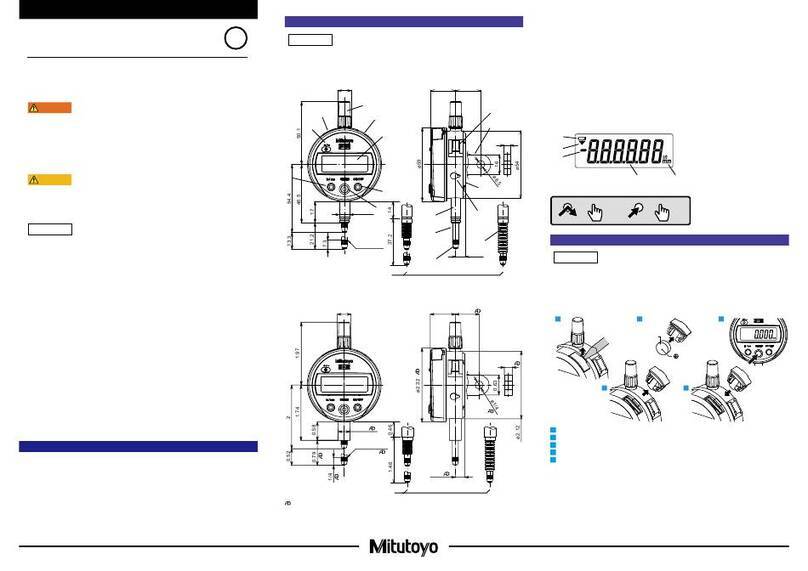

The battery is not installed into the product at purchase. Install the battery as follows.

1Use the supplied Phillips screwdriver (No.05CAA952) to loosen and remove the battery

compartment cover fixing screws (M1.7 x 0.35 x 4/No.04AAB541).

2If replacing an existing battery, remove the old battery.

3Insert the battery (SR44) with the positive side facing upward.

Confirm that the gasket (No.05SAA372) is installed correctly in the proper position.

4

Place the battery compartment cover over the battery compartment and hold down the edge by

hand while making sure there is no gap between the cover and body, and then tighten it using

the screws.

》 The "------" display blinks.

5Press the [PRESET] key.

》 Count display appears and counting starts.

3

4

1

5

①

+ -

+ terminal

- terminal

SR44

②

SR44

Tips

• Re-installing the battery will erase the PRESET value (reference point) position. Perform

reference point setting again (refer to "4. Reference Point Setting").

• If an abnormal display is shown, such as an error display or not counting, etc., try removing the

battery and reinstalling.

3. Precautions for Use

■Precautions for Measurement

•

This product, which is not equipped with a constant pressure device, is configured with heavier

operation than normal outside micrometers. The interior hydraulic oil will increase in viscosity if

used in low temperatures or left unused for a long time, and operation may feel heavier. In this

case, operate the thimble at full stroke several times to recover normal operation.

•

Use caution when measuring magnetized workpieces. If the product becomes magnetized,

measurement results may be affected.

■Precautions after Use

• After use, clean the entire product and check that none of the parts are damaged.

•

If using in places exposed to water-based cutting fluid, always apply anti-rust treatment after cleaning.

• If the product is to be out of use for three months or more, remove the battery before storage.

4. Reference Point Setting

Set an arbitrary preset value (reference point registration) prior to setting the reference point

(reference point setting).

•

Be sure to follow the procedure below to confirm and set the reference point prior to measuring.

•

When setting the reference point for this product, make sure to use a calibrated gage (setting ring, etc.).

• Remove any dirt or oil from the measuring surfaces of the gage and product prior to

setting the reference point.

•

Use the same orientation and conditions when measuring and setting the reference point.

• The preset value is within 999.999 mm (for metric products). To measure over 1000

mm, adjust the preset switch so that 1000 mm is 0 mm.

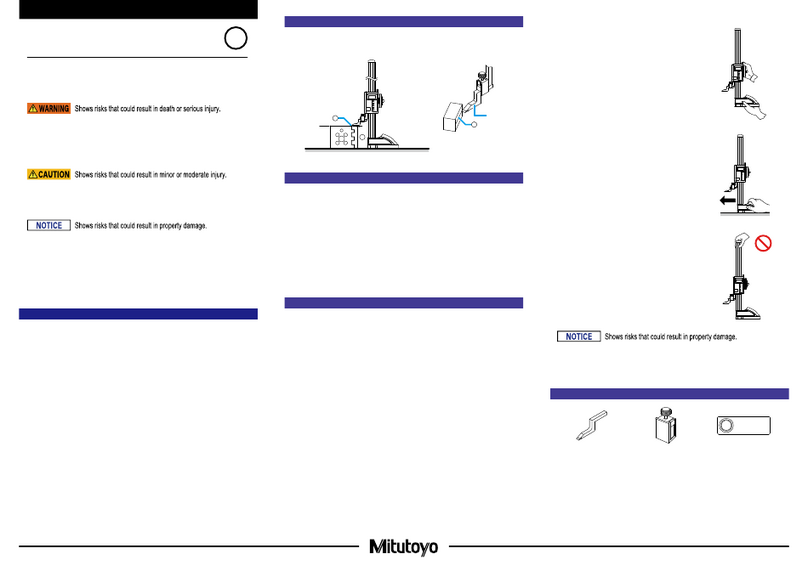

1) Reference point registration

Register (preset) the gage dimensions to the product. Two preset values (P1 and P2) can be

registered to the product.

Tips

Press and hold the [HOLD] key to switch between P1 and P2.

<Example> Registering 200.000 mm to P1

1 Briefly press the [PRESET] key.

》

The previously registered number is displayed and [P1] blinks.

Tips

•

Zero will be displayed immediately after replacing the battery.

• If [P2] is blinking, press and hold the [HOLD] key to

cause [P1] to blink.

2Press and hold the [PRESET] key.

》 The sign blinks.

Tips

Briefly press the [PRESET] key to switch between [+]

and [-].

3Press and hold the [PRESET] key.

》 The number on the left blinks.

Tips

The numbers will switch in order from [0] to [1] to [2] up to [9]

and then [0] each time the [PRESET] key is briefly pressed.

4 Briefly press the [PRESET] key until [2] is displayed.

5Press and hold the [PRESET] key.

》 The number in the next digit blinks.

6Repeat steps 4and 5, so that [0] and [0] are

displayed for each digit.

7Press and hold the [PRESET] key until [P1] blinks.

8 Briefly press the [PRESET] key.

》 [P1] goes out and registration is complete.

1

2

3

4

5

6

PRESET

PRESET

7

8

Tips

•

To stop reference point registration, press the [ZERO/ABS]

key to return to the original display value.

• The display will not change during registration, even if

the thimble is rotated.

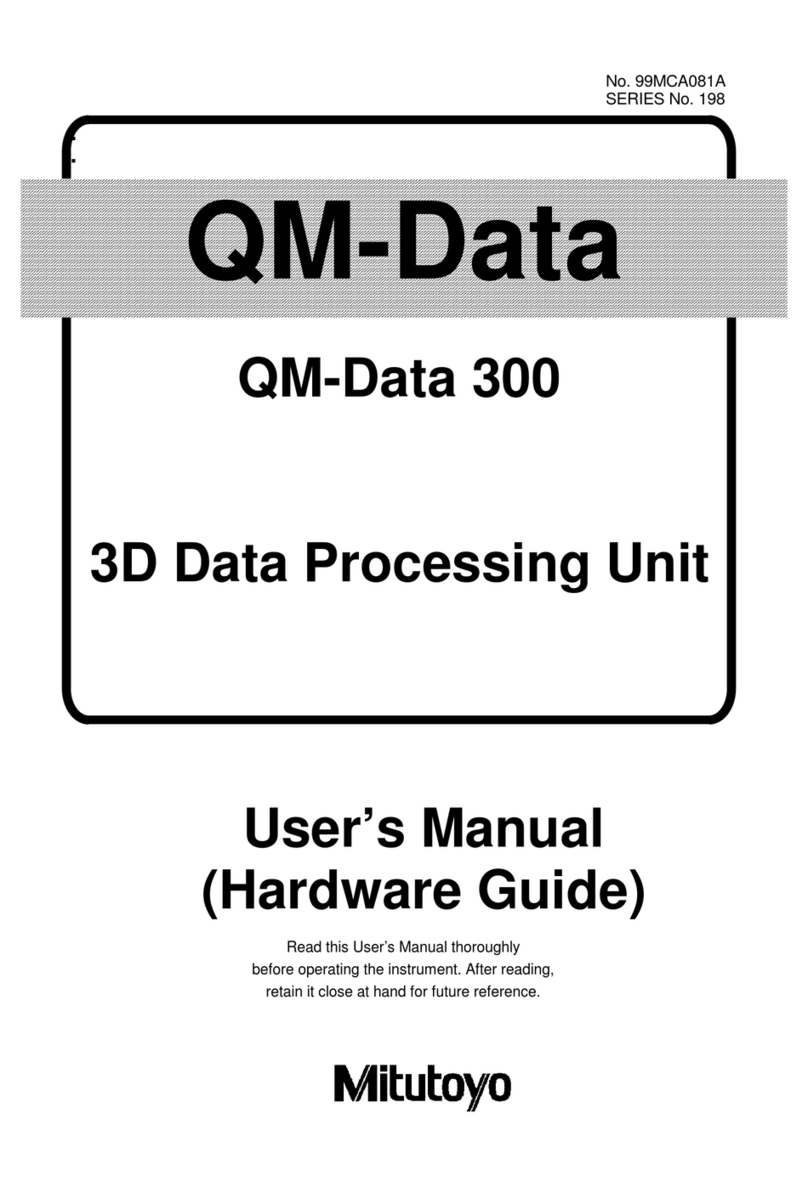

2) Reference point setting

1Remove any dirt or dust from the measuring surfaces of

the gage and the product.

2Set the dimension of the product slightly smaller than

that of the gage, and then slowly insert it into the gage.

3Rotate the thimble and bring the measuring surface

gently into contact with the gage.

4Move it in the direction of the arrow in Figure 1 within a

cross-section perpendicular to the axis to determine the

highest point (refer to Figure 1).

5

Move it in the direction of the arrow in Figure 2 with

regard to the axis to determine the lowest point (refer to

Figure 2).

6 Briefly press the [PRESET] key.

》 [P1] or [P2] blinks, and the registered preset value

(zero if not registered) is displayed.

Tips

• Press and hold the [HOLD] key to switch between P1

and P2.

• To change the preset value, refer to steps 2through

8in "1) Reference point registration".

7 Briefly press the [PRESET] key.

》 [P1] or [P2] goes out.

To use thimble graduations as well, set using the procedure

below.

8Perform steps 1through 4, and then use a hex

wrench to loosen the setting screw.

9Slightly rotate the sleeve and align it with the proper

display value.

10

Use the hex wrench to tighten the setting screw and fix

the sleeve.

11

Perform steps 1through 5, and confirm that the

proper number is displayed.

If the proper number is displayed, setting is complete. If it is

not displayed, repeat steps 8through

10

.

Tips

• The display of this product automatically turns off if not

used for 20 minutes or more. To display again, either

rotate the thimble or press the [ZERO/ABS] key.

• If the [PRESET] key is accidentally pressed during

measurement, press the [ZERO/ABS] key to return to

the former state. If this does not enable the product to

recover, perform the reference point setting procedure

once more.

• Once the product has been inserted, do not move it

until the reference point has been set.

Key operation icon

=

> 2 s

=

< 1 s

5

45

0

4

5

Figure 1. Top view

Figure 2. Side view

8

9

10