Molex Standard Manual Assembly Press

Order No: TM-011316356 Release Date: 0 -05-99 UNCONTROLLED COPY Page 5 of 16

Revision: D Revision Date: 10-08-09

General Descr pt on

1.1 Descr pt on

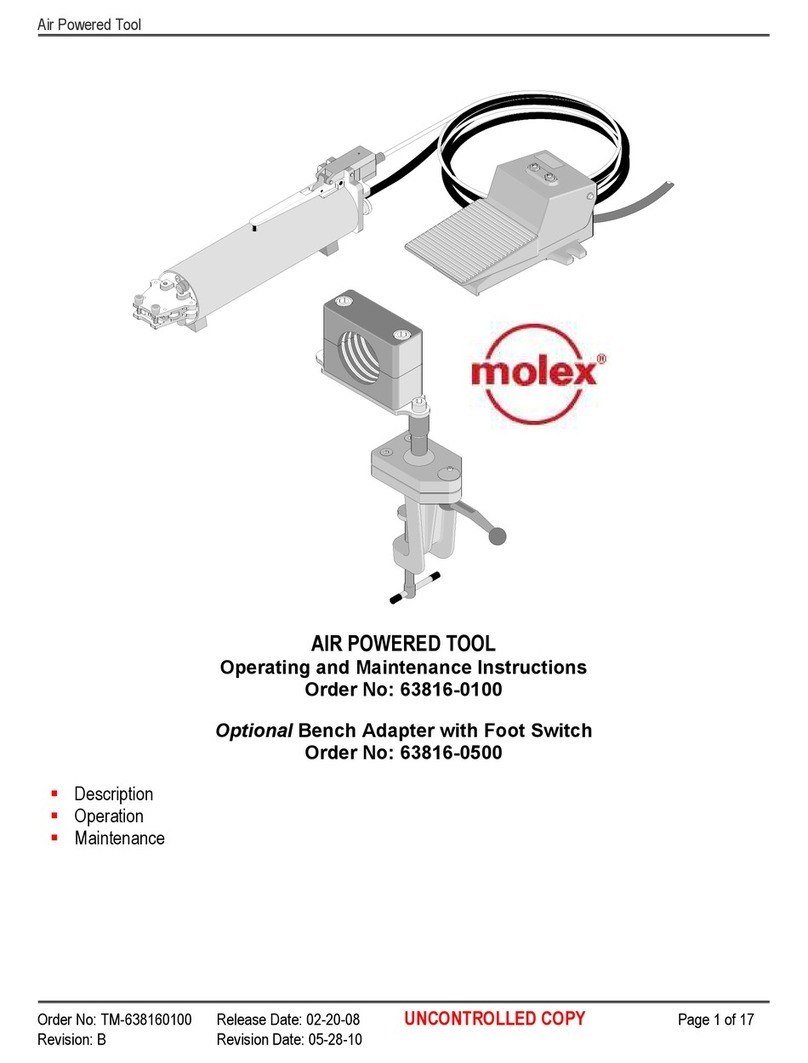

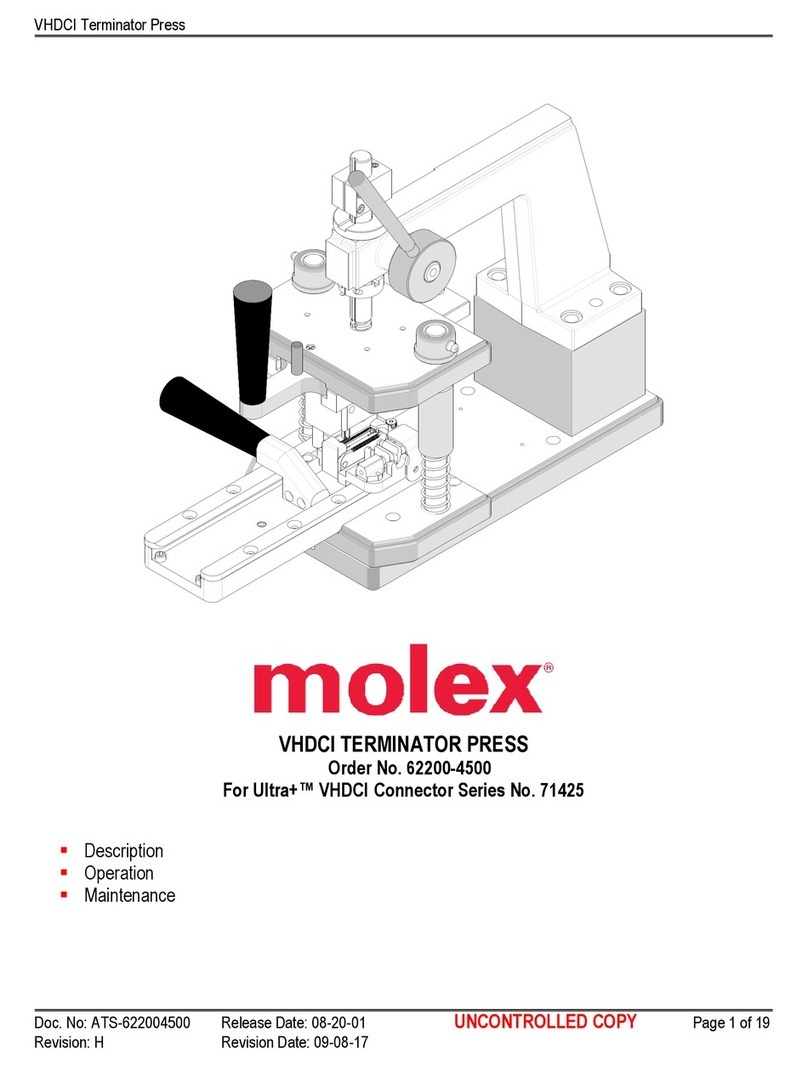

The Molex Standard Manual Assembly Press (11-

31-6356) is versatile, reliable, and inexpensive to

operate. It is designed to provide an effective

method of apply force to a wide variety of

terminating and crimping dies. The Press is easily

converted from right to left hand operation. When

the combinations of crimping dies have been

installed the operator pulls the handle down and

then returns it to the original position. A ratchet

mechanism insures that the press goes through a

full cycle for a complete termination. The press is

suited for low to mid-volume production

requirements.

1.2 Features

Press and tooling is easily portable.

Accepts a wide variety of terminating and

crimping tools kits.

Full cycle ratchet assures complete termination

Easily setup for left or right hand operation.

Tooling changeover is simple and quick.

Termination height is easily adjusted in the

upper tooling holder.

Manually operated, no shop air or electricity

required.

Low handle force to reduce operator fatigue.

1.3 Techn cal Spec f cat ons

D mens ons Press w th tool ng

Height 533mm ( 1.00”)

Width 15 mm (6.00“)

Depth 67mm (10.50“)

Unpacked weight 3. kg (50.5 lbs)

Product on Rate

300 cycles per hour maximum, depending on

operator skill and tool kit installed.

Operat ng Parameters

Maximum Force 13.3kN (3,000lbs)

Shut Height 4 .0mm (1.65”)

Stroke Length 43.0mm (1.69”)

Adjustment 5. 6mm (. 07”)

1.4 Del very Check

The following items are included in this package :

Decription: Quantity

Molex Standard Assembly Press

11-31-6356 (AM-600 6-50) 1

Instruction Manual TM-011316356 1

1.5 Tools

The following tools are recommended for setup and

adjustments to the this tool.

Adjustable wrench

Needle nose pliers

English hex wrench set for some non-metric tools.