VHDCI Terminator Press

Doc. No: ATS-622004500 Release Date: 0 -20-01 UNCONTROLLED COPY Page 9 of 19

Revision: H Revision Date: 09-0 -17

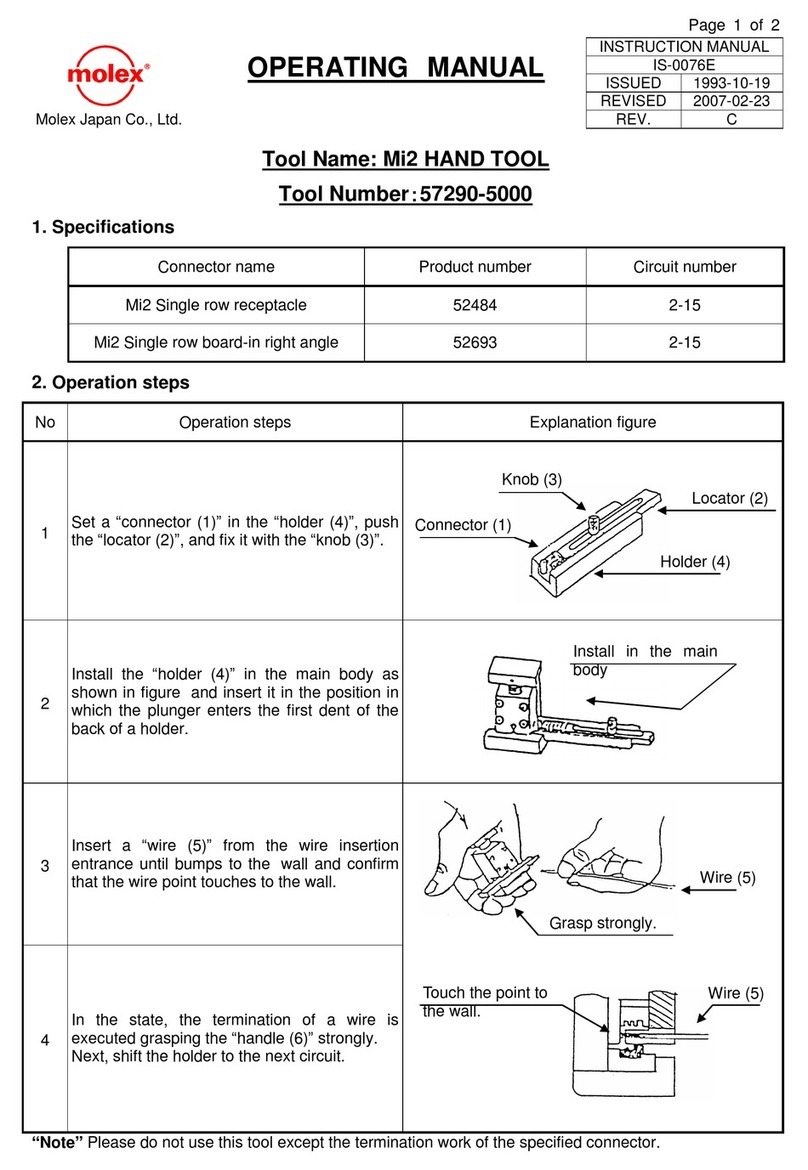

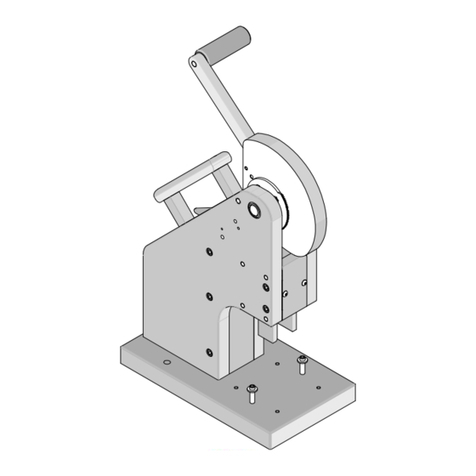

Figure 2-3

SET SCREWS

DOWN STOP

Figure 2-2

2.1 Ins alla ion

Place termination press on a solid level surface

with enough space around it to allow for operation

and easy loading of connectors.

Holes are provided for 1/4in lag bolts to secure the

press to work surface if desired.

Make sure there is adequate lighting and enough

room around the press to allow easy access to the

press and easy handling of cables and connectors.

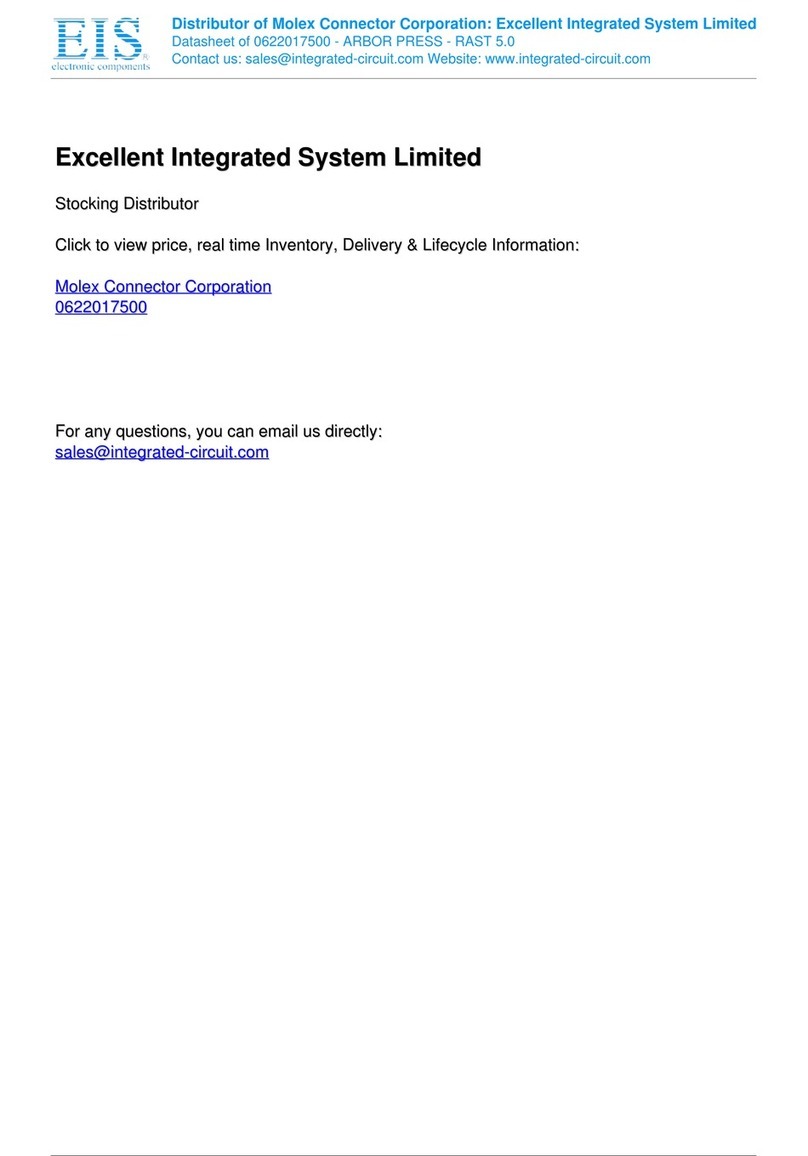

2.2 Se up

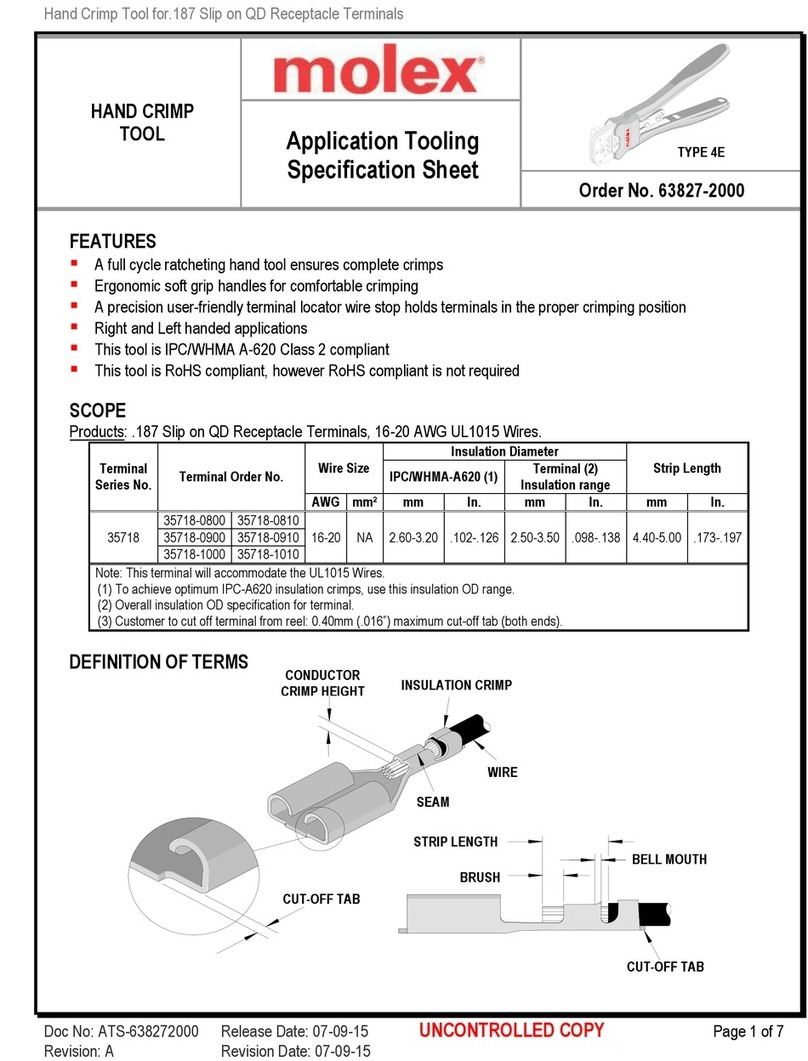

Termina ion Dep h Adjus men

The termination depth can be changed by adjusting

the set screws on the Adjustable Down Stop.

Turning them clockwise (CW) reduces termination

depth, while turning them counter-clockwise (CCW)

increases the termination depth. See Figure 2-2.

Die blocks should be used to set tool closure height

at 4.61 ± 0.12mm (.1 2±.005)

Termina ing 28 AWG Wire

The Termination Press is furnished with the 30 AWG

wire comb and nest spring pad installed.

Terminators using 2 AWG wire require wire comb

order no. 62200-4510 and nest spring pad order

no.62200-4507.

To change the wire comb and nest spring pad follow

the steps below: (see Sheet 2 of the Assembly

Drawing.)

1. Remove the (2) #10 screws from the front of the

lower slide and pull the lower tooling out of the

slide.

2. Turn the lower tooling over. Remove the (4) #

screws located in the middle of the tooling using

a 9/64” hex key.

3. Remove the nest assembly Item numbers (6, 7,

, and 9) from the lower tooling,

4. Remove the (2) # BHCS holding the combs

(Item 6).

5. Install the appropriate nest spring pad (Item 7)

and springs.

6. Install the appropriate wire comb (Item 6) to the

left and right locators (Item and 9).

7. Install the nest assembly on the lower tooling.

. Put the lower tooling back in its slide.

9. Install the (2) #10 screws in the front of the lower

slides.

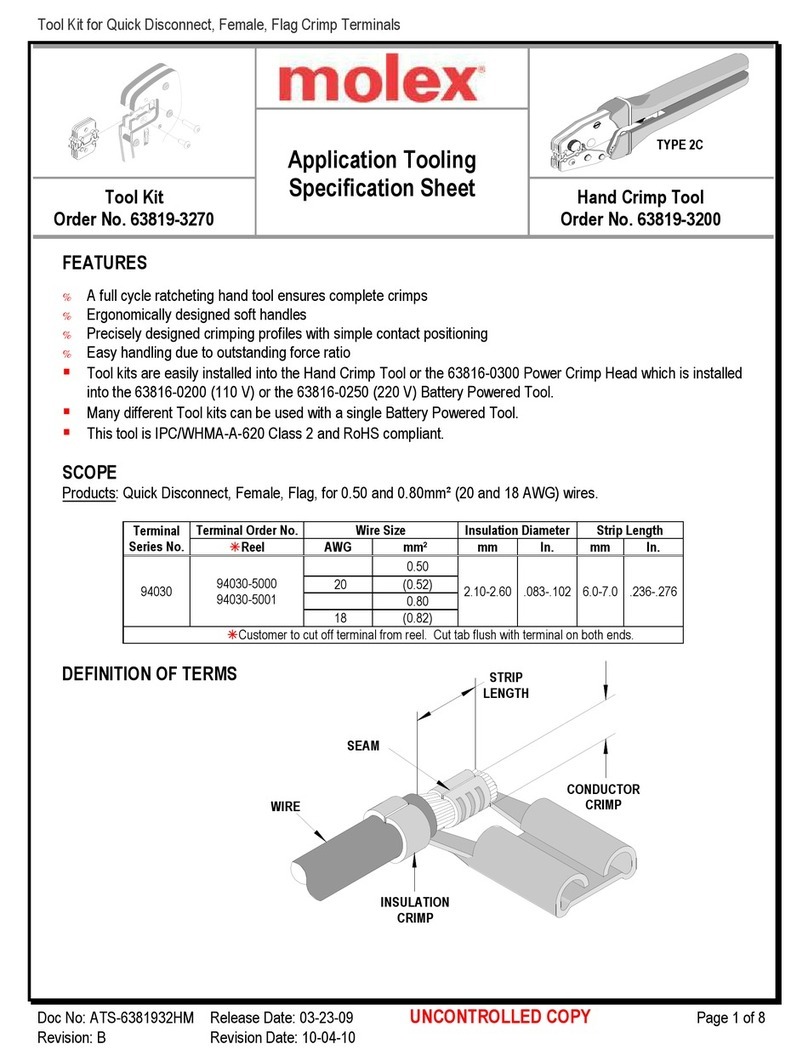

2.3 Opera ion

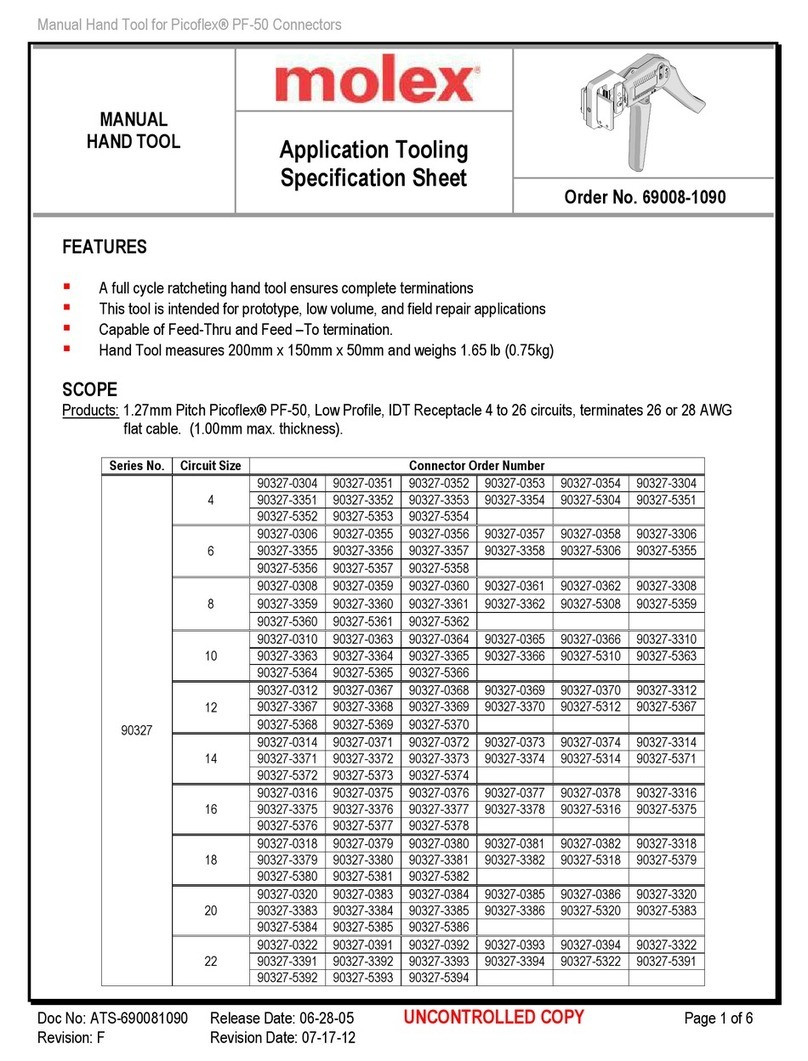

Firs Side Termina ion

1. Pull the bottom slide out to access the nest.

2. Load the Wire Cover into the Nest with the wire

cover grooves facing up. See Figure 2-3.

3. Place the cable into the Nest and press into the

clamp making sure the cable is against the

Cable Jacket Stop.

4. Fold the wires under the Wire Retainer Hook to

keep wires clear while loading the nest. See

Figure 2-4.