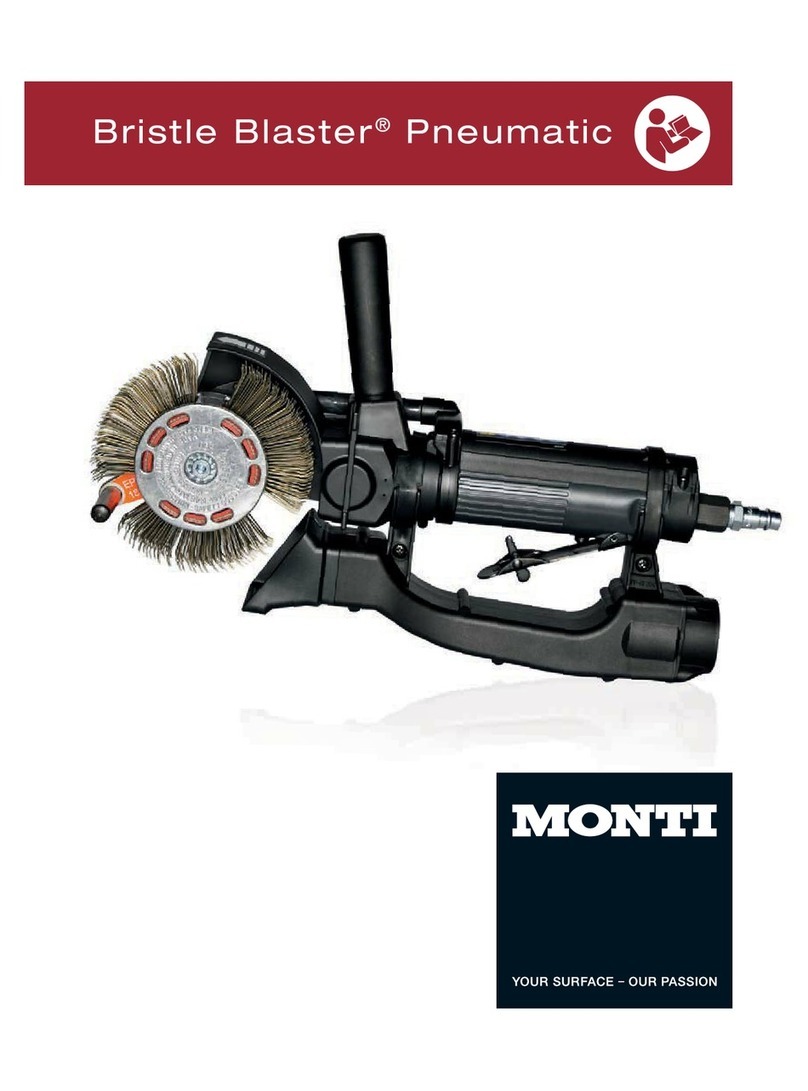

Operating instructions

20

GB MBX

®

Die Blaster

®

Placing in operation6.

Application:

The new version of the Die Blaster

®

with accelerator bar has advantages in many fields of application compared to

the conventional MBX

®

system.

Good examples are rusty flanged rims of doors and covers, roof joints and wheel arches. With the accelerator bar

much more energy is available.

How to use the tool

Use suitable sealing material such as Teflon1.

®

tape for fastening

the compressed air hose connection.

On the selection of the2. MBX

®

Die Blaster

®

belts, take into

account the surface to be machined. The following MBX

®

Die Blaster

®

belts are to your disposal: 11mm coarse left-hand

side, 11mm coarse right-hand side and 11mm coarse.

Interrupt supply of compressed air, then fasten the3. MBX

®

Die Blaster

®

11 mm belt correctly to the tool using the related

adaptor system AS012 (pay attention to direction of travel)

and the related serrated lock washer and screw. See Fig. 1

and Fig. 2

For4. MBX

®

Die Blaster

®

11 mm belt only use MBX

®

28 mm

accelerator bar (VE2, ZU064).

Start tool by pressing the starter lever. Move the safety stop5. forward and press the starter lever. The starter lever returns to

its initial position when released.

To obtain the best performance, it is to be ensured the accel-6. erator bar is guided close to the surface to be machined. If the

accelerator bar is too far from the surface, the performance will

drop significantly.

When machining contours of hard-to- reach areas, it can be7. advisable to remove the accelerator bar. The entire unit can be

removed from its guide by pulling the button.

However, a loss in power must be accepted in this case.

To achieve optimum performanceandexcellent work result, it is8. advisable to hold the brush always perpendicular to the surface

to be machined if possible.

Only work using minimum contact pressure. Excessive contact9. pressure will limit the performance. In rare cases, however,

it might be necessary. In this cases it might be advisable to

reducethe speedin extremecontour areasby "playing"with the

start lever and, simultaneously, to increase the pressure.

In all circumstances, prevent the entry of water (moist air) into10. the pneumatic tool.

Fig. 1

Fig. 2

Fig. 3