Fein FMT250 Setup guide

Other Fein Power Tools manuals

Fein

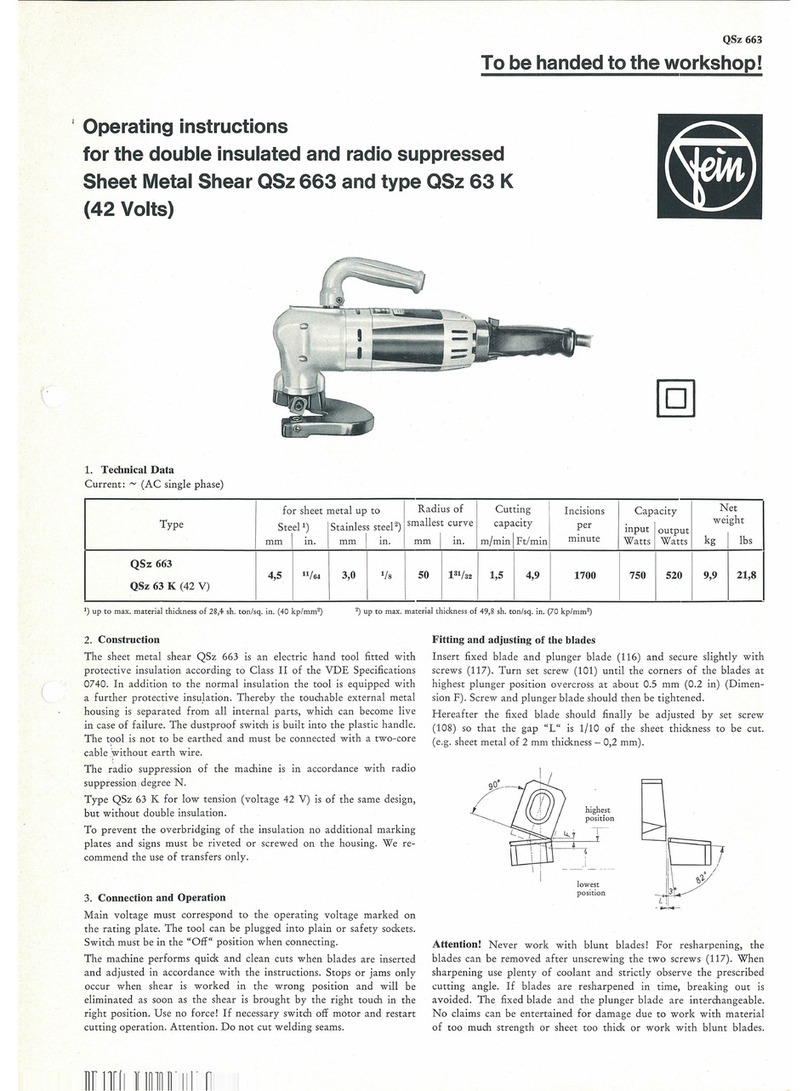

Fein QSz 63 K User manual

Fein

Fein AMM700 1.7Q AS User manual

Fein

Fein MultiMaster AFMM18QSL User manual

Fein

Fein AFSC18Q User manual

Fein

Fein BLK1.3T User manual

Fein

Fein ADAS 18 User manual

Fein

Fein KFH17-15 Series User manual

Fein

Fein ABLS18-1.6E User manual

Fein

Fein FSC 1.7 Q User manual

Fein

Fein AMM 500 Plus Series User manual

Fein

Fein KFH17-8R Setup guide

Fein

Fein ASte 638 User manual

Fein

Fein BLK1.3TE User manual

Fein

Fein AFMM18 QSL User manual

Fein

Fein MOtlx 6-25 User manual

Fein

Fein 7 232 32/BLK 1.6 Setup guide

Fein

Fein MULTIMASTER FMM 250 User manual

Fein

Fein KFH17-8 Series User manual

Fein

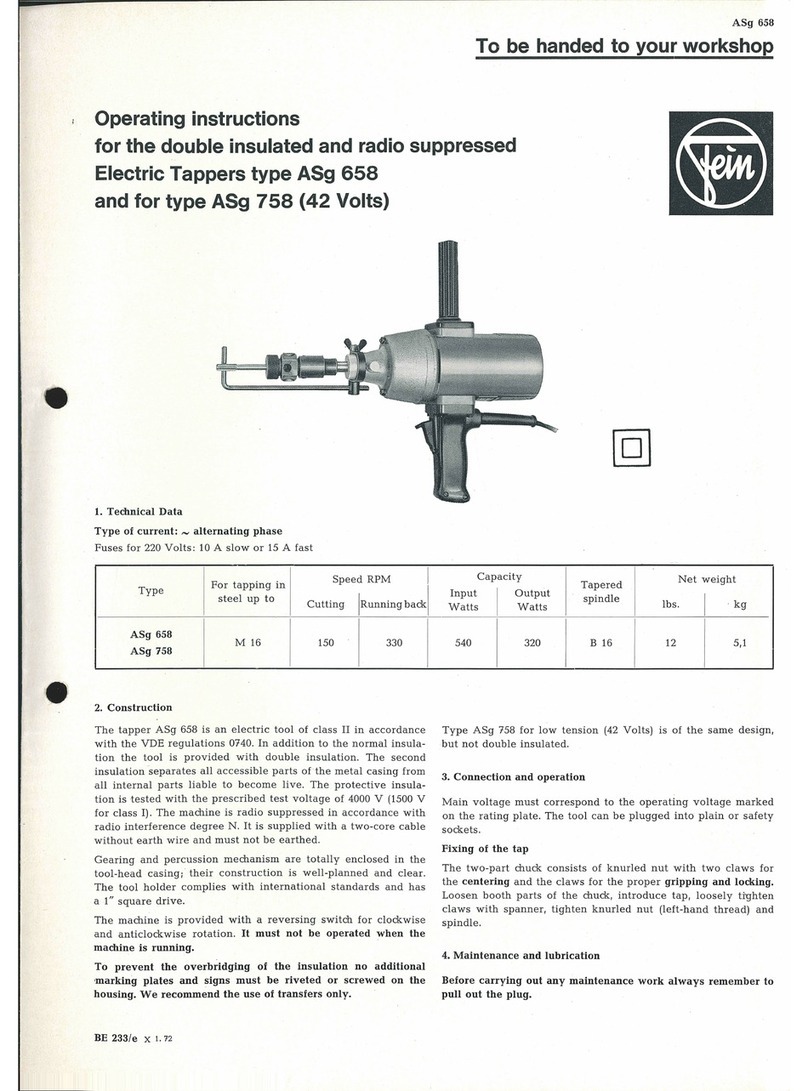

Fein ASg 658 User manual

Fein

Fein ABLK1.3TE User manual

Popular Power Tools manuals by other brands

WABCO

WABCO OptiTire installation manual

EINHELL

EINHELL TE-MS 18/210 Li Original operating instructions

Orgapack

Orgapack OR-T 85 Operating and safety instructions

TOUGHCUT

TOUGHCUT Diamond 400 instruction manual

Yaros

Yaros PB-3603 user manual

Baileigh Industrial

Baileigh Industrial SS-2725 Operator's manual