10

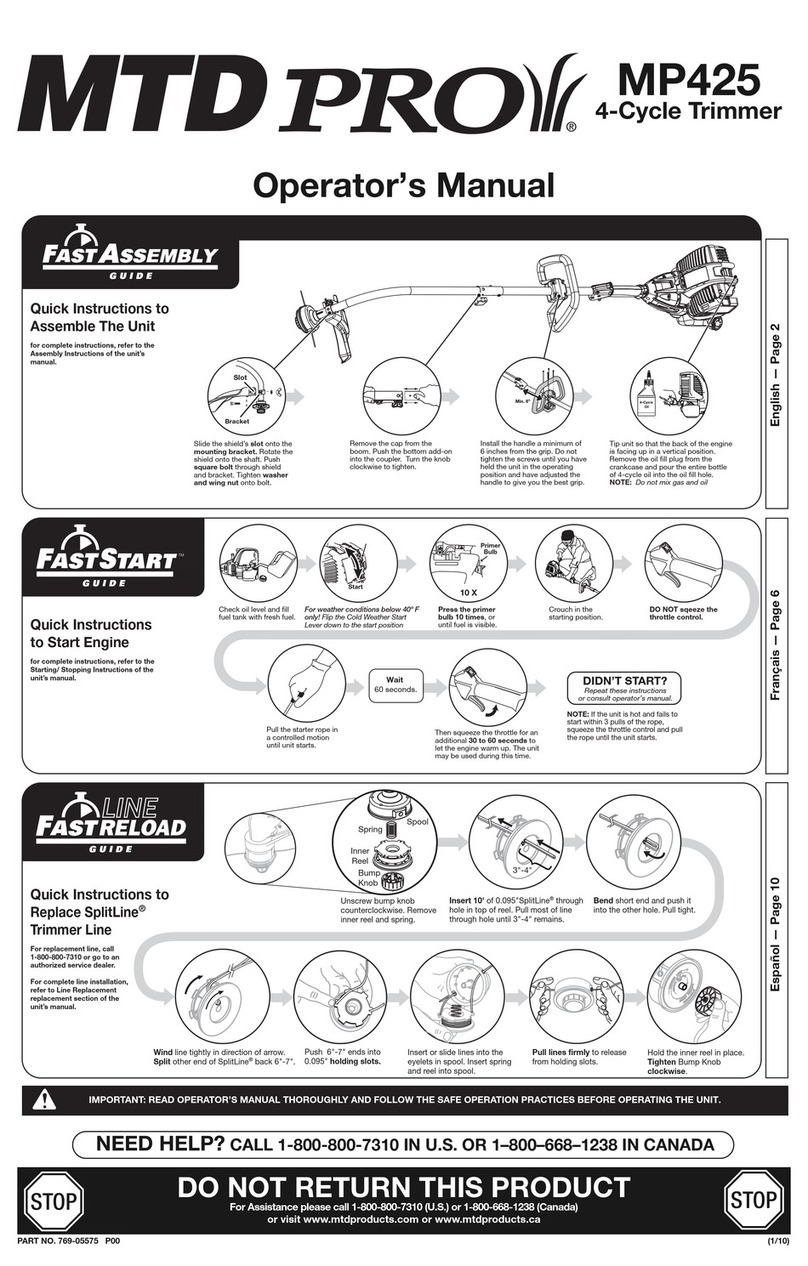

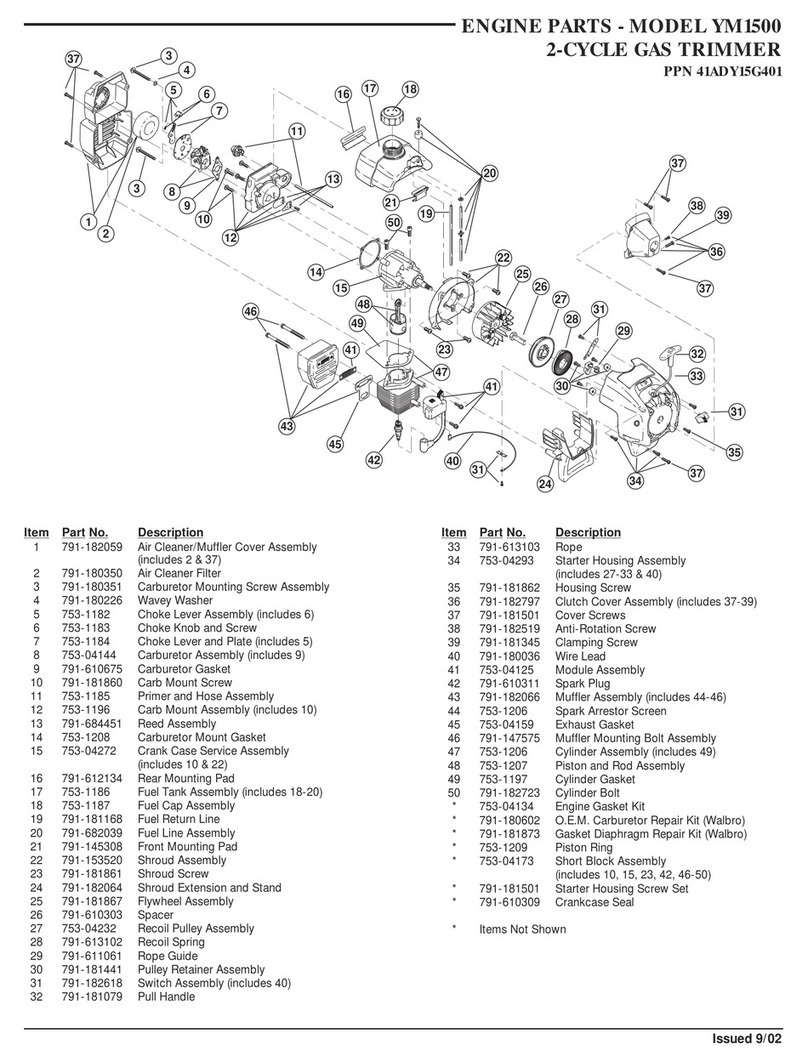

Instalación de la línea individual

Lea la instalación de la línea SplitLine™ en el paso 8.

6. Tome aproximadamente 5.4 m (18 pies) de nueva línea

de corte, enlácela en dos longitudes iguales. Inserte

cada extremo de la línea a través de uno de los dos

orificios del carrete interior (Fig. 12). Pase la línea a

través del carrete interior de modo que el lazo sea lo

más pequeño posible.

7. Bobine las líneas en capas parejas y ajustadas sobre el

carrete (Fig. 13). Bobine la línea en la dirección indicada

en el carrete interior. Coloque su dedo índice entre las

dos líneas para evitar que se superpongan. No

superponga los extremos de la línea. Proceda al paso 12.

Instalación de la línea SplitLine™

8. Tome aproximadamente 2.7 m (9 pies) de nueva línea

de corte. Inserte un extremo de la línea a través de uno

de los orificios del carrete interior (Fig. 14). Pase la

línea a través del carrete interior hasta que queden

sólo 4 pulgadas fuera.

9. Inserte el extremo de la línea en el orificio abierto del

carrete interior y tire de la línea en forma ajustada a fin

de que el lazo sea lo más pequeño posible (Fig. 14).

10. Antes de bobinar, separe la línea alrededor de 6 pulgadas.

11. Bobine la línea en capas parejas y ajustadas en la

dirección indicada en el carrete interior.

NOTA: Si no bobina la línea en la dirección indicada, el

accesorio de corte no funcionará en forma correcta.

12. Inserte los extremos de la línea en las dos ranuras de

fijación (Fig. 15).

13. Inserte los extremos de la línea a través de los ojalillos

de la bobina exterior y coloque el carrete interior con el

resorte dentro de la bobina exterior (Fig. 16). Empuje el

carrete interior y la bobina exterior entre sí.

NOTA: El resorte debe estar ensamblado en el carrete

interior antes de volver a ensamblar el accesorio de

corte.

14. Sostenga el carrete interior en su lugar y coloque e

instale la perilla percusiva enroscándola en sentido

horario. Ajuste bien.

15. Tome los extremos y tire con firmeza para soltar la línea de las ranuras de fijación de la bobina.

INSTALACIÓN DE UN CARRETE PREBOBINADO

1. Sostenga la bobina exterior con una mano y desenrosque la perilla percusiva en sentido antihorario (Fig. 9). Inspeccione el perno

dentro del botón de tope para verificar que se mueva con libertad. Cambie el botón de tope si está dañado.

2. Saque el carrete interior viejo de la bobina exterior (Fig. 10).

3. Saque el resorte del carrete interior viejo (Fig. 10).

4. Coloque el resorte en el carrete interior nuevo.

NOTA: El resorte debe estar ensamblado en el carrete interior antes de volver a instalar el accesorio de corte.

5. Inserte los extremos de la línea en los ojalillos de la bobina exterior (Fig. 16).

6. Coloque el nuevo carrete interior dentro de la bobina exterior. Empuje el carrete interior y la

bobina exterior entre sí. Mientras sostiene el carrete interior y la bobina exterior, tome los

extremos y tire con firmeza para soltar la línea de las ranuras de retención de la bobina.

7. Sostenga el carrete interior en su lugar e instale el botón de tope girándolo en sentido horario.

Ajuste bien.

MANTENIMIENTO DEL FILTRO DE AIRE

Remoción de la cubierta del silenciador/ filtro de aire

1. Coloque la palanca azul del obturador en la Posición 2.

2. Saque los cuatro (4) tornillos que sostienen la cubierta

del silenciador / filtro de aire (Fig. 17). Use un

destornillador de vástago plano o de broca Torx N° T20.

3. Quite la tapa del motor al empujarla hacia arriba y

halarla hacia atrás. No la fuerce.

Limpieza del Filtro de Aire

Limpie y vuelva a aceitar el filtro de aire cada 10 horas de

operación. Es una de las partes cuyo mantenimiento es

importante. No mantener debidamente su filtro de aire

puede resultar en funcionamiento inadecuado o puede

causar daño permanente a su motor.

1. Saque la cubierta del silenciador / filtro de aire. Lea la

sección de Remoción e Instalación de la cubierta del

silenciador / filtro de aire.

2. Gire la tapa y ubique el filtro de aire adentro. Saque el

filtro de aire de adentro de la tapa del filtro de aire /

silenciador (Fig. 18).

3. Lave el filtro con agua y detergente (Fig. 19). Enjuague

bien el filtro. Escurra el exceso de agua. Déjelo secar

por completo.

4. Aplique suficiente aceite limpio SAE 30 para recubrir

ligeramente el filtro (Fig. 20).

5. Apriete el filtro para esparcir y retirar el exceso de

aceite (Fig. 21).

6. Cambie el filtro de aire dentro de la tapa del filtro de

aire / silenciador (Fig. 18).

NOTA: Si opera la unidad sin el filtro de aire y el ensamble de la cubierta del silenciador / filtro de aire, su garantía quedará ANULADA.

Reinstalación de la cubierta del silenciador/ filtro de aire

1. Coloque la cubierta del silenciador / filtro de aire sobre la parte posterior del carburador y del silenciador. Alinee los orificios de los

tornillos.

2. Inserte los cuatro (4) tornillos en los orificios de la cubierta del silenciador / filtro de aire (Fig. 17) y ajústelos. No los ajuste demasiado.

MANTENIMIENTO DEL PARACHISPAS

1. Quite el filtro de aire / tapa del silenciador. Ver Remoción de la Tapa del Filtro / Silenciador.

2. Localice el silenciador, pero no lo quite. Busque el tornillo en la parte inferior del silenciador

(Fig. 2). Quite el tornillo usando una llave torx No. 20 o un destornillador plano.

3. Levante cuidadosamente haciendo palanca el lado izquierdo de la cubierta del parachispas.

Dos lengüetas actúan como bisagras en el lado derecho de la cubierta. Abra con un golpe

rápido la cubierta del parachispas, como si fuera una puerta, y después hale las lengüetas para

sacarlas de las ranuras del silenciador.

4. Con un destornillador de punta plana, levante cuidadosamente haciendo palanca la rejilla del

parachispas, sacándola del interior de la cubierta del parachispas.

5. Limpie la rejila del parachispas con un cepillo de cerdas metálicas. Cámbiela si está dañada o

si no la puede limpiar completamente.

6. Reinstale la rejilla del parachispas, ajustándola en forma ceñida de nuevo en la cubierta del

parachispas.

7. Reinstale las dos lengüetas de la cubierta en las dos ranuras y cierre la cubierta del parachispas con un golpe rápido.

8. Vuelva a colocar el tornillo que quitó en el Paso 2 y apriétele firmemente.

9. Reinstale la tapa del filtro de aire / silenciador.

AJUSTE DEL CARBURADOR

La velocidad lenta del motor puede ser ajustada por la cubierta del silenciador / filtro de aire (Fig. 23).

NOTA: Los ajustes realizados sin cuidado pueden dañar seriamente su unidad. Los ajustes del

carburador deben ser realizados por un proveedor de servicio autorizado.

Controle la mezcla del combustible

Una mezcla incorrecta o vieja de combustible es en general el motivo por el cual la unidad no

funciona adecuadamente. Drene y vuelva a llenar el tanque con combustible nuevo y bien mezclado

antes de hacer ningún ajuste. Consulte la Información sobre Aceite y Combustible.

Limpie el filtro de aire

La condición del filtro de aire es importante para la operación de la unidad. Un filtro de aire sucio

limitará el flujo de aire y cambiará la mezcla de combustible y aire en el carburador. Esto con

frecuencia se confunde con un carburador mal ajustado. Verifique la condición del filtro de aire

antes de ajustar el tornillo de marcha lenta. Consulte Mantenimiento del Filtro de Aire.

Ajuste del tornillo de marcha lenta

Si luego de verificar la mezcla del combustible y limpiar el filtro de aire el motor aún no funciona en mínima, ajuste el tornillo de velocidad

lenta de la siguiente manera.

1. Arranque el motor y déjelo funcionar en marcha lenta durante un minuto para calentarlo. Lea las Instrucciones de arranque y apagado.

2. Suelte el gatillo del regulador y deje que el motor funcione en marcha lenta. Si el motor se para, inserte un pequeño destornillador

Phillips o de vástago plano en el orificio de la cubierta del silenciador / filtro de aire (Fig. 23). Gire el tornillo de marcha lenta en sentido

horario, de a 1/8 de vuelta por vez (según sea necesario) hasta que el motor funciona en mínima.

NOTA: El accesorio de corte no debe girar mientras el motor está en marcha lenta.

3. Si el accesorio de corte gira cuando el motor está en marcha lenta, gire el tornillo de marcha lenta en sentido antihorario 1/8 de vuelta

por vez (según sea necesario) para reducir la marcha en vacío.El control de la mezcla de combustible, la limpieza del filtro de aire y el

ajuste del tornillo de marcha en vacío deben resolver la mayoría de los problemas del motor.

De no ser así y si:

• El motor no funciona en mínima

•El motor fluctúa o se para al acelerar

• Existe una pérdida de fuerza motriz

Lleve el carburador a un proveedor de servicio autorizado para que lo ajuste.

CAMBIO DE LA BUJIA DE ENCENDIDO

Use una bujía de encendido #791-610311B, Champion RDJ7Y (o similar). La separación correcta

es de 0,635 mm (0,025 pulg.). Retire la bujía luego de cada 25 horas de operación e inspeccione

su estado.

1. Apague el motor y espere que se enfríe. Tome el alambre de la bujía con firmeza y sáquelo de

la bujía de encendido.

2. Limpie alrededor de la bujía de encendido. Saque la bujía de encendido de la cabeza del

cilindro girando una llave de casquillo de 5/8 de pulgada en sentido antihorario.

3. Cambie las bujías que estén rajadas, sucias o deterioradas. Fije la separación de aire a 0,635

mm (0,025 pulgadas) utilizando un calibrador (Fig. 24).

4. Instale una bujía de encendido con la separación correcta en la cabeza del cilindro. Ajuste girando la llave de casquillo de 5/8 pulg. en

sentido horario hasta que esté ajustada sin huelgo.

Si usa una llave de torsión, ajuste a:

12,3-13,5 N•m (110-120 pulg.•libras). No ajuste demasiado.

LIMPIEZA

Use un cepillo pequeño para limpiar la parte exterior de la unidad. No use detergentes fuertes. Los limpiadores domésticos que contienen

aceites aromáticos como pino y limón, y con solventes como el queroseno pueden dañar el bastidor de plástico y la manija. Seque toda

la humedad con un paño suave.

Fig. 19

Fig. 20

ADVERTENCIA: El accesorio de corte puede estar girando durante los ajustes del carburador. Use ropa que lo proteja y

cumpla con todas las instrucciones de seguridad para prevenir graves lesiones personales.

Filtre à air

Protection du filtre dans le silencieux

Fig. 18

Fig. 21

Ranuras

Capó del

parachispas

Tornillo

Fig. 22

Lengüetas Pantalla del

parachispas

Motor

Silenciador

Tornillo de

marcha en

vacío

Fig. 23

Blue Choke

Lever

Screws

Position 2

Fig. 17

Screws

ADVERTENCIA: Si el capó del parachispas y pantalla del parachispas no se aprieta fijamente se puede caer y causarle

daño a la unidad y posibles lesiones personales graves.

ADVERTENCIA: Para evitar graves lesiones personales, apague siempre su

recortador y espere que se enfríe antes de limpiarlo o realizar todo tipo de

mantenimiento.

INSTRUCCIONES DE MANTENIMIENTO Y REPARACIÓN

0,635 mm

(0,025 pulg)

Fig. 24

ADVERTENCIA: No limpie con chorro de arena, ni raspe ni limpie los

electrodos. El motor podría dañarse si penetran pequeñas partículas en el cilindro.

ADVERTENCIA:

Para evitar graves lesiones personales, apague siempre su recortador y espere que se enfríe antes de

limpiarlo o realizar cualquier tipo de mantenimiento.

CAUSA ACCIÓN

El control de encendido/apagado está en apagado (OFF)

Mettez-la en position de DÉMARRAGE

El tanque de combustible está vacío Remplissez-le de carburant bien mélangé.

La bombilla de cebado no fue oprimida lo suficiente

En posición 3, pressez-la complètement et lentement de 10 fois

El motor está inundado Utilisez la procédure de démarrage

El combustible es viejo o está mal mezclado Drene el tanque de gasolina/Agregue mezcla de combustible nueva

La bujía de encendido está arruinada Remplacez ou nettoyez-le

Parachispas obstruido Nettoyez ou remplacez le pare-étincelles

CAUSA ACCIÓN

El filtro de aire está obstruido Cambie o limpie el filtro de aire

El combustible es viejo o está mal mezclado Drene el tanque de gasolina/Agregue mezcla de combustible nueva

El carburador no está ajustado en forma correcta Ajuste según las instrucciones

CAUSA ACCIÓN

El combustible es viejo o está mal mezclado Drene el tanque de gasolina/Agregue mezcla de combustible nueva

El carburador no está ajustado en forma correcta Lleve la unidad a un proveedor de servicio autoriza do para hacer

un ajuste de carburador

El accesorio de corte está atascado de hierba Pare el motor y limpie el accesorio de corte

El filtro de aire está sucio Limpie o cambie el filtro de aire

Parachispas obstruido Limpie o cambie el parachispas

EL MOTOR NO ARRANCA

EL MOTOR NO FUNCIONA EN MINIMA

EL MOTOR NO ACELERA

RESOLUCIÓN DE PROBLEMAS

MOTOR*

EJE IMPULSOR Y ACCESORIO DE CORTE*

Tipo de motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Enfriado por aire, de 2 ciclos

Carrera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31,75 mm (1,25 pulg)

Desplazamiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 cc (1,9 pulg cúbicas)

R.P.M. de operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.800+ r.p.m.

R.P.M. de marcha lenta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.800-4.400 r.p.m.

Tipo de encendido . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electrónico

Interruptor de encendido . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Interruptor oscilante

Separación de la bujía de encendido . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,635 mm (0,025 pulg)

Lubricación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mezcla de combustible y aceite

Proporción de combustible - aceite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40:1

Carburador. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diafragma, multiposicional

Arranque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . EZ-Pull Version 3™

Silenciador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Desviado con protección

Regulador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Retroceso manual a resorte

Capacidad del tanque de combustible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341 ml (12 onzas)

Bastidor del eje impulsor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tubo de acero

Control del regulador. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gatillo para el dedo

Peso de la unidad (Sin combustible, con accesorio de corte, y manija en D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,5 kg (10 libras)

Mecanismo de corte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bump Head™

Correa para el hombro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Opcional

Diámetro de la bobina de línea. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76,2 mm (3 pulg)

Diámetro de la línea de corte. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,03 mm (0,080 pulg)

Diámetro de la trayectoria de corte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43,18 cm (17 pulg)

ESPECIFICACIONES

CAUSA ACCIÓN

El combustible es viejo o está mal mezclado Drene el tanque de gasolina/Agregue mezcla de combustible nueva

El carburador no está ajustado en forma correcta Faites-le régler par un concessionnaire agréé

La bujía de encendido está arruinada Remplacez ou nettoyez-la

Parachispas obstruido Limpie o cambie el parachispas

CAUSA ACCIÓN

El accesorio de corte está atascado de hierba Pare el motor y limpie el accesorio de corte

El accesorio de corte no tiene línea Coloque una línea nueva

El carrete interior está trabado Rebobine el carrete interior

La cabeza de corte está sucia Limpie el carrete interior y la bobina exterior

La línea se ha soldado Desarme, saque la sección soldada y rebobine la línea

La línea se retorció al reponerla Desarme y rebobine la línea

No hay suficiente línea expuesta

Oprima el botón de tope y tire de la línea hasta sacar 102 mm (4 pulg) de

línea fuera del accesorio de corte

CAUSA ACCIÓN

El cabezal de corte tiene aceite Limpie el aditamento de corte

Si necesita asistencia adicional, comuníquese con su proveedor de servicio autorizado.

EL MOTOR NO TIENE SUFICIENTE POTENCIA O SE AHOGA AL CORTAR

LA LÍNEA DE CORTE AVANZA SIN CONTROL

LA CABEZA DE CORTE NO HACE AVANZAR LINEA

* Toda las especificaciones contenidas en este manual se basan en la información más reciente disponible en el momento de impresión

del manual. Nos reservamos el derecho de hacer cambios en cualquier momento sin aviso previo.

Lazo

Fig. 12

Fig. 13

Lazo

Fig. 14

Dientes de posición

Fig. 11

Ranuras de

fijación

Fig. 15

Resorte

Fig. 16

Ojalillos

ALMACENAMIENTO

• No guarde nunca la unidad con combustible en el tanque donde los vapores puedan llegar a una llama o chispa.

• Espere que el motor se enfríe antes de guardar la unidad.

• Guarde la unidad bajo llave para prevenir el uso por

personas no autorizadas y su daño.

• Guarde la unidad en un área seca y bien ventilada.

• Guarde la unidad fuera del alcance de los niños.

ALMACENAMIENTO PROLONGADO

Si planea guardar la unidad durante un largo período de tiempo, siga el siguiente procedimiento para su almacenamiento.

1. Drene todo el combustible del tanque de combustible en un recipiente que contenga la misma mezcla de combustible de 2 ciclos. No

use combustible que haya permanecido guardado durante más de 60 días. Deseche la mezcla vieja de combustible y aceite de

acuerdo a las regulaciones federales, estatales y locales.

2. Arranque el motor y déjelo funcionar hasta que se ahogue. Esto asegura que todo el combustible ha sido drenado del carburador.

3. Espere que el motor se enfríe. Retire la bujía de encendido y coloque alrededor de 30 ml (1 onza) de cualquier aceite para motor de 2

ciclos de buena calidad dentro del cilindro. Tire de la cuerda de arranque lentamente para esparcir el aceite. Vuelva a instalar la bujía

de encendido.

NOTA: Saque la bujía de encendido y drene todo el aceite del cilindro antes de intentar arrancar el recortador después de su

almacenamiento.

4. Limpie bien la unidad e inspeccione para ver si existen partes flojas o dañadas. Repare o cambie las partes dañadas y ajuste los

tornillos, tuercas o pernos que puedan estar flojos. La unidad está ahora lista para ser guardada.

TRANSPORTE

• Espere que el motor se enfríe antes de su transporte.

• Drene el combustible de la unidad.

• Ajuste la tapa del combustible antes del transporte.

• Asegure la unidad durante su transporte.

INSTRUCCIONES DE MANTENIMIENTO Y REPARACIÓN