2)Donotallowpiecesofmetal,wireclippings,orfinemetallicfillingsfrominstallationtoentertheproduct

orelseitmayleadtoasafetyhazardthatmayinturnendangerlifeorcauseelectricalshocktotheoperator.

Productimprovementandupgradeisaconstantprocedure.SoformoreupdatedoperatinginformationandSupport,

PleasecontactourHelpline:9978991474/76/82orEmailat

Ver:1807

[email protected]A

B

C

D

EF

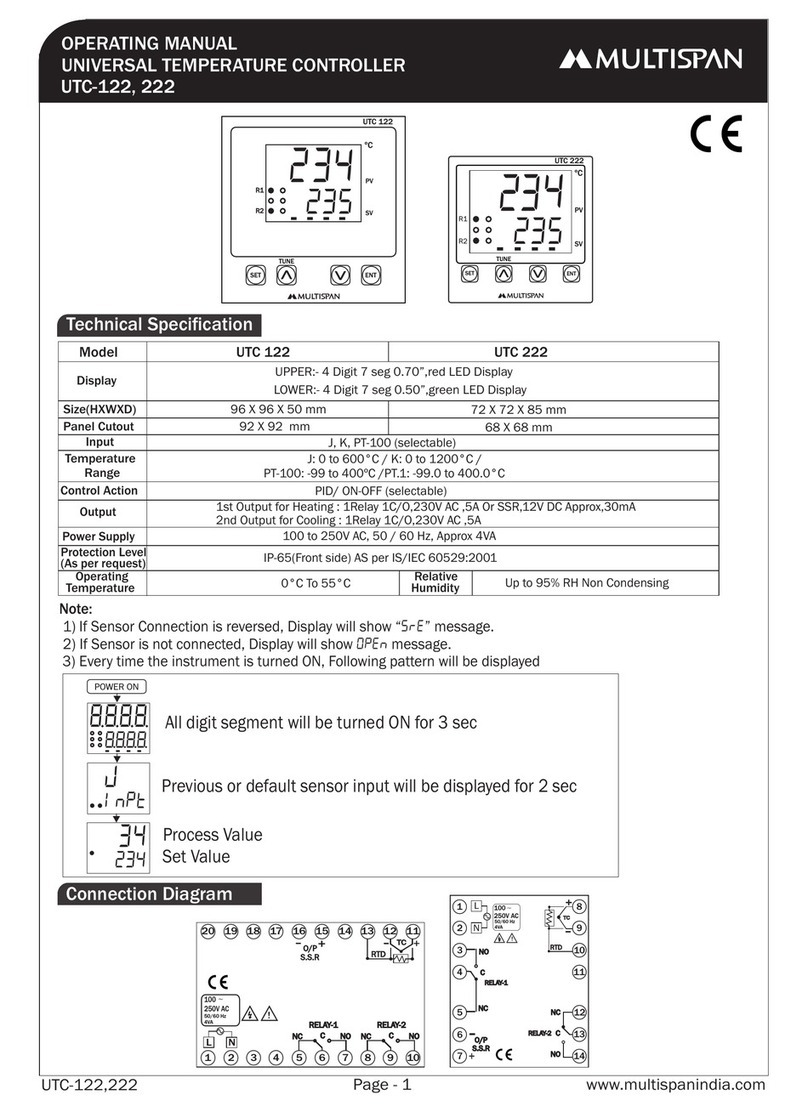

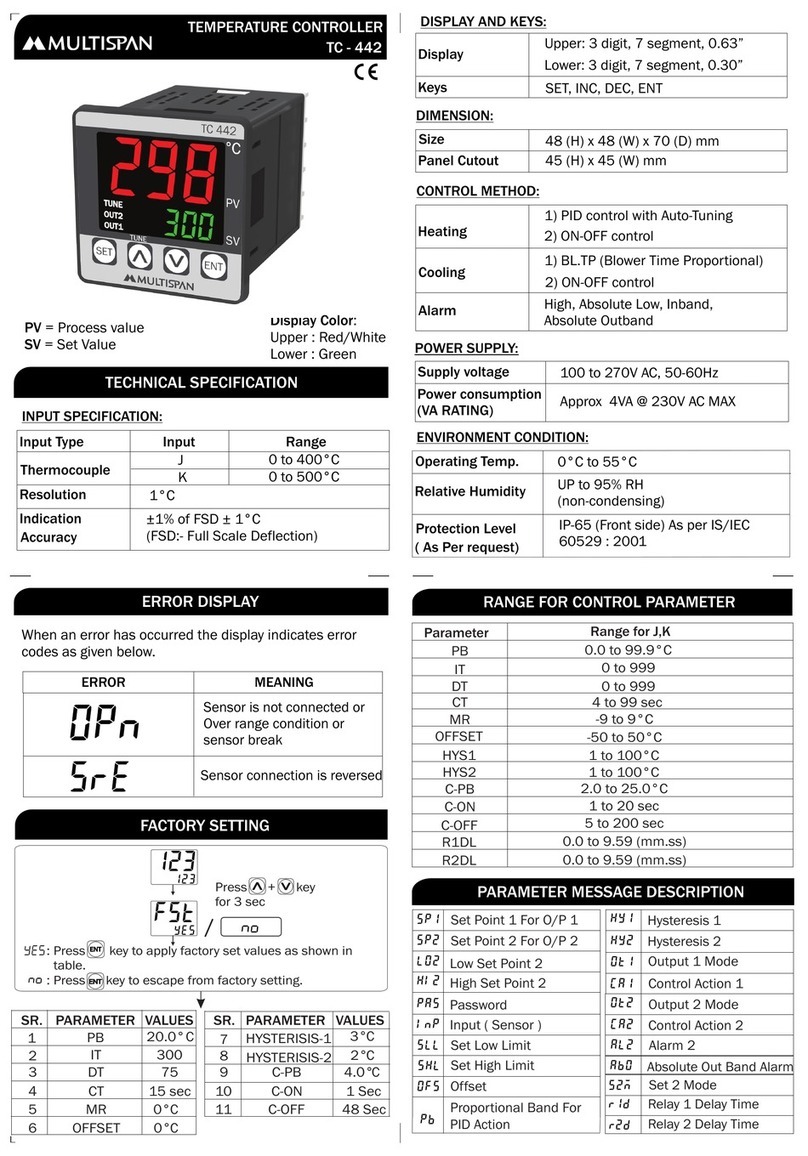

MODEL A

48mm 48mm 44mm 44mm 3mm 95mm

BC

D E

F

DIMENSIONS

Allsafetyrelatedcodifications,symbolsandinstructionsthatappearinthisoperatingmanualoronthe

equipmentmustbestrictlyfollowedtoensurethesafetyoftheoperatingpersonnelaswellasthe

instrument.

Ifalltheequipmentisnothandledinamannerspecifiedbythemanufacturer,itmightimpairthe

protectionprovidedbytheequipment.

=>Readcompleteinstructionspriortoinstallationandoperationoftheunit.

WARNING : Risk of electric shock.

3)Cableusedforconnectiontopowersource,musthaveacrosssectionof1mmorgreater.Thesewires

shouldhaveinsulationscapacitymadeofatleast1.5kV.

2)Toreduceelectromagneticinterference,usewirewithadequateratingandtwistsofthesameofequal

sizeshallbemadewithshortestconnection.

1)TopreventtheriskofelectricshockpowersupplytotheequipmentmustbekeptOFFwhiledoingthe

wiringarrangement.Donottouchtheterminalswhilepowerisbeingsupplied.

4)Abetteranti-noiseeffectcanbeexpectedbyusingstandardpowersupplycablefortheinstrument.

1)Thisequipment,beingbuilt-in-type,normallybecomesapartofmaincontrolpanelandinsuchcasethe

terminalsdonotremainaccessibletotheenduserafterinstallationandinternalwiring.

3)Circuitbreakerormainsswitchmustbeinstalledbetweenpowersourceandsupplyterminaltofacilitate

powerONorOFFfunction.Howeverthismainsswitchorcircuitbreakermustbe

installedatconvenientplacenormallyaccessibletotheoperator.

4)Useandstoretheinstrumentwithinthespecifiedambienttemperatureandhumidityrangesas

mentionedinthismanual.

1)Preparethepanelcutoutwithproperdimensionsasshowabove.

2)Fittheunitintothepanelwiththehelpofclampgiven.

3)Theequipmentinitsinstalledstatemustnotcomeincloseproximitytoanyheatingsource,

causticvapors,oilssteam,orotherunwantedprocessbyproducts.

4)Usethespecifiedsizeofcrimpterminal(M3.5screws)towiretheterminalblock.Tighteningthe

screwsontheterminalblockusingthetighteningtorqueoftherangeof1.2N.m.

5)Donotconnectanythingtounusedterminals.

1)Theequipmentshouldbecleanedregularlytoavoidblockageofventilatingparts.

2)Cleantheequipmentwithacleansoftcloth.Donotuseisopropylalcoholoranyothercleaningagent.

3)Fusibleresistormustnotbereplacedbyoperator.

136mm - 5.35 inches

120mm - 4.72 inches

www.multispanindia.com

Page-3UTC-4201A

SafetyPrecautions

WarningGuidelines

InstallationGuidelines

MechanicalInstallation

Maintenance