5 of 43

www.NabcoEntrances.com GT20 Wire and Programming Manual

Rev 5-7-18 P/N C-00140

Notice: All electrical troublshooting or service must be performed by qualied electrical technicians and

must comply with all applicable governing agency codes.

Note: A Reseable Fuse is located in the Power Supply Module. Do not aempt to repair the U30 Microprocessor Control or the

Power Supply Module other than reseng the fuse.

Aenon: Electrical circuit to Nabco operator must not be not shared with other equipment such as lighng,

cash registers, or any device that might cause electrical interference on the circuit

XThe GT20 swing door drive mechanism may only be installed and operated for indoor use. If this condition cannot be

X

X

in order to continue the operation of the installation.

XIt is the responsibility of the installing door technician to install all warning and instructional labels in accordance

XIt is the responsibility of the purchasing facility or end user to keep warning and instructional labels and literature

assistance.

X

CHAPTER 3: SCOPE

SECTION 31: To the Installer

The purpose of this manual is to familiarize the installer and purchaser with the proper installaon and operaon of this system.

It is essenal that this equipment be properly installed and operaonal before the door is used by the public. It is the installer’s

responsibility to inspect the operaon of the entrance system to be sure it complies with any applicable standards. In the United

States, ANSI Standard 156.10 (Full Power) and ANSI Standard 156.19 (Low Energy) covers the GT20 Swing Door Operator Assembly.

Other local standards or codes may apply. Use them in addion to the ANSI standard. Both Full Power and Low Energy Swing door

Units are listed by UL according to UL325 and is idened as such on the label.

Instruct the building owners and operator on the essenals of the operaon of this device. The owner should follow these

instrucons to determine whether the door is operang properly and should immediately call for service if there is any malfuncon.

All installaon changes and adjustments must be made by qualied, NABCO trained technicians.

Replacement labels and literature may be obtained from local NABCO Entrances, Inc. Distributors. If the name of the local distributor

is unknown, contact NABCO Entrances, Inc. at 1-877-622-2694 for assistance.

The owner should determine that the door is operang properly and should immediately call for service if there is any malfuncon.

All installaon changes and adjustments must be made by qualied, NABCO trained technicians.

SECTION 32: Objecve

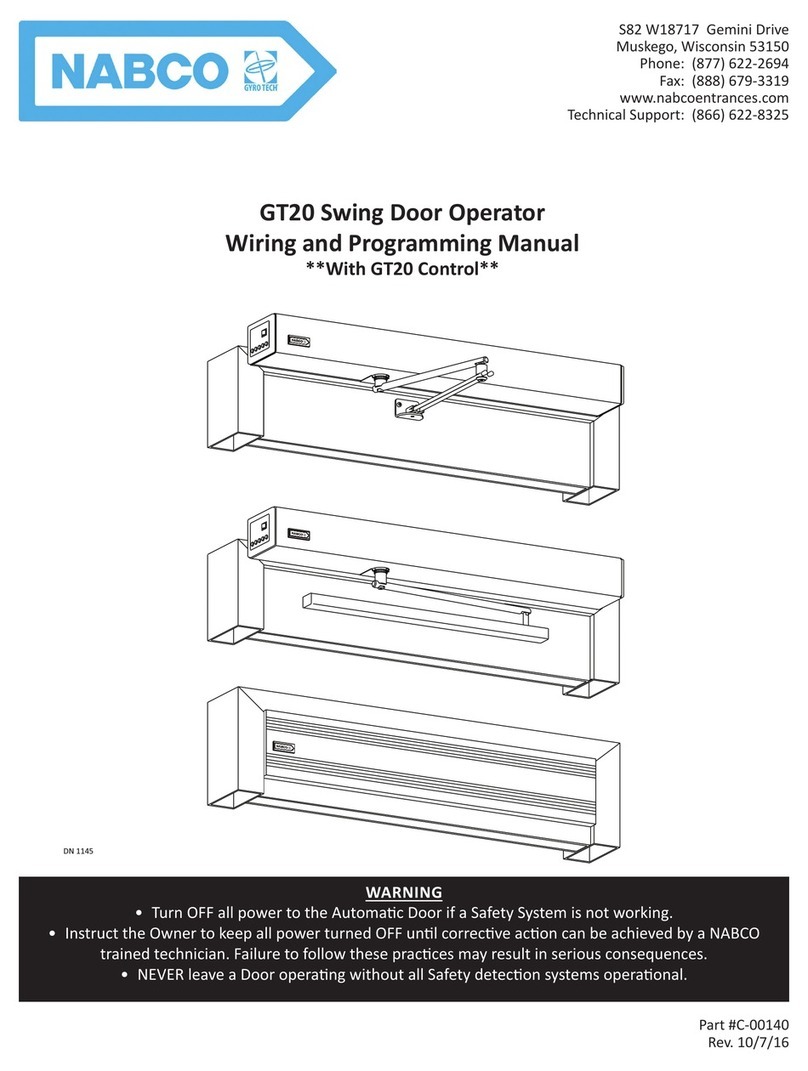

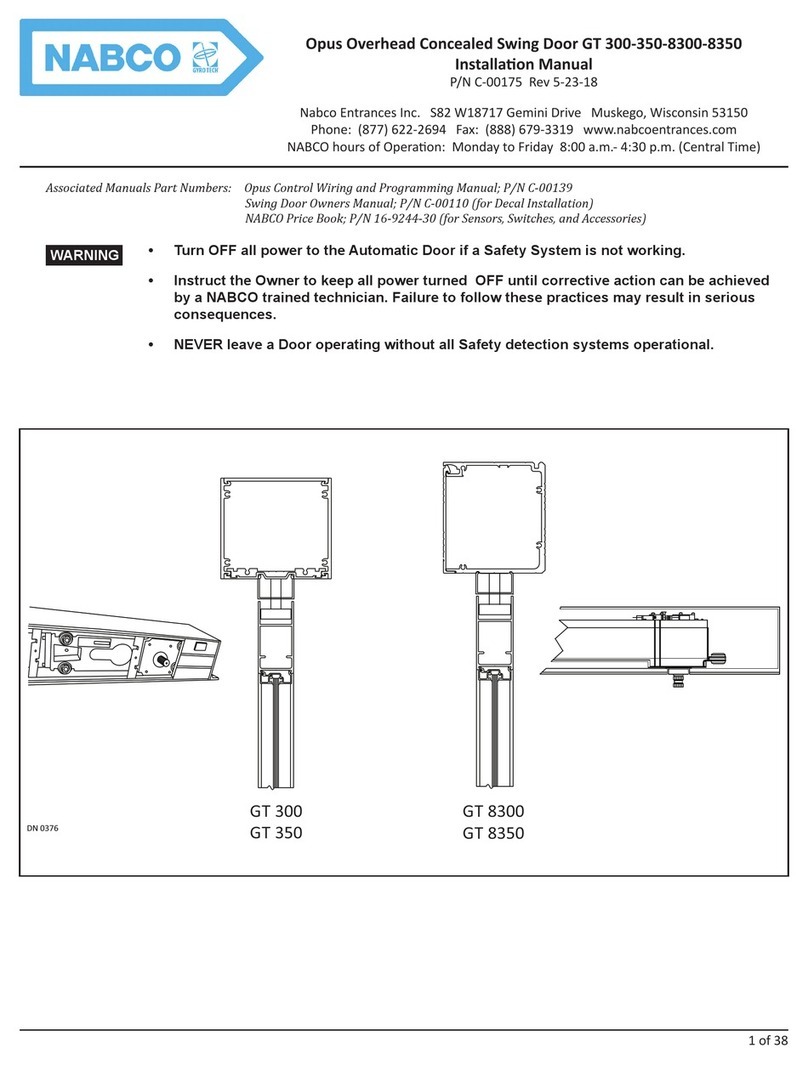

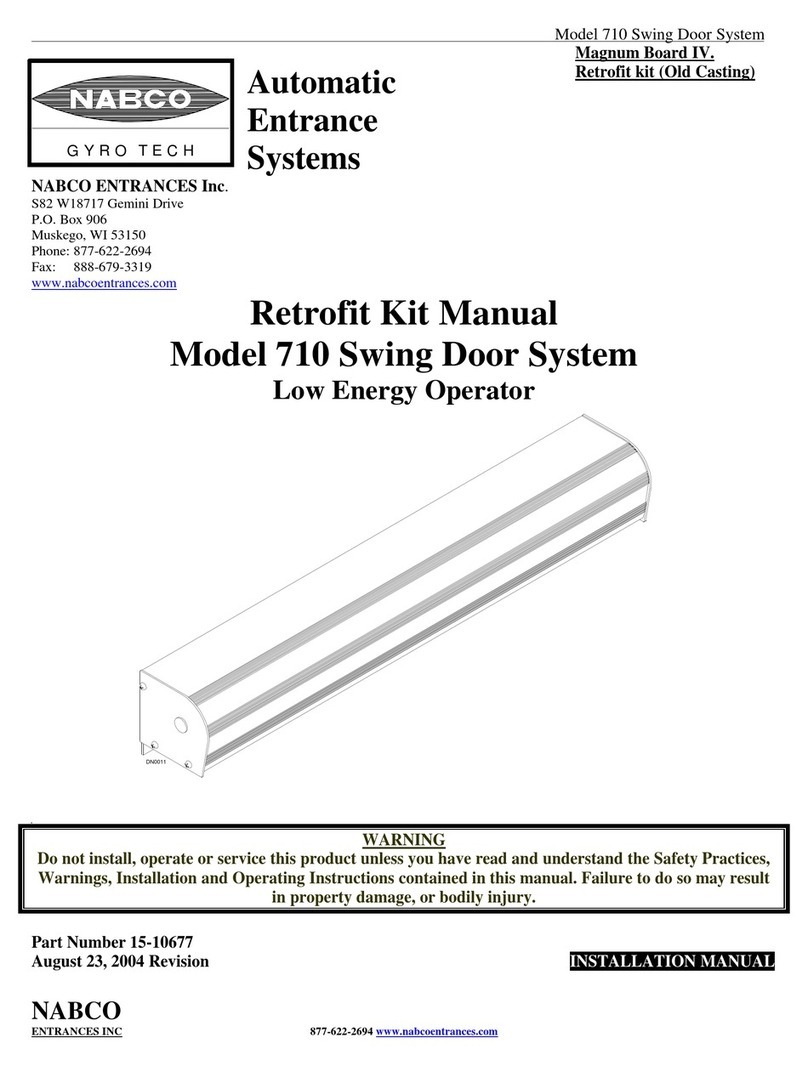

The Swing Door Operator assembly is designed to be installed onto the top surface of the Door Frame, or Door Panel. This manual

was created to oer step by step instrucons..

A pedestrian Door that does not have Its glass secons installed at the Factory

shall specify that the glazing material employed is to comply with the requirement in

UL 325 par2951:

“The glazing material in both xed and sliding panels of all sliding doors and in all

unframed swinging doors shall comply with the requirements in the Performance

Specicaons and Methods of Test for Safety Glazing Material Used in Buildings,

ANSI Z971 Glazing material for other pedestrian doors shall also comply with

ANSI Z971, except that single strength or heavier glass may be used for those

porons of doors involving a glazed area of less than 12 (09 m2) and having no

dimension greater than 18 in (457 mm)”