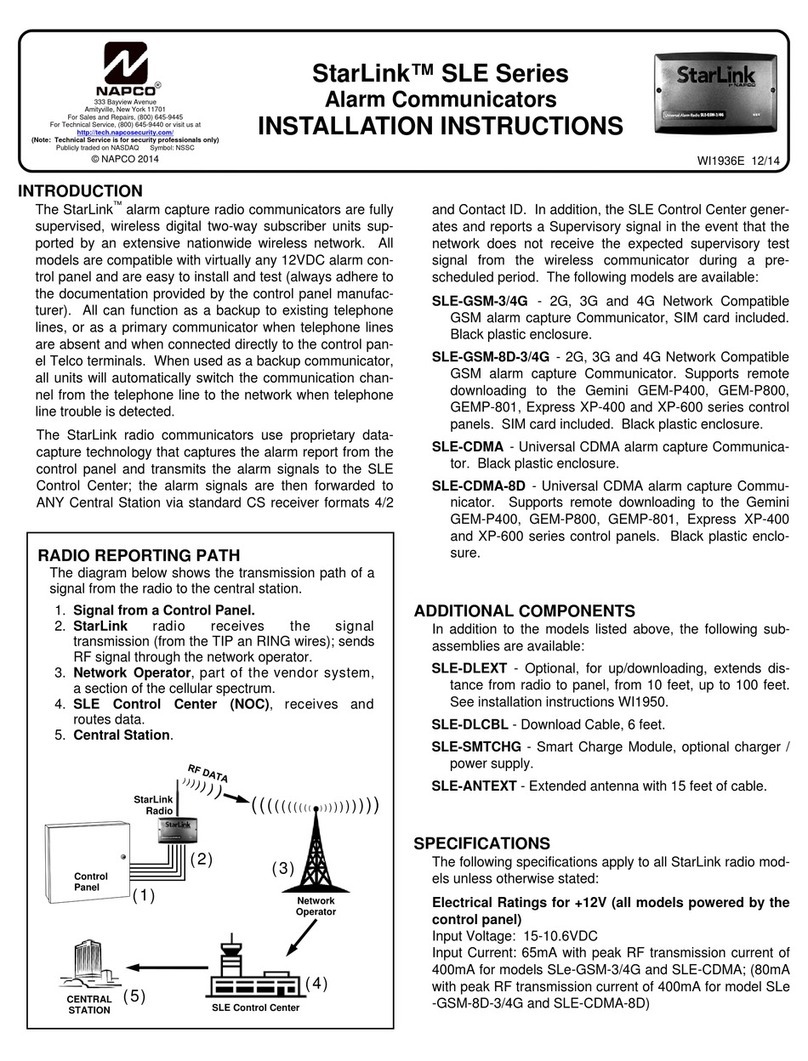

6StarLink™ SLE-LTEVI-FIRE & SLE-LTEAI-FIRE Commercial Series Dual-Path Alarm Communicators -- Installation Instructions

page 5. Note: These event codes and zone numbers can

be changed from the Management Center screen (located at

www.NapcoNOC.com).

Upon alarm, the NOC can optionally send an SMS message

to a third party that includes the appropriate Contact ID

alarm code, including the zone or user number, if applicable.

The "STARLINK RADIO RELATED EVENT REPORT

CODES" table also includes the most common Contact ID

alarm codes.

Programming StarLink Radio Troubles

It is required that if a StarLink radio or control panel trouble

is detected, that it is reported to the central station.

When the StarLink radio detects and sends a trouble to the

control panel, the control panel must be programmed to

annunciate this trouble. The radio can detect multiple trou-

bles as indicated by the "Red Trouble LED" ("D5"). For

these troubles to be annunciated at the control panel, there

are several methods, some of them are configurable at the

Management Center screen (www.NapcoNOC.com):

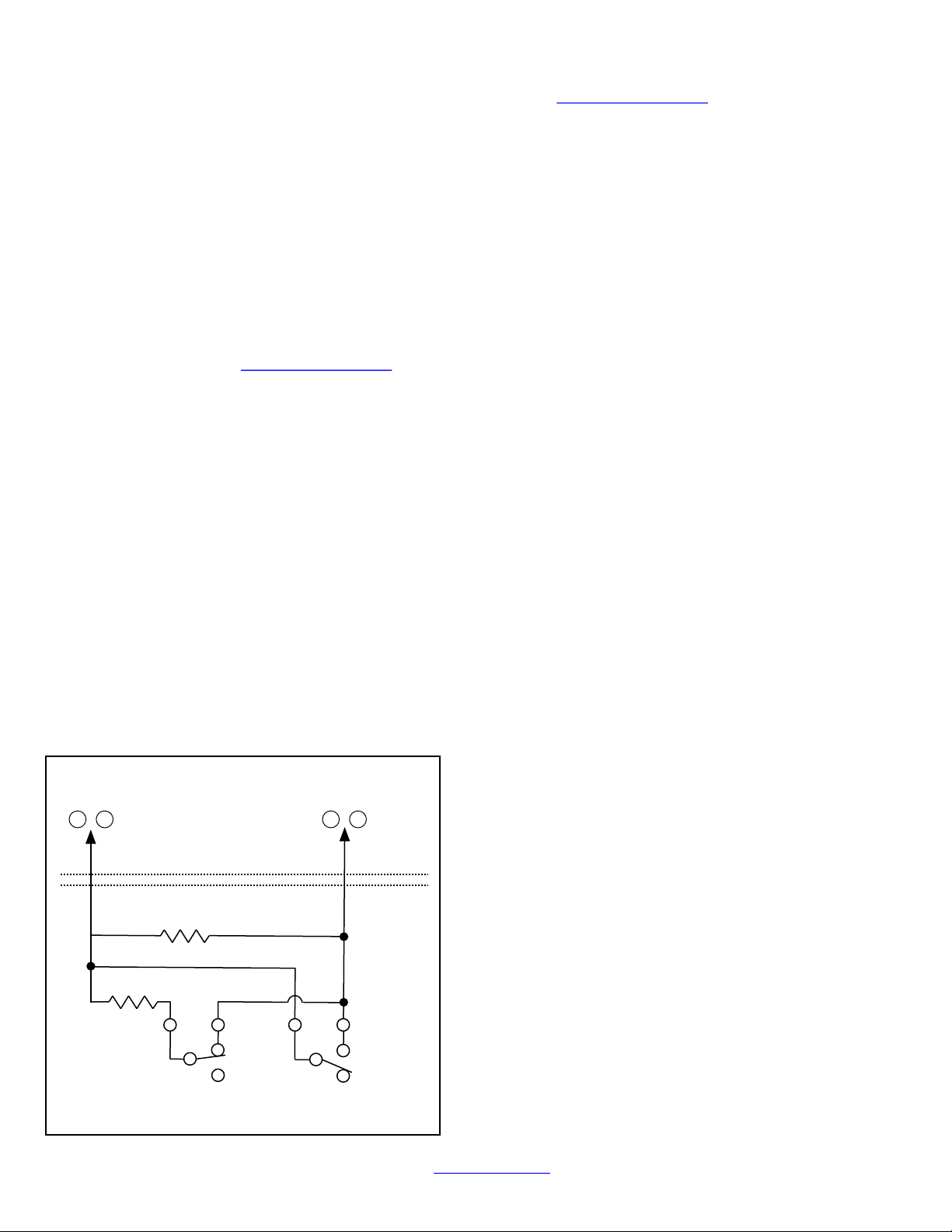

Wire the radio OUT1 relay to a dedicated control panel

zone (input) to annunciate the trouble. Two wiring options

are available:

Activate the trouble with an open by wiring the

EOLR in series with the Common and N/C of the

OUT1 relay;

Activate the trouble with a short by wiring the

EOLR in parallel with the Common and N/O of

the OUT1 relay

The radio must also report this trouble to the central station.

With NAPCO GEMC series control panels, wire the zone as

indicated in the wiring diagrams further in this manual.

Optionally, the FACP trouble relay can be used to trigger a

report to the central station.

Wire the FACP trouble relay to IN2; Common and N/O ter-

minals in parallel with a 10K EOLR. With Gemini C-Series

(GEMC) control panels, we recommend using the Fire Aux

Relay. Program the Fire Aux Relay to activate as a trouble

relay. Wire this relay to the StarLink module IN 2 terminal;

by wiring the EOLR in parallel with Common and N/O of the

OUT1 relay. Note: We recommend using the text

"Radio Trouble" as the Zone Description.

StarLink Radio Supervision

If the two Telco wires (DACT interconnect wiring to the ra-

dio) between the StarLink radio and the control panel are

cut or otherwise disconnected, the control panel must de-

tect and generate a local trouble indication. Program the

control panel for telephone supervision. Program the Star-

Link radio using the Management Center Advanced Fea-

tures screen (at www.NapcoNOC.com) to enable Tip/

Ring Wiring Fault Report. Refer to wiring diagram.

Supervision Time Schedule Considerations

If a status change (alarm trouble, etc.) is transmitted, the

radio supervision timer is restarted.

For example, if a status change is sent, the next regular

supervision transmission will occur at the interval deter-

mined by your rate plan.

Configuration Download / Firmware Updates

Technician on site required.

For Commercial Installations a technician is required to be

STEP 5: SIGNAL VERIFICATION

After triggering channels, use the StarLink radio Signal

Verification to ensure that the StarLink radio Network has

properly received the signals.

Verify Online: To verify that the signals have been

received by the StarLink radio Network online, go to

www.NapcoNOC.com, log in with your Username and

Password, enter your Company ID number and the

StarLink Radio Number, then click Signal Log.

IMPORTANT: Verify that the signals transmitted by t he

StarLink radio have been properly received by your central

station before leaving the premises.

NOTE: This equipment has been tested and found to

comply with the limits for a Class B Unintentional Radiator,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful

interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the In-

struction Manual, may cause harmful interference to radio

communications. However, there is no guarantee that in-

terference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or tele-

vision reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to cor-

rect the interference by one of more of the following

measures: 1. Reorient or relocate the receiving antenna;

2. Increase the separation between the equipment and re-

ceiver; 3. Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected; 4.

Consult the dealer or an experienced radio/TV technician

for help.

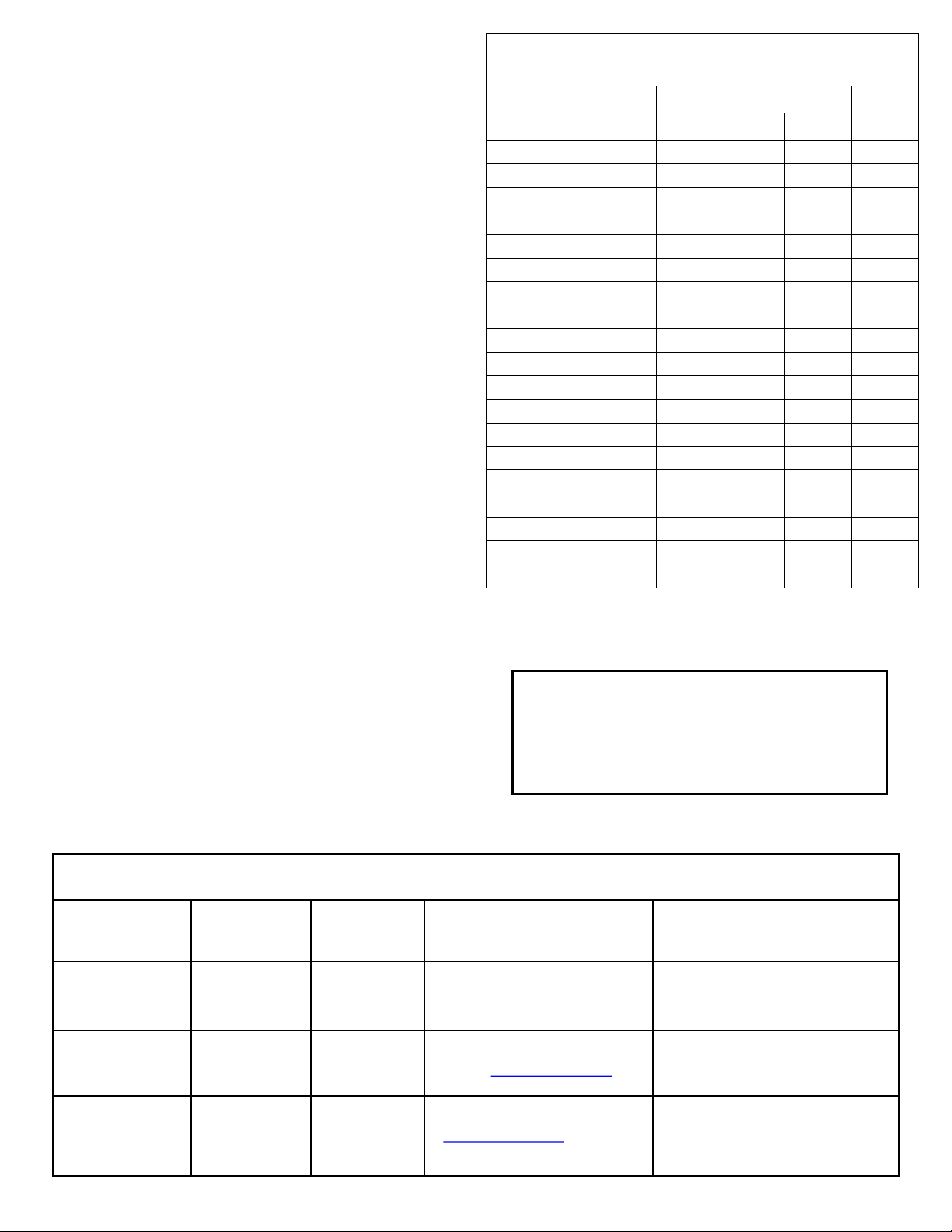

NAPCO GEMINI C-SERIES (GEMC)

CONTROL PANEL PROGRAMMING

To program the central station receiver reporting format,

use PCD-Windows Quickloader download software. Open

the Digital Communications screen, Central Station Re-

ceivers tab, as shown in the following image:

A "Point ID" (also called "Contact ID") receiver format pro-

gramming example:

The radio can transmit to any central station capable of

receiving SIA Contact ID or 4/2 via DACR technology or

the DSC Sur-Gard Model System II or Sur-Gard System V

central station receivers, Bosch D6100IPV6 or Bosch

D6600 Receiver (with ITS-D6686 Ethernet Adapter) via

TCP/IP using standard line security.

Note: A receiver reporting format must be entered for

each telephone number used, but each telephone number

may be assigned a different format.

CAUTION: The installer should always be certain an

area code is programmed into the control panel.

Optional: If you wish the StarLink radio to report a code

and zone number (Contact ID by default) to the central sta-

tion in response to a triggered input event, see the table on