6 StarLink™SLE-LTEVI-FIRE Commercial Series Dual-Path Alarm Communicator -- Installation Instructions

STEP 5: SIGNAL VERIFICATION

After triggering channels, use the StarLink radio Signal

Verification to ensure that the StarLink radio Network has

properly received the signals.

Verify Online: To verify that the signals have been

received by the StarLink radio GSM Network online, go

to www.NapcoNOC.com, log in with your Username and

Password, enter your Company ID number and the

StarLink GSM Radio Number, then click Signal Log.

IMPORTANT: Verify that the signals transmitted by the

StarLink radio have been properly received by your central

station before leaving the premises.

NOTE: This equipment has been tested and found to

comply with the limits for a Class B Unintentional Radiator,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful

interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the In-

struction Manual, may cause harmful interference to radio

communications. However, there is no guarantee that in-

terference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or tele-

vision reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to cor-

rect the interference by one of more of the following

measures: 1. Reorient or relocate the receiving antenna;

2. Increase the separation between the equipment and re-

ceiver; 3. Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected; 4.

Consult the dealer or an experienced radio/TV technician

for help.

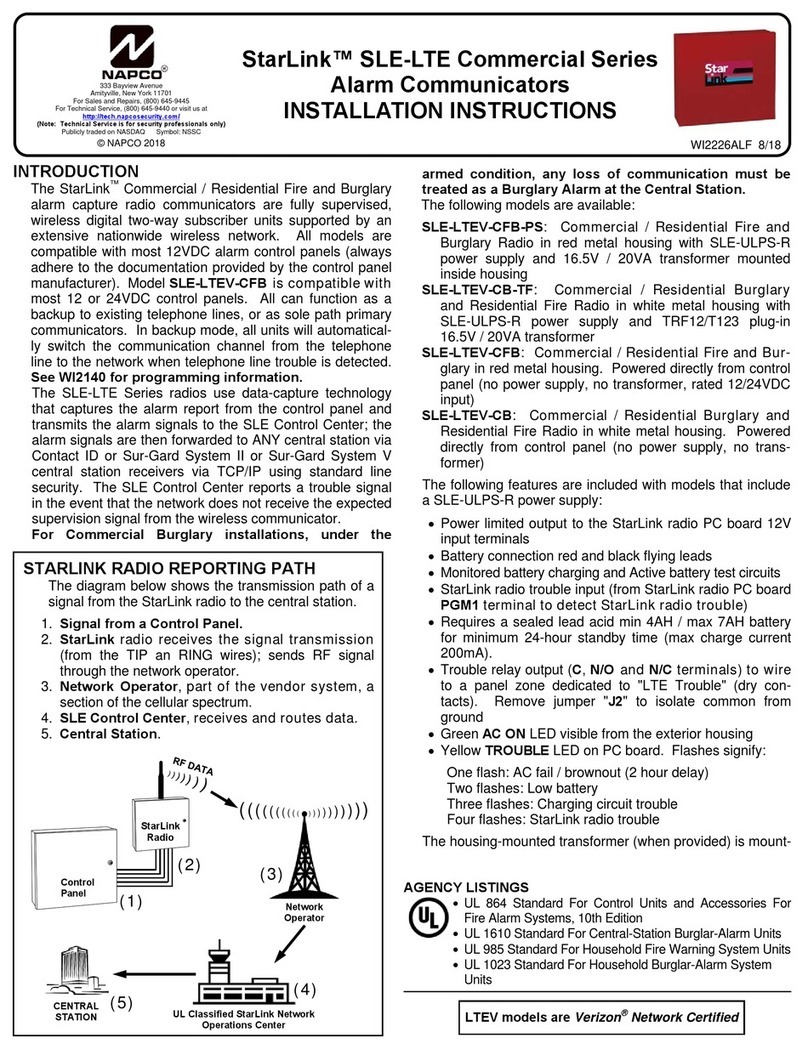

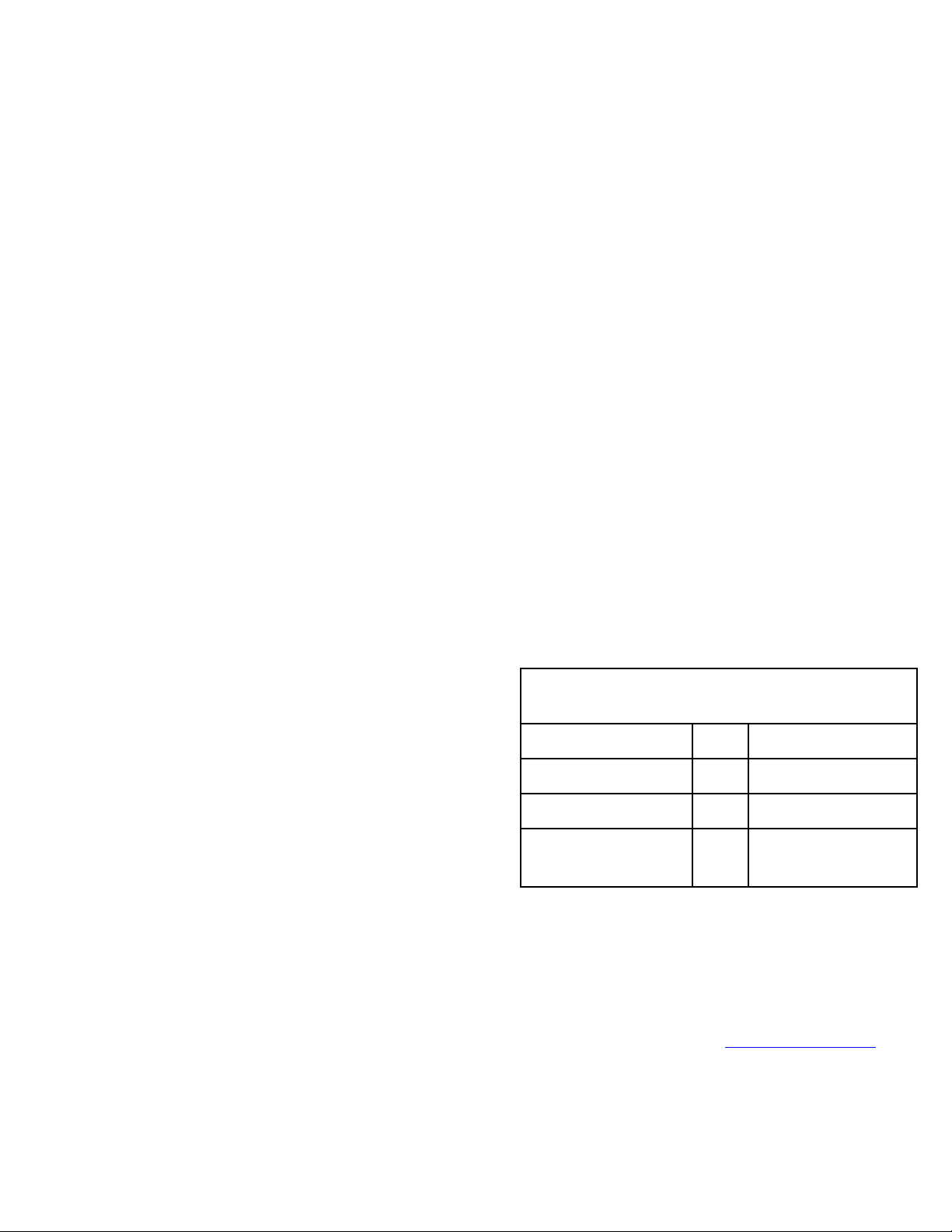

NAPCO GEMINI C-SERIES (GEMC)

CONTROL PANEL PROGRAMMING

To program the central station receiver reporting format,

use PCD-Windows Quickloader download software. Open

the Digital Communications screen, Central Station Re-

ceivers tab, as shown in the following image:

A "Point ID" (also called "Contact ID") receiver format pro-

gramming example:

The radio can transmit to any central station capable of

receiving SIA Contact ID or 4/2 via DACR technology or

the DSC Sur-Gard Model System II or Sur-Gard System V

central station receivers, Bosch D6100IPV6 or Bosch

D6600 Receiver (with ITS-D6686 Ethernet Adapter) via

TCP/IP using standard line security.

Note: A receiver reporting format must be entered for

each telephone number used, but each telephone number

may be assigned a different format.

A fair amount of care may be required to mount the ra-

dio so as to achieve an optimal RF path. The installer

should spend as much time as needed to obtain the

highest signal level possible.

a. Before applying power, be sure to connect the

antenna. Temporarily connect power to the radio

from a fully charged 12V (4AH minimum) battery.

DO NOT mount the StarLink radio at this time. Press

Tamper switch to send a signal.

b. Position the unit in the desired mounting location,

with antenna oriented vertically. The signal strength

is displayed by the Green "Signal Strength LED" la-

beled "D3" (located at the lower right corner of the

PC board). The GSM radio tower signal strength

may fluctuate from day to day, therefore it is best to

try to find a mounting location where the LED pro-

vides a minimum of 4 blinks.

c. Once a location has been selected based on signal

coverage, permanently secure the unit using #8

screws (not supplied) in the two mounting holes.

WARNING: To ensure user safety and to satisfy FCC

RF exposure requirements, this unit must be installed so

that a minimum separation distance of 60cm (24") is al-

ways maintained between the antenna of the transmitting

device and nearby persons.

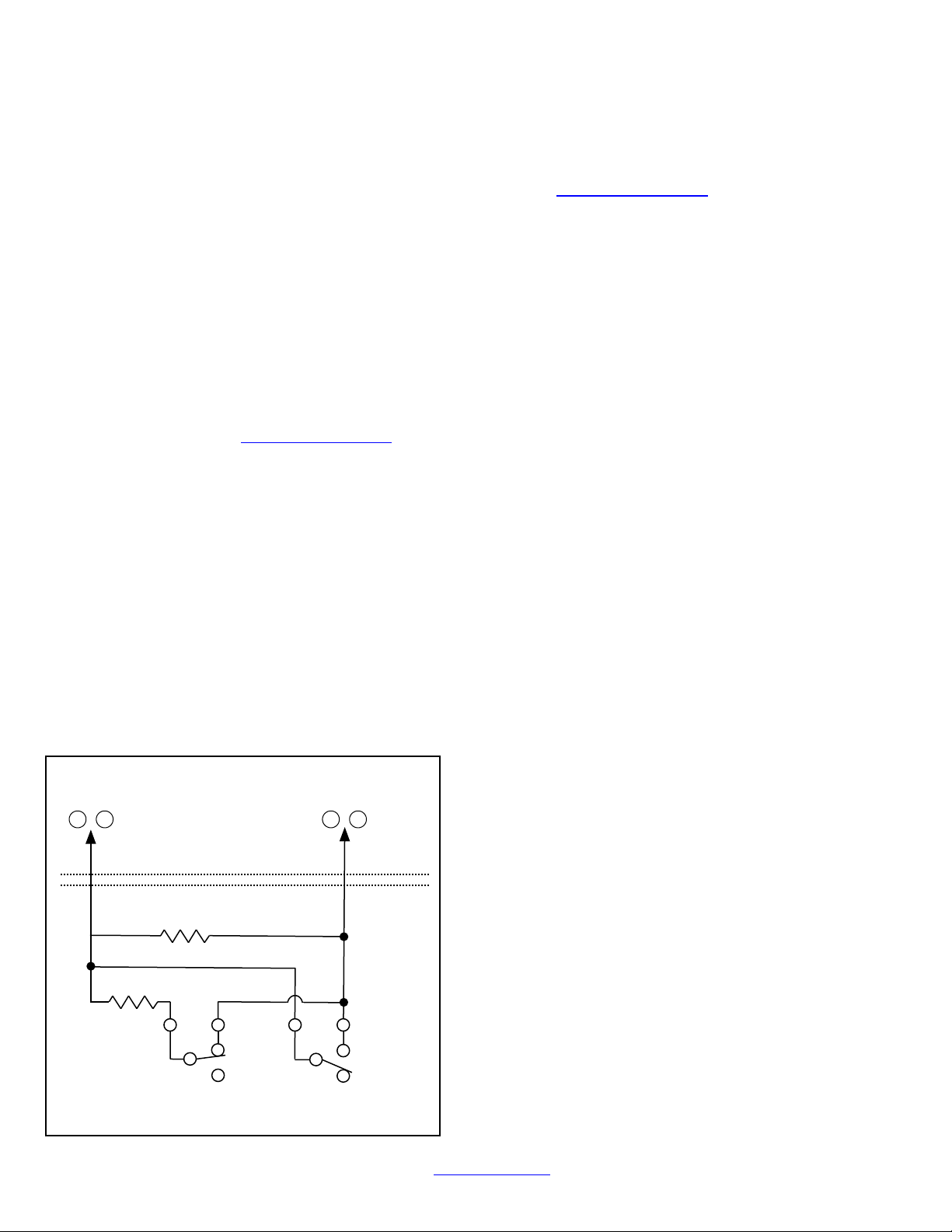

STEP 3: WIRING

22-gauge wire may be used if mounted up to 50 feet from

the control panel, and 18-gauge wire should be used for up

to 100 feet. Reference the wiring diagrams further in this

manual. See the section CONTROL PANEL PROGRAM-

MING further in this manual.

The wiring between the control panel and the StarLink ra-

dio is over several wires, as follows:

TB1: PWR

TB2: PWR GND (–)

TB21: N/C OUT1: Wired to the (+) of a zone dedi-

cated to monitoring the radio status. Should be pro-

grammed on Napco GEMC control panels as Monitor

or Supervisory Zone.

TELCO PRIMARY to FACP Telco 1 RJ-45 socket.

TELCO SECONDARY to FACP Telco 2 RJ-45 socket.

(Place JP1 shunt on bottom two pins)

Optional: Wire IN2 with a 10K EOLR in parallel with

the FACP trouble relay output Common and N/O (or in

series with Common and N/C).

Wiring Methods

Strip wire carefully to avoid exposed conductors after

installation, etc.)

Use of Listed wire, ensuring that all conductors are to be

insulated for the maximum voltage of any conductor in

the enclosure

All wiring methods must be performed in accordance

with NFPA70, Articles 725, and 800

STEP 4: APPLY POWER

Attach antennas before applying power !

Apply 12/24VDC to terminals 1 and 2.