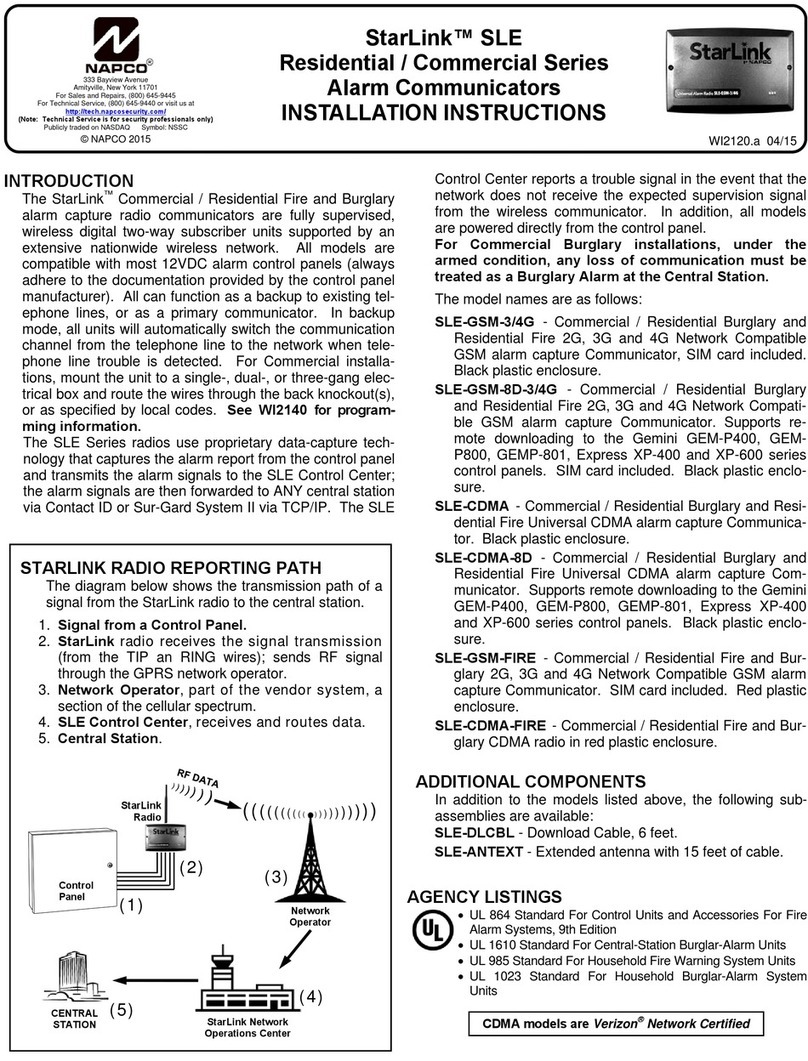

StarLink™SLE Commercial LTEVI & LTEAI Series Dual-Path Alarm Communicators -- Installation Instructions 5

(Place JP1 shunt on bottom two pins)

Wiring Methods

Strip wire carefully to avoid exposed conductors after

installation, etc.

Use UL Listed wire, ensuring that all conductors are to

be insulated for the maximum voltage of any conductor

in the enclosure

All wiring methods must be performed in accordance

with NFPA 70, Articles 725, and 800

STEP 4: APPLY POWER

Attach antennas before applying power !

Apply 12/24VDC to terminals 1 and 2. (For models

without the charger board SLE-ULPS-R). For models

with the SLE-ULPS-R, apply power to the unit.

STEP 5: SIGNAL VERIFICATION

Verify Online: To verify that the signals have been

received by the StarLink radio Network online, go to

www.NapcoNOC.com, log in with your Username and

Password, enter your Company ID number and the

StarLink Radio Number, then click Signal Log.

IMPORTANT: Verify that the signals transmitted by the

StarLink radio have been properly received by your central

station before leaving the premises.

NAPCO GEMINI C-SERIES (GEMC)

CONTROL PANEL PROGRAMMING

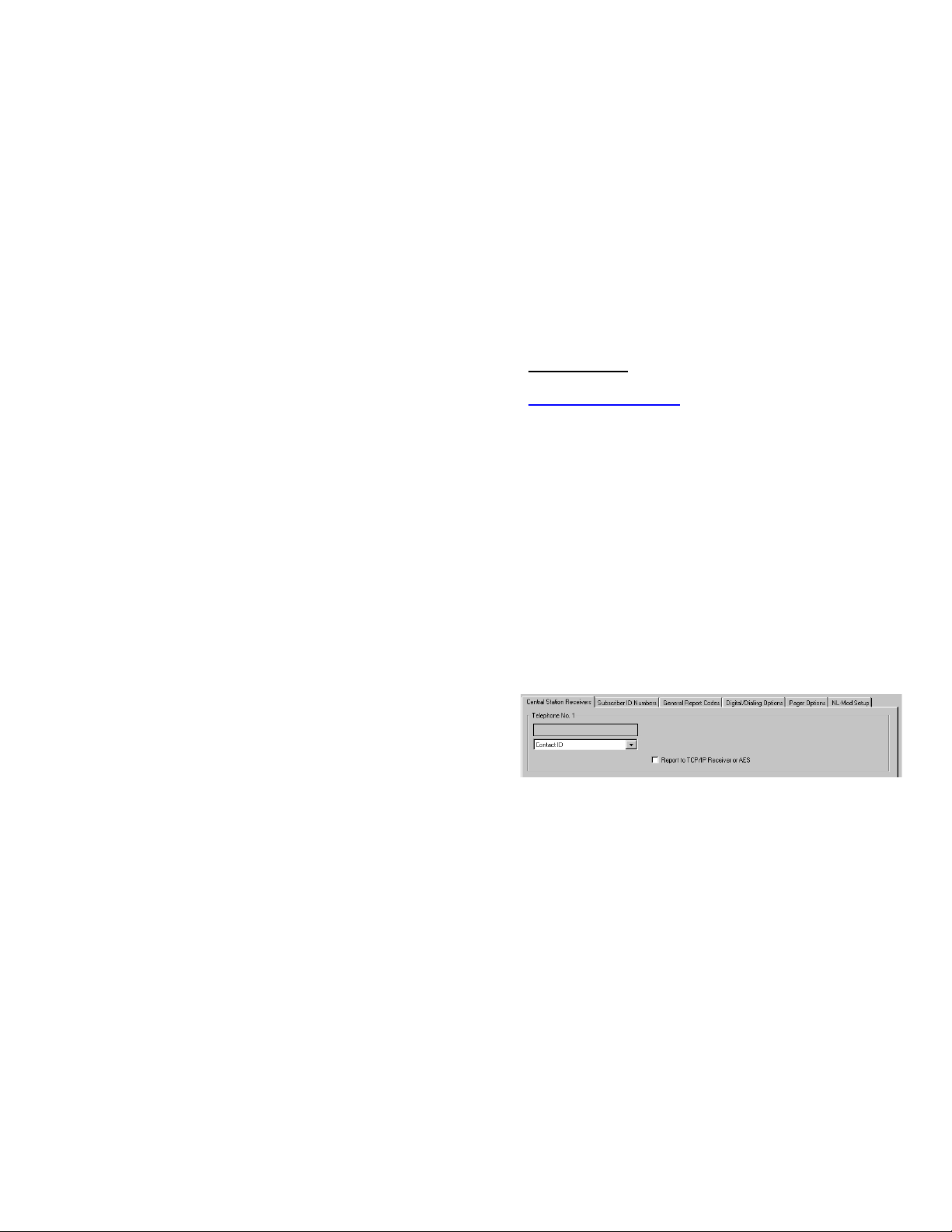

To program the central station receiver reporting format,

use PCD-Windows Quickloader download software. Open

the Digital Communications screen, Central Station Re-

ceivers tab, as shown in the following image:

A "Point ID" (also called "Contact ID") receiver format pro-

gramming example is shown:

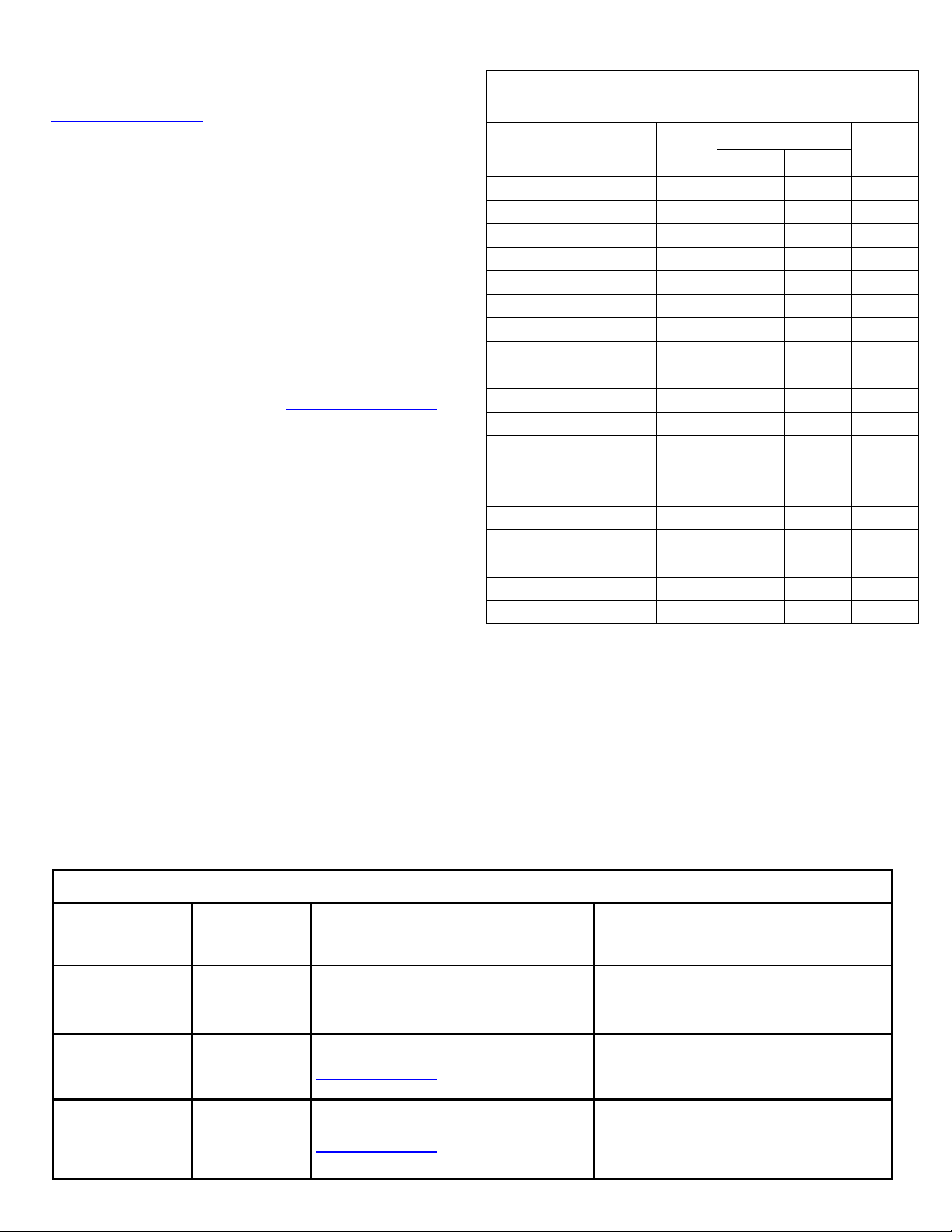

The radio can transmit to any central station capable of

receiving SIA Contact ID or 4/2 via DACR technology or

the DSC Sur-Gard Model System II or Sur-Gard System V

central station receivers, Bosch D6100IPV6 or Bosch

D6600 Receiver (with ITS-D6686 Ethernet Adapter) via

TCP/IP using standard line security.

Note: A receiver reporting format must be entered for

each telephone number used, but each telephone number

may be assigned a different format.

Note: UL Listed for UL 1076 APOU Proprietary Alarm

Systems and UL 365 APAW Police Connect when report-

ing to a UL Listed Central Station Receiver Listed for UL

1076 APOU Proprietary Alarm Systems or UL 365 APAW

Police Connect, respectively. For TCP/IP only Bosch

D6600 or D6100IPV6 for UL1076 and UL365 applications.

CAUTION: The installer should always be certain an

area code is programmed into the control panel.

Optional: If you wish the StarLink radio to report a code

and zone number (Contact ID by default) to the central sta-

ules registered via the Internet are enabled for activation

within 24 hours.

STEP 2: SELECT A MOUNTING LOCATION

The mounting location should be indoors within the protect-

ed area and selected based on RF performance. It is

HIGHLY recommended that the installer carefully adhere to

the following recommendations BEFORE any wires are

installed.

Generally, high locations are best. DO NOT mount ra-

dio in basements or below grade as unpredictable per-

formance may result.

DO NOT mount the radio in non-climate controlled envi-

ronments (i.e. attics may become extremely hot in sum-

mer, garages may become extremely cold in winter).

Avoid mounting locations within 3 feet of AC power

lines, fluorescent light fixtures, or large metal objects (air

conditioners, metal garage doors, etc.) as these loca-

tions have been shown to have a detrimental effect on

signal strength.

A fair amount of care may be required to mount the

StarLink radio so as to achieve an optimal RF path. The

installer should spend as much time as needed to obtain

the highest signal level possible.

a. Before applying power, be sure to connect the

antenna. Temporarily connect power to the

StarLink radio from a fully charged 12V (4AH mini-

mum) battery. DO NOT mount the radio at this

time. Press Tamper switch to send a signal.

b. Position the unit in the desired mounting location,

with antenna oriented vertically. The signal strength

is displayed by the Green "Signal Strength LED"

labeled "D3" (located at the lower right corner of the

PC board). The radio tower signal strength may

fluctuate from day to day, therefore it is best to try to

find a mounting location where the LED provides a

minimum of 2 blinks.

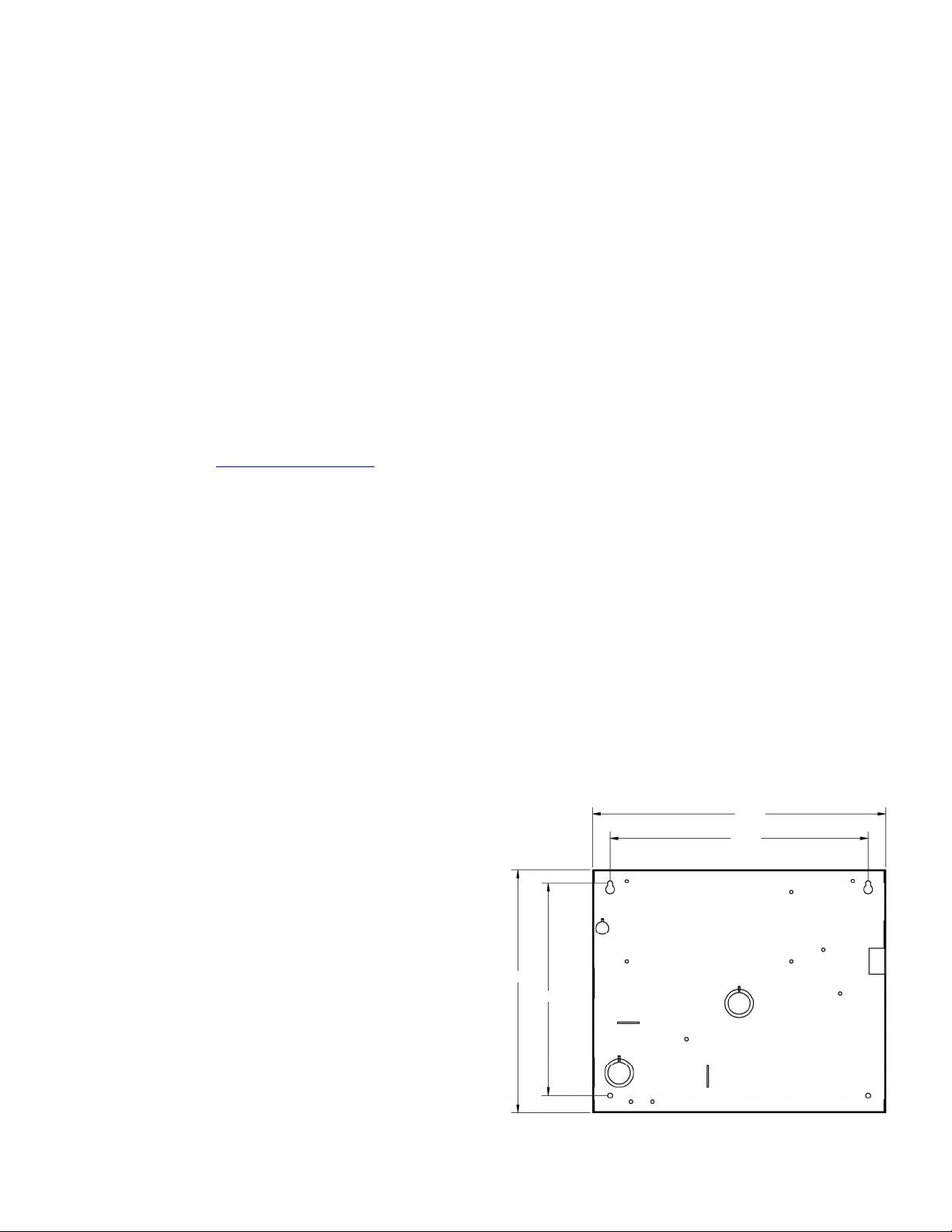

c. Once a location has been selected based on signal

coverage, permanently secure the unit using #8

screws (not supplied) in the two mounting holes.

WARNING: To ensure user safety and to satisfy FCC

RF exposure requirements, this unit must be installed so

that a minimum separation distance of 60cm (24") is al-

ways maintained between the antenna of the transmitting

device and nearby persons.

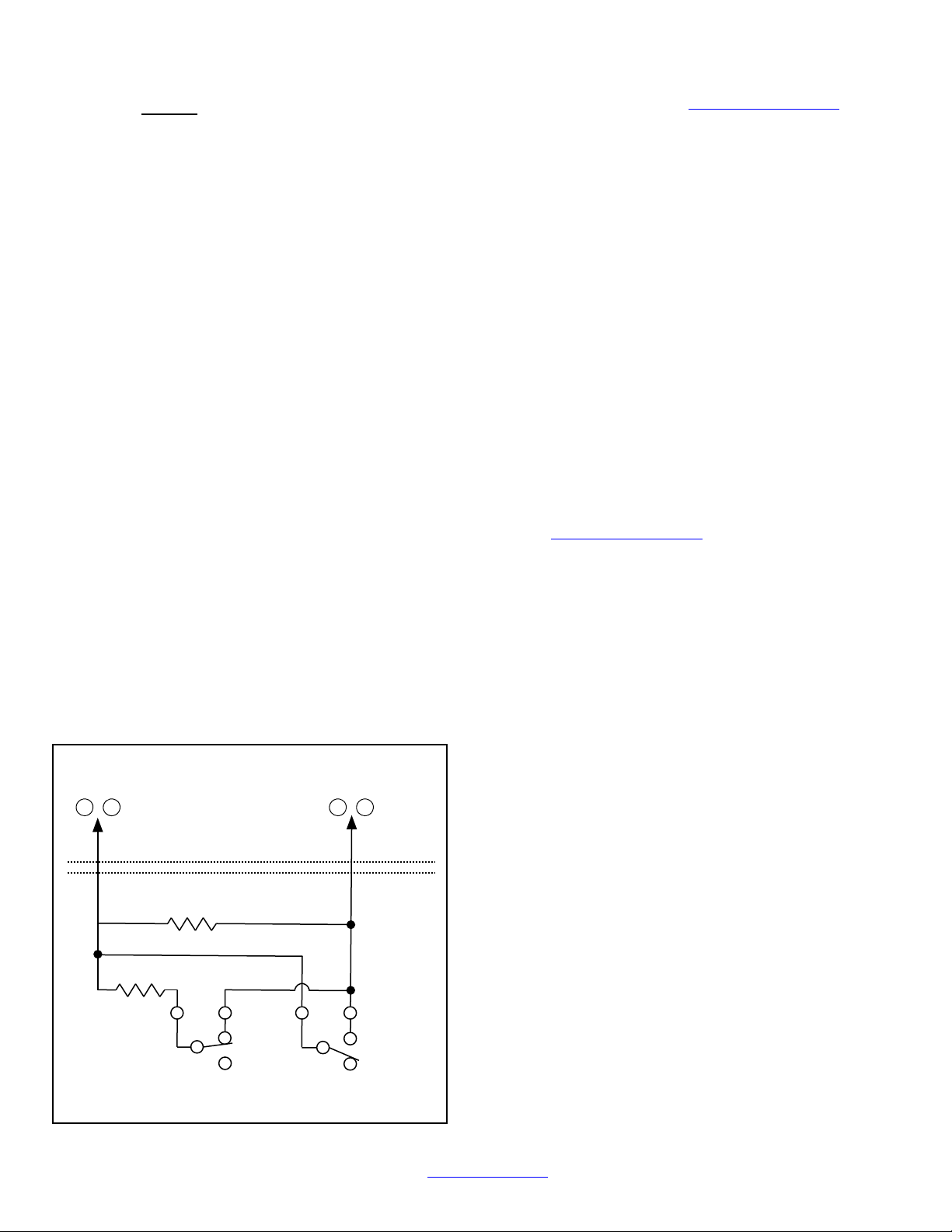

STEP 3: WIRING (PRIMARY MODE)

22-gauge wire may be used if mounted up to 50 feet from

the control panel, and 18-gauge wire should be used for up

to 100 feet. Reference the wiring diagrams further in this

manual. See the section CONTROL PANEL PROGRAM-

MING further in this manual.

For Primary Mode:

The wiring between the control panel and the StarLink ra-

dio is over several wires, as follows:

TB1: PWR (+12V): Rated 12/24VDC input.

TB2: PWR GND (–)

TB21: N/C OUT1: Wired to the (+) of a zone dedi-

cated to monitoring the radio status. Should be pro-

grammed on Napco GEMC control panels as Monitor

or Supervisory Zone.

TELCO PRIMARY to FACP Telco 1 RJ-45 socket.

TELCO SECONDARY to FACP Telco 2 RJ-45 socket.