ISSUED:06-16-09 SHEET#:055-XXXX-1

Visit the Peerless Web Site at www.peerlessmounts.com 2 of 9 For customer care call 1-800-729-0307 or 708-865-8870.

Table of Contents

Parts List.................................................................................................................................................................... 3

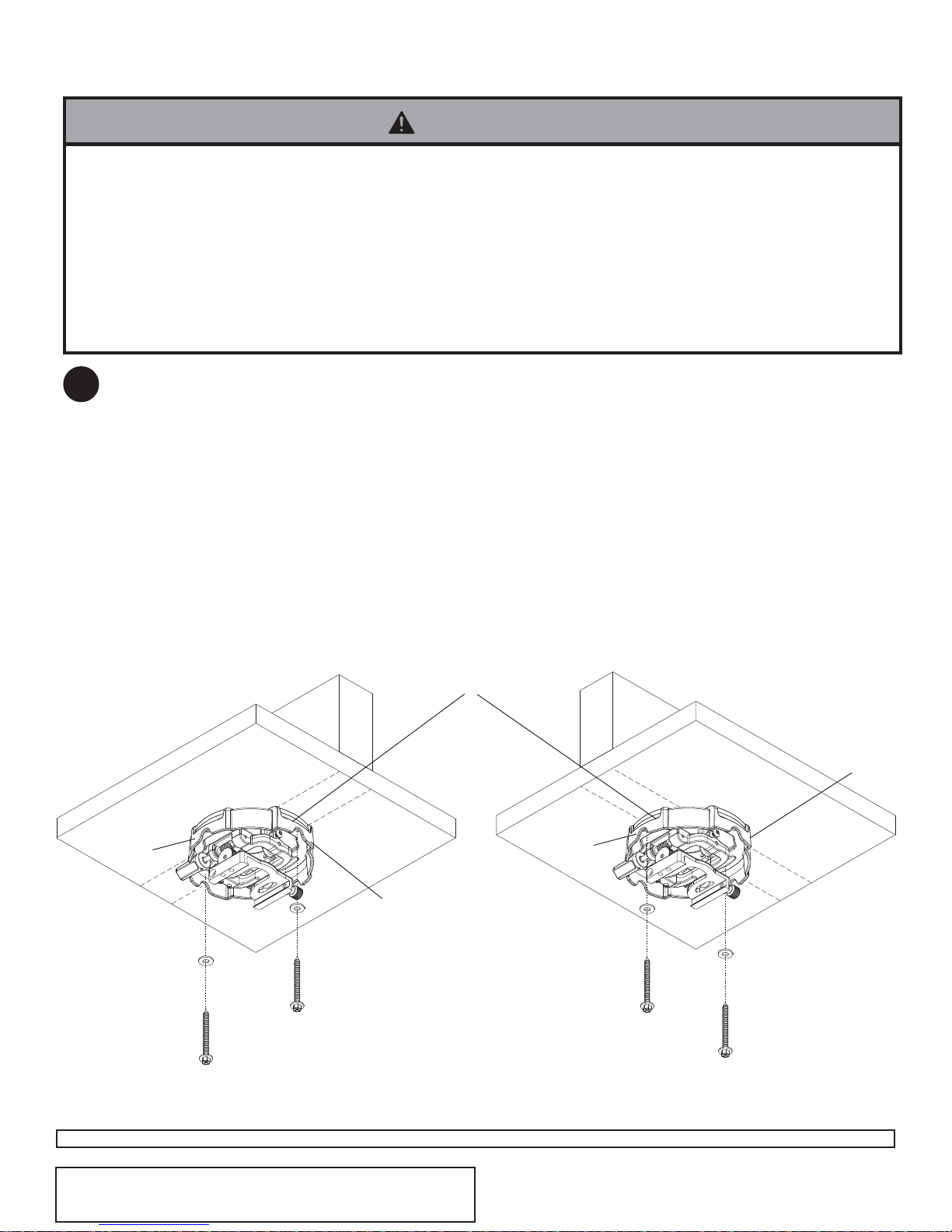

Installation to Wood Joist Ceilings .............................................................................................................................. 4

InstallationtoConcreteCeilings.................................................................................................................................. 5

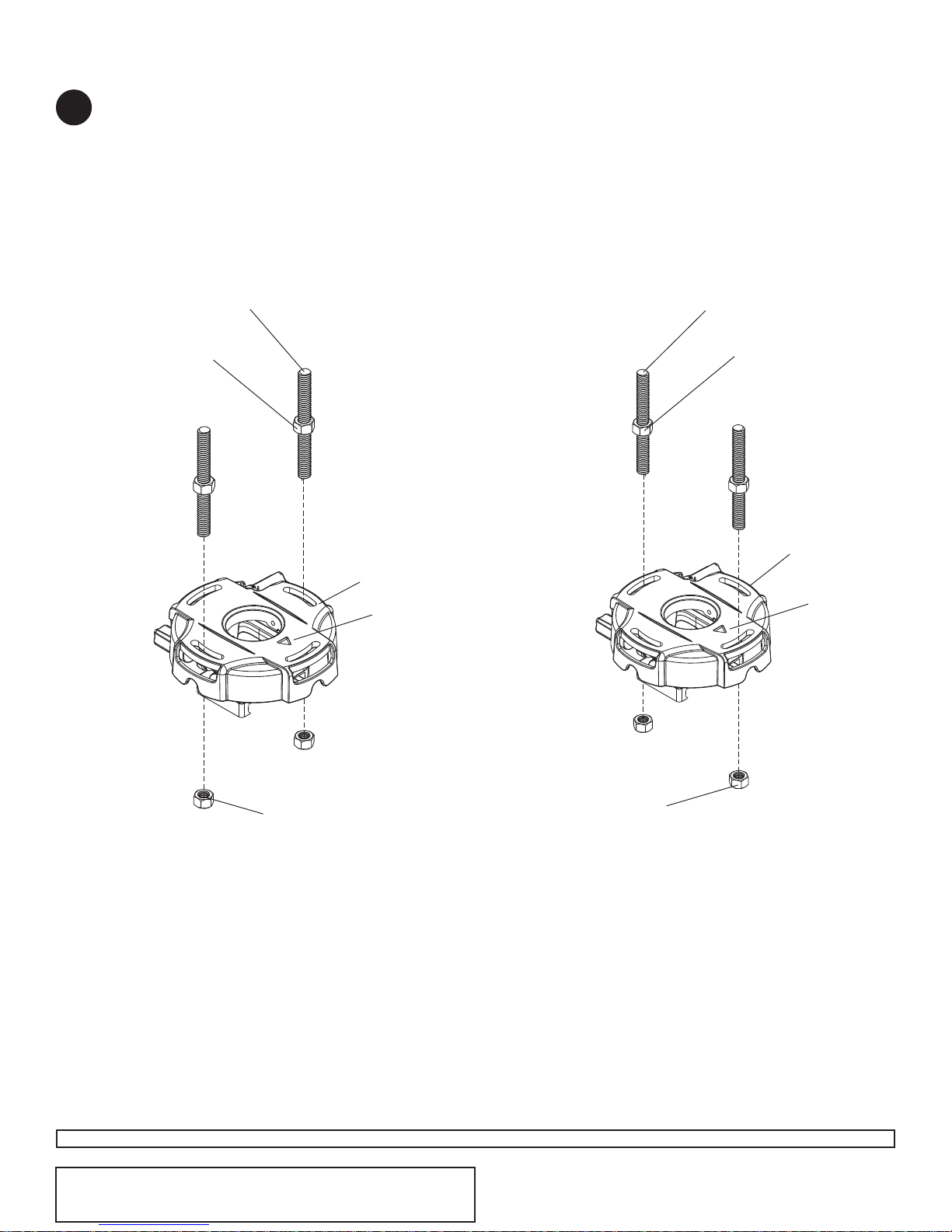

InstallationtoThreadedRods...................................................................................................................................... 6

Installation to Extension Columns / Ceiling Plate........................................................................................................ 7

Attaching Adapter Plate to Projector........................................................................................................................... 8

ProjectorAlignment .................................................................................................................................................... 9

Tools Needed for Assembly

•studfinder ("edge to edge" stud finder is recommended)

•phillipsscrewdriver

•drill

•1/4" bit for concrete surface

•5/32" bit for wood studs

•openendwrench

•level

• It is the responsibility of the installer to ensure that the

projectoris properly ventilated.

CAUTION

NOTE: Read entire instruction sheet before you start installation and assembly.

• Donot begin toinstall your Peerlessproduct until youhave read andunderstood the instructionsand warnings con-

tained in this Installation Sheet. If you have any questions regarding any of the instructions or warnings, call Peerless

customercareat 1-800-729-0307.

• This product should only be installed by someone of good mechanical aptitude, has experience with basic building

construction, and fully understands these instructions.

• Makesure that the supporting surface will safely support the combined load of theequipment and allattached hard-

wareandcomponents.

• Neverexceed theMaximum LoadCapacity.

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tighten screwsfirmly, butdo notovertighten. Overtighteningcan damagethe items,greatly reducingtheir holding

power. Seesuggested torquevalues whereapplicable withinthese instructions.

• Thisproduct is intendedfor indoor useonly.Use of thisproduct outdoorscould lead toproduct failure andpersonal

injury.

WARNING